Research Article Open Access

Comparisons of Cooking and Eating Qualities of Two Indica Rice Cultivars

Nnaemeka Emmanuel Okpala1,2, Lixin Duan1, Guoan Shen1, Guiquan Zhang3 and Xiaoquan Qi1*1Key Laboratory of Plant Molecular Physiology, Institute of Botany, Chinese Academy of Sciences, Beijing 100093, China

2University of Chinese Academy of Sciences, Beijing, China

3Guangdong Key Laboratory of Plant Molecular Breeding, College of Agriculture, South China Agricultural University, Guangzhou 510642, China

- Corresponding Author:

- Professor Xiaoquan Qi

Key Laboratory of Plant Molecular Physiology

Institute of Botany, Chinese Academy of Sciences, Beijing, China

Tel: +8618301259180

E-mail: xqi@ibca.ac.cn

Received Date: March 12, 2017; Accepted Date: April 13, 2017; Published Date: April 21, 2017

Citation: Okpala NE, Duan L, Shen G, Zhang G, Qi X (2017) Comparisons of Cooking and Eating Qualities of Two Indica Rice Cultivars. J Rice Res 5:180. doi:10.4172/2375-4338.1000180

Copyright: © 2017 Okpala NE, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Rice Research: Open Access

Abstract

The cooking and eating qualities of rice are some of the problems facing by rice producers and consumers around the world. In this study we investigated the cooking and eating qualities of Basmati 385 and Hua Jing Xian 74. Both are rice cultivars with different phenotypic traits.

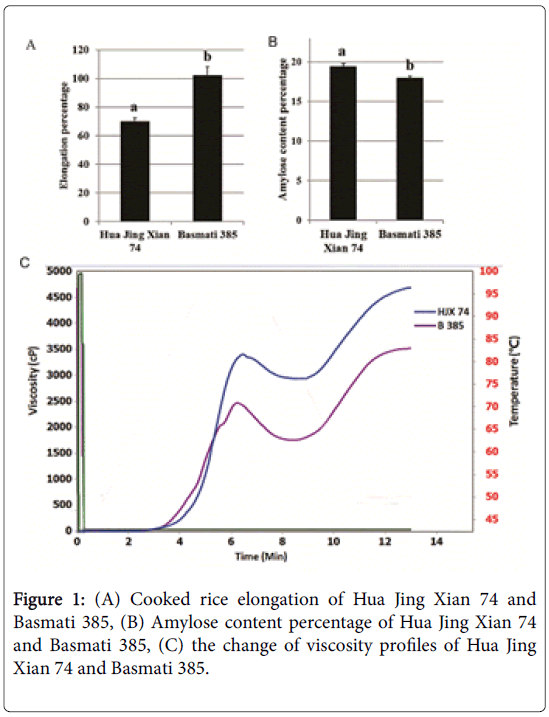

The results show that Basmati 385 increased by an average of 102.14% after cooking while Hua Jing Xian 74 increased by an average of 69.91% after cooking. Basmati 385 had a pasting temperature of 78°C, while Hua Jing Xian 74 had a pasting temperature of 84°C. However, Hua Jing Xian 74 had a final viscosity of 4,686 cP while Basmati 385 had a final viscosity of 3,514 cP. The amylose contents of the two cultivars were also different; Hua Jing Xian 74 had an amylose content of 19.4%, while that of Basmati 385 was 18%. We also discovered that the starch granule morphology of the two cultivars were remarkably different.

The lower pasting temperature of Basmati 385 positively correlated with good cooking qualities of rice. However, Hua Jing Xian 74 appears to have relatively better eating qualities due to its higher viscosity and higher amylose content. It would be pertinent to do more research about hybrid lines resulting from a cross of Hua Jing Xian 74 and Basmati 385, to see if they possess the good cooking qualities of Basmati 385 and the good eating qualities of Hua Jing Xian 74.

Keywords

Cooking qualities; Eating qualities; Basmati 385; Hua Jing Xian 74

Abbreviations

B 385: Basmati 385; cP: Centipoise; HJX 74: Hua Jing Xian 74.

Introduction

Rice (Oryza sativa L.) is one of the leading food crops of the world and is a staple food for over half of the world’s population. Most commercial rice cultivars are from either japonica or indica subspecies, and these subspecies exhibit marked differences in both agronomic and physiological traits [1]. In countries with high human populations like China and India, rice is consumed daily in a variety of ways. Rice is the most widely cultivated crop in China. Rice production in India has increased remarkably in the recent past and now represents approximately one third of the global rice production [2]. Rice is also a staple food in Africa, where it is cultivated widely with a steady increase in consumption.

As household incomes increases, rice consumers are demanding rice with better cooking and eating qualities. Rice grain quality remains an important concern for rice breeders, producers, and consumers all over the world [3]. Improvement of grain quality is an aim for most rice breeders, because it affects the commercial value of rice [4]. Increased production efficiency for rice is needed all over the world, not just because of the inevitable expansion of the human population, but also because of the projected decrease of arable land. The major components of rice quality include its appearance, cooking quality, eating quality and nutritional quality [5].

Cooked rice elongation, water absorption, amylose content, and pasting temperature are some of the traits that have been identified to represent the cooking and eating quality of rice [6]. The aim of this study was: (i) to discern the differences in cooking and eating qualities between Hua Jing Xian 74 and Basmati 385 by comparing traits including cooked rice elongation length, pasting properties, starch granule morphology and amylose content, (ii) to determine if starch granule morphology affects the pasting temperature of rice varieties used for the study.

Materials and Methods

Rice grains

The ten rice varieties used in this study were cultivated in Hainan, China in November, 2014 and were harvested and stored under the same condition in April, 2015. The ten varieties are Basmati 385, Hua Jing Xian 74 and eight other varieties listed in Supplementary Table 1.

Since part of this study was to compare the effect of starch granule morphology on the pasting temperature of Hua Jing Xian 74 and Basmati 385, we decided to add the eight varieties also to study the effect of starch granule morphology on their pasting temperature.

Dehusking, milling and pulverizing

Whole and mature grains of ten varieties were dehusked using Jing Ao Liang Yong Qi Cai Chang JLGJ-45 de-husker machine. Rice grains that got broken during the process were discarded, as were immature grains. Whole and mature dehusked rice grains were milled with Taizhou Jing Ao LTJM-2008 milling machine. The objective of milling was to remove rice bran, which consists of the aleurone and pericarp tissues. Rice grains were all milled for three minutes.

Milled rice grains were pulverized with a Retsch Mixer Mill MM 400. The frequency was set at 30/sec and the grains were milled for 50 sec. Note that the mixer mill was extremely efficient for these samples; the samples remained cool after pulverizing.

Cooked rice elongation

Cooked rice elongation was here represented as the difference between the length of grains measured before and after cooking (see detailed cooking protocol below). In this kind of investigation, precision is very crucial; therefore a Microtek ScanMaker i56 scanner was used to make all of the length measurements.

Raw rice and cooked rice measurement

For each line, 60 grains of milled rice were measured. 20 raw grains were measured at a time in ScanMaker i56. Each grain was then transferred to a PCR plate containing 155μl of distilled water. The grains were allowed to soak for 30 min. The PCR plate containing the rice grains was then placed in a PCR thermocycler and the rice grains were individually cooked for 20 min at 98°C and then for 5 min at 20°C. The cooked rice grains were then removed from the PCR plate and placed on a filter paper. After drying for 5 min at room temperature, they were transferred to a petri dish to be re-measured with the scanner. As with the raw grains, 20 cooked grains were remeasured simultaneously; this helped to control the variability of water content that could have resulted from unequal resting times between measurements. These experiments used 20 grains per cultivar per each of the three replicates..

Elongation of cooked rice

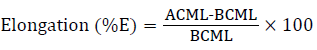

In other to determine the elongation percentage of the cooked rice for each cultivar, the mean value of each replicate was determined (before and after cooking). The following formula was used to determine the elongation percentage:

Where %E is elongation percentage; ACML is the after cooking mean length and BCML is the before cooking mean length.

Total starch and amylose content analysis

This experiment was performed strictly in compliance with the instructions stipulated by Megazyme in the instruction manual for their Amylose/Amylopectin Assay kit; however, Sodium azide was not used in this experiment. As all solvents were used within 1 week and were well preserved during use, there was no need for sodium azide.

Pasting properties

Pasting property analysis was carried out using Perten RVA TecMASTER instrument. 25 mL of distilled water was poured into the sample canister prior to adding 3 g of pulverized and sieved rice into the canister. The instrument paddle was placed prior to analysis.

Scanning electron microscopy (SEM)

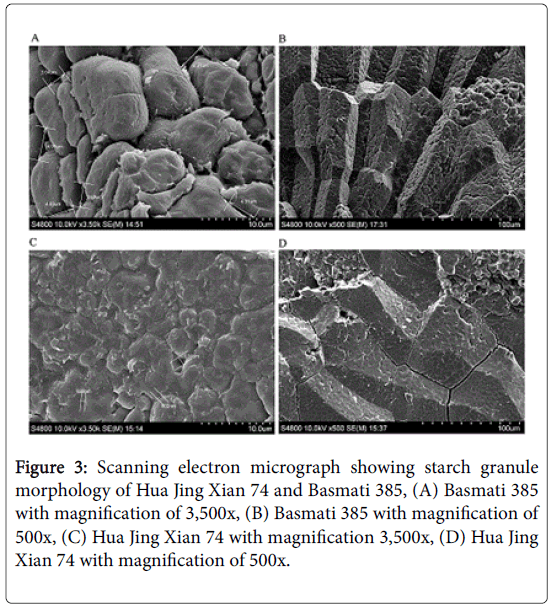

SEM analysis was done with a Hitachi S-4800 electron microscope. Rice grains were cut with scalpel and fixed in formalin-acetic-alcohol solution and were sputter-coated with gold and examined at a magnification of 500 and 3,500 at 10.0 kV.

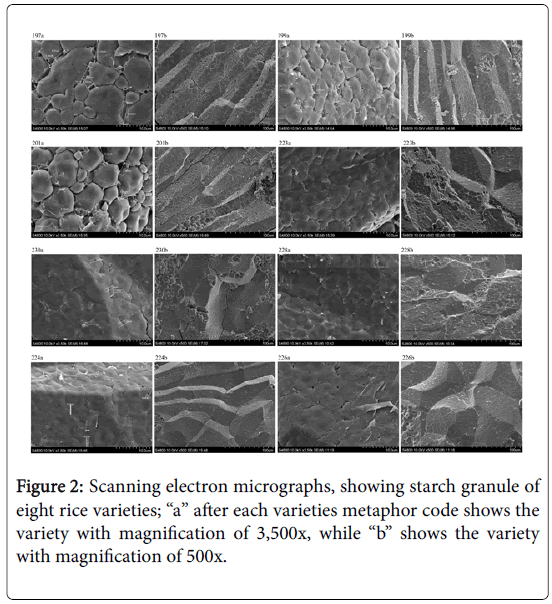

Starch granule morphology of each variety was observed with magnification of 500x and 3,500x. The starch granules were more conspicuous with magnification of 3,500x, but with magnification of 500x more area could be seen.

Results and Discussion

Cooked rice elongation

Hua Jing Xian 74 is an indica cultivar [7] and Basmati 385 is also an indica cultivar [8]. Studies have suggested that cooked rice grains with extensive elongation are often more desirable rice varieties [6].

In this study, the length of Basmati 385 increased by an average of 102.14% while Hua Jing Xian 74 increased by an average of 69.91% as shown in Figure 1A. The extensive elongation of Basmati 385 is desirable trait.

Amylose content

Amylose content is another vital parameter in determining the eating quality of cooked rice. Amylose content has been widely reported to affect the quality of cooked rice [6,9]. The relatively lower amylose content characteristics of the kernels of chalky rice, has been postulated to be responsible for their poor eating quality as compared to translucent kernels which typically have higher amylose content [10]. Rice starch can be classified as waxy with (0-2% amylose), very low starch (5-12% amylose), low starch (12-20% amylose), intermediate starch (20-25% amylose), or high starch (25-33% amylose) [11,12]. Hua Jing Xian 74 and Basmati 385 both fell into low starch content category with 19.4% and 18% amylose content, respectively. Note that the amylose content of Hua Jing Xian 74 is higher than that of Basmati 385 (Figure 1B). It is not unprecedented for some rice cultivars with long grains to have low amylose content. Studies have reported that amylose content of long-grain rice starches ranged from 17% to 35.7% [13,14].

Pasting properties

Pasting properties of starch, including viscosity and pasting temperature are important indicators of how the starch will behave during processing. Starch is generally regarded by researchers concerned with the eating quality to be the most important constituent of rice. The pasting properties of starch are used in determining the suitability of use for particular sources of starch in various foods and other allied product applications. Table 1 reveals that Hua Jing Xian 74 has a higher final viscosity of 4686 cP, higher pasting temperature of 84°C compared to Basmati 385 with final viscosity of 3514 cP and pasting temperature of 78°C. Due to its high viscosity, food processed from Hua Jing Xian 74 will likely have a better appearance as compared to food processed from Basmati 385. This supposition is based on [15], who reported that peak viscosity is often positively correlated with the quality of end-products and also represents an excellent indication of the viscous load likely to be encountered by a mixing cooker.

| Test Variety | Final Viscosity (cP) | Pasting Temp (°C) |

|---|---|---|

| Hua Jing Xian 74 | 4686 | 84 |

| Basmati 385 | 3514 | 78.3 |

Starch granule morphology

Figure 2 shows that 197, 199, and 201 have bigger airspaces and more pronounced starch granules compared to 223, 230, 228, 224, and 226.

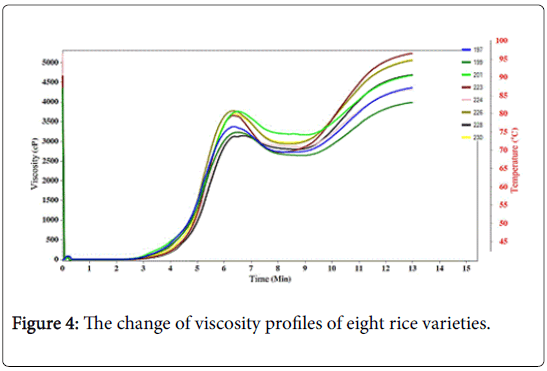

We also discovered that 197, 199, and 201 also have lower pasting temperatures, compared to 223, 230, 228, 224, and 226 with higher pasting temperature as shown in Table 2. Supplementary Figure 1 also shows that 197, 199, and 201 have greater extent of grain elongation compared to 223, 230, 228, 224, and 226.

| Test Variety | Pasting Temp (°C) |

|---|---|

| 223 | 84.05 |

| 230 | 82.35 |

| 228 | 83.95 |

| 224 | 84.85 |

| 226 | 80.75 |

| 197 | 75.05 |

| 199 | 77.45 |

| 201 | 73.55 |

Table 2: Pasting temperature of eight rice cultivars.

The starch granule morphology of Hua Jing Xian 74 and Basmati 385 are remarkably different as shown in Figure 3. Basmati 385 has bigger airspaces and more pronounced starch granules as compared to Hua Jing Xian 74. With these bigger airspaces, Basmati 385 seems more likely to be able to absorb water quite rapidly, and which should result in reduced cooking times. This situation would explain the reason for the lower pasting temperature of Basmati 385, 197, 199, and 201 reported above. This finding is consistent with [16,17] who reported that rice grains with loosely packed starch granules with numerous airspaces absorb water more rapidly than do rice grains with few airspaces and tightly packed starch granules (Figure 4).

Conclusion

This study showed that starch granule morphology likely affects the pasting temperature of rice. In this investigation, varieties with bigger and loosely packed starch granules and larger airspaces spaces have a lower pasting temperature.

In this study we also characterised differences between Hua Jing Xian 74 and Basmati 385 grains. On the one hand, Basmati 385 grains appear to have relatively better cooking qualities compared to Hua Jing Xian 74 because it requires less water and less time to cook due its lower pasting temperature, and bigger airspaces. On the other hand, Hua Jing Xian 74 appears to have relatively better eating qualities due to its higher viscosity and higher amylose content. Moreover, Hua Jing Xian 74 appears to be relatively more stable for use in processed food applications due to its higher viscosity. Since rice consumers are known to show a preference for rice with extensive grain elongation, it would be pertinent to do more research about hybrid lines resulting from a cross of Hua Jing Xian 74 and Basmati 385. It would be interesting to see if some of such lines possessed the good cooking qualities of Basmati 385 and also possessed the good eating qualities of Hua Jing Xian 74. If the hybrid lines possess these properties, it would almost certainly increase their economic value.

Authors’ Contributions

XQ, GZ and NEO designed the experiments. NEO conducted the experiments with the help of LD and GS. NEO wrote the manuscript. All authors approved of the manuscript.

Competing Interests

The authors declare that they have no competing interests.

Consent for Publication

Not applicable

Ethics Approval and Consent to Participate

Not applicable

Funding

This study was supported by The World Academy of Sciences and the Chinese Academy of Sciences.

References

- Hu C, Shi J, Quan S, Cui B, Kleessen S, et al. (2014) Metabolic variation between japonica and indica rice cultivars as revealed by non-targeted metabolomics. Sci Rep 4: 5067.

- Bagchi TB, Sharma S, Chattopadhyay K (2015) Development of NIRS models to predict protein and amylose content of brown rice and proximate compositions of rice bran. Food Chem 191: 21-27.

- Fan CC, Yu XQ, Xing YZ, Xu CG, Luo LJ, et al. (2005) The main effects, epistatic effects and environmental interactions of QTLs on the cooking and eating quality of rice in a doubled haploid line population. TheorAppl Genet 110: 1445-1452.

- Koutroubas SD, Mazzini F, Pons B, Ntanos DA (2004) Grain quality variation and relationships with morpho-physiological traits in rice (Oryzasativa L.) genetic resources in Europe. Field Crop Res 86: 115-130.

- Zhang Q (2007) Strategies for developing green super rice. ProcNatlAcadSci USA 104: 16402-16409.

- Tian R, Jiang GH, Shen LH, Wang LQ, He YQ (2005) Mapping quantitative trait loci underlying the cooking and eating quality of rice using a DH population. Mol Breeding 15: 117-124.

- Xi ZY, He FH, Zeng RZ, Zhang ZM, Ding XH, et al. (2006) Development of a wide population of chromosome single-segment substitution lines in the genetic background of an elite cultivar of rice (Oryzasativa L.). Genome 49: 476-84.

- Mumm R, Hageman JA, Calingacion MN, de Vos RCH, Jonker HH, et al. (2016) Multi-platform metabolomics analyses of a broad collection of fragrant and non-fragrant rice varieties reveals the high complexity of grain quality characteristics. Metabolomics 12: 38.

- Tan YF, Li JX, Yu SB, Xing YZ, Xu GC, et al. (1999) The three important traits for cooking and eating quality of rice grains are controlled by a single locus in an elite hybrid, Shanyou 63. TheorAppl Genet 99: 642-648.

- Chun A, Song J, Kim KJ, Lee HJ (2009) Quality of Head and Chalky Rice and Deterioration of Eating Quality by Chalky Rice. J Crop Sci Biotech 12: 239-244.

- Juliano BO, Perez CM, Blakeney AB, Castillo DT, Kongseree N, et al. (1981) International cooperative testing on the amylose content of milled rice. Starch/Starke 33: 157-62.

- Yu S, Ma Y, Menager L, Sun DW (2012) Physicochemical properties of starch and flour from different rice cultivars. Food Bioprocess Tech 5: 626-637.

- Patindol J, Gonzalez B, Wang YJ, McClung AM (2007) Starch fine structure and physicochemical properties of specialty rice for canning. J Cereal Sci 45: 209-18.

- Puchongkavarin H, Varavinit S, Bergthaller W (2005) Comparative study of pilo scale rice starch production by an alkaline and an enzymatic process. Starch/Starke 57: 134-44.

- Ragaee S, Abdel-Aal ESM (2006) Pasting properties of starch and protein in selected cereals and quality of their food products. Food Chem 95: 9-18.

- Lisle AJ, Martin M, Fitzgerald MA (2000) Chalky and translucent rice grains differ in starch composition and structure and cooking properties. Cereal Chem 77: 627-632.

- Singh N, Singh J, Kaur L, Sodhi NS, Gill BS (2003) Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem 81: 219-31.

Relevant Topics

- Basmati Rice

- Drought Tolerence

- Golden Rice

- Leaf Diseases

- Long Grain Rice

- Par Boiled Rice

- Raw Rice

- Rice

- Rice and Aquaculture

- Rice and Nutrition

- Rice Blast

- Rice Bran

- Rice Diseases

- Rice Economics

- Rice Genome

- Rice husk

- Rice production

- Rice research

- Rice Yield

- Sticky Rice

- Stress Resistant Rice

- Unpolished Rice

- White Rice

Recommended Journals

Article Tools

Article Usage

- Total views: 4723

- [From(publication date):

June-2017 - Apr 05, 2025] - Breakdown by view type

- HTML page views : 3771

- PDF downloads : 952