Determination of Optimum Macro and Micronutrients Combination Rate for Hydroponic Fodder Production

Received: 12-May-2023 / Manuscript No. ACST-23-98632 / Editor assigned: 15-May-2023 / PreQC No. ACST-23-98632 (PQ) / Reviewed: 30-May-2023 / QC No. ACST-23-98632 / Revised: 26-Jan-2024 / Manuscript No. ACST-23-98632 (R) / Published Date: 02-Feb-2024

Abstract

Greenhouse experiment was conducted to determine the optimum macro and micronutrients combination rate for hydroponic fodder production at Haramaya university. The trial was laid out in completely randomized design comprised of five nutrient combination rates in four replications and four growing cycles using HB1307 barley variety. The seeds were cleaned, washed, disinfected with 1.5% NaOCl and soaked to sprout. The sprouts were spread on aluminum trays and allowed to grow for ten days through the application of nutrient solutions twice a day (early in the morning and late afternoon). Every tenth days the required agronomic data were collected for four growing cycles. Total fresh and dry biomasses, separate shoot and root fresh and dry biomass yields, shoot and root lengths showed highly significant (P<0.0001) difference in response to the treatments. The highest total fresh and dry biomasses of 7.26 and 0.67 kg kg-1 and fresh shoot and root biomasses of 2.36 and 4.90 kg kg-1 seed were obtained at the highest nutrient combination rate, respectively. Similarly, shoot and root dry biomass yields of (0.115 and 0.571 kg kg-1) were recorded at the same treatment. The same treatment also showed significant different (P<0.0001) on shoot and root lengths. Opposite to the shoot, the root lengths decreased as the nutrient concentration increased with the shortest length record at the highest rate applied. The laboratory analysis showed that the highest nutritional value of mineral contents of the fodder at the highest fertilizer rate applied. Thus, it could be concluded that the use of the highest nutrient combination rate used in this experiment is reasonable and substantial to get the highest biomass yield of better nutritional quality of hydroponic fodder.

Keywords

Biomass yield; Hydroponic fodder; Nutrient combination rate; Fodder quality

Introduction

Nowadays scarcity of land has been shown as a great constraint to forage production for ruminant animals like sheep, goat and cattle. The ruminant animals cannot always be dependent on cereal grains like that of mono-gastric animals. In the presence of this and climatic related constraints, the use of alternative forage production technologies like the hydroponic is indispensable [1-3]. Feeding hydroponic fodder resulted in improvement of livestock performance [4]. Therefore, countries like Ethiopia where livestock possess significant economic, cultural and social values but improved forage production is not widely adopted and the demand for animal products are increasing, sustainable and efficient land, water and other agricultural inputs utilizing production system, i.e., hydroponic forage production needs to be adopted to support the existing conventional production method. Accordingly, this experiment was conducted with the objective to determine optimum macro and micronutrients combination rate for barley under hydroponic fodder production method.

Hydroponically grown fodder is highly water efficient and reduces waste of water and other essential natural and manmade resources required to grow fodder while controlling the effects of climate and the growing conditions [5]. Water is one of the basic requirements for seed germination and seedling growth as it is essential for enzyme activation, reserve storage breakdown, translocation and seedling growth [6].

Hydroponic fodder production involves supplying cereal grain with necessary moisture and nutrients, to enable germination and its growth in the absence of a solid growing medium (soil and others). The resulting green shoots and root mat are harvested and fed to livestock within seven to ten days. The grain responds to the supply of moisture and nutrients by germinating, sprouting and then producing a 200-250 mm long vegetative green shoot with interwoven roots [7]. A nutrient solution for hydroponic systems is an aqueous solution containing mainly inorganic ions from soluble salts of essential elements for higher plants [8]. An essential element has a clear physiological role and its absence prevents the complete plant life cycle [9].

Even though fodder production and livestock feeding are the two important aspects for the sustainability of products and productivity in animal husbandry, feed scarcity had been the major limiting factor in improving the livestock productivity. In many parts of the world, the production of sufficient conventional green fodder to feed the huge livestock population has become a big challenge [10]. This is due to limited land resource, labour, fertilizer and manure requirements for cultivation, and lack of irrigation facilities, prevailing water scarcity and natural calamity (frequent draught) [11]. Fodder shortages are continuously hindering the sustainable livestock production resulted in poor productive and reproductive performance of the animals. To overcome this problem, hydroponic fodder production technology is emerging as an alternative to grow sufficient quality fodder for livestock [12-15].

Different types of fodder crops viz. barley, oats, wheat, sorghum, alfalfa, cowpea and maize can be produced by hydroponic technology. It has also been recognized as a viable method of producing vegetables and ornamental crops such as herbs, roses, freesia and foliage plants. Hydroponic fodder is more palatable, digestible and nutritious while providing other health benefits to the animals [16]. Feeding of hydroponic maize and barley fodder to growing goats increased total dry matter intake, per cent feed conversion efficiency, total body weight gain and economically valid [17]. Growing of hydroponic maize fodder proved improved nutrient content with less water, less space used and cost effective [18].

Hydroponic fodder production is a method of fodder production, in which fodder seeds are germinated into a high quality, highly nutritious, disease free animal food in a hygienic environment. Hydroponic cultivation is an eco-friendly method of growing fodder and hydroponically grown cereals grow up to 50% faster and produce higher yields of better quality fodder. It takes place in an intensive hydroponic growing unit in which only water and nutrients are used to produce nutrient rich grass and root combination. It is highly water efficient and reduces water waste and essential natural and man-made resources required to grow fodder while controlling the effects of climate and growing conditions [19,20].

Hydroponically growing fodder is the transformation of grains into high quality, very lush, highly nutritious, disease free grass and root combination animal feed produced in a versatile and intensive hydroponic unit. Sprouting of grains has resulted in an increase of quantity and quality of protein, sugars, minerals, vitamins and optimizing the general health and performance of young animals while minimizing feed costs.

Biomass production of different crops is limited by various factors, such as the decrease of land available for sowing, adverse weather conditions and high labour costs. Due to this limitation, it forces agricultural producers to seek other options for the biomass production of animal feed containing a high protein content (ryegrass, sorghum, and oat), fresh and plentiful, that are not impacted by climate changes and it does not require large areas with low cost.

In hydroponics, fertilizers are supplied as ions in the nutrient solution. Several formulations of essential macro and micronutrients have been developed to enhance nutrient uptake and plant growth. As the nutrient solution is the only source of mineral nutrients in hydroponically grown plants, extremely low concentrations of nutrients limits growth while extremely high nutrient concentration causes osmotic stress, ionic toxicity, and growth restriction indicating that determining the optimum rate lead to high production and cost effective.

Appropriate fertilizer application will reduce the financial, environmental and ecological costs of intensive farming, yet the crop requirement for nutrients must be met in order to maintain and increase yields. Therefore, determination of optimum macro and micronutrient nutrient combinations rate for hydroponic fodder production of barley is essential for optimum biomass yield and to reduce production cost and environmental pollution.

Materials and Methods

Experimental site description

This experiment was executed for more than five months period from March 19 to August 18, 2020, in a 15 m by 5 m plastic greenhouse in the goat farm of Haramaya university, main campus. The geographical location of the site is 9° 25’ N latitude and 42°2’ E longitude at an altitude of 2057 m above sea level and 515 km east of Addis Ababa. It has an average temperature of 16°C with mean maximum and minimum annual temperatures of 24.02°C and 9.73°C, respectively. The area has a bimodal type of rainfall pattern and receives an average annual rainfall of 790 mm. The study was conducted in 15 meter by 5 meter insect proof plastic greenhouse where the active production area was not more than 16 m2. The greenhouse had one meter wide window on both of its long sides with plastic net for aeration. The greenhouse was installed with three overlapped rows of wooden shelves on which planting trays of aluminum sheet were placed. The trays have 1 m width, 1 m length and 4 cm depth and holes at one side to drain excess water and nutrient solution. Soaked seeds were sown on the trays and allowed to grow to ten days hydroponic fodder. The applications of treatments (tap water and nutrient solutions) were done twice a day (early in the morning and late afternoon).

Experimental procedure

Improved seeds (C1) of barley (Hordeum vulgare L.) were cleaned, washed and dipped in a 1.5% sodium hypochlorite solution (household bleach) for 45 minutes to avoid the formation of mould during germination and growth periods of the hydroponic fodder. The seeds were cleaned again from the disinfectant and incubated in plastic bucket f or 12 hours for root initiation. Thereafter, sprouted seeds were spread on the hydroponic tray according to the proposed seed rate to be tested. The trays were arranged in CRD design with four replications and grown for four planting cycles. During the growth period from the 3rd date of planting on the tray, different rates of macro and micronutrient solution was applied based on the treatment partitions. The treatment combinations of the nutrient solutions are shown on (Table 1). On the 10th day morning of all the four growing cycles, all the required data measurements were taken accordingly.

| Treatments | ||||

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| Tap water (control) | 22.3 (Ca) | 44.6 (Ca) | 89.20 (Ca) | 133.8 (Ca) |

| 20.5 (K) | 40.95 (K) | 81.90 (K) | 122.85 (K) | |

| 19 (N) | 37.55 (N) | 75.10 (N) | 122.65 (N) | |

| 0.45 (Fe) | 0.9 (Fe) | 1.80 (Fe) | 2.7 (Fe) | |

| 5.4 (Mg) | 10.40 (Mg) | 20.80 (Mg) | 31.2 (Mg) | |

| 10.8 (S) | 21.6 (S) | 43.20 (S) | 64.8 (S) | |

| 0.8 (P) | 1.6 (P) | 3.2 (P) | 4.8 (P) | |

| 0.1 (Zn) | 0.20 (Zn) | 0.40 (Zn) | 0.6 (Zn) | |

| 0.125 (Mn) | 0.25 (Mn) | 0.5 (Mn) | 0.75 (Mn) | |

| 0.025 (Cu) | 0.05 (Cu) | 0.01 (Cu) | 0.75 (Cu) | |

| 0.25 (B) | 0.5 (B) | 0.1 (B) | 0.15 (B) | |

| 0.25 (Na) | 0.5 (Na) | 0.1 (Na) | 0.15 (Na) | |

Table 1: Macro and micronutrients (ppm) combinations used in the experiment.

Adjusting the pH of the water

From the analysis of the chemical property of the tap water used in the process of hydroponic fodder production, its pH and EC were 7.7 and 0.055 dS/m, respectively (Table 2). However, the optimum levels of pH and EC for hydroponic fodder production range from 5.8 to 6.5 and 1.5 to 2.5 dS/m, respectively. In a nutrient solution, pH determines the availability of essential plant elements. EC refers to the total ionic concentration of a nutrient solution which determines the growth, development and production of plants, because, solutes reduce the free energy of water through dilution thus affecting the absorption of the nutrients in the solution by the plants. Thus, the adjustment of the pH of the solution was very essential for normal growth of the fodder. Based on this principle, the pH of the nutrient solutions was adjusted by applying few drops of phosphoric acid and the final pH of the nutrient solutions of the treatments was reduced from 7.7 to 6.25.

| EC | PH | Na(mg/l) | Ca (mg/l) | Mg(mg/l) | Cl (mg/l) | CO3 (mg/l) | SO4 (mg/l) | NO3 (mg/l) |

|---|---|---|---|---|---|---|---|---|

| 0.55 dS/m | 7.7 | 2.3474 | 10.89866 | 29.54545 | 50.055 | 3.6 | 115.942 | 1.0986 |

Table 2: Laboratory result of the tap water used for hydroponic fodder production.

Data collection

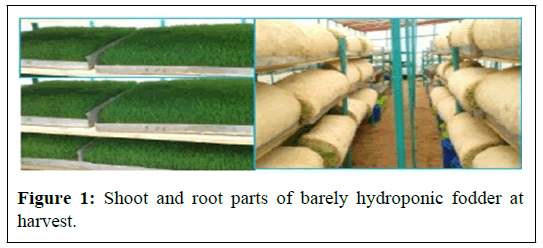

Every ten days of all the four growing cycles, the produced fodder from all trays was weighed to determine its total fresh weight and dry biomass yield (Figure 1).

Ten plants were carefully removed from each treatment and their shoot and root lengths were measured using a standard ruler. The root length was measured from the cuticle to the tip of the longest root segment and the shoot length was measured from the base of the hypocotyls to the tip of the longest leaf. The shoot and root biomass of the hydroponic fodder were weighed and recorded. A kg of fodder samples were taken from each tray and separated into shoots and roots parts. The shoots were separated from the roots by cutting at the base of the hypocotyls. The weight of root and shoot were measured separately and the data were recorded. Finally, the separate shoot and root samples were oven dried at 75°C for 48 hours to determine both moisture and dry matter contents of the fodder.

Analytical procedures

The hydroponic feeds were sub-sampled, ovens dried at 75°C for 48 hrs, ground and passed through a 1 mm mesh screen sieve and were analyzed as per (AOAC, 1990) to determine nutritional content of the fodder applied with different macro and micro nutrients solution rates. Crude Protein (CP), Crude Fiber (CF), energy MJ/kg DM, carbohydrate content and individual mineral contents of the fodder were determined according to van Soest PJ, et al. Total nitrogen content was analyzed using the Kjeldahl nitrogen determination and CP was calculated as total N × 6.25. DM was determined by drying the samples at 75°C in a forced air oven for 48 h. Phosphorus was determined using spectrophotometer (Genway 630); while, Ca, K, Mg, Fe, Mn, Zn and Cu were determined by atomic adsorption spectrometer using analytical procedure.

Data analysis

The data were statistically analyzed using analysis of variance (ANOVA) according to SAS software according to the procedure outlined by Fisher RA, et al. Differences among treatment means were delineated using Tukey's Honest Significant Difference (HSD) test at 5% probability level when the ANOVA showed significant effects.

Results

Total fresh biomass yield

The analysis of variance revealed that there is significant difference (P<0.0001) in fresh biomass yield per kg seed due to the effect of macro and micronutrient combinations applied (Table 3). The biomass yield variation in response to the application of nutrient solution increased consistently from T1 (control) to T5 (the highest level of fertilizer combination) in this experiment. Increasing the rate of fertilizer from T1 to T5 resulted in a fresh biomass yield increase of 24.1%. This result confirmed that 726 kg green fodder biomass yield of barley can be produced from 20 trays staked on 16 m2 area of land in one planting cycle (ten days) using 5 seed kg tray 1 under hydroponic system with the application of macro and micronutrient combination rate containing: Ca (133.8), K (122.85), N (122.65), Fe (2.7), Mg (31.2), S (64.8), P (4.8), Zn (0.6), Mn (0.75), Cu (0.75), B (0.15), Na (0.15) ppm.

| Fresh biomass yield (kg/kg seed) | Nutrient combination rate (ppm) | F-test | CV | ||||

|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | |||

| TFBY | 5.85a | 6.3b | 6.7c | 6.9d | 7.26e | *** | 0.085 |

| SFBY | 1.90a | 2.05b | 2.18c | 2.24d | 2.36e | *** | 0.26 |

| Shoot as % of total yield | 32.48 | 32.54 | 32.54 | 32.46 | 32.51 | ||

| RFBY | 3.95a | 4.25b | 4.52c | 4.66d | 4.90e | *** | 0.502 |

| Root as % of total yield | 67.52 | 67.46 | 67.46 | 67.54 | 67.36 | ||

Note: Means followed by the same letter within a row are not significantly different according to Tukey's Studentized Range (HSD) Test at 5% level of significance; ***=significant at P<0.0001; CV: Coefficient of Variation; NCR: Nutrient Concentration Rate; TFBY=Total Fresh Biomass Yields; SFBY: Shoot Fresh Biomass Yield; RFBY: Root Fresh Biomass Yield.

Table 3: Effect of NCR on total fresh biomass, shoot and root yields of hydroponic fodder of barley.

Shoot and root fresh biomass yield

Results of analysis of variance revealed that shoot and root fresh biomass were significantly (p<0.0001) varied due to macro and micronutrient combinations rate. Shoot length increased as nutrient solution rate increased from T1 to T5. Whereas, root length decreased significantly (P<0.0001) as nutrient solution rate increased from T1 to T5 in Table 3.

Total dry matter yield

The effect of macro and micronutrient combinations rate was significant (P<0.0001) on total dry matter content of hydroponic fodder of barley per kg seed. There was a dry matter yield difference of 9.35% between T1 and T5 with consistent increment across the treatment (Table 4). The positive response of dry matter accumulation of the fodder due to the applied nutrient solution might be the reason for high yield of both fresh biomass and dry matter yields. The highest dry matter yield weight of barley hydroponic forage in this study might be due to the highest plant height and number of roots developed in response to the fertilizer application.

| Dry matter yield (kg/kg seed) | Treatments (Nutrient combination rate(ppm)) | LSD (α=0.05) | ||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | ||

| TDMY | 0.620a | 0.630b | 0.640c | 0.660d | 0.686e | 0.0024 |

| SDM | 0.11190a | 0.1122a | 0.1131b | 0.1142c | 0.1153d | 0.0004 |

| Shoot as % of total yield | 18.05 | 17.81 | 17.67 | 17.3 | 17.05 | |

| RDM | 0.5081a | 0.5178b | 0.5269c | 0.5458d | 0.5707e | 0.0075 |

| Root as % of total yield | 81.95 | 82.19 | 82.32 | 82.69 | 84.17 | |

Note: a,e, Values bearing different superscript (a-e) in a row differ significantly. TDMY: Total Dry Matter Yield; SDM: Shoot Dry Matter; RDM: Root Dry Matter.

Table 4: Effect of NCR on total, shoot and root dry matter yields of hydroponic fodder of barley.

Shoot and root dry matter yields

The ANOVA revealed that there was a highly significant (P<0.0001) variation in the dry matter accumulation of shoot and root parts Table 4. In shoot, consistent DM increase was recorded among the treatments except T1 and T2 where no significant variation was observed. Alike the shoot part, consistent DM increase was observed in the root part from T1 to T5 in response to the rate of hydroponic nutrient solution applied.

Shoot and root lengths

Analysis of variance showed that the treatment (rate of macro and micronutrient combinations) had highly significant effect (P<0.0001) on shoot and root lengths of the hydroponic barley fodder produced (Table 5). Both shoot and root lengths increased as the concentration of nutrient solution increased from T1 to T5 and the maximum lengths of both organs were recorded at T5. Increased lengths of 27.87% and 36.94% were observed between T1 and T5 in both shoot and root parts, respectively. In both the agronomic parameters of the fodder measured (shoot and root lengths) there were consistent increase in response to the macro and micronutrient concentration rates applied.

| Agronomic parameters | NCR (ppm) | F test | CV | ||||

|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | |||

| Shoot | 13.15a | 14.43b | 14.61c | 15.82d | 18.23e | *** | 0.683 |

| Root | 11.10a | 8.35b | 8.00c | 7.50d | 7.00e | *** | 0.947 |

Note: *Values bearing different superscript (a-e) in a row differ significantly; NCR: Nutrient Concentration Rate

Table 5: The effects of nutrient concentration rate on shoot and root lengths of hydroponic fodder.

Feed quality analysis of hydroponic fodder of barley

The result of the laboratory analysis showed the application of nutrient solution to barley hydroponic fodder improved its nutritional content (Table 6). Accordingly, all the feed quality parameters assessed were increased in consistent with the increase of nutrient solution rates. In all cases, the minimum values were recorded at T1 (tap water only) and the maximum values of all the feed quality parameters measured were obtained at the highest rate of macro and microelements combination (T5) supplied to the growing fodder.

| Treatment | CP (%) | CF (%) | Metabolizable energy (MJ/kg DM) | Carbohydrate (g/kg DM) |

|---|---|---|---|---|

| 1 | 13.13 | 8.121 | 8.11 | 58.09 |

| 2 | 13.64 | 8.83 | 8.12 | 60.13 |

| 3 | 14.09 | 9.121 | 9.23 | 61.11 |

| 4 | 15.85 | 9.692 | 9. 56 | 62.43 |

| 5 | 19.98 | 10.386 | 12.68 | 63.48 |

Note: T1: Control (only tap water), T2: Ca (22.3), K (20.5), N (19), Fe (0.45), Mg (5.4), S (10.8), P (0.8), Zn (0.1), Mn (0.125), Cu (0.025) B (0.25), Na (0.25) T3: Ca (44.6), K(40.95) (N) 37.55 (Fe) 0.9 (Mg) 10.40 (S) 21.6 (P) 1.6 (Zn) 0.20 (Mn) 0.25 (Cu) 0.05(B) 0.5 (Na) 0.5, T4: (Ca) 89.20 (K) 81.90 (N) 75.10 (Fe) 1.80 (Mg) 20.80 (S) 43.20 (P) 3.2 (Zn) 0.40 (Mn) 0.5 (Cu) 0.01 (B) 0.1 (Na) 0.1, T5: Ca (133.8) K (122.85) N (122.65) Fe (2.7) Mg (31.2) S (64.8) P (4.8) Zn (0.6) Mn (0.75) Cu (0.75) B (0.15) Na (0.15); CP: Crude Protein; CF: Crude Fiber.

Table 6: Effect of fertilizer application on nutritional content of barley hydroponic fodder.

Effect of fertilizer application on mineral contents of the hydroponic fodder

To evaluate the importance of fertilizer application to hydroponic fodder and its effect on fodder quality, it is necessary to consider the mineral concentration change in response to the applied fertilizer through laboratory analysis. Accordingly, the laboratory analysis result of the hydroponic fodder of barley received various concentration rates of macro and micro minerals (T1 to T5) were shown on Table 7.

Based on these results, the concentration of all the applied minerals except boron and sulfur (which were not analyzed due to the absence of the required facilities) revealed consistent increase with the increase of fertilizer solution concentration across the treatments. Accordingly, the highest macro and micro mineral concentrations was recorded at T5 while the least concentration was recorded at T1 (control treatment, which was only tap water).

| Treatment | Concentration of minerals(ppm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ca | N | Mg | Zn | Fe | Mn | Cu | P | K | Na | |

| 1 | 1.64 | 1.38 | 2.55 | 16.85 | 90 | 20.9 | 7.6 | 1.18 | 4.04 | 18.2 |

| 2 | 1.71 | 1.82 | 2.86 | 19.66 | 93.6 | 23.1 | 5.4 | 1.31 | 4.43 | 36.4 |

| 3 | 1.76 | 2.22 | 3.29 | 22.47 | 94.6 | 23.4 | 7.6 | 1.36 | 4.81 | 54.6 |

| 4 | 1.93 | 2.4 | 3.63 | 22.75 | 99.1 | 24.3 | 7.7 | 1.36 | 5 | 58.3 |

| 5 | 2.01 | 2.65 | 3.96 | 25.28 | 108.2 | 24.7 | 11.1 | 1.42 | 5.39 | 60.2 |

Table 7: Effect of treatment on mineral concentration of barley hydroponic fodder.

Discussion

Total fresh biomass yield

The highest fresh biomass recorded at T5 might be attributed to the effect of nitrogen in the nutrient solution on vegetative growth of the fodder and the productivity per unit area of the hydroponic system. This result is in agreement with the work of who reported fodder production is accelerated by as much as 25% by applying the nutrient solutions directly to the plants. The biomass yield increase due to fertilizer application of hydroponic fodder was also reported by Al Ajmi A, et al., who stated that average green forage yield ranged from less than 90 tones/ha with tap water to around 130 tones/ha through the application of irrigation water containing high nitrogen which is equivalent to 50% increase in fodder production. Similarly, also reported that a water solution mixed with vital plant nutrients hastens the growth of hydroponic fodder. Bamikole and Bakishi, et al., well reported that maize hydroponic fodder yields were higher when irrigated with nutrient solution. Contrary to these, it was reported that there was no additional advantage of using nutrient solution for producing hydroponic fodder. Similarly, reported that the use of nutrient solution for production of hydroponics forage is not mandatory as it can also be produced by tap water only.

In this study, considering only the total net productive area of the greenhouse about 16 m2 with overlapped floor of shelves that accommodated 20 trays of 1 m2 size at an average productivity potential of 36.3 kg from 5 kg seed of barley with the application of nutrient solution containing, Ca (133.8), K (122.85), N (122.65), Fe (2.7), Mg (31.2), S (64.8), P (4.8), Zn (0.6), Mn (0.75), Cu (0.75), B (0.15), and Na (0.15) ppm, 2.18 tons of fresh fodder can be harvested in a month period. Whereas, under conventional farming (geoponic system), the average fresh forage biomass produced from maize (a crop with high biomass yield potential) was reported to be 28.43 and 30.67 tons ha-1 at planting space of 75 and 35.5 cm, respectively, which is equivalent to 2.24 to 3.07 kg m-2 of land area, that is by far lower than 36.3 kg biomass yield m-2 obtained under this experiment shows the highest efficiency of hydroponic fodder technology in terms of land utilization, water and fertilizer without the influence of climatic factors. Based on the productivity of the present experiment, only 3 m2 land is required to produce 100 kg green fodder everyday against 2-12 ha of land under conventional production system. Moreover, the land area requirement of hydroponic fodder can be reduced through vertical farming where trays can be overlapped on racks of shelves.

Total, leaf and root dry weight

The highest total, leaf and root dry weights of the fodder obtained at the highest rate of nutrient solution applied might be attributed to the increase in the absorption of the available nutrients as low nutrient concentration limits plant growth. In line with this finding, reported that there is an increase in dry matter weight of plants in response to the concentration of nutrient through its effect on growth rate of the plant. A similar result reported by Fageria VD, et al., ascertained the nutrient interactions on crop plants growth are generally measured in terms of growth response and change in concentration of nutrients. Moreover, Dung, et al., a and b reported that the application of nutrient solution increases DM accumulation, which may be due to the absorption of minerals thus increasing the ash content leading to the final weight of the hydroponic fodder. However, dry matter loss of hydroponic fodder is the result of the physiological activities during seed soaking through activating enzymes that convert the starch stored in endosperm to a simple sugar to produce energy and gives off carbon dioxide and water, leading to loss of DM with a shift from starch in the seed to fiber and pectin in the roots and green shoots of the growing plants. To add, a number of studies reported that sprouting resulted in 7%-47% loss in DM from the original seed after sprouting mainly due to respiration during the sprouting process. Whatsoever, Yu, et al., reported that dry matter accumulation is the result of the growth process in plants which varies at different growth stages?

Shoot and root dry matter yield

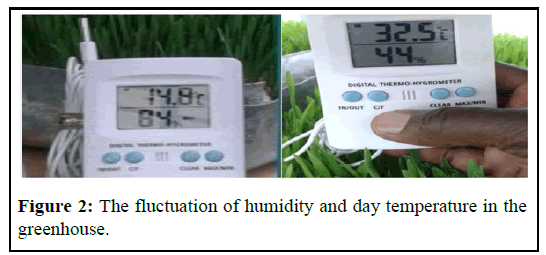

The shoot and root dry matter content of the current experiment was similar to the finding of Naik, et al., who reported shoot and root dry matter of maize hydroponic fodder as 16.56% and 83.3%, respectively. Moreover, many scholars concluded that the dry matter content of hydroponic forages are mainly influenced by the type of crops, stage of growth, type and quality of seed, seed rate, seed treatment, water quality, pH, irrigation frequencies, light, temperature and humidity in the greenhouse. In line with this conclusion, there were great fluctuations of temperature and humidity in the greenhouse of the current experiment with the minimum and maximum temperatures and humidity values of 14.8°C and 32.5°C and 44% and 84%, respectively (Figure 2).

Shoot and root lengths

The consistent increase in shoot and decrease in root lengths with increasing nutrient solution concentration from T1 (only tap water) to T5 clearly showed the synergetic effect of macro and micronutrients combination on the plant growth and development, while, the decrease in root length may be related to the availability of the nutrient concentration in the rhizosphere. In line with this result, Comfort, et al., reported that high rates of nitrogen application reduced root growth and depth of rooting in wheat. On the other hand, it was stated that more root length is developed in soils that are deficient in nutrients.

Feed nutritional quality analysis of hydroponic fodder of barley

The improvement of the nutritional quality of the fodder due to the application of nutrient solutions was in line with the findings of Kleiber, et al., and Wortman, who reported that nutrient solutions applied to feed hydroponically germinated seeds determine the nutritional value of the fodder. The CP content of barley fodder from T5 in this study was 19.98% which was comparable to the CP content of hydroponically grown barley fodder of 19.70% and 19.80% reported by Fazaeli, et al. and Abd Rahim, et al., respectively. But, it was greater than the CP content (13.86%) of hydroponically grown barley fodder reported by Weldegerima Dung, et al. concluded that the use of nutrient solution enhances the CP content of hydroponic fodder. Similarly, Saidi and Abo Omar reported that the absorption and metabolism of nitrogenous compounds, increasing the crude protein content of hydroponic fodder. However, Pattanaik, et al., reported that the increase in CP content may be attributed to the loss of DM, particularly carbohydrates, as the result of the respiration during germination and longer sprouting time is responsible for losses in DM and increase in protein content. On the other hand, the consistent increase in crude fiber from T1 to T5 may be attributed to the enhancement of the nutrients solution in the build-up of cellulose, hemicelluloses and lignin as reported by Cuddeford. The metabolizable energy (12.68 MJ/kg DM) found at T5 of this experiment was comparable to the finding of Sneath and McIntosh who reported the metabolizable energy content of barley grass was ranged from 8.7 to 12 MJ/kg. The better energy content recorded under the current experiment might be resulted from the application of high macro and micronutrients rate. On the other hand, the carbohydrate content of barley hydroponic fodder obtained under this experiment was comparable to the finding of Fazaeli, et al, who reported that the carbohydrate content of hydroponic barley fodder as 64.4 gkg-1. In general, Reddy, et al., reported that the nutrient content of barley hydroponic fodders were superior to certain cereal fodders, but comparable to leguminous fodders. Therefore, the maximum nutritional values recorded in response to the application of the highest macro and micronutrient combination rate under the current study could be due to the absorption of the readily available nutrient solution applied with irrigation water.

Effect of fertilizer application on mineral content of the hydroponic fodder

Minerals have a major nutritional significance for human and animals and deficiencies in elements, such as Ca, Fe, Mn, Zn, can lead to a variety of health problems from anemia to osteoporosis Liu, et al. The laboratory result of this study was in agreement with the finding of Al-Ajmi, et al., Peer and Leeson, Dung, et al. and Fazaeli, et al., who reported that the Ca, K, P, Mg, Na, Fe, Cu and Zn concentrations were higher in barley fodder produced using nutrient solution. It was also stated that the biological yield of crops depends on optimum availability of resources like nutrients, space, light and water. Other researchers have reported that nutrient solutions used to feed hydroponically grown fodder determine its nutritional value. Snow, et al., added that variation in mineral contents of hydroponic barley fodder could be due to the type of irrigated water and the level of nutrients solution concentration applied. It is also reported that the comparative evaluation of hydroponic barley produced by using tap water or nutrient solution revealed that sprouts grown with nutrient solution had higher crude protein and ash contents than those grown with tap water only. Generally, Bruulsema, et al., confirmed that high rates of nutrient application can be resulted in high recovery efficiencies of the plants.

Conclusion

It is recognized that the biomass yield and nutritional quality of hydroponic fodder depends on the level of fertilizer rate. The results of this study showed that the use of the combination of macro and micronutrients solution to produce hydroponic fodder of barley increased biomass yield, fresh and dry weights and shoot length while the short root length was related to the nutrient availability at short distance. Similarly, the mineral content of the fodder improved in relation to the nutrient concentration applied as growth and the nutritional values of the hydroponic fodder depends on the concentration of the nutrient solution in the irrigation. However, root length reduced as nutrient concentration increased. In all the parameters measured, the highest mineral values were recorded at the maximum rate of fertilizer combination (treatment) applied. From this result, it can be concluded that hydroponic fodder production enhances nutrient use efficiency, high biomass yield and better nutritional quality of fodder through the application of small quantity of macro and micronutrient combinations. However, still there is a room for additional biomass yield beyond the maximum rate applied where the upper limit or the yield response curve did not decline. Therefore, as a recommendation, the use the macro and micronutrients combination rate containing Ca (133.8), K (122.85), N (122.65), Fe (2.7), Mg (31.2), S (64.8), P (4.8), Zn (0.6), Mn (0.75), Cu (0.75), B (0.15), and Na (0.15) ppm is technically feasible to produce 36.3 kgm-2 tray of fresh hydroponic fodder within ten days. Moreover, it is important to carry out further research to identify the optimum rate of macro and micronutrients combination at which the maximum biomass yield with the highest nutritional contents of hydroponic fodder of barley can be obtained.

Author Contributions

Conceptualization: G.K.M; writing-original draft preparation: G.K.M; editing: G.K.M, N.D. M.U and T.T; supervision: N.D, M.U. and T.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the ministry of education of Ethiopia, Haramaya and Debre Berhan universities for the research fund and material support of the research of Gebre Kiross Meko at Haramaya university, Ethiopia.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Naik PK, Dhuri RB, Karunakaran M, Swain BK, Singh NP (2014) Effect of feeding hydroponics maize fodder on digestibility of nutrients and milk production in lactating cows. Indian J Anim Sci 84: 880-883.

- Naik PK, Swain BK, Singh NP (2015) Production and utilisation of hydroponics fodder. Indian J Anim Sci 32: 1-9.

- Rodriguez-Muela C, Flores A, Grado JA, Arzola C (2004) Use of green fodder produced in hydroponic system as supplement for lactating cows during the dry season. In the Proceeding of the American Society of Animal Science, 271-274.

- Chandrashekara K, Radhakrishna AP, Somashekarappa HM (2015) Concentration of natural and artificial radionuclides in Mesua Ferea Auct Linn-A Medicinal Plant. Int J Life Sci Res 2: 219-223.

- Copeland OL, McDonald MB (1995) Seed science and technology. 3rd edition. Chapman and Hall, New York, NY, USA.

- Steiner AA (1961) A universal method for preparing nutrient solutions of a certain desired composition. Plant Soil 15: 134-154.

- Dung DD, Godwin IR, Nolan JV (2010) Nutrient content and in sacco digestibility of barley grain and sprouted barley. J Anim Vet Adv 9: 2485-2492.

- Naik, P.K. 2012. Hydroponics technology for fodder production. ICAR News, 18 (3): 4.

- Naik PK, Gaikwad SP, Gupta MJ, Dhuri RB, Dhumal GM, et al. (2013) Low cost devices for hydroponics fodder production. Indian Dairyman 65: 68-72.

- Al-Karaki GN, Al-Hashimi M (2012) Green fodder production and water use efficiency of some forage crops under hydroponic conditions. Int Sch Res 2012: 1-5.

- Gebremedhin WK (2015) Nutritional benefit and economic value of feeding hydroponically grown maize and barley fodder for Konkan Kanyal goats. IOSR J Agric Vet Sci 8: 24-30.

- Kide W, Desai B, Kumar S (2015) Nutritional improvement and economic value of hydroponically sprouted maize fodder. Life Sci Int Res J 2: 76-79.

- Jensen H, Malter A (1995) Protected agriculture a global review. World Bank Tech Pap 253: 156-157.

- Al-Hashmi MM (2008) Hydroponic green fodder production in the Arabian Gulf Region. MSc. Thesis, Faculty of Graduate Studies, Arabian Gulf University, Bahrain.

- Emam MS (2016) The sprout production and water use efficiency of some barley cultivars under intensive hydroponic system. Middle East J Agric Res 5: 161-170.

- Iyer D, Santhini SN (2015) Analysis of the antibacterial activity of five mushrooms on clinical isolates and comparison of the efficacy of their various extracts. J Life SciInt Res 2:159-163.

- Kide WE, Abrha RA (2016) Yield and nutritive value of barley (Hordeum vilgari L.) fodder grown in soil and hydroponic system. Int J Life Sci Res 3: 194-197.

- Carneiro M, Moreira R, Gominho J, Fabiao A (2014) Could control of invasive acacias be a source of biomass for energy under mediterranean conditions. Chem Eng 37: 187-192.

- Weinwurm F, Theuretzbacher F, Drljo A, Leidinger D, Wannasek L, et al. (2014) Assessment of sweet sorghum as a feedstock for a dual fuel biorefinery concept. Chem Eng Trans 39: 973-978.

- Rivera A, Moronta M, Gonzalez-Estopinan M, Gonzalez D, Perdomo D, et al. (2010) Hydroponic green fodder production of corn (Zea mays L.) under deficient lighting conditions. Zootec Trop 28: 33-41.

Citation: Meko GK, Dachassa N, Urge M, Tana T (2024) Determination of Optimum Macro and Micronutrients Combination Rate for Hydroponic Fodder Production. Adv Crop Sci Tech 12: 664.

Copyright: © 2024 Meko GK, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 1322

- [From(publication date): 0-2024 - Apr 28, 2025]

- Breakdown by view type

- HTML page views: 1065

- PDF downloads: 257