Research Article Open Access

Design and Theory for Creating Hover Board

Praneet Sah*Department of Science, Bedi International School, Bareilly, India

- *Corresponding Author:

- Praneet Sah

Department of Science, Bedi International School

Bareilly, India

Tel: +91-812-661-4444

E-mail: hello@praneetSah.com

Received date: August 29, 2016; Accepted date: September 21, 2016; Published date: September 27, 2016

Citation: Praneet Sah (2016) Design and Theory for Creating Hover Board. Int J Adv Innovat Thoughts Ideas 3:162. doi:10.4172/2277-1891.1000162

Copyright: © 2016 Praneet S. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at International Journal of Advance Innovations, Thoughts & Ideas

Abstract

Hover board can be confused with a Segway but a real hover board is one that can float in air and move around. Despite huge interest from people and much technological advancement, we have not been able to invent a fullyfledged Hover board yet that could levitate and work on most of the surfaces. Although we have been able to levitate stuff (using Maglev or Super-Conductors) but in doing that in a small, portable and feasible form factor has not been quite possible yet. Few companies tried creating a Hover board but they are limited to work only on metallic surfaces and as a matter of fact, we do not get to see roads getting paved out of metals anywhere. This paper proposes a way and design on harnessing the power of pressurized vapour that would be enough to generate a lift which could levitate most of you on the Hover board and if you could balance it, you can ride it. There exist numerous implications for this theory and Hover board is just the one of best example out there.

Keywords

Pressurized steam; Levitation; Hover board; Pressure vessel; Design innovation

Introduction

Hover board is science-fiction term that is given to a skateboard which has the capabilities to float in air. A better way to understand it is to take a normal skateboard, remove the wheels from it and attach a system that could make it move around in air. They were first seen in a Hollywood movie of 1989 called “Back to the Future Part II” and since then there has been a craze for people to own a Hover board. In the past, there have been multiple companies that claimed to have built a real Hover board but unfortunately most of them were prank, out of which one even included a famous skater ‘Tony Hawk’. Amongst all of these fake claims, we had two companies whose claim was genuine. Lexus and Hendon are those two companies. Both of them made a working Hover board but they both have their limitation. None of them can work on every surfaces but metallic [1]. Moreover, the Lexus Hover board requires liquid nitrogen to work which cannot be easily acquired by consumers and as a matter of fact, the Hendon Hover board retails with a price tag of USD 10,000 with a run time of just 7 minutes [2]. If we could make a more realistic Hover board, then it is sure to make a breakthrough. The thing that’s now left to do is to make it a reality.

The basic idea that we aim to achieve with a Hover board is to create a whole new mode of transportation, that is not in contact with the ground but rather, it levitates above it. This paper proposes a way in which we can make Hover board a reality, using a new design and a new thought process for the working of a Hover board. As with any other vehicle, I will be using rechargeable high energy density batteries and water as the fuel for this Hover board. And both of these substances are feasibly available at most of the places, electricity to charge and water as fuel. This paper first discusses the components required, the working of each component, the methodology and finally there’s a review on how the Hover board would work. A conclusion is provided on what we have achieved through this and what else can be done on this.

Components

There are two prominent things that we want to sustain throughout the Hover board. Firstly, the whole system needs to run on such a fuel that is feasible to obtain and secondly, it needs to be portable by being as light as possible. The majority of the weight adds up by the use of pressure vessel and the battery which is responsible to power up heating coils, however the pressure generated is enough to lift those two comparatively heavy components plus the weight of an average human, riding the board [3]. The essential components involved are listed as following with their minimum specification.

Cylindrical pressure vessel with semi-elliptical ends

The pressure vessel is the prominent component for the whole system. The water is kept inside it and later heated to convert into pressurized steam. Since we are dealing with pressurized steam, therefore the pressure vessel must be able to withstand a pressure of at least 6000 PSI. The vessel will also have nozzles four pressure relief valves (nozzles) attached to them which automatically get activated as soon as the internal pressure hits 2575 PSI [4]. The volume of the vessel is kept in accordance to the space available under the deck of the skateboard and it turns out that 0.2 m3 is the most effective volume which will contain approximately 20 ltr of water. Also, the water adds up another 20 kg of weight to the system. The material of construction for the vessel will be Alloy C-276 due to its resistance towards corrosion which is likely to occur in a system using water [5].

Flat zigzag heating coils

They were chosen over conventional form of heating the contents of a pressure vessel because heating coils provide the fastest way to heat the materials that are present inside the vessel. Using heat exchangers would not suffice and would also result in wastage of a lot of energy, neither would they be portable enough [6]. Flat zigzag design is chosen in order to cover larger area and to heat evenly throughout the vessel. The material of constriction for the coils would be Titanium because of their properties like light weight, corrosion resistance and the ability to work in high temperatures.

High power density battery

As with most of the gadgets out there, this one also requires the use of batteries, of a very special kind, in order to power up the Heating coils. Batteries generally tend to be heavy and huge, that is why it is necessary to have a battery that offers very high power density in order to minimize the volume it occupies along with its weight. The most suitable batteries for our purpose are the Lithium Thionyl Chloride (LiSOCl2) batteries due to their high power density which implies that we can get more energy with less weight [7]. These batteries can provide up to 1420 watt-h/ ltr volume or in other words 500 to 700 watt-hrs/kg.

Deck (skateboard without wheels)

All of our components and electronics will go beneath the deck. Wood decks are not very durable and are comparatively heavy also. Since strength along with the weight is an important factor for us, therefore the deck needs be crafted out of carbon fibre, for which companies do exist, and this will drag down the weight of deck to a mere 560 gms with an increased strength of the board [8].

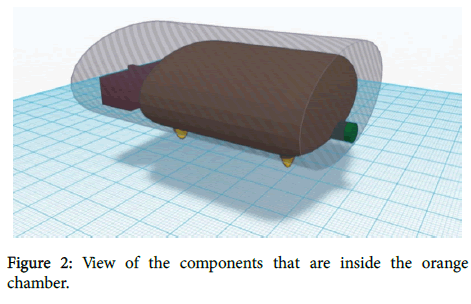

Design

The main thing happens inside the orange chamber, which is more of a protective casing, as shown in Figure 1. The black colour object is the deck which goes on the top and serves the purpose of a platform for the person to stand. Beneath the deck we have the chamber, marked with orange colour, which contains the pressure vessel and the batteries, as shown in Figure 2. This chamber acts more like a protective casing because there are chances that things may go wrong with the pressure vessel. So, in order to protect ourselves from the mishap, this chamber/casing is provided to the whole system.

Design constraints

1. The summation of cross sectional area of all the four nozzles is 1cm2.

2. The vessel and the battery are securely screwed to the outer casing.

3. The vessel can withstand 6,000 PSI and exceeding that limit may result in bursting on the vessel or other unfortunate events.

4. The external casing is crafted out of a Magnesium allow which is the toughest metal despite being as light as aluminium metal. The casing should be able to decrease the effect of any unfortunate occurrences.

Marking the connections

1. The orange chamber has been shown with black-striped casing in transparent form in order to see the connections that it holds inside it.

2. The green colour port on the right side of the casing acts as the inlet for putting the water inside the vessel. It directly opens inside the vessel with a secure rubberized seal which will prevent unwanted pressure leakage.

3. A port on the left side is provided to charge up the battery.

4. Positive and negative terminal wires are going inside the vessel from the battery in order to turn on the heating coils. The battery’s connection is completed by turning ON the switch that is given on the other side of the casing.

5. The heating coils are inside the vessel, arranged in a flat zigzag manner.

6. The yellow colour objects on the bottommost part are the nozzles from which the pressure would come out, directed towards the floor.

Theory

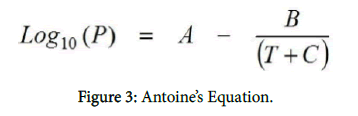

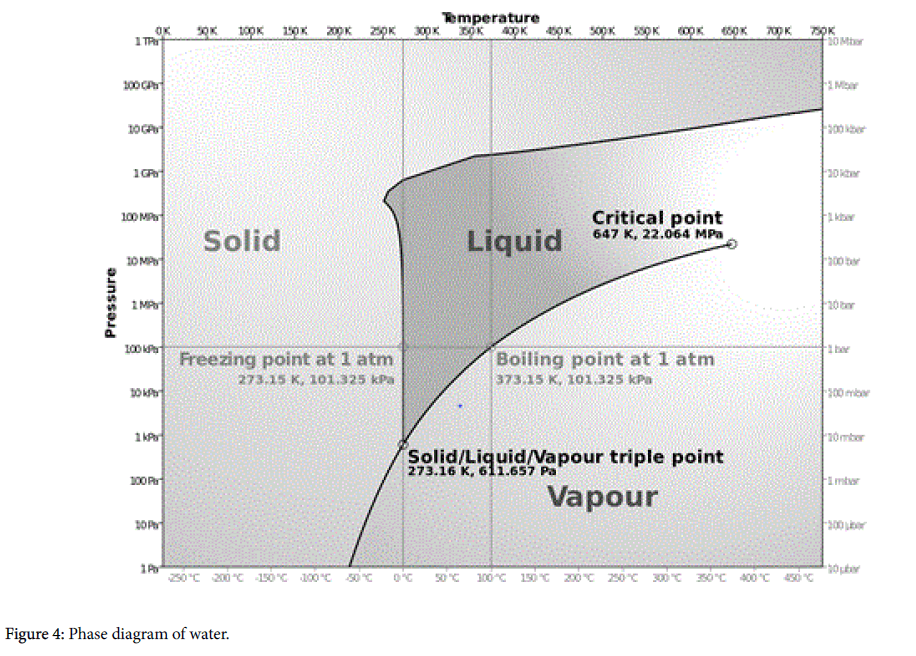

Pressurized gas contains a lot of potential in them and it is just a matter of figuring out on how to harness them. However, the challenge was in figuring out the production of high pressurized gas in a portable form factor. The basic guideline for this technology to work is to use choose a feasibly available component for fuel, and water just served our purpose. It is cheap and widely available in most of the regions. The phase diagram of water is given in Figure 4 and it is evident that water has the potential to generate large pressure at high temperatures [9].

Using the Antoine’s equation (Figure 3) and with the help of phase diagram (Figure 4), we can find that at the critical point, 374°C, water keeps a potential of reaching 3,151 PSI which is quite a lot of pressure. For comparison, most of the pressure cookers that we use in our homes are made to handle 15 PSI and water has potential to reach 210 times pressure of that [10]. At high temperatures, water also has the property to change pressure rapidly with a very little change in temperature, thus making it a strictly increasing function and very volatile. There could be severe high pressure developments which could result in a mishap, if there happens to be mistakes or if the valves fail to release pressure.

After considering the weight of various components included (such as batteries, coils, vessel, deck etc.), 356° C comes out to be the most appropriate temperature to heat the water inside the vessel for our purpose which will provide us with 2,575 PSI. It is appropriate because it provides enough force that could lift all of that weight plus the weight of an average North American which is 81 kg [3]. With that much amount of pressure getting released through an area of 1 centimetre square, then it is capable enough to lift weights up to 181 kg.

As soon as the pressure starts getting released through the nozzles, the pressure inside the vessel would start decreasing. In order to maintain a consistent pressure output of at least ~2,575 PSI, we would need to increase the temperature at which the water is being heated. This is done in order to compensate for the pressure drop which happened because of its release. Doing so will lead to two things, firstly the fuel, which is water, will now be used in a lot more quantity and secondly the internal pressure created by the conversion of water into gaseous state will begin to rise a lot more than 2,575 PSI. The immense rise in the production of vapour, which would be nearly 1.5 times the pressure exiting, is one of the reasons to why we require a pressure vessel that can bear 6,000 PSI. The critical point for the water is 374° C, due to this limit; the temperature would be limited to 374° C. However, a perfect system cannot exist and because of the fact that the relationship between temperature and pressure is a ‘strictly-increasing’ function, therefore an excess amount of pressure generation can be witnessed. Safety becomes the topmost priority and especially in such unfortunate cases, the outer shell acts as a shield of protection for this system.

Working

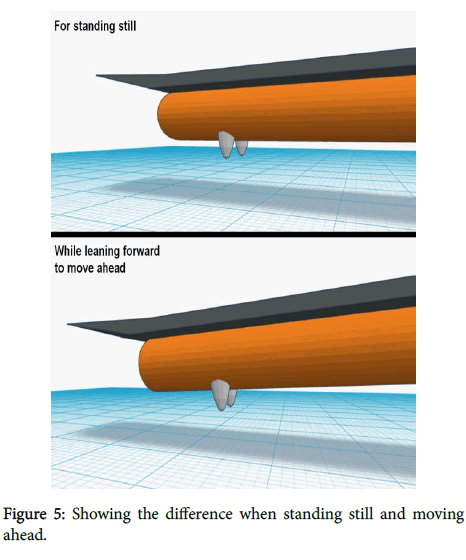

Generating the necessary amount of pressure is a vital process which we achieved in the section 4. The challenge now is to direct the pressure in such a way that it could actually make the Hover board levitate in air. For this, the location of each four nozzles has been strategically chosen to be closer to the front side. This is done so that when the operator leans forward, the pressure nozzles of the front end would come closer to the surface thus causing an imbalance between the pressure exerted from the front end nozzles and the back end nozzles. Using the Newton’s third law, it can be very well derived that the front nozzles would create a more ‘push’ effect on the board thereby causing the board to move in the front direction as shown in Figure 5 [11]. This design does not cater to the working of Hover board in the backwards direction and is supposed to be taken in front direction only.

For moving the Hover board sideways, the controller would be required to tilt the Hover board on the side that he wishes to move. So in this case, one nozzle from each set, front and back, would be closer to the ground. Overall, the Hover board will work in this manner: The user would power ON the battery which will start the heating coils fixed inside the vessel. Within minutes of heating the water at 365° C, we would have hit 2,575 PSI of pressure which will then start getting released through the 4 nozzles which are pointing towards the ground. This will produce a lift of 181 kg and the person could then stand on the Hover board and ride it by leaning in the direction he wishes to move. In order to turn off the Hover board, the user needs to power OFF the batteries which will stop the heating coils from further heating the water. This will result in decreased production of vapour which will ultimately decrease the pressure. Soon, the Hover board will come to a stop.

Prospective developments

The current model will give you a working Hover board however there are some areas that can be developed further along with some areas that can be improved. First being the time that it takes to starts which is almost a minute. The current model heats the water in this time and does the same for every run. This is a sheer wastage of energy and can be further improved if we create a thermally intact vessel that would not allow the water to lose its heat content by a large proportion, after the first use. So this way, in the next run, the time it takes to heat the water would reduce significantly thus reducing the overall time taken to start.

Another area of improvement is to find another feasibly available material which, on heating, can produce a lot of pressure without a lot of consumption of that material itself. This way we can reduce the refilling cycles which is currently on the higher side as water would run out in minutes. A better aerodynamics can be applied to reduce the friction that the Hover board will have with the air.

Conclusions

In this paper, I have proposed a way in which Hover board can be made a reality. By using substances as common as water and harnessing its pressure, we can make the first Hover board that could work on most of the surfaces. Firstly, we looked at all the main components that are required along with their properties. Using Antoine’s equation and the phase diagram, we concluded that water has the potential to reach generate high vapour pressure. Figuring out on how to do this in a compact form, we finally created a system that could generate a lift of 181 kg. Directing this pressure against the surface will lead you to a levitating Hover board that can be controlled, if you could.

Hover boards have already been hyped a lot and the only type of board that we didn’t have in the market was the one that could work on actual streets, rather than just specially built metallic skate parks. With this theory, we can be seeing our own Hover board in less than a decade or maybe a lot earlier.

References

- Allain Rhett (2014) The Physics of the Hendo Hoverboard. Wired.

- https://www.kickstarter.com/projects/142464853/hendo-hoverboards-worlds-first-real-hoverboard

- Sarah CW, David PM, Phil E, John C, Gretchen S, et al. (2012) The weight of nations: an estimation of adult human biomass. BMC public health 12:439

- "Pressure relief valve." U.S. Patent 4,206,870, issued June 10, 1980.

- Qiang Zhang, Rui Tang, Kaiju Yin, Lefu Zhang (2009) Corrosion behavior of Hastelloy C-276 in supercritical water. Corrosion Science 51: 2092-2097.

- Hewitt, Geoffrey Frederick, George L. Shires,Theodore Reginald Bott (1994) Process heat transfer. Boca Raton, Vol. 113. FL: CRC press.

- Samuel C. Levy, Per Bro (1994) Lithium/Thionyl Chloride Batteries. Battery Hazards and Accident Prevention 211-232.

- https://www.kickstarter.com/projects/121cboards/121c-boards-the-out-of-this-world-cruiser-skateboa

- George C. Kennedy (1950) Pressure-volume-temperature relations in water at elevated temperatures and pressures." American Journal of Science 252: 225·241

- Morrison Jr Willard L (1951) "Safety pressure release for pressure cookers." U.S. Patent No. 2,552,642. 15

- Zarankin, Ilya (Newton’s Third Law. Revitalizing Achievement by using Instrumentation in Science Education 2004-2007

Relevant Topics

- Advance Techniques in cancer treatments

- Advanced Techniques in Rehabilitation

- Artificial Intelligence

- Blockchain Technology

- Diabetes care

- Digital Transformation

- Innovations & Tends in Pharma

- Innovations in Diagnosis & Treatment

- Innovations in Immunology

- Innovations in Neuroscience

- Innovations in ophthalmology

- Life Science and Brain research

- Machine Learning

- New inventions & Patents

- Quantum Computing

Recommended Journals

Article Tools

Article Usage

- Total views: 17486

- [From(publication date):

October-2016 - Apr 03, 2025] - Breakdown by view type

- HTML page views : 16025

- PDF downloads : 1461