Design and Fabrication of Biomass Extruder of 50 mm Diameter Briquette Size

Received: 27-Dec-2015 / Accepted Date: 13-Jan-2016 / Published Date: 21-Jan-2016

Abstract

Agricultural residues are producing in large amount but they are used inefficiently that pollute the environment. Apart from the problems of transportation, storage, and handling, the direct burning of loose biomass in conventional grates is associated with very low thermal efficiency and widespread air pollution. To overcome these problems the biomass materials is compressed as 1000 kg/m3 and can increase its density and durability. In this study a machine was designed to densify grinded biomass materials at optimum level of density to obtain more than 90% durability. The machine was consist on power screw and slotted tapper die. The grinded material of particle size less than 5 mm and moisture contents less than 12% passed through hopper and power screw which was rotating at 300 rpm with a 15 kW electric motor compressed this material through tapper die which was heated externally by electric heaters. The capacity of machine was 200 kg/h. The payback period of machine was 4 months.

Keywords: Crop residue; Biomass extruder; Machine design; Fabrication; Briquette

18442Introduction

Pakistan is extremely dependent on the use of fossil fuels, mainly coal and petroleum. The dependency is even more evident in the semiurban areas. On the one hand, several small scale industries such as brick kiln manufacturers, industrial boilers, and food processing and pharmaceutical industries use coal for thermal/heating purposes, which results in high greenhouse gas emissions, which are responsible for climate change [1]. On the other hand, institutional kitchens use expensive and polluting LPG (liquefied petroleum gas). However, the rural population in Pakistan does not have access to reliable energy. The main source of energy for this section of the society is the use of firewood. The people living in rural areas burn firewood inefficiently (mainly for cooking), which causes indoor air pollution and releases harmful black smoke. Thus, only unreliable and dirty energy is available to the rural population and industries in semi-urban areas [2,3]. Pakistan has millions of tons of unused and available biomass waste. This loose biomass is currently treated as a waste with no economic value. It is often burnt inefficiently in open fields, causing air pollution. However, this ‘waste’ can be turned into a completely environmentfriendly source of energy through briquetting. It contains more oxygen and low carbon with respect to other fuels [4]. Agricultural residues are an abundant biomass feedstock [5]. There is a great concern in using biomass solid fuel, such as pellets or briquettes [6]. Briquettes are compressed biomass material, which can be used for heat and electricity generation. Unused, loose, and low-density biomass can be briquetted to a bulk density of more than 1000 kg/m3. Biomass briquettes can be used for small and big thermal installations, replacing coal and LPG [7]. This, in turn, results in significant emission reduction. Biomass briquettes can also be used in small- and big-scale smokeless stoves that are based on the gasification technology for commercial cooking, as well as at home, replacing LPG and firewood. In addition, they can be utilized in bio-digesters and gasifiers for decentralized power generation [8]. Energy resources like natural gas, oil, hydro and nuclear, coal and liquefied petroleum gas (LPG) contribute to 48.3%, 32.1%, 11.3%, 7.6% and 0.6%, respectively of primary energy supplies of Pakistan [9].

The use of briquettes based on biomass, a renewable source, will reduce the amount of CO2 (carbon dioxide) emitted due to the burning of fossil fuels like coal and LPG [10]. In addition, the collection and densification of biomass will generate income for the rural people, as well as provide a clean energy for the local industry in an environmentally sustainable manner [11]. Most of the biomass materials are, however, not suitable for direct utilization, because they are fluffy, uneven in size and shape and have very low density [12]. These differences not only make difficult to handle, transport and store the biomass material in raw form. There are numerous ways to resolve these problems, of which briquetting is the most commonly utilized technologies [12]. Briquettes are commonly made in piston press which produces solid briquettes [13]. But, to date, in Pakistan there is no biomass briquette machine is being manufactured and only one unit of piston press is currently available which is imported from India and not in working condition due to unavailability of spare parts. Therefore, every year thousands of tons biomass is being wasted due to lack of briquetting machine because farmer do not have enough time and space to store biomass in a huge quantity. So, a study was planned to design and fabricate indigenous biomass screw press machine at low price and also insured the availability of its spare parts.

Methodology

The study was conducted with an overall objective to design and fabricate an extruder type biomass briquette forming machine.

Procurement of materials

Following materials were purchased to fabricate the extruder type briquette forming machine (Table 1).

| Part Name | Quantity | Description |

|---|---|---|

| Electric motor | 1 No | 20 hp×900 rpm |

| Power screw | 3 No’s | High carbide steel |

| Electric heater (coils) | 3 No’s | 1.75 kW each |

| Barrel | 1 No | size according to screw size |

| Die | 1 No | 50 mm inner diameter |

| V-Pulleys | 2 no’s | 150 mm and 540 mm diameter |

| V-belts | 4 No’s | A-64 |

| Bearings | 2 No’s | UC-250 with brackets |

| Angle Iron and M.S Sheet | - | Sheet - Main frame and body |

| Electric panel board | - | Breakers, thermostat, temperature gauge, on off switches etc. |

Table 1: Materials purchased to fabricate the extruder type briquette forming machine.

Design of machine

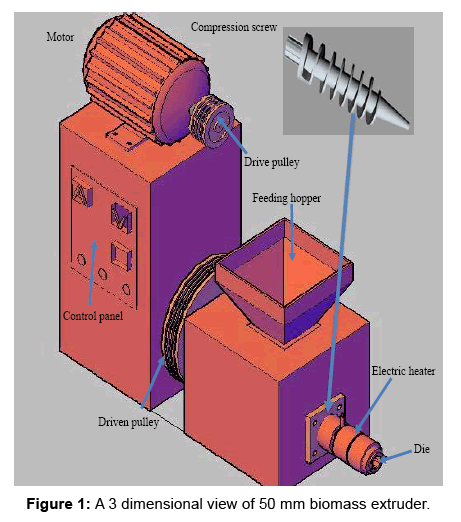

The machine designed for briquetting was of single extrusion heated-die screw-press type. The main parts of the machine are motor, pulleys and belts, screw, barrel, heater die and briquette die. Power is transmitted through pulleys and belts from the motor to screw. The outer surface of the die was fixed with an electrical coil to heat it about 300ºC. The temperature of heater is maintained by thermostat. The temperature is helpful to melt the lignin in the biomass and used as a binder. After starting the motor, raw material is fed into screw that compressed it and extruded through die.

Results were reveled from laboratory experiments (detailed discussion in R&D section) that 30 MPa is required to compact biomass upto 1000 kg/m3 at 8% moisture content and less than 5 mm particle size. The machine was designed with following assumption and requirements

Requirements

From review of literature few assumptions and requirements was set for machine design such as the minimum capacity of machine was assumed 200 kg/h with density of the briquettes ≤ 1000 kg/m3 because the densities of raw materials are ranger from 80 kg/m3-129 kg/ m3. The durability must be greater than 90% for safe storage, handling and transportation. The diameter of briquettes was selected as 50 mm because these briquettes will be used in steam boilers so if diameter reduce from 50 mm the thickness of wall will also be reduced because 15 mm center hole also necessary for because this hole is due to screw shaft and also for air circulation during burning. The solid briquettes not burn completely especially from center point. This hole is also an advantage of screw press over piston press (Table 2).

| Shape of briquette | Cylindrical |

| Outer diameter of briquette | 50 mm |

| Inner hole diameter of briquette | 15 mm |

| Length of briquette | 300 mm |

| Machine capacity | ≈ 200 kg/h |

| Compaction ratio [14] | 10 |

| Diameter of screw shaft | 50 mm |

| Size of last feeding zone flight | Diameter =100 mm and pitch=46 mm |

| Density of shredded biomass material | 100 kg/m3 |

Table 2: Requirements to design machine.

Calculations

Diameter and pitch of last flight of compression zone

Volume of last flight of feeding zone=

(1)

(1)

To calculate pitch of compression zone assume diameter of last flight of compression zone was 65 mm, and

(2)

(2)

We assumed that the compression ratio was 10. So,

(3)

(3)

Pc=20mm3

As we know that the density of feeding material was 100 kg/m3, so the mass of material conveyed in one complete revolution of feeding zone was,

m=100 kg/m3 × 2.708 ×10-4 m3=0.027 kg

The efficiency of the screw conveyor is 50% [15], than mass of material conveyed in one full flight of feeding zone in one revolution was

m=0.02708 × 0.5=0.0135 kg

Now, the density of compacted briquette was assumed, 1000 kg/m3

ρb =1000 kg/m3

Volume of briquette was,

Vb=π/4 {(50)2- (15)2} × 300=535762.5 mm3=5.35 ×10-4 m3

Mass of briquette was,

mb =1000 kg/m3 × 5.35× 10-4 m3=0.535 kg

Number of revolutions required to make one briquette,

N= 0.535/0.0135=39.5 revolutions (4)

Capacity of machine was assumed, 200 kg/h.

Number of briquettes made in 200 kg,

Number of briquettes= 200/0.535=373.83 briquettes ≈374 briquettes

374 briquettes were made in one hour or 3600 s so,

Time required for one briquette= 3600/374=9.62 s

We know that revolution required for one briquette was 39.5 so,

Time required for one revolution= 39.5/9.62=4.10 s

And revolutions per minutes was

R.P.M=246.36 ≈246

Driving system

Motor RPM was 900 so design of driving system as follow

D1 × R1=D2 × R2(5)

Consider belt slip as 2% of each belt. So the calculated RPM of driven pulley was 250.

D2=540 mm

Motor power required

We know that the outside diameter of last flight of compression zone was 65 mm. We also know that from laboratory experiments that the pressure required to compact biomass up to 1000 kg/m3 was 30 MPa. Speed of screw was calculated as 246 RPM (Figure 1).

Coefficient of friction between screw and feeding material was, μ=0.25 [15]. Helix angle (α) of acme thread calculated as

(6)

(6)

μ1 = virtual coefficient of friction

β = angle of acme thread

As the angle for Acme threads is β = 14.5°, so virtual coefficient of friction,

(7)

(7)

We know that the force required overcoming friction at the screw,

P=W tan (α+φ1) (8)

W = axial load exerted by screw

Amount of load (W) was calculated form laboratory experiments as follow,

Pressure= (Force)/Area and Force=Pressure × Area (9)

Pressure = 30 MPa and cross sectional area of briquette was

Force=30 N/mm2 ×1785.87 mm2=53565 N

P= 20590.6 N

Mean diameter of last flight of compression zone

(10)

(10)

Torque required overcoming friction at the screw.

(11)

(11)

We know that power required to drive the screw, was

(12)

(12)

Results And Discussion

The study was based on three objectives and the results from this study were discussed according to these objectives. First objectives was “To design and development a hollow die screw press briquette forming machine” The complete design of the machine already discussed in previous chapter (Methodology) a software for designing screw press briquette machine of any capacity (kg/h), briquette size (diameter) and compression ratio was developed. This software required some primary parameters of machine and the subsequent calculations of different sample characteristics will emerge on the sheet as results.

Performance evaluation of briquette forming machine

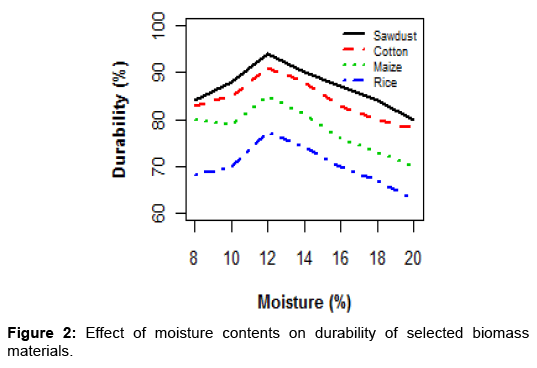

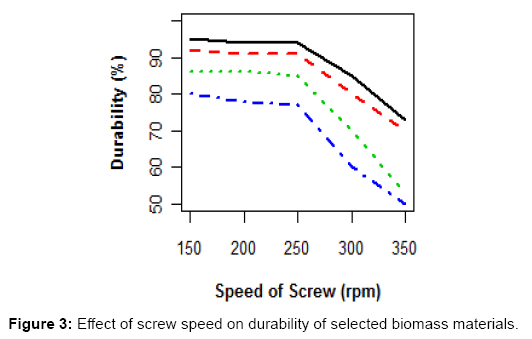

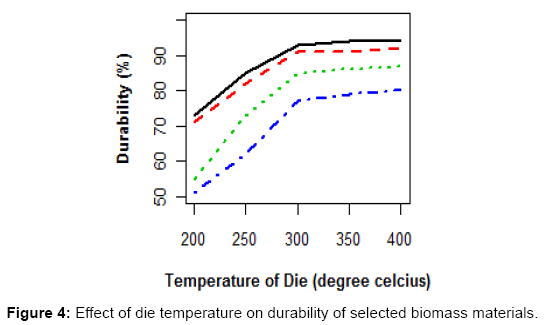

Once the full design was completed, initially machine was tested with three parameters like moisture contents of selected raw materials, speed of screw and temperature of die and results shown in Figures 2-4. All the tests were conducted with a 3 phases, 20 horse power, and 970 rpm electric motor. The testing of the screw press gave information about briquette quality and capacity. The most important findings in this first step were that the moisture contents, speed of screw, particle size and temperature of die must be kept at 10%, 250 rpm, 3 mm and 300 °C to certify a good performance respectively [14]. Concluding from their research, the highest density (1136 kg/m3) of corn stover was produced from 3.2 mm particle size and at 12% moisture contents [16] said that the compression ratio was ranging from 5.2-8.6 and recommended that a maximum of 8.6 times. Temperature played a crucial role in briquetting process. According to given conditions, the capacity of machine was found to be 200 kg/h determined in a 120 minute test. The linear speed at the outlet was 30 mm/s. The average individual density was 975 kg/m3-1000 kg/m3, and the densification ratio was found to be 10, which agreed well with the calculated densification ratio of 10 as determined during the design of the screw. Once the first test was finished, the full experimental design was carried out.

Effect of moisture contents

The trends of effect of moisture content lines on durability of all type of biomass materials were almost same as shown in Figure 2. The maximum value of durability for all materials like sawdust, cotton stalks, maize straw and rice straw at 12% moisture contents. As moisture level were increasing continuously from 12% to onward the durability of briquettes were decreasing and after 20% moisture contents the machine was unable to produce briquettes and compacted material was stuck into the die of machine. When moisture level was too high than material cannot flow into the flights of screw and die and stuck badly.

Effect of screw speed

Five different size of driving pulleys were also used to determine the effect of screw speed on durability of selected biomass materials. It was observed that briquettes were more durable at slow speed because of more compaction was occurred but this trend was up to 250 rpm. As the speed of screw was increased from 250 rpm the compaction was not firmly and durability of briquettes were decreased as shown in Figure 3. To attain good quality briquettes screw speed should be 250 rpm and further tests were conducted at 250 rpm of screw.

Effect of die temperature

The third and last parameter was temperature of die from which required shape of briquettes were produced. The machine was unable to produced briquettes at a temperature of die below 200°C and compacted materials were not flowing within die and stuck. After 200°C the machine produced briquettes but not as much good quality as required so this test extended up to 300°C. The durability of all type of biomass materials were maximum at 300°C and this value was constant beyond 300°C so the further tests were conducted at die temperature of 300°C (Figure 4).

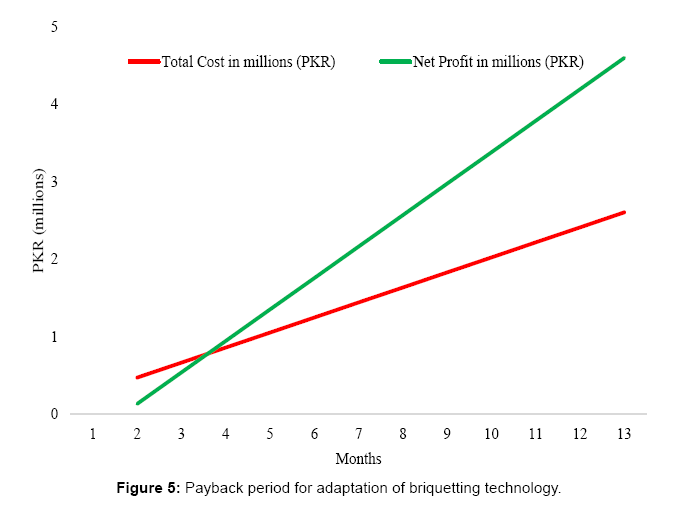

Economic analysis

In Figure 5 red line shown the total cost of briquetting technology including machines, labor and operational costs and green line shown the net profit if machine operate 8 h per day and almost 25 days in a month. By adopting this technology farmers can get some additional money from crop residues which he presently wasting and polluting the environment and as mentioned in case study this technology can also solve electricity problem of rural areas. This technology is highly economically viable in rural areas of Pakistan and the payback period of this technology was just 4 months [17,18]. Concluded that the payback period of piston press briquetting technology was 6 months (Tables 3 and 4).

| Items | PKR | Remarks |

|---|---|---|

| Cost of Shredder | 75,000 | Complete fabrication cost |

| Cost of Compactor | 200,000 | Complete fabrication cost |

| Cost of raw material (cotton stalk) | 2/kg | Harvesting+transportation of stalks |

| Operating cost shredder + Compactor (Electricity) | 500/h | PKR 20/kW |

| Operating cost (Labor) | 100/h | 10,000/month |

| Miscellaneous | 100/h | Belts+Screw+barrel maintenance etc. |

| Total expenditures in one hour | 1100/h | Electricity + labor + maintenance |

| Machine Capacity | 200 kg/h | |

| Market price of briquettes | 12.5/kg | PKR 500/40 kg |

| Total production | 2500/h | rupees 12.5/kg |

| Net profit | 1400/h | 11,200/day and 2,80,000/month at 8 h/day |

| Average land holding farmers in Pakistan | 2.83 ha | 7 acre |

| Average production of cotton stalks from 3 ha | 2900 kg/ha | 7.5 tones |

| Payback period | 1.5 years* | Making briquettes of 40 tons biomass |

Table 3: Economic analysis of briquetting technology.

| Months | Machine Cost (PKR, Millions) | Operational Cost on monthly basis in PKR (millions) | Total Cost in millions (PKR) | Briquettes production at PKR 0.0125 M/t | Net Profit in PKR (millions) | Quantity of biomass (tones) | ||

|---|---|---|---|---|---|---|---|---|

| Operating Cost (Electricity) | Operating cost (labor) | Maintenance cost | ||||||

| 1 | 0.275 | 0.15 | 0.02 | 0.024 | 0.469 | 0.6 | 0.131 | 48 |

| 2 | 0 | 0.15 | 0.02 | 0.024 | 0.663 | 1.2 | 0.537 | 96 |

| 3 | 0 | 0.15 | 0.02 | 0.024 | 0.857 | 1.8 | 0.943 | 144 |

| 4 | 0 | 0.15 | 0.02 | 0.024 | 1.051 | 2.4 | 1.349 | 192 |

| 5 | 0 | 0.15 | 0.02 | 0.024 | 1.245 | 3 | 1.755 | 240 |

| 6 | 0 | 0.15 | 0.02 | 0.024 | 1.439 | 3.6 | 2.161 | 288 |

| 7 | 0 | 0.15 | 0.02 | 0.024 | 1.633 | 4.2 | 2.567 | 336 |

| 8 | 0 | 0.15 | 0.02 | 0.024 | 1.827 | 4.8 | 2.973 | 384 |

| 9 | 0 | 0.15 | 0.02 | 0.024 | 2.021 | 5.4 | 3.379 | 432 |

| 10 | 0 | 0.15 | 0.02 | 0.024 | 2.215 | 6 | 3.785 | 480 |

| 11 | 0 | 0.15 | 0.02 | 0.024 | 2.409 | 6.6 | 4.191 | 528 |

| 12 | 0 | 0.15 | 0.02 | 0.024 | 2.603 | 7.2 | 4.597 | 576 |

Table 4: Economic analysis for adaptation of briquetting technology.

Conclusion

From the results we concluded that the production capacity of screw press machine is 200 kg/m3 with 20 hp electric motor power. Variables like moisture content and particle size plays an important role in the flow behavior of raw biomass material through any densification system. The recommended temperature for good quality briquettes of all biomass materials is 300°C. The optimum range of moisture contents of raw material for screw press is 8%-10%. From the different experiments it is concluded that the proposed particle size for better quality briquettes is 3 mm. Biomass densification is a result of solid bridges forming between biomass particles that are dependent on applied pressures and moisture in the biomass. Cost of shredder and screw press are rupees 75,000 and 200,000 (PKR) respectively. Payback period for adaptation of this briquetting technology is just 4 months. Small farmers (4-5 hectare) can easily afford/adopt this technology and also can earn additional money.

Acknowledgements

We are thankful to Higher Education Commission (HEC), Pakistan and Endowment Fund University of Agriculture, Faisalabad who financially support our project and without their support we are unable to develop this machine.

References

- Javaid MA, Hussain S, Maqsood A, Arshad Z, Arshad MA, et al. (2011) Electrical energy crisis in Pakistan and their possible solutions. International Journal of Basic & Applied Sciences11: 26-35.

- Bezzon G, Cortez L (1999) Biomass use in Brazil. Energy and Agriculture towards the third millennium conference 2-5 June 1999, Athens, Greece.

- Strehler A (2000) Technologies of Wood Combustion. Ecological Engineering (Supplement) 16: 25-40.

- Demirbas A(2004) Combustion characteristics of different biomass fuels. Progress in Energy and Combustion Science 30: 219-30.

- Chen L, Xing L, Han L (2009) Renewable energy from agro-residues in China: solid biofuels and biomass briquetting technology, Renewable and Sustainable Energy Reviews 13: 2689-2695.

- Liu Z, Liu XE, Fei B, Jiang Z, Cai Z, et al. (2013)The properties of pelletsfrom mixingbamboo and rice straw. RenewableEnergy 55: 1-5.

- Walker CFJ (2006) Primary Wood Processing: Principles and Practice. University of Canterbury, (2ndedn), Christchurch, New Zealand, pp. 542-543.

- Maciejewska A, Veringa H, Sanders JPM, Peteves SD (2006) Co-firing of biomass with coal: Constraints and role of biomass pre-treatment, Luxembourg: Office for Official Publications of the European Communities.

- PEYB (2009) Pakistan Energy Year Book. Hydrocarbon development institute of Pakistan. Islamabad, Pakistan: Ministry of Petroleum and Natural Resources, Pakistan.

- Gawlik BM, Sobiecka E, Vaccaron S, Ciceri G (2007)Quality management organisation, validation of standards, developments and inquiries for solid-recovered fuels: an overview on the QUOVADIS project. Energy Policy 35: 6293-6298.

- Chen L, Xing L, Han L (2009) Renewable energy fromagro-residues in China:Solid biofuels and biomass briquetting technology. Renewable and SustainableEnergy Reviews 13: 2689-2695.

- Kaliyan N, Morey RV (2009) Factors affecting strength and durability of densified biomass products. Biomass and Bioenergy 33: 337-359.

- Zeng X, Ma Y, Ma L (2007) Utilization of straw in biomass energy in China. Renewable and Sustainable Energy Reviews 11: 976-987.

- Mani S, Tabil LG, Sokhansanj S (2006) Specific energy requirement for compacting corn stover.Bioresource Technology 97:1420-1426.

- Khurmi RS, Gupta JK (2005) A Textbook of Machine Design, (14thedn), Eurasia Publishing house (PVT) LTD, Ram Nagar,New Delhi.

- Jha AK, Sharma C, Singh N, Ramesh R, Purvaja R, et al. (2008) Greenhouse gas emission from municipal solid waste management in Indian mega cities: A case study of Chennai landfill sites. Chemosphere 71:750-758.

- Maninder, Rupinderjit SK, Sonia G (2010) Using Agricultural Residues as a Biomass Briquetting: An Alternative Source of Energy.IOSR Journal of Electrical and Electronics Engineering (IOSRJEEE) 1:11-15.

- Granada E, López González LM, MÃguez JL, Moran J (2002)Fuel lignocellulosicbriquettes, die design and products study. RenewableEnergy 27: 561-573.

Citation: Muhammad SN, Muhammad AA, Abdul N, Anjum M (2016) Design and Fabrication of Biomass Extruder of 50 Mm Diameter Briquette Size. Innov Ener Res 5: 128.

Copyright: ©2016 Muhammad SN, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 30691

- [From(publication date): 6-2016 - Apr 03, 2025]

- Breakdown by view type

- HTML page views: 28199

- PDF downloads: 2492