Coexistence of Rheopexy and Dilatancy in Polymer Suspensions Filled with Ceramic Nanoparticles

Received: 30-Aug-2017 / Accepted Date: 06-Sep-2017 / Published Date: 13-Sep-2017

Abstract

The present paper is about poorly studied phenomenon rheopexy and its existence with dilatancy in polymer suspensions filled with ceramic nanoparticles at the same range of shear stresses. According to the proposed flow model of “rheopexic–pseudoplastic–thixotropic” system it was established, that rheopexy is a measure of the solidity of the suspension and characterizes its elastic properties. Rheopexy degree R is the energy consumed for the restoration of the initial microstructure. At the same time, dilatant increasing of the effective viscosity at the low shear stresses characterizes the system resistance to shearing and the strength of structural bonds. Thus, a coexistence of rheopexy and dilatancy is the consequence of the impact of energy-structural and structural-mechanical factors.

Keywords: Rheology; Shear thickening; Rheopexy; Pseudoplasticity; Thixotropy

4268Introduction

Polymer suspensions based on nano-sized ceramic particles are typical non-Newtonian fluids that attract great interest last decades due to the miniaturization tendency: replacing of traditional micro-sized particles with nanometre-sized particles results in the development of a new class of fluids with better-enhanced processing properties [1,2]. Another advantage of nanofluids is an economic effect due to low concentrations because of the large specific surface area and chemical reactivity of nanoparticles. However, using of nano-sized solid particles raises a number of issues such as the nanodimension stabilization, physico-chemistry of the interactions between large polymer molecules with smaller nanoparticles and finally requires the development of new suspensions compositions. Since the operation of most polymeric suspensions typically bases on the principle effects of shear stress, the rheological properties become a very important field of their characterization.

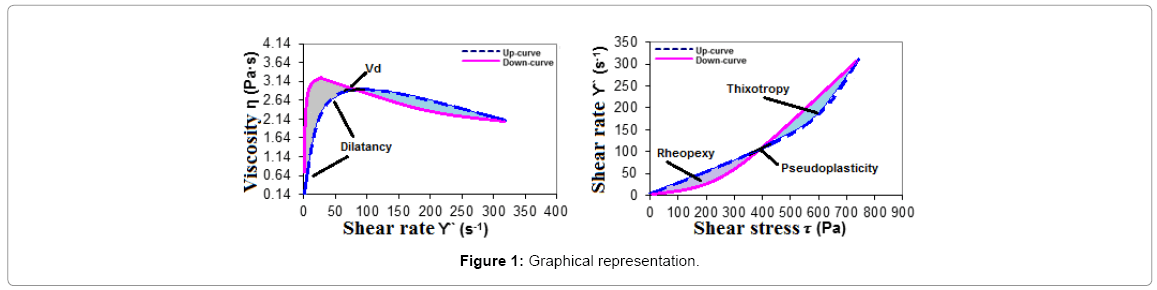

Investigation of non-Newtonian fluids rheology is present in many publications and pseudoplastic and plastic liquids are of particular interest. If the disrupted system in a quiescent state restores its own structure, it is thixotropic liquid, graphically expressing in hysteresis loop between up- and down flow curves. In turn, the thixotropy of conventional polymer suspensions of solid particles is caused by the reversible changing of initial microstructure [3-6] due to flocculation of solid particles through polymer bridging [7,8]. However, if the effective viscosity of the system increases with the raising of shear stresses it demonstrates rheopexic properties [9-12]. The counterclockwise hysteresis loop indicates rheopexy and the area between up- and down- flow curves is the rheopexy degree R [3]. Thus, thixotropy and rheopexy are two opposite states of structured liquids.

Rheopexy phenomenon is quite rare and poorly studied. Masalova et al. [13] give just a few references to publications. Particularly, Soltero et al. [14] demonstrated the effect of rheopexy on surfactant- based lamellar liquid crystals. Escalante and Hoffmann [15] showed that prolonged shearing could result in an increase in viscosity due to the alignment of domains of the ionically charged lamellar phase and its transition to a vesicle phase. The characteristic time of this process decreases with increasing shear rate. Kamai and Amari [16] demonstrated the increased viscosity under shearing of ferric-oxide suspensions in mineral oil 33% by weight and called it “antithixotropy”.

However, increasing the effective viscosity during shearing could be observed due to dilatancy phenomenon [17-19]. According to Efremov [18] increased shearing leads to particles transition into the less packaging state and to liquid absorption into the formed pores. Herewith the increasing of volume and dissipation energy of the system takes place.

As for as both phenomena characterize the viscosity increasing, Masalova et al. [13] propose to distinguish rheopexy and dilatancy by the interval of shear rates corresponding to shear thickening. The authors associate rheopexy with slight displacement of the system and its elastic deformation and relaxation. In turn, the dilatancy is compared with high shear rates and topological transformations of structural elements.

Most authors, revealing the essence of these phenomena, are right. Nevertheless, there are unique systems exhibiting rheopexy and dilatancy during the same interval of shear rates. In particular, this work is devoted to the establishment of the causes and consequences of coexistence of rheopexy and dilatancy in polymer suspensions filled with ceramic nanoparticles.

Discussion

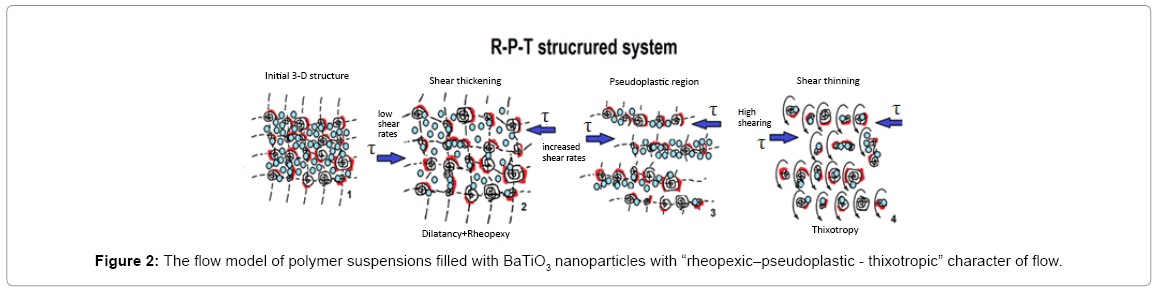

In our previous works, it was established, that plasticized polymer suspensions based on BaTiO3 nanopowder were thixotropic systems exhibiting shear thickening behavior at low shear stresses and subsequent shear thinning at high shearing. However, some concentrations of plasticizer DBP caused appearance of rheopexy at the interval of low shear stresses indicating increasing of effective viscosity due to the faster restoring of the initial microstructure [20,21]. For a better understanding of rheopexy phenomenon, we consider the behavior of the systems with “rheopexic-pseudoplastic-thixotropic” character of flow.

Figure 1 shows, that suspension pass three structural states during increased shearing. High-concentrated polymer suspensions form aggregates as doublets or chains united into spatial 3-D network with some solid properties [22,23]. Before Vd the system deforms elastically and after exceeding of yield stress value the initial microstructure begins to disrupt.

Rheological specificity of the suspensions with “rheopexicpseudoplastic- thixotropic” character of flow could be explained with the following model of the process (Figure 2). Along up-curve, the beginning of deformation corresponds to a dilatant viscosity increasing because of the elastic properties of the solid-like system (Figure 1). Herewith separate molecules, their segments, microfibrils and clusters of polymer molecules and nanoparticles were predominantly spherical-shaped. They partially overlapped forming additional molecular engagements, due to which the initial network resisted to deformation. Graphically it could be observed in shear thickening during dilatant region (Figure 1). However, increasing of shear stresses and exceeding of Vd value led to the occurrence of overstrain condition of the transverse structural links. The system became a pseudoplastic two-dimensional state (Figures 1 and 2) due to the forced orientation of structural elements. During the pseudoplastic flow region (on the average length of 20-55 Pa) the system was in an equilibrium state and flowed layer wise. Further shearing led to the difference in shear rates between structural layers and to disrupting of longitudinal bonds. Thus, the system becomes a thixotropic one-dimensional structural state. Thixotropic destruction reflected in gradual viscosity decreasing due to simultaneous disruption and violation of the molecular orientation. The structural elements moved with the average velocity of the gradient flow and rotated in a perpendicular direction. Then they collided and mutually shielded, affecting the rotating rate. The final destruction of the system became after achieving and exceeding of strength stress value.

Relaxation processes have reflected in character of down-curve. Decreasing of shear stresses led to the gradual increase of viscosity. Herewith, the value of appropriate viscosity was lower than on the upcurve. Such difference in values causes the formation of the thixotropic hysteresis loop. Throughout the thixotropic region, lowering of shear stress led to the formation of instantaneous local engagements between clusters in the longitudinal direction. Further decreasing of shearing caused increasing the longitudinal clusters engagement and led to the pseudoplasticity. Because the continuous reduction of shear stresses led to the difference in rates between structural layers, the probability of their contact increased. The transverse structural links were arisen on the contact points, forming 3-D structure and rheopexic hysteresis loop. Calculated effective hydrodynamic radii of the structural elements along down-curve in work [21] lead to the conclusion that the rheopexy was caused by the enlargement of floccules size after stress removing. Thus, in the case of polymer suspensions filled with ceramic nanoparticles, the dilatancy and rheopexy could coexist in the same interval of shear stresses, causing an increase of effective viscosity.

Conclusion

It was found, that both rheopexy and dilatancy could coexist in polymer suspensions filled with ceramic nanoparticles at the same range of shear stresses. To explain the complex nature of the flow the authors were proposed the flow model of “rheopexic–pseudoplastic– thixotropic” system. According to this model, it was established that the dilatant increasing of the effective viscosity at the initial stage of deformation appears along up-flow curve and characterizes the initial microstructure resistance to applied shear stresses. In turn, rheopexy phenomenon develops along down-flow curve at the almost final stage of relaxation, reflecting the system approximation to the solid-like state and characterizing its elastic properties. Herewith, the hydrodynamic radius of floccules increases and a system recovers to a larger value of effective viscosity. Thus, it could be concluded, that the strength of initial microstructure was characterized by the rheopexy degree (energy-structural component) and dilatancy degree (structuralmechanical component).

References

- Sharma AK (2016) Rheological behavior of nanofluids: A review. RenewSust Energy Rev 53: 779-791

- Rueda MM (2017) Rheology and applications of highly filled polymers: A review of current understanding. Prog Polym Sci 66: 22-53

- Dullaert K (2005) A model system for thixotropy studies. Rheol Acta 45: 23-32.

- Dullaert K (2005) Thixotropy: Build-up and breakdown curves during flow. J Rheol 49: 1213-1230

- Dullaert K (2006) A structural kinetics model for thixotropy. J Nonnewton Fluid Mech 139: 21-30.

- Otsubo Y (1999) Rheological behavior of suspensions flocculated by weak bridging of polymer coils. J Colloid Interface Sci 215: 99-105

- Otsubo Y (1992) Effect of particle size on the bridging structure and elastic properties of flocculated suspensions. J Colloid Interface Sci 153: 584-586.

- Schramm G (2003) A practical approach to rheology and rheometry. Gebrueder Haake GmbH, Karlsruhe, p: 312.

- Mikami Y (1982) Interpretation of the rheopexy by a two process kinetic model. J Rheol 26: 263-276.

- Buitenhuis J (2003) Negative thixotropy of polymer solutions a model explaining time-dependent viscosity. Colloid Polym Sci 281: 253-259

- Masalova I (2005) Rheopexy in highly concentrated emulsions. J Rheol 49: 839-849

- Soltero J (1995) Thixotropic-antithixotropic behavior of surfactant-based lamellar liquid crystals under shear flows. J Rheol 39: 235-240

- Escalante J (2000) Non-linear rheology and flow induced transition to a lamellar to vesicle phase in ternary systems of alkyldimethyl oxide/alcohol/water. Rheol Acta 39: 209-214.

- Kamai A (1995) Negative thixotropy in ferric-oxide suspensions. Rheol Acta 34: 303-310.

- Brown E (2014) Shear thickening in concentrated suspensions phenomenology, mechanisms and relations to jamming. Rep Prog Phys 77: 046602

- Efremov IF (1982)The dilatancy of colloidal structures and polymer solutions. Russ Chem Rev 51: 160-177

- Woodcock LV (1984) Origins of shear dilatancy and shear thickening phenomena. Chem Phys Lett 111: 455-461

- Umerova S (2016) Rheology of plasticized screen printing pastes based on BaTiO3 nanopowder. Appl Rheol 3: 1-9.

- Umerova S (2017) Shear thickening of Batio3 nanoparticles-filled non-Newtonian polymer suspensions. Rheol Open Access 1: 105

- Goodwin JW (1987) The rheology of colloidal dispersions. Solid/liquid dispersions Ed Tadros L, p: 199

- Barnes HA (2000) Handbook of elementary rheology. Institute of non-Newtonian fluid mechanics, University of Wales, Aberystwyth, p: 201.

Citation: Umerova S, Ragulya A (2017) Coexistence of Rheopexy and Dilatancy in Polymer Suspensions Filled with Ceramic Nanoparticles. Rheol: open access 1: e102.

Copyright: © 2017 Umerova S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Open Access Journals

Article Usage

- Total views: 6060

- [From(publication date): 0-2017 - Mar 28, 2025]

- Breakdown by view type

- HTML page views: 5099

- PDF downloads: 961