Design of Manure Treatment Alternatives for Hillside Farms Pennsylvania, USA

Received: 07-Dec-2017 / Accepted Date: 14-Dec-2017 / Published Date: 02-Jan-2018 DOI: 10.4172/2155-6199.1000423

Abstract

An alternative treatment system for cow manure at The Lands at Hillside Farms, a 60 cow dairy farm located in Shavertown, Pennsylvania, was designed. The treatment system was sized for Hillside Farm’s 530,000 kg of annual manure production. The following systems were explored: lagoon, traditional composting, traditional anaerobic digester, anaerobic bag digester, and vermicomposting. The most practical manure treatment system was determined to be a vermicomposting system. The vermicomposting system employs Eisenia Fetida, a type of earth worm, to process the manure. The vermicomposting system consists of 12 units, each with a length and width of 4.6 m, and a depth of 0.3 m. To reduce costs and take advantage of Eisenia Fetida’s rapid reproduction ability, it was decided to initially purchase 5% of the total required worms. Each vermicomposting unit was estimated to cost $1,035, resulting in a total cost of $12,420. The primary concern for the treatment system is in regard to its performance during periods of low temperature. Eisenia Fetida’s manure processing rate declines with temperature. Hillside Farms should investigate the feasibility of installing a greenhouse or similar structure to insulate the vermicomposting units. The research paper herein contains valuable information that may assist other small farms exploring manure treatment options.

Keywords: Manure; Eisenia fetida ; Lagoon; Traditional composting; Traditional anaerobic digester; Anaerobic bag digester; Vermicomposting

Introduction

The Lands at Hillside Farms is a nonprofit dairy farm located in Shavertown, Pennsylvania, that is interested in a more sustainable approach to manure management. As a result of this research, three manure treatment systems have been designed for Hillside Farms for their consideration. The facility is a hands-on educational farm open to the public; it organizes a variety of events and activities to promote conservation and sustainability. They would like to be considered as a model for other farms, businesses, and even individuals regarding how to live and operate in a more environmentally conscious manner. At the farm, 60 milking cows are comprised of three species: Jersey, Holstein, and Brown Swiss. Julie Fallon, agricultural educator at Hillside Farms, estimates that the selected treatment facility should be sized to process 530,000 kg of cow manure per year. The size of the treatment facility must also take into account manure density and detention time. Other animals at Hillside Farms include oxen, chickens, sheep, goats, donkeys, and horses.

The three manure treatment designs included an anaerobic digester, a lagoon, and a vermicomposting system. Grant opportunities to assist the farm with funding have been explored. The recommended option should mitigate the adverse effects of manure on the environment while making the farm’s operations more efficient and highlighting its mission of environmental sustainability. Hillside Farms is the primary beneficiary of the project, but it will also benefit the public. The manure treatment alternative will reduce the farm’s negative impacts on the environment and contribute to their environmentally conscious mission.

Objectives

The main objectives of this study are:

• To study and evaluate the three designs-an anaerobic digester, a lagoon, and a vermicomposting system were developed.

• To investigate the feasibility of installing a greenhouse or similar structure to insulate the vermicomposting units.

• Design manure treatment alternatives for a nonprofit farm to mitigate the adverse effects of agricultural runoff containing animal manure on the environment while making the farm’s operations more efficient and highlighting its mission of environmental sustainability.

• Provide cost analysis for each design option.

Literature Review

The most important environmental issues stemming from untreated manure are water, soil, and air pollution. Farm and dairy operations produce large quantities of manure that must be used and stored properly or risk damage to the surrounding environment. Heavy rainstorms and snowmelt have the ability to carry manure into nearby waterways or groundwater. Manure is rich with substances that can cause adverse environmental effects, including pathogens, phosphorous, ammonia, and nitrogen.

Huntsville Creek is adjacent to the feeding barn at Hillside Farms, which puts the creek at immediate risk for runoff from the feeding barn. The creek flows into the Susquehanna River, which flows into the Chesapeake Bay. The Chesapeake Bay has problems with excessive nutrients, which are often attributed to agricultural runoff. The Chesapeake Bay Foundation, a nonprofit organization dedicated to the health of the Bay, gave a grade of critical and poor to nitrogen and phosphorous pollution in its 2012 State of the Bay Report [1]. Manure runoff can create algae blooms, which deplete oxygen, devastating aquatic life. Manure can also make soil infertile if it is spread untreated on the field as a result of high nutrient concentration. In addition, untreated manure can cause significant air-quality problems. Manure management systems may be designed to deal with contaminants like dust, smog, greenhouse gases, and odors [2]. However, manure also has positive qualities. It is a significant source of fertilizer because it contains nutrients such as nitrogen, phosphorus, and potassium. In moderation, it adds organic matter to the soil, which may improve soil structure, aeration, soil moistureholding capacity, and water infiltration.

The current system at Hillside Farms holds cows in two different barns. In the primary barn, manure is deposited in a trough and an automated scraping system is operated as needed. The manure is scraped from the trough by metal chains and is transported to a loader, which is able to transport the manure to fields for spreading. The entire system had to be replaced in 2012. The metal chains had to be replaced as a result of wear and tear. The chains also sometimes fell off the track, diverting labor that could have been used elsewhere. According to Julie Fallon, a cobblestone foundation is buried approximately 25 cm beneath the soil of the original design site, which results in increased runoff. The primary feeding barn was constructed in the late 1800 s, a time before environmental health issues existed to the extent they do today. There exists a secondary barn approximately 30 meters away where manure is manually collected.

Three design options were originally researched for implementation: a composting system, a lagoon, and a traditional anaerobic digester. These original options developed and evolved over the course of the project. The composting system was ruled out in favor of a vermicomposting system. This modification is expected to lower the amount of labor involved in the composting process. The lagoon was eliminated from consideration due to its large land footprint, expense associated with excavation, and the catastrophic consequences stemming from its possible failure. The traditional anaerobic digester was shelved in favor of a bag digester. The bag digester is a less financially burdensome form of anaerobic digestion [3]. Near the conclusion of the project, the bag digester was ruled out due to the large amount of water it requires to operate. While feasible, the bag digester is not as practical as the vermicomposting system in the context of our project.

Anaerobic digester

Brick-and-mortar anaerobic digesters require significant capital investment. Greer [4] conducted research on the economics of anaerobic digesters. Greer reported that Geerlings Hillside Farm, located in southwestern Michigan, installed a 2082 m3 anaerobic digester in 2007. The number of cows in this study was unavailable. Their digester treated 30,283 m3 per year of hog and cow manure. The project was estimated to cost $1 million. This figure includes the main digester tank ($350,000), the liquid storage tank ($70,000), construction costs ($75,000), electrical generation equipment ($150,000), separation equipment ($55,000), a pellet mill ($50,000), and a dissolved air flotation system ($100,000). Underscoring the importance of grants, their farm received $250,000 from the Michigan Department of Agricultural Innovation Fund and a $325,000 grant from the U.S. Department of Agriculture. The sum of the two grants combined to total over half of the digester’s estimated $1,000,000 overall cost. The system returns capital, however, with the collection of methane. Greer estimated that the necessary hookup required selling the resultant power back to the grid costs $50,000 to $75,000, a prohibitive figure. Instead, the farm uses the power to run its own operations [4].

Small-scale dairies, like Hillside Farms, have been able to successfully implement less costly small-scale anaerobic digesters. Greer [5] reported that Jerry Jennisssen, owner of a 150 cow dairy farm in Brooten, Minnesota, gave three reasons for his acquisition of an anaerobic digester: an additional stream of revenue, an alternative method of storing manure, and insulation against future environmental regulations. The produced biogas was comprised of approximately 65% methane. The methane passes through a water bubble bed, which removes particulates, carbon dioxide, and hydrogen sulfide. Their digester was successful enough that it reached its 40 kW capacity; the farm was unable to process all of the methane and had to resort to flaring the excess [5].

Continuing with the collection of methane, dairy farms can utilize their cow manure for power to both use and sell. Blue Spruce Farm in Bridport, Vermont, produces enough power for 400 homes with their herd of 1000 milking cows [6]. Blue Spruce Farm has invested $1.3 million in the system but generate $120,000 per year in electricity sales. They will recoup their investment within just 7 years. In addition, the 2002 Farm Bill provides funding opportunities through the Renewable Energy Systems and Energy-Efficiency Improvements Program, making the addition of a methane collection system even more financially manageable and appealing. Cow manure is a renewable resource that avoids the emission of greenhouse gases; it fits well within Hillside Farm’s environmental mission of sustainability.

The microorganisms used in anaerobic digestion are predominantly mesophilic. They operate under conditions between 20 and 45°C. Thermophilic bacteria may also be used. They operate under temperatures greater than 45°C. They are capable of breaking down manure at a faster rate than mesophilic bacteria, but they tend to be fragile in the face of changing conditions. Mesophilic bacteria are preferred for their stability. The temperature at the site will often fall below the threshold for mesophilic bacteria. This necessitates artificially warming the digester to enable mesophilic bacteria, or leaving psychrophilic bacteria to decompose the manure at a much slower rate in the colder months. According to Naddafi et al. [7], the results of their study indicated that there was not a significant difference between the growth rate of the earth warm at 20 and 25 c, while the earth warm growth rate at 15 c was significantly lower (p>0.05).

Vermicomposting

Originally, a conventional composting system was considered by the project team. This idea has evolved into a vermicomposting system. Vermicomposting is the process of using earthworms to process organic waste. The earthworms process manure into vermicompost, which can then be added to soil as a form of fertilizer. Earthworms convert 50% of the manure into vermicompost. Vermicompost can be applied to fields at a greater rate than compost because they release nutrients at a slower rate. This advantage means that the magnitude of agricultural runoff is limited because the vegetation is able to absorb more of the released nutrients. Red wiggler earthworms are the preferred species for vermicomposting. They can survive between 0° and 35°C; the processing rate declines with decreasing temperature. This is a concern given the location of Hillside Farms. Borah et al. [8] in their study vermicomposting is rich in several enzymes and growth regulations such as auxins, and gibberellins.

Vermicomposting holds other advantages over conventional composting. It occurs at a quicker rate, taking 22-32 days compared with 30-40 days for the same volume composted conventionally. Also, the community around Hillside Farms is saturated with compost suppliers. Farms and other places of business distribute it freely, making it difficult to sell to consumers. Vermicomposting, in addition to vermicomposting, produces worms. Excess worms can be sold for profit to offset the cost of the system. Vermicomposting also does not require intermittent turning or mixing like conventional composting. The burrowing of the earthworms serves as a substitute for these costly or time-consuming labors.

Vermicomposting is practiced extensively in India. The Andhra Pradesh Rural Livelihoods Program, located in Sripuram, India, has initiated a vermicomposting system [9]. It was introduced to enhance crop productivity and allows farmers to get a higher per-hectare yield. Many farmers in Rajasthan, India, have adopted vermicomposting. Over 30 farmers now produce vermicomposting on a large scale. They use this low-cost technology on their own fields to produce higher yields. Two farmers have monetized vermicomposting and now sell their excess to farmers with lower production rates. Borah et al. [8] stated that there are path ways for nitrogen loss: A) leaching, B) vitalization and C) denitrification.

Design Considerations

This project encountered and accommodated various constraints. First and foremost, the area supplied by Hillside Farms was not ideal. The area initially suggested by Hillside Farms, approximately 730 m2, is small and compact, which lead to design complications. Lagoons, specifically, require a large surface area [10]. Our working area is shown in Figure 1.

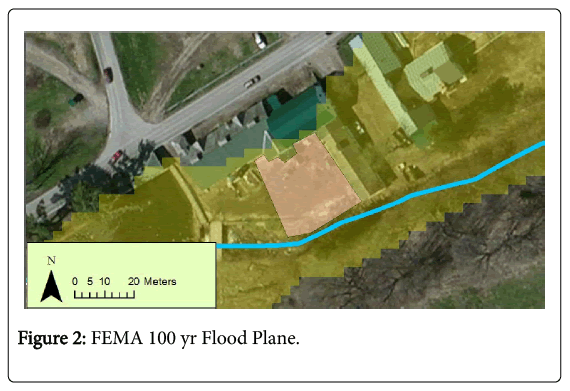

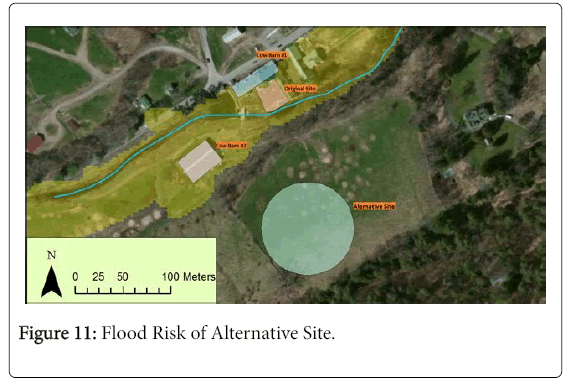

According to FEMA, the area is also located in the floodplain of the 100 yr storm event. This may be an unacceptable risk, given that failure of our design may cause serious adverse environmental effects and financial penalties from regulators; Huntsville Creek runs adjacent to the project area. The 100 yr flood plain is displayed in Figure 2.

In addition, the area is muddy, and runoff tends to pool in the center. Figure 3 shows the topography of the site.

The area must also accommodate a pathway for a tractor to traverse it. In summary, the area is ill-equipped to host a manure treatment center. The project team highlighted these concerns with Hillside Farm staff. A different, more suitable site, was chosen and will be requested to Hillside Farms. Hillside may already be considering moving their cow barn to another location. If that occurs, it would make sense to locate and construct the treatment facility nearby.

Because Hillside Farms is a nonprofit organization, the financial components of our designs were a limiting factor. The farm operates on approximately $400,000 per year. One of our original treatment options was an anaerobic digester, which has been estimated at $500,000 per 100 cows, ignoring operating costs. This already exceeds the yearly operating budget for Hillside Farms. A drastically less expensive version, an anaerobic bag digester, was considered. This version is estimated to cost approximately $12,420. The other treatment option was a lagoon, which, due to the massive amount of earth moving required, is not an inexpensive option [10-12]. The least expensive option was a vermicomposting system at $9,590.

Our manure treatment design must be in full accordance with all applicable federal, state, and local regulations [13]. Local regulations were expected to be the most limiting and therefore received the team’s primary focus. Hillside Farm is located in Kingston Township. The project team contacted this governing body to discuss the impact of regulations on the three proposed options and received no response. The proximity of Huntsville Creek may pose a problem. Lagoons have historically faced public opposition when proposed. Also, an anaerobic digester, in the worst-case scenario, can explode if the gas products are not properly managed. The vermicomposting system is expected to run into the least amount of regulatory hurdles. Hillside Farms should further explore the topic of regulations before implementing the project team’s recommendations to be absolutely certain that the recommendations are law-abiding.

Results and Discussion

Originally, three manure treatment systems were explored: a lagoon, a composting system, and an anaerobic digester. The lagoon was eliminated, and variants of the remaining two options were examined. Two systems were designed, a vermicomposter and an anaerobic bag digester. The project team decided that the vermicomposting system was the most appropriate for Hillside Farms. See the Design Application section of the report for more detailed information.

Both the vermicomposting and bag digester units are adversely affected by cold climates because they both rely on biological processes. These biological processes slow, and eventually cease, in cold weather. Hillside Farm must have considered implementing a greenhouse, or other similar structure capable of insulating the systems, if they require the system to run year round. The cost of this structure will likely surpass the cost of the system itself. Alternatively, Hillside Farms may choose to operate the manure treatment system only in the warmer months.

The vermicomposting unit was deemed more practical than the anaerobic bag digester for various reasons. The bag digester requires, at a minimum, 3 parts water per 1 part manure. This produces a significant quantity of wastewater which then must be stored or treated with expensive techniques like chemical precipitation or oxidation to remove the phosphates and nitrates. In addition, each bag digester was designed to carry 8.7 m3 of manure, corresponding to 4,350 kg, and 26.1 m3 of water, corresponding to 26,100 kg. Therefore, the total slurry volume would weigh approximately 30,000 kg per bag, a very large figure. Also, bag digesters have durability concerns. Bag digesters may become punctured as a result of sharp rocks, careless handling, or wildlife. The sun can also degrade the polyethylene bag. The field lifetime for an anaerobic bag digester is much shorter than that of a vermicomposting system comprised of more durable materials like wood and steel mesh.

Hillside Farms is a relatively small farm, housing just 60 dairy cows. Manure treatment systems typically require substantial time, money, and effort to implement. For these reasons, manure treatment systems are generally associated with larger, more “industrial” farms [14]. This belief can scare small farms away from manure treatment. The project team refutes that notion. Small farms, like Hillside Farms, have viable options in manure treatment. See Table 1 for a cost breakdown of the recommended vermicomposting system.

| Component | Information | Cost |

|---|---|---|

| Mesh | Galvanized Steel Diamond Mesh, 1" | $300($8.80/1.7 m2) |

| Wooden Frame | 3/4"Maple Plywood | $375($40/3.0 m2) |

| Worms | Red Wiggler Worms | $360 |

| Labor | Community Project | |

| $1,305/unit | ||

| $12,420 |

Table 1: Vermicomposting Cost Breakdown.

The vermicomposting system is not very labor intensive; it does not require overly specialized work. Ideally, a community group interested in volunteering at Hillside Farms will construct the system under the supervision of more technical-minded person such as farm staff. Assuming 5% are initially purchased, $360 per unit is spent on worms. Each vermicomposting bin will need to support approximately 3,100 kg of weight, or approximately 150 kg/m2. The structural properties of the galvanized steel mesh and wooden frame should be ascertained from the supplier to ensure that the material is capable of supporting the weight. The project team was unable to source material with the exact specifications that were required. Cost estimates for the mesh and wooden frame were determined by applying the cost per area ratio of a smaller sized piece to the required area of the component. This is not a perfect methodology. Although, cost per area generally declines as area increases, meaning the given cost for the mesh and frame is likely on the high end. Hillside Farms may approach a supplier to discuss customized dimensions.

For comparison purposes, the cost breakdown of the anaerobic bag digester system is displayed in Table 2. The primary, and most expensive component, are the polyethylene sheets. The project team was unable to source an appropriately sized polyethylene bag, so the design focused on sheets. A sheet can be transformed into a bag by sealing the ends together. Gluing and using an iron are popular methods used to seal polyethylene sheets together. A 6.3 m width was chosen as it is the width needed to procure a 2 m diameter. To increase durability, the bag digesters are double-lined which necessitates the purchase of two sheets. The mil, or thickness, of the bags may be increased if deemed appropriate. The literature suggests that 12 mil is suitable. The labor cost was approximated, assuming that each digester requires two people working for 6 hours at a rate of $14 per hour. The material cost is high enough to make slight fluctuations in the labor cost permissible and a near non-factor.

| Component | Information | Cost |

|---|---|---|

| 12 mil Polyethylene Sheet (2x) | 14.3 m × 6.3 m | $754 ($0.39/ft2) |

| PVC Inlet & Outlet | 6" | $35 |

| Labor | 6 hours*$14/hr* 2 people | $170 |

| $959/unit | ||

| $9,590 |

Table 2: Anaerobic Bag Digester Cost Breakdown.

Design Application

Anaerobic digester

The first step of installing an anaerobic bag digester is determining its necessary size. With a detention time of 30 days, the bag digester contains 87 m3 of manure and, with a 3:1 water to manure ratio, 261 m3 of water. Approximately 1,650 m3 of gas will be produced during the detention time. Assuming that the bag digester will contain 100 m3 of gas at any one point, the total volume of the bag digester is 450 m3 . This total volume has been chosen to be partitioned across 10 units. With a chosen diameter of 2 m, the length of each unit reaches 14.3 m.

A suitable location must then be determined. Our site is out of the 100 yr flood plain, has fairly flat topography, and is near the two sources of manure production. Preferably, the manure travels by gravity to the inlet of the bag digester, although this may not be possible in practice. Typically, a trench is dug in a trapezoidal fashion to promote stability while allowing room for maintenance. It’s vital to ensure that the lining of the trench is absent of any sharp rocks or other protrusions that may puncture the bag digester.

The polyethylene bag is the primary and most important piece of the design, although individual sheets may be used if bags may not be procured. If sheets must be used, they can be joined together using a variety of methods, the simplest of which are gluing and using a hot clothes iron. These bags contain an ultraviolet filter which assists their durability when exposed to the sun. Two bags are generally used to increase the strength and durability of the bag digester. Increasing the mill, or thickness, of the bags will increase their lifespan and cost. A suitable thickness is roughly 10 mils. The two bags should fit together with minimal folds or creases.

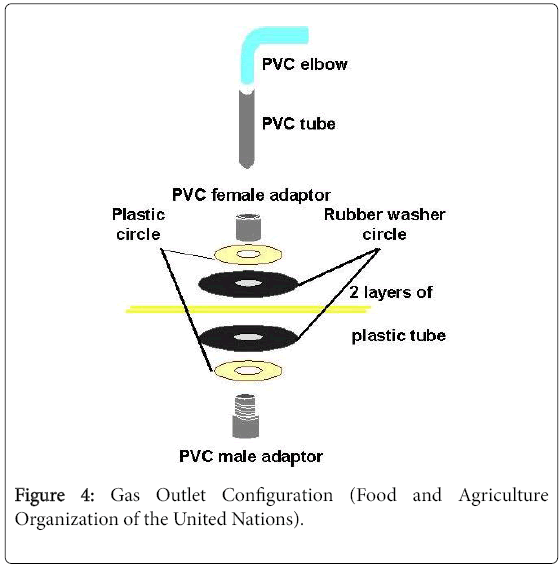

The gas outlet allows the produced biogas to be collected and utilized. Approximately 60% of the biogas will be composed of methane. After the appropriate measures are taken to eliminate hydrogen sulfide, the methane may be used to power operations at the farm. Hydrogen sulfide is a corrosive gas which can be eliminated via scrubbing or filtration through activated carbon. It is expected that the bag digester will produce 55 m3 of gas per day which is equivalent to 290 kWh. Figure 4 for a concise overview of the gas outlet. It is generally placed in the middle of the bag.

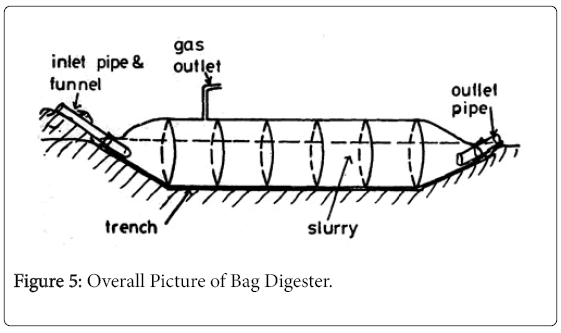

The inlet and outlet are usually constructed of PVC pipe. Half of the pipe length should be inserted into the interior bag. The pipes are secured to the bag with heavy-grade rubber bands with each one overlapping the previous. The bag is then pumped full of air to give it structure. These steps should be conducted in the trench so that transportation of the constructed bag digester is not required (Figure 5).

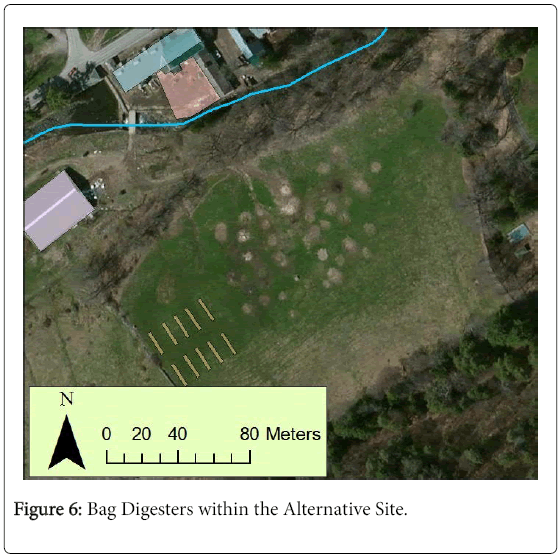

The placement of the bag digester within the alternative site is shown in Figure 6.

Vermicompost

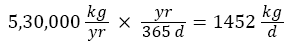

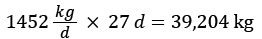

A preliminary vermicomposting batch system has been designed. Red wiggler worms, Eisenia Fetida , can consume approximately 75% of their bodyweight per day [15]. The treatment center must process 1450 kg of manure per day to prevent accumulation.

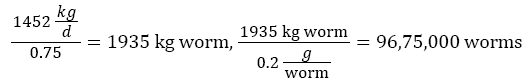

This necessitates 1935 kg of worms or, at 0.2 g per worm, 9,675,000 worms.

On average, it takes 27 days for the worms to convert the waste into vermicompost, although longer retention times will result in a more efficient process. Therefore, the system must accommodate 39,200 kg of manure.

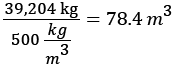

Assuming a cow manure density of 500 kg/m3, the total volume is 78.3 m3 . The manure density should be measured in the field to ascertain the assumption’s accuracy. The density may also change when it is confined to the vermicomposting bins.

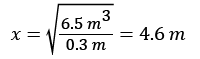

Breaking down the area of the vermicomposting system will provide flexibility and durability to the system. Therefore, the project team designed twelve vermicomposting piles that will each carry a cow manure volume of 6.5 m3 . The maximum depth of the bin should not exceed 0.3 m. The depth is limited to 0.3 m so that compaction does not occur. If compaction does occur, the worms may have difficulty migrating through the system. The minimum dimensions of the vermicomposting bin should therefore be 0.3 m × 4.6 m × 4.6 m, with added room for freeboard. The length and width may be modified to fit field conditions if required.

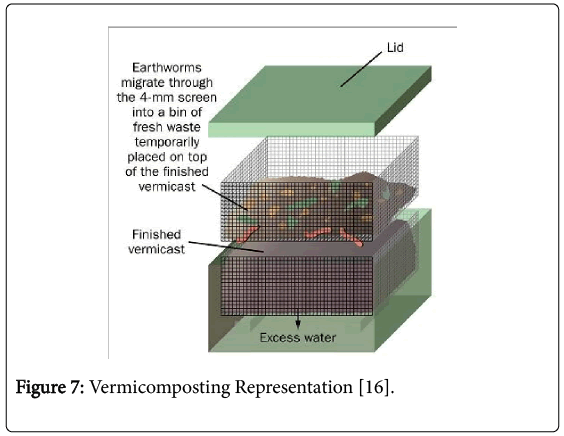

This bin will overlay another bin of the same dimensions. Each bin is constructed with wire-like material to facilitate oxygen transfer. The two bins provide redundancy and allow the collection of the vermicompost. When one bin has finished processing, overlaying the next bin with a new batch of manure on top will allow the worms to migrate to their new food source while leaving the vermicompost behind for collection. There should be a drain at the bottom of each bin to remove excess water; this water can be turned into “worm tea,” which is a nutrientrich fertilizer. The system is designed to collect the liquid fertilizer for collection by the farm, so unintentional runoff is not a concern. The system should be covered to protect the worms from light. Figure 7 displays a basic representation of the system.

The supplies needed to build this system are red wiggler worms and wooden boxes with the dimensions described above. The wooden boxes can be constructed as a community project. It would be a great opportunity for Hillside Farms to share their sustainability development with the community.

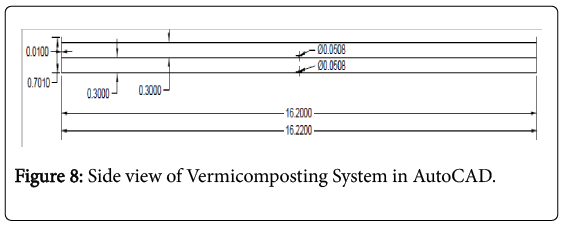

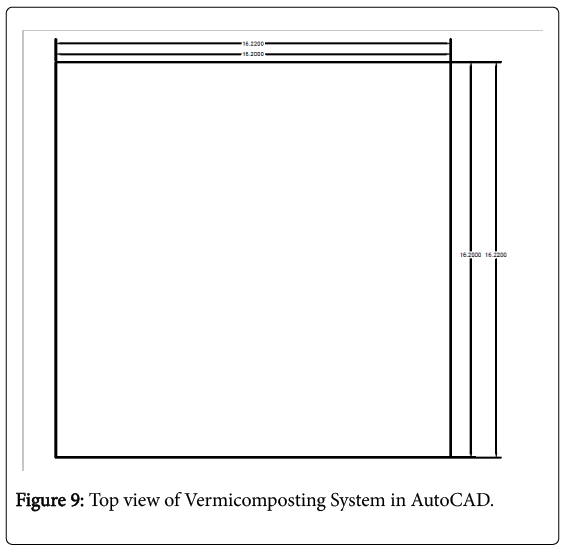

Figure 8 displays the system in side view. Figure 9 displays the system in top view. All units are in meters. The left, right, and bottom sides of the system have an extra 0.01 m exposed to air to facilitate oxygen transfer. There is 0.1 m of freeboard. The drain diameter is 0.0508 m. Future renditions of this design may incorporate an internal slope to ease draining.

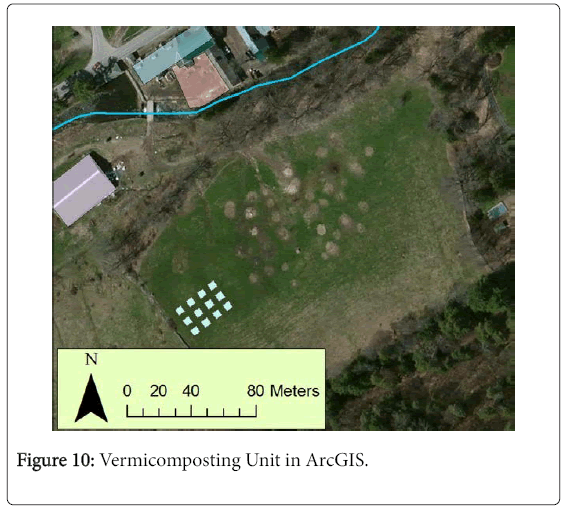

The design is shown at the alternative site in Figure 10. Since the worms in the vermicomposting system are sensitive to cold climate and the bag digester retention time increases in cold climate, the idea of installing a greenhouse is negotiable. The greenhouse gives the advantage of running the treatment facility all year, which prevents the accumulation of cow manure in the barn in cold weather, and provides the required environment for both systems to work efficiently. The green house will be designed to occupy both systems, the bag digester and the vermicomposting system. Morton Brothers INC is a leading U.S. greenhouse manufacturer that constructs greenhouses according to the desired size of the customer. The desired greenhouse design is a gutter-connected house that is 18 meter in width, 29 meter in length, and 5 meter in high. The gutter is constructed of 18 gauge galvanized steel and polyethylene covers. The greenhouse will provide the required environment for both systems to work efficiently at a cost of $8,700.

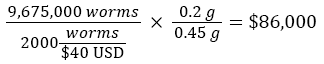

As stated previously, the system requires 9,675,000 red wiggler worms to process the daily manure production. For cost estimation purposes, online retailer WORM PAL offers 2000 red wiggler worms, or 2 pounds, for $40 USD. Assuming that the advertised 2 pound figure is all worm-weight, with no filler, each worm would weigh in at 0.45 g, over double our 0.2 g estimation. The worm cost of a vermicomposting system using WORM PAL as an example is shown below.

Red wiggler worms are capable of doubling their population in 60 days. It may be best to start with smaller system, gauge the worm’s success, and then determine whether to purchase more worms; they may reproduce to the point that purchase of additional worms is not necessary. If 5% of the worms are purchased initially, with expectation that they’ll grow to meet the full manure processing demand, the initial worm cost is $4,320.

Alternative site

The flood likelihood and the lack of available space has resulted in the search for an alternative site. South of the original site, the new site is out of the 100 yr flood plain while still featuring fairly flat topography. It is also nearby, although the site necessitates transporting manure across the creek and uphill over a ridge. Figure 11 show the alternative site, with the original site, the two cow barns, the 100 yr flood plain, and Huntsville Creek shown.

Conclusions

Initial designs for three manure treatment facilities were developed. These original three developed into two feasible options-a vermicomposting and an anaerobic bag digester system. Of the two, the project team decided that vermicomposting is Hillside Farm’s best option. A cost analysis accompanied each of final two designs.

Acknowledgment

The authors would like to thanks professors Holly Frederick and Brian Redmond from Wilkes University, Department of Environmental Engineering and Earth Science for their support and discussions. Thanks also extended to Mrs. Julie Fallon from the land at Hillside Farms.

References

- Zhu J (2002) The effectiveness of aerobes used as manure additives for swine manure odor control. Swine Health Prod 8: 5-9.

- Arsova L (2010) Anaerobic Digestion of food waste: current status, problems and an alternative product. Columbia University, New York, USA.

- Greer D (2010) Anaerobic digestion for smaller dairies. BioCycle 51: 24-26.

- Motavalli J (2007) Cow Power in Vermont. The Environmental Magazine 18: 10-11.

- Naddafi KZ, Zamanzadeh M, Azimi AA, Omrani GA, Mesdaghimia AR, et al. (2004) Effect of Temperature, Dry Solid and C/N Ratio on Vermicomposting of waste Activated Sludge. Pakistan Journal of Biological Science 7: 1217-1220.

- Borah MC, Mahanta P, Kakoty S, Sala UK, Sahasrabud LE (2007) Study of quality Parameters in Vermicomposting. Indian Journal of Biotechnology 6: 410-413.

- Sunitha (2006) Global Theme on Biotechnology and Crop Improvement. Abstracts of Students’ Research Projects 38: 728-754.Â

- Chastian JP, Henry S (2001) Management of Lagoons and Storage Structures for Dairy Manure.

- Aga D (2007) Fate of pharmaceuticals in the environment and in water treatment systems. CRC Press, Boca Raton, Florida, USA.

- Chastian JP, Vanotti MB, Wingfield MM (2001) Effectiveness of Liquid-Solid Separation for Treatment of Flushed Dairy Manure: A Case Study. Applied Engineering in Agriculture 17: 343.

- Cornell Waste Management Institute (2014) Compost Fact Sheet 3: Improving and Maintaining Compost Quality.

- Timms LL (2008) Characteristics and Use of Separated Manure Solids (following anaerobic digestion) For Dairy Freestall Bedding, and Effects on Animal Health and Performance in Three Iowa Dairy Herds. Animal Industry Report, vol: 654.

- Governo J, Faucette B (2005) Vermiculture facility grows in the southeast. Biocycle 46: 47-48.

- Chaoui H (2010) Vermicasting (or vermicomposting): processing organic wastes through earthworms.

Citation: Noura AS, Joseph C (2018) Design of Manure Treatment Alternatives for Hillside Farms Pennsylvania, USA. J Bioremediat Biodegrad 9: 423. DOI: 10.4172/2155-6199.1000423

Copyright: © 2018 Noura AS, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 7223

- [From(publication date): 0-2018 - Nov 16, 2025]

- Breakdown by view type

- HTML page views: 6167

- PDF downloads: 1056