Comparative Performance Assessment of Vegetable Oils as Suitable Lubricants under Extreme Temperature and Pressure Conditions

Received: 01-Feb-2023 / Manuscript No. iep-23-88078 / Editor assigned: 03-Feb-2023 / PreQC No. iep-23-88078 (PQ) / Reviewed: 17-Feb-2023 / Revised: 24-Feb-2023 / Manuscript No. iep-23-88078 (R) / Published Date: 28-Feb-2023 DOI: 10.4172/2576-1463.1000327

Abstract

The environmental pollution caused by mineral oil (petroleum based) lubricants coupled with the depletion of petroleum reserves have encouraged the sourcing of more biodegradable and environmental friendly lubricants. To this end, vegetable oils have been sponsored as suitable replacements to these petroleum based lubricants. This chiefly because of their biodegradable nature and plethora in the environment. One major limitation in the use of vegetable oils as lubricants is their seemingly poor performance when exposed to extreme temperature and pressure scenarios. This is due to the fact that they undergo oxidation at high temperature operations which causes an altering of its physical as well as chemical nature. Upon this degradation, the released oxygen bond becomes harmful to metals as it sponsors oxidation on the metals surface which tantamount in structural weakness evident in the near future as rusts. This paper tested the high temperature and pressure performance of vegetable oils using a fourball tribometer according to ASTM D2783. The lubricants used for this comparative testes were commercial hydraulic oil, RBD palm olein, palm fatty acid distillate, jatropha oil and commercial stamping oil. The end performance evaluation showed that jatroha oil, a vegetable based oil has higher coefficient of friction in comparison to the other oils which were mineral (petroleum based) oils. The study also exposed that the wear scars on the metal surface when machined with the vegetable oil is lower than that when the mineral oils were used. Hence the vegetable oils are very suitable for use as lubricants under extreme high temperature and pressure regimes.

Keywords

Tribology; Biodegradation; Lubricants; Pollution; Coefficient of friction

Introduction

Petroleum is in high demand right now because of rising industrialization, modernization, and development. From 1990 to 2008, Nigeria's overall energy consumption grew at an average yearly rate of 7.2% of which petroleum sources amounted for more than 80% of this. According to reports, the European Union uses about 320,000 tonnes of petroleum annually. Some of this petroleum is used as coolant for high-quality manufacturing processes and as lubricant for metal cutting and shaping procedures in mineral oil-based fluids for metalworking applications where it can boost productivity. This oil is really helpful, but it also poses a threat to the environment because at least two thirds of the used oil needs to be disposed of in special means as they are not biodegradable. Research has exposed that skin contact with cutting fluids causes nearly 80% of all occupational illnesses affecting machine operators [1]. For instance, out of a million workers in the USA, almost 700,000 are exposed to fluids used in metalworking. These liquids' have intricate chemical make-up and high concentration of microbial toxins which irritate or trigger allergic reactions to the human skin [1]. Scientists have been looking for alternatives that are economically viable, clean, renewable, and dependable as a result of this issue. The introduction of biodiesel as a more environmentally friendly renewable fuel that may take the place of diesel fuel in the transportation industry was one of the best discoveries [2].

Vegetable oil has therefore been tried out and seems to have the ability to take the place of mineral oil-based fluids. High viscosity index, high lubricity, low volatility, and advanced traits that can be compared to mineral oil, such as low toxicity and high biodegradability, are only a few of the qualities that are necessary in a lubricant that are present in vegetable oils [3].

Triglycerides, which are glycerol molecules with three long-chain fatty acids connected at the hydroxyl group via ester bonds, make up the majority of vegetable oils. Natural vegetable oils contain a variety of fatty acids, each with a unique chain length and amount of double bonds.

The ratio and placement of carbon-carbon double bonds define the fatty acid makeup. Oleic, linoleic, and linolenic fatty acid constituents, respectively, have one, two, or three double bonds holding them together. The majority of fatty acids found in plant-based oils range from four to twelve. Boundary lubrication benefits from the glyceride structure. They can produce high strength lubricant coatings that interact aggressively with metallic surfaces thanks to their long and polar fatty acid chains [4]. They also possess high viscosity coefficient, which results from the strong intermolecular interactions, makes the viscosity more stable and resistant to temperature variations. Strong molecular connections like these ones provide a long-lasting lubricating layer.

Vegetable oil lubricants are biodegradable and have low levels of toxicity during their entire life. Based on the advantages and drawbacks of vegetable oils, lubricant formulations are being created. Vegetable oils outperformed mineral-based oils in terms of fatigue resistance, scuffing load capacity, and anti-wear and friction [5]. This is why even while vegetable oil exhibits worse thermal and oxidative stability, it generates a low friction coefficient, similar scuffing load capacity, and greater pitting resistance. Under heavy weights, vegetable oil also loses effectiveness. Given that the high polarity of the entire base oil for robust interactions with lubricated surfaces, this suggests that vegetable oils are particularly useful as boundary lubricants [5]. Sunflower oil, coconut oil, and palm oil are a few of the vegetable oils that have undergone testing. Based on earlier research, coconut oil has been used in metal-cutting machining applications. Regarding cutting speed, depth of cut, and feed rate, it performed superbly. In addition, the specimen's surface was smoother than mineral oil's. It has been demonstrated that palm oil produces smoother surfaces when used in milling than mineral oil, and it also increases tool life. When sunflower oil was tested in drilling equipment, the outcomes were the same [6]. Vegetable oils should be able to be used for hydraulic or stamping applications despite the fact that prior studies have shown that they are less effective than mineral oil for severe loads. Seven different oils, these being, commercial hydraulic oil, commercial stamping oil, jatropha oil, PFAD, RBD palm olein oil, palm kernel oil, and soybean oil—were examined in this experiment.

Material and Method

Fourball tribotester

The fourball tribometer is used to gauge the extreme pressure (EP) and anti-wear (AW) capabilities of lubricating oil and grease. A typical ball bearing with a diameter of 12.7 mm was used for the test. Under a specific load, the lubricant was submerged in a revolving ball bearing with a point of contact interface against three stationary ball bearings. The machine's specifications, such as the typical load, rotational speed, and temperature, were set in accordance with ASTM regulations. Different methods are used to analyze the fourball tribometer test's qualities, including evaluating the wear scar diameter where welding occurs and the normal load under high pressure. For lubrication oil and grease, the standards employed for these trials are ASTM D 2783 and ASTM D 2596, respectively. Under varying load conditions, the top bearing rotates at 1770 ± 60 rpm in opposition to three stationary ball bearings.

For a period of 10 seconds, the lubricating fluid has a temperature of around 27 °C ± 8 °C. Up until welding, the experiment was run with increasing loads. The sole objective of this test was to establish the characteristics of the lubricating oil and grease at low, medium, and high pressure levels. This methodology was not used in the determination of anti-ware behaviour. It was made to test lubricant properties under more demanding conditions and larger loads in order to identify failure areas.

Test lubricants

In this paper, three types of vegetable oils were used as test lubricants: jatropha oil (JAT), RBD palm olein (PO), and palm fatty acid distillate (PFAD). Their performances were compared with commercial stamping oil (STP) and hydraulic oil (HYD). The viscosity for all the test lubricants was almost the same at 40ºC, which was between 37 – 70 mm /s. 2

Results and Discussion

Coefficient of friction (COF)

The fourball tribotester's friction torque was measured during the experiments. The equation below has been used to calculate the lubricant's coefficient of friction from the friction torque value.

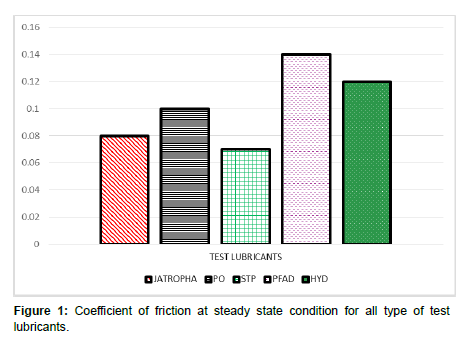

Where is the distance in mm (3.67) from the center of the contact surface on lower balls to the axis of rotation, T is the frictional torque in kg.mm, W is the applied weight in kg, and is the coefficient of friction [9]. Figure 1 displays the coefficient of friction (COF) values for all test lubricants. Vegetable oils clearly exhibit a high coefficient of friction while working under high pressure settings with a typical load of 126 kg, as shown in Figure 1 (Figure 1). The distillate of palm fatty acids (PFAD) demonstrated the highest coefficient of friction. This is due to the fact that at room temperature it is semi-solid. The semi-solid form of PFAD makes it difficult to flow.

Under a high normal load, PFAD lubricant film easily degrades. The amount of metal-to-metal contact and friction increased (coefficient of friction). At room temperature, both jatropha and RBD palm olein are still liquid and can sustain the lubricating film. The coefficient of friction was low for the mineral oil representatives (commercial stamping oil). This is because the mixture contains an anti-wear ingredient [7-10].

Wear scar diameter (WSD)

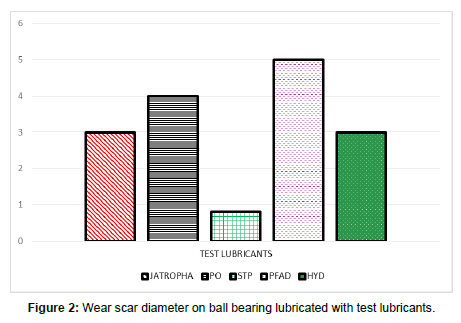

The distribution of the wear scar diameter for each test lubricant is shown in Figure 2. The wear scar diameter is smallest while using commercial stamping oil (STP). This is so that the oil's anti-wear ingredients can aid to slow down the rate of wear. Although hydraulic oil (HYD) also contains additives, it is not used to resist movement like the fourball tribometer; rather, hydraulic oil is utilized to transfer energy in the hydraulic system. The ball bearing lubricated with jatropha oil had the least wear scar diameter when compared to the other vegetable oils, which were palm olein and palm fatty acid distillate. The chemical chain of palm fatty acid distillate had the most oxygen double bonds. The oxygen double bond tends to react with another element, most likely the ball bearing's substance, when a ball bearing rotates under high pressure [11]. The ball bearing's substance oxidizes and weakens as a result. A third body abrasion mechanism would cause a significant wear rate in the material. The frictional resistance would rise due to the metal-to-metal contact between the top and bottom ball bearings. As a result, as previously seen in Figure 1, the coefficient of friction rises.

Worn scar observation

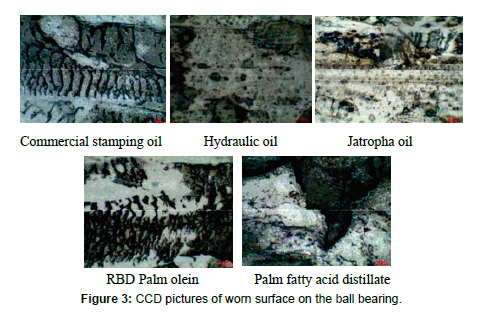

It is extremely clear how much wear scar is developed between oils. Some of the oils failed to operate as lubricant in cases when a bearing's wear scar diameter was greater than 4 mm or all four ball bearings were welded together, using a standard load of 126 kg as a point of comparison. Due to the 5.25 mm diameter ball bearing wear that PFAD oil in this experiment induced, as depicted in figure 2, it can be said to have failed. Commercial stamping oil operates admirably under this load and creates wear scars with a 0.62mm diameter. Despite producing significant wear scars, the remaining oils tested (aside from PFAD) showed low friction coefficients, comparable to commercial stamping oils. This experiment produced fascinating wear scar surfaces, including smooth surfaces, metal burns, shear surfaces, and wedge-shaped metal formations. Figure 3 demonstrates that the only stamping lubricant that provided a flat surface was commercial stamping oil. A portion of the commercial hydraulic oil wear scar revealed burnt metal along with adhesive wear [12]. This charred metal demonstrates that the presence of oxygen must have caused the temperature in that location to rise.

Commercial oil's oxidation stability deteriorates under this load, resulting in abrasive wear. These microscopic cutting forms are indicative of the surface hardness and are found in ductile materials. Jatropha oil and RBD palm olein oil both have worn scar surfaces that are similar in that they have a lot of shear surface in the middle and wedge cutting on the edge [13]. The wedge cutting is caused by abrasive wear of the brittle surface, whereas this shear surface is caused by adhesive wear. The extra oxygen present during the experiment must have caused the wear scar's edge to become brittle.

Conclusion

Based on the results of these tests, it can be said that vegetable oil has the potential to become a useful industrial lubricant.

Even though the steel ballwear scar diameters and friction coefficient values were slightly bigger than those obtained using commercial stamping oil, this issue could be resolved by using the right additives.

The investigation of acceptable additives for vegetable oil will be covered in the upcoming experimental efforts as it is outside the purview of this study.

References

- Wan Nik WB, Ani FB, Masjuki HH, Eng Giap SG (2005) Rheology of Bio-edible Oils According to Several Rheology Models and its Potential as Hydraulic Fluid. Ind Crops Prod 22: 249-255.

- Kasolang S, Ahmad MA, Bakar MAA, Hamid AHA (2012) Specific Wear Rate of Kenaf Epoxy Composite and Oil Palm Empty Fruit Bunch (OPEFB) Epoxy Composite in Dry Sliding. J. Teknol 58: 85-88.

- Syahrullail S, Zubil BM, Azwadi CSN, Ridzuan MJM (2011) Experimental Evaluation of Palm Oil as Lubricant in Cold Forward Extrusion Process. IJMS 53: 549-555.

- Syahrullail S, Nakanishi K, Kamitani S (2005) Investigation of the Effects of Frictional Constraint with Application of Palm Olein Oil Lubricant and Paraffin Mineral Oil Lubricant on Plastic Deformation by Plane Strain Extrusion. J. Jpn. Soc. Tribol 50: 877-885.

- Kasolang S, Ahmad MA, Joyce RSD (2011) Measurement of Circumferential Viscosity Profile in Stationary Journal Bearing by Shear Ultrasonic Reflection. Tribol. Int 44: 1264-1270.

- Hwai CO, Mahlia T, Masjuki H, Norhasyima RS (2011) Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renew Sust Energ Rev 15: 3501-3515.

- Tiong CI, Azli Y, Rafiq AKM, Syahrullail S (2012) Tribological Evaluation of Refined, Bleached and Deodorized Palm Stearin using Four-ball Tribotester with Different Normal Loads. J Zhejiang Univ Sci 13: 633-640.

- Wan N, WB, Maleque MA, Ani FN, Masjuki HH (2007) Experimental Investigation on System Performance using Palm Oil as Hydraulic Fluid ILT 59: 200-208.

- Syahrullail S, Tiong CI, Rafiq AKM, Azli Y (2012) The Effect of Temperature on the Tribological Behavior of RBD Palm Stearinx. Tribol Trans 55: 539-548.

- Lawal SA, Nukman Y (2012) Application of vegetable oil-based metalworking fluids in machining ferrous metals: A review. Int J Mach Tools Manuf 52: 1-12.

- Quinchia LA, Delgado MA (2010) Viscosity modification of different vegetable oils with EVA copolymer for lubricant applications. Ind Crops Prod 32: 607-612.

- Shashidhara YM, Jayaram SR (2010) Vegetable oils as a potential cutting fluid: An evolution. Tribol Int 43: 1073-1081.

- Nadia S, Jumat S, Emad Y (2011) The physicochemical and tribological properties of oleic acid based trimester biolubricants. Ind Crops Prod 34: 1089-1096.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Daniel X (2023) Comparative Performance Assessment of Vegetable Oils as Suitable Lubricants under Extreme Temperature and Pressure Conditions. Innov Ener Res, 12: 327. DOI: 10.4172/2576-1463.1000327

Copyright: © 2023 Daniel X. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 1463

- [From(publication date): 0-2023 - Mar 28, 2025]

- Breakdown by view type

- HTML page views: 1172

- PDF downloads: 291