Short Communication Open Access

Comparative Evaluation of Underground Pit Storage Systems for Grain Quality Attributes in Jigjiga and Awubarre Districts of Fafen Zone, Ethiopia

Abraham Mulu1* and Zelalem Belayneh21Department of Dryland Crop Science, College of Dryland Agriculture, Jigjiga University, Ethiopia

- Corresponding Author:

- Abraham Mulu Oljira

Department of Dryland Crop Science

College of Dryland Agriculture

Jigjiga University, Ethiopia

Tel: +2517752779/+251923254861

E-mail: abrahammulu09@gmail.com

Received date: July 04, 2016; Accepted date: August 09, 2016; Published date: August 10, 2016

Citation: Mulu A, Belayneh Z (2016) Comparative Evaluation of Underground Pit Storage Systems for Grain Quality Attributes in Jigjiga and Awubarre Districts of Fafen Zone, Ethiopia. Adv Crop Sci Tech 4:235. doi:10.4172/2329-8863.1000235

Copyright: © 2016 Mulu A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Advances in Crop Science and Technology

Abstract

Sorghum and maize grain stored in traditionally prepared pit in Jigjiga and Awubarre districts of Ethiopian Somali region were evaluated for seven months after of underground storage. We collected data on socio-economic profile of survey participants, grain drying duration on the field, amount of grain stored and sold, and comparative evaluation of grain physical quality stored in bare traditional and plastic lined pit. We used semi-structured interviews, focus group discussions and participants’ storage pit observation. Survey result indicated that 30% to 56% respondents dry harvested grain on the field from two weeks to one month. Majority of the respondents 57 rated ‘very good’ for grain stored in the plastic lined pit storage for quality attributes such as grain color, taste, odor, seed germination, and market preference, market price and for human health, however more than 34 respondents rated ‘bad’ for grain stored in bare traditional pit stored. This finding, thus, puts forward a need to use plastic lined pit storage so that the grain quality attributes are preferred by consumers.

Keywords

Postharvest storage; Traditional pit; Plastic lined pit; Grain quality; Visual assessment

Introduction

Underground pit storage is recognized and used in lowland areas where water table does not endanger the storage. Losses of 25% to 50% in traditional farm storages and occasional 100% losses in underground pit storages were reported in the 1950s and 1960s Boxall [1]. The losses includes qualitative and quantitative of grain at every postharvest stage involves harvesting, threshing, transportation, and storing. Losses that happen during storage are caused by a wide variety of factors including abiotic (granary architecture, humidity, temperature, soil type) and biotic (micro-organisms, insect, rodents) factors Scott [2]. The main cause of storage loss particularly in pits is insect infestation, although damage is partially attributed to molding and soil contamination.

Minimizing grain storage losses, therefore, becomes crucial not only from the perspective of improving food security but also from the need to preserve harvested grain on which farmers have invested their knowledge, finance, labor and time. Seen from this point of view, any intervention that is aimed at improving agricultural productivity per unit of land will not achieve its purpose unless backed by a parallel system that also minimizes post-harvest losses. Otherwise, more harvests equate to more losses. Storing the grain in underground pit is known in drylands of Ethiopia where there is shortage of wood and other materials for construction of above ground storage bins Boxall and Abraham [3,4]. In a national wide survey undertaken in Ethiopia, it was reported that more than 12% of the interviewed farmers use pit stores Abraham [4]. In addition, 70%-75% of the farmers exclusively interviewed at Eastern Ethiopia used underground pits for grain storage while 8-12% used them in conjunction with other storage types Boxall [3]. Pit grain structures are dug normally in black cotton soils as exemplified in Kobo-Alamata and Jigjga areas of Ethiopia. The pit gate is covered with a combination of locally available materials such as strips of timber, stone, soil, animal dung and mud Mashilla [5].

Underground pit is efficient in protecting the grain stored against insects, mites, fire and theft as well as low construction and operational costs Abdalla and Nageeb (Bodholt and Diop) [6-8]. However, the main disadvantages are increasing moisture content of the grain with storage duration that leads to mould development and grain deterioration, lower grain quality and reduction of viability and some nutritional value Bakheit [9] operational difficulties such as manual grain filling and emptying the pits and rain water moisture migration through the pit gate and pit wall Abdalla [6]. An assessment made by Boxall [1] showed that, grain losses are severe in some part of Ethiopia where underground pit storage is widely used. Similar finding recommended improving pit storage as a major priority by lining the pit to reduce grain deterioration by molds. Based on these situations, the present study was conducted to assess grain field drying duration and grain physical quality attributes stored in bare and plastic lined pit storage.

Materials and Methods

Study area

The assessment was conducted in Somali Region, Ethiopia in 2013 on newly harvested pit stored grain of maize and sorghum. The Somali Region is geographically located in south-eastern part of Ethiopia, between 4° N and 11° N latitude and 40° E and 48° E longitude. The altitude of the region ranges between 400-1600 meters above sea level (masl), with most areas lying below 900 masl, and it is the second largest region in Ethiopia [10].

The livelihood of Jigjiga and Awubarre districts is mainly agropastoralism. Increasingly, agro-pastoralists are become settled farmers Mahdi Egge et al. [11]. Pit storage has significant importance when they move from one location to other for search of water and pasture for their herds of livestock by keeping their grain safely from fire and theft. Agro-pastoralists in the districts produce sorghum, maize and wheat.

Data collection and analysis

Data collection was conducted through Focus group discussion held with 60 household and individual interview with 100 purposively selected agro-pastoralists for visual scaling of grain quality attributes. They households were selected based on willingness to participate, those household stores more than 500 kg of sorghum or maize grain both plastic lined and bare traditional pit. All of the respondents were less than five month experience in using the plastic lined in their traditional pit storage. The statistical analysis was performed with the Excel of Microsoft window’s program of 2013 version.

Results and Discussion

Socio-economic profile of survey participants

Majority of respondent 98% and 96% from Jigjiga and Awubarre woreda were males respectively, showing that more males were involved on post-harvest grain storage of sorghum in the study area. The current finding is in agreement with Mahdi Egge et al. [11] were the role of women were limited on crop production activities around Jigjiga woreda. This is consistent with the fact that grain management activities in the pit were mostly conducted by males in study districts as the nature of pit opening, entering, sealing and closing was labor intensive, and therefore male dominated. Majority of the respondent participated on the study was in the productive age group between 30-50 years of age. Those with primary education are 24% and 22% in Jigjiga and Awubarre woreda respectively and 4% respondent were recorded in Jigjiga woreda for secondary education. This statistics shows that majority of the farmers are illiterate. This could be a contributory factor to post-harvest storage losses of sorghum because only farmers with knowledge to read and write can appreciate and use the post-harvest extension available.

Majority of the respondents 60% and 70% in Jigjiga and Awubarre districts respectively have allocated greater than 2 ha for crop production. Averagely 829 and 654 kg of sorghum and maize were produced respectively per survey respondents. Out of this, 672 and 483 kg sorghum and maize was stored in traditional pit respectively. Therefore, minimizing pit storage losses could be strategic intervention.

On farm storage duration

The survey has shown that farmers keep the harvested crop on the field for drying. Most of the agro-pastoralists 56% and 58% from Jigjiga and Awubarre districts mentioned that they keep harvested crop on the field up to one month (Table 1). The survey has shown that agro-pastoralists keep their produce for drying and due to peak labor demand at this time. However, keeping the harvested crops such a long time create and enhance the chance of field fungi contamination and the consequence may be aggravated if the harvested grain stored in the pit with high granary temperature and diffusion of moisture through the cracked pit wall.

|

Field Drying Duration |

|||

|---|---|---|---|

|

Districts |

Two weeks |

One month |

Three months |

|

Jigjiga |

36% |

56% |

4% |

|

Avubarre |

30% |

58% |

12% |

Table 1: Field grain drying duration practices of Jigjiga and Awubarre District, 2013.

Pit storages evaluation

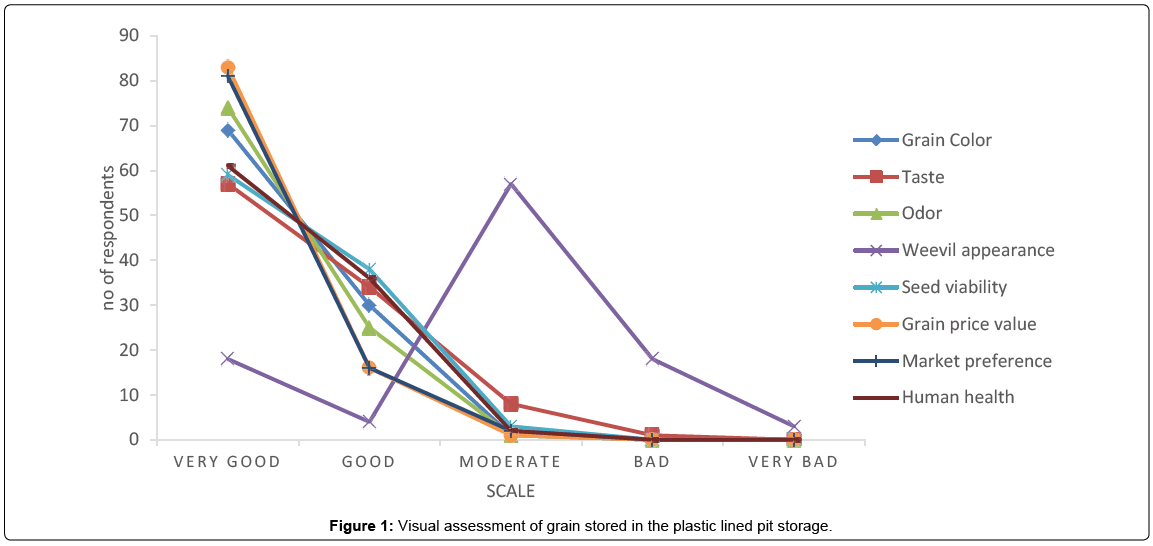

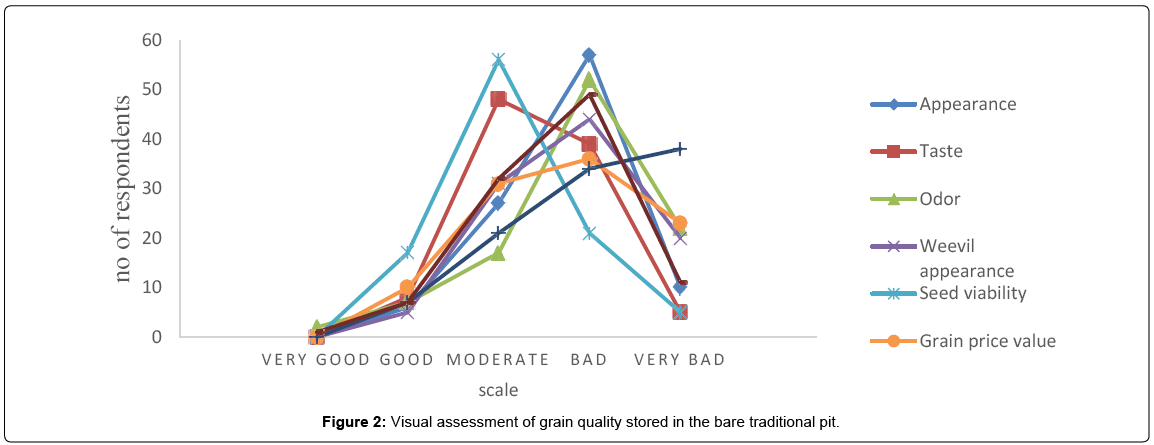

The visual observations, upon opening of all the pits, showed that the sorghum and maize grain quality stored in the plastic lined pits was much better than traditional bare pits store in both districts for different types of grain quality attributes. Visual assessment of respondents, consumers and researchers for grain/seed quality attributes were surveyed for plastic lined and traditional bare pit (Figures 1 and 2).

Plastic lined pit stored grain observation

Of agro-pastoralists we interviewed, more than 57 respondents suggest ‘very good’ scale for quality such as color, taste, odor, seed viability, market preference, market price and human health of grain stored in plastic lined pit storage. This study showed that, pit lined plastic should form a barrier against diffusion of rain/runoff water from the walls and the bottom of the pit therefore, improve the grain quality over traditional bare pit by keeping the grain drier for a longer time. The plastic lined pits had better quality sorghum in terms of colour, smell, taste and viability, expressed as germination percentage. Similar finding was reported by Abdalla et al. and Abdalla [6,12] on the study of chaff lined pit underground storage of sorghum for various soils type in Sudan. However, weevil appearance was abundantly observed as critical problem on the plastic lined pit (Figure 1). At the time of filling the traditional bare pit storage with newly harvested grain, the residues of old grain are not always completely removed, and these serve as a source of storage pest infestation for new grain. These impurities can attract pests from the exterior.

Traditional bare pit stored grain observation

Most of interviewed agro-pastoralists rated ‘moderate’ and ‘bad’ for the grain stored in traditional bare pit for grain color, taste, odor, storage pest, seed viability, market preference, market price and human health (Figure 2). Similar finding was reported by Abdalla et al. [12] in unlined underground pit storage where grain quality is poor due formation of cake, white mold color, bad smell, bad taste experienced by agro pastoralists, consumers and the authors while the pits are opened for this study. Lack of hygiene in traditional granaries is reported by many authors Bell and Ngamo (Hoogland and Holen) [13-15]. Higher temperature and moisture migration through the pit wall favors fungus development.

Agro-pastoralists opinions on pit storage

From this study we understood that, 95% of respondents use underground pits as the only means of storage. Most of the agro pastoralists 65% use pits as precaution against hunger, fire and theft. About 100% of respondents thought that, there is need for adoption of plastic lining material to control grain soiling and moisture diffusion through the cracked pit wall. Important advantage mentioned by all respondents is the reduction of women burden to separate grain from impurities such as soil mixture, molds and grain drying duration. Another very important factor is that 94% of the agro-pastoralists use no chemicals at all with pits, while 6% reported they use some traditionally identified medicinal plant by putting the leaf on the top of the grain stored in the pit (Figure 2). All respondents reported that traditional pits storage need design improvement to fit with plastic design.

Conclusion

Water seeping through the cracked pit wall and moisture diffusion through the soil pores were identified to be the most important grain deterioration factors in underground pit storage. Indigenous underground pit storages are considered to be cheap and cost effective for storing grain for consumption but not when it comes to preserving the viability of seed germination. They can also be laborious during construction for households with labor shortage. Nevertheless, they remain an important grain storage system for agro-pastoralists of study area. Therefore in an effort to minimize losses in underground pit storage use of plastic lining resulted in better grain quality by preventing moisture entrance. However, such modifications should be cost effective, culturally viable and inclusive of storage pest control for wider adoption.

Acknowledgements

The Authors acknowledge financial support of Mercy Corps to conduct this study. Authors are also grateful to Jigjiga University for logistics support.

References

- Boxall RA (1998) Grain post-harvest loss assessment in Ethiopia. Report No 2377 NRI, University of Greenwhich, UK.

- Scotti G (1978) Les insects et les acariens des céréals stockées. Normes et Technique. Institut technique des céréales et des fourrages. Association française de Normalisation AFNOR.

- Boxall RA (1974) Underground storage of grain in Harar Province, Ethiopia. Tropical Stored Products Information 28:39-48.

- Abraham T (2003) Studies on some non-chemical insect pest management options on farm-stored maize in Ethiopia. PhD Thesis, Justus Liebig University of Giessen, Germany.

- Mashilla D (2004) Grain storage methods and their effects on sorghum grain quality in Hararghe, Ethiopia. PhD Thesis, Swedish University of Agriculture Science, Uppsala, Sweden,p:101.

- Abdalla AT (1998)An evaluation of the durability of sorghum grain in traditional and modified underground storage pits in Central Sudan.PhD Thesis, Department of Environmental Sciences and Natural Resources, University of Gezira, Wad Medani, Sudan, p: 420.

- Nageeb IB, Kees S, Ahmed TA(2001) Underground storage of sorghum as a banking alternative. LEISA Magazine17:13.

- Bodholt O, Diop A (1987) Construction and operation of small solid wall bins. FAO Agricultural Services Bulletin, FAO, Rome69:20.

- Bakheit NI (1997) Some economic aspects of traditional underground grain storage pits (matmura) in Sennar State, Sudan. MSc Thesis, Department of Agricultural Economics, University of Gezira, Wad Medani, Sudan, p:75.

- Somali Regional State Environmental Protection & Energy & Mines Resources Development Agency(2011).

- Mahdi E, Pichai T, Savitree R, Sayan T (2011) Preferred Sources of Information among Sorghum Farmers in Awbere District of Somali Regional State, Ethiopia. Kasetsart J Soc Sci 32: 319-326.

- Abdalla AT, Stigter CT, Bakhiet NI, Gough MC, Mohamed HA, et al.(2002)Traditional Underground Grain Storage in Clay Soils in Sudan Improved by Recent Innovations. Tropicultura20:170-175.

- Bell A (1996) Protection des épis de maïs contre les ravageurs des stocks sans employ d'insecticides synthétiques. GTZ, Eschborn, Allemange, pp:1-6.

- Ngamo LST (2000)Protection intégrée des stocks de céréales et de légumineuses alimentaires. Phytosanitary News Bulletin 26 and 27: 13-15.

- Hoogland M, Holen P(2001) Les greniers CTA. Serie Agrodoc No 25.

Relevant Topics

- Agricultural science

- Agronomy

- Climate impact on crops

- Crop Productivity

- Crop Sciences

- Crop Technology

- Field Crops Research

- Hybrid Seed Technology

- Irrigation Technology

- Organic Cover Crops

- Organic Crops

- Pest Management

- Plant Genetics

- Plant Breeding

- Plant Nutrition

- Seed Production

- Seed Science and Technology

- Soil Fertility

- Weed Control

Recommended Journals

Article Tools

Article Usage

- Total views: 13409

- [From(publication date):

August-2016 - Apr 03, 2025] - Breakdown by view type

- HTML page views : 12373

- PDF downloads : 1036