Research Article Open Access

Characterization of Yellow Pigments Produced by Pencillium sp. under Solid State Cultivation

Supreet Kaur*, Nidhi Arora and Sawinder KaurDepartment of Biotechnology, Lovely Professional University, Punjab, India

- Corresponding Author:

- Kaur S

Department of Biotechnology

Lovely Professional University, Punjab, India

Tel: +9781427507

E-mail: supreet306@gmail.com

Received date: April 13, 2017; Accepted date: May 25, 2017; Published date: June 02, 2017

Citation: Kaur S, Arora N, Kaur S (2017) Characterization of Yellow Pigments Produced by Pencillium sp. under Solid State Cultivation. J Biotechnol Biomater 7:259. doi:10.4172/2155-952X.1000259

Copyright: © 2017 Kaur S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Visit for more related articles at Journal of Biotechnology & Biomaterials

Abstract

Solid state fermentation was carried out for the production of pigments by using agricultural wastes. Yellow pigments were produced; the absorbance maxima of Pigment extract was measured by spectral analysis. Out of these agricultural wastes broken wheat (0.996 OD) was best for the pigment production. The maximum pigment yield (137.8 U/g) was seen at 12th day. The study revealed that the addition of nitrogen source improves the metabolic activity of the organism. Monosodium glutamate and ammonium nitrate improved the growth than other supplements. Various parameters were optimized to check the pigment stability. Pigments showed high stability at low temperatures (30-60°C) and become low at high temperature (above 60°C) and high stability at near-neutrality pH values (8.0) when compared to acidic pH values (4.0-6.0). FTIR analysis was performed to determine the chemical bonds in a molecule by infrared absorption spectra of Pigments. IR indicated that it is a phenolic compound and has broad stretching OH, C=C and C-H groups of the aromatic ring. It can be concluded that the microbial pigment produced can find application in the areas of textile, pharmaceuticals and food industries.

Keywords

Pencillium sp.; Solid state fermentation; Nitrogen sources; Column chromatography; Pigment Stability; FTIR

Introduction

Pigments produced from natural sources are of worldwide interest and is gaining importance. These pigments are looked upon for their safe use as a natural food dye in replacement of synthetic ones because of undesirable toxic effects including mutagenicity and potential carcinogenicity. The various advantages of producing pigments from microorganisms include independence from weather conditions, easy and fast growth, colours of different shades and growth on cheap substances and give a full range of colours. Pigments have a variety of applications that includes plastics, ink and coating applications and can easily react with amino group containing compounds in the medium such as proteins, amino acids or nucleic acids to form water-soluble pigments [1].

The structure of pigments depends on type of substrate and other specific factors during culture such as pH, temperature and moisture content [2]. Biopigments produced by fermentation present a great potential for food applications, because they are natural, produced quickly (when compared with vegetable or animal pigments) and at any time of the year. Commercial biopigments produced by fermentation include riboflavin (vitamin B2, a yellow pigment with permitted use in most countries), biopigments from Monascus (red pigments, widely used in Asia, specially China, Japan, Thailand and Indonesia, but not yet regulated in several other countries), carotenoids (yellow to red pigments produced by several microorganisms, but as yet produced economically only using micro algae), and phycobiliproteins such as phycocyanin (a blue pigment used in food and cosmetics [3].

Pigments are compounds with characteristics of importance to many industries. In the food industry they are used as additives, color intensifiers, antioxidants, etc. Pigments come in a wide variety of colors and some are water-soluble mostly natural pigments utilize from plants and animals. These additives have numerous drawbacks such as instability and low water solubility and are often not available throughout the year. Microbial pigments are of industrial interest because they are often more stable and soluble than those from plant or animal sources [4].

Natural pigments possess anticancer activity, contain pro-vitamin A and have some desirable properties like stability to light, heat and pH. Plants, animals and microbes are the sources of natural pigments and when the microbial cells are used to produce the color the term refers to ‘Microbial Pigments’ [5].

The types of secondary metabolites produced from the Monascus sp. include: a group of pigments (yellow pigment, ankaflavin and monascin; orange pigment, monascorubrin and rubropunctanin; red pigment, monascorubramine and rubropuctamine [6], a group of antihypercholesterolemic agents including monacolin K and hypotensive agent, γ-aminobutyric acid (GABA) [7], antioxidant compounds including dimerumic acid [8] and 3-hydoxy-4-methoxybenzoic acid [9] and an antibacterial activity compound including pigment and citrinin (also known as monascidin) [10].

Solid state cultivation results in higher pigment yield than cultivation in shake culture because pigments are released into grains under solid state culture rather than accumulated in the mycelium under submerged to cultivation [11]. Most of the pigment production studies have been conducted using Monascus and still the requirement of other potential strains is felt. This study was taken up with the objective to; produce natural food colorant by the solid-state fermentation of broken wheat and broken rice using Pencillium sp.

Material and Methods

Production of pigments by Pencillium sp.

Natural pigments mainly from plants and animals sources but due to some drawbacks such as instability, low water solubility and are often not available throughout the year. Microbial pigments are of industrial interest because they are often more stable and soluble than those from plant or animal sources. Microorganisms can grow rapidly, which can lead to high productivity, and can produce a product throughout the year [12]. Microorganisms belonging to the genera Aspergillus and Penicillium have also been studied as potential producers of natural pigments [13,14].

Substrate: Broken Wheat and Broken rice purchased from the local market were used as the substrate for pigments production using Pencillium sp.

Inoculum preparation: Spore suspension was prepared by adding 10 ml of sterile water to the slants and scrapping the surface in order to suspend spore in the solution. The spore suspension was used as inoculum. The inoculum size was adjusted to between 1.0 × 106 and 5.0 × 106 spores/ml by microscopic enumeration with a cell-counting hematocytometer.

Microbial bioconversion of substrates for production of pigments: 10 g each of broken wheat and broken rice were soaked in water for overnight and the extra water is drained and the flasks were sterilized at 121°C for 20 min by autoclaving. The flasks were allowed to cool and inoculated with 10% of the inoculum and incubated for 10-12 days at 28°C. After incubation period the flasks were sterilized at 121°C for 30 min by autoclaving. The sterilized fermented substrates were dried at 50°C for 24 h. Dried substrates were pulverized and stored for further analysis.

Pigment extraction: 0.5 g of dried fermented substrate was extracted with 80% ethanol and the final volume was made up to 50 ml. The mixture was kept on a rotary shaker at 200 rpm for 1 h. Then it was centrifuged for 30 min at 5000 rpm and the supernatant was collected for pigment analysis [11].

Characterization of pigments produced by Pencillum sp.

Pigment estimation: Pigment estimation was done in which the optical density at its absorbance maxima were expressed as the concentration of pigment produced. The absorbance maxima of pigment extract was measured by spectral analysis at 375-750 nm to analyze the pigments [12].

Effect of different nitrogen sources on production of pigments: 10 g broken wheat was soaked overnight in 250 ml tap water. Water drained broken wheat were added with 0.5% of different nitrogen sources (peptone, yeast extract, ammonium nitrate and monosodium glutamate) separately and sterilized at 121°C for 30 min by autoclaving. It was allowed to cool and inoculated with 10% of the inoculum and incubated for 12 days at 28°C. The growth of fungus and pigment production was visualized after 2 days, 6 days and then 12 days. After incubation the flasks were sterilized at 121°C for 30 min by autoclaving. The sterilized Pencillium fermented wheat (PFW) was dried at 50°C for 24 h. Dried PFW was pulverized and stored for further analysis [11].

Purification of pigments using column chromatography: The pigments were purified by silica gel (60-120 mesh) column chromatography. The column was packed with silica gel by slurry method. The column was pre eluted using the solvent chloroform: ethanol (9:1 v/v). Then 10 ml extract of Pencillium fermented wheat (PFW) and Pencillium fermented rice (PFR) were added separately in different column and it was eluted the same. The different fraction of the pigment was collected and spectral analysis was done.

TLC of crude Extracts: Concentrated ethanolic extracts were analyzed by thin layer chromatography. The spotted silica gel plated were developed with chloroform:ethanol:water (65:25:4) to compare the Rf values of pigments.

Evaluation of pigment stability: For thermal stability tests, pigment solutions were incubated at 30°, 40°, 60° or 80°C from 0 to 200 min at pH 6.0. For pH stability studies, pigment solutions of different pH values (4.0–8.0) were incubated at 80°C from 0 to 180 min [15].The absorbance maxima of pigment extract was measured by spectral analysis at 375 nm and expressed as percentage absorbance [15].

FTIR analysis: FTIR analysis was performed to determine the chemical bonds in a molecule by producing infrared absorption spectra of Pigments. The measurements were carried out at infra-red spectra between 500-4,000 cm-1 [16].

Results and Discussion

For pigment production, solid state cultivation was superior to submerged cultivation. As a substrate for the solid state fermentation to produce pigments, broken wheat was more effective than broken rice, as there were viewable difference (Table 1) seen in the yield of broken wheat (BW) and broken rice (BR) at 12th day.

| Pigment yield at 375nm | Pigment yield at 475nm | Pigment yield at 555nm | |||||

|---|---|---|---|---|---|---|---|

| S. No. | days | (BW) (Units/g) |

(BR) (Units/g) |

(BW) (Units/g) |

(BR) (Units/g) |

(BW) (Units/g) |

(BR) (Units/g) |

| 1. | 6 | 59.1 | 22.1 | 11.6 | 10.8 | 9 | 11 |

| 2. | 8 | 37.3 | 46.7 | 15.6 | 12.5 | 1.7 | 1.5 |

| 3. | 10 | 109.5 | 45.1 | 26.9 | 16.1 | 11.8 | 15.3 |

| 4. | 12 | 137.8 | 62.2 | 51.4 | 34.8 | 17.5 | 20.7 |

| 5. | 15 | 75.5 | 53.9 | 21.4 | 19.6 | 4.9 | 7.5 |

Table 1: Pigment yield.

Pigment analysis

Amongst the two substrates broken wheat showed maximum pigment production after 12 days (Figure 1). The maximum absorbance was observed at 375 nm. The dominating wavelength of 375 nm corresponds to yellow pigments.

Pigment yield

Production of pigments were carried out for 6 days, 8 days, 10 days, 12 days and 15 days by using broken wheat and broken rice as substrates. Amongst the two substrates studied broken wheat showed maximum pigment yield (137.8 U/g) after incubation period of 12 days while broken rice yielded 62.2 U/g (Table 1).

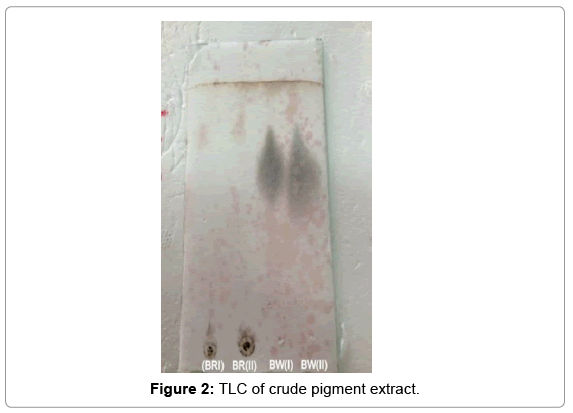

TLC of pigment extracts

Concentrated ethanolic extracts were analyzed by thin layer chromatography. The spots were appeared as dark brown color. Bands were distinguished based on their Rf values. The Rf value (Figure 2) of broken wheat (I) was (Rf 0.87) and broken wheat (II) was (Rf 0.83).

Evaluation of pigment stability

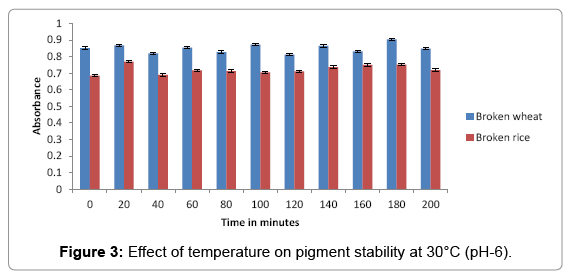

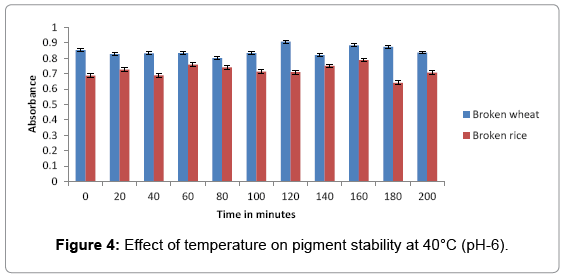

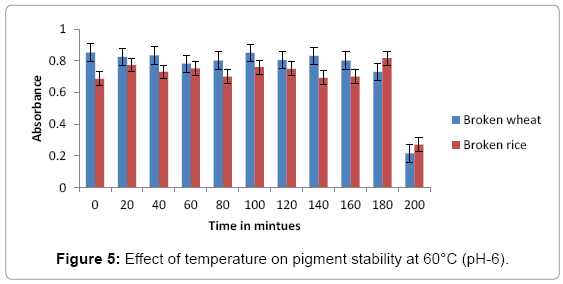

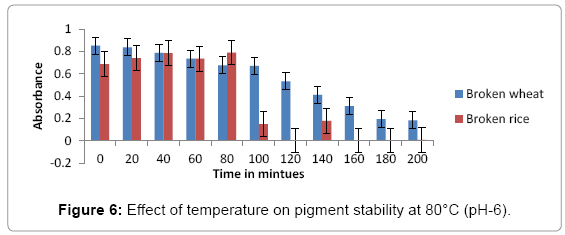

Effect of temperature: Studies on pigments stability to different temperature values (pH 6) were carried out, and pigments maintained their initial colour up to 60°C, after that colour degradation takes place which indicates pigments showed (Tables 2-5 and Figures 3-6) high stability at low temperatures (30°-60°) compared to that at high temperature (above 60°C).

| S. No. | Time (min) | ABS(BW) ± SD | ABS(BR) ± SD |

|---|---|---|---|

| 1. | 0 | 0.852 ± 0.0003 | 0.686 ± 0.014 |

| 2. | 20 | 0.826 ± 0.007 | 0.770 ± 0.024 |

| 3. | 40 | 0.831 ± 0.004 | 0.690 ± 0.007 |

| 4. | 60 | 0.833 ± 0.002 | 0.717 ± 0.055 |

| 5. | 80 | 0.801 ± 0.004 | 0.713 ± 0.046 |

| 6. | 100 | 0.833 ± 0.005 | 0.705 ± 0.007 |

| 7. | 120 | 0.908 ± 0.012 | 0.711 ± 0.007 |

| 8. | 140 | 0.819 ± 0.006 | 0.736 ± 0.055 |

| 9. | 160 | 0.883 ± 0.005 | 0.750 ± 0.051 |

| 10. | 180 | 0.873 ± 0.008 | 0.782 ± 0.021 |

| 11. | 200 | 0.837 ± 0.0014 | 0.719 ± 0.059 |

Table 2: Effect of temperature on pigment stability at 30°C.

| S. No. | Time (min) | ABS (BW) ± SD | ABS (BR) ± SD |

|---|---|---|---|

| 1. | 0 | 0.852 ± 0.0003 | 0.686 ± 0.014 |

| 2. | 20 | 0.826 ± 0.007 | 0.770 ± 0.024 |

| 3. | 40 | 0.831 ± 0.004 | 0.690 ± 0.007 |

| 4. | 60 | 0.833 ± 0.002 | 0.717 ± 0.055 |

| 5. | 80 | 0.801 ± 0.004 | 0.713 ± 0.046 |

| 6. | 100 | 0.833 ± 0.005 | 0.705 ± 0.007 |

| 7. | 120 | 0.908 ± 0.012 | 0.711 ± 0.007 |

| 8. | 140 | 0.819 ± 0.006 | 0.736 ± 0.055 |

| 9. | 160 | 0.883 ± 0.005 | 0.750 ± 0.051 |

| 10. | 180 | 0.873 ± 0.008 | 0.782 ± 0.021 |

| 11. | 200 | 0.837 ± 0.0014 | 0.719 ± 0.059 |

Table 3: Effect of temperature on pigment stability at 40°C.

| S. No. | Time (min) | ABS (BW) ± SD | ABS (BR) ± SD |

|---|---|---|---|

| 1. | 0 | 0.852 ± 0.0003 | 0.686 ± 0.014 |

| 2. | 20 | 0.825 ± 0.007 | 0.774 ± 0.024 |

| 3. | 40 | 0.835 ± 0.004 | 0.730 ± 0.007 |

| 4. | 60 | 0.782 ± 0.002 | 0.752 ± 0.055 |

| 5. | 80 | 0.802 ± 0.004 | 0.701 ± 0.046 |

| 6. | 100 | 0.850 ± 0.005 | 0.761 ± 0.007 |

| 7. | 120 | 0.805 ± 0.012 | 0.750 ± 0.007 |

| 8. | 140 | 0.832 ± 0.006 | 0.693 ± 0.055 |

| 9. | 160 | 0.802 ± 0.005 | 0.701 ± 0.051 |

| 10. | 180 | 0.730 ± 0.008 | 0.818 ± 0.021 |

| 11. | 200 | 0.216 ± 0.0014 | 0.271 ± 0.059 |

Table 4: Effect of temperature on pigment stability at 60°C.

| S. No. | Time (min) | ABS (BW) ± SD | ABS (BR) ± SD |

|---|---|---|---|

| 1. | 0 | 0.852 ± 0.0003 | 0.686 ± 0.014 |

| 2. | 20 | 0.838 ± 0.016 | 0.771 ± 0.046 |

| 3. | 40 | 0.787 ± 0.004 | 0.786 ± 0.016 |

| 4. | 60 | 0.735 ± 0.014 | 0.735 ± 0.072 |

| 5. | 80 | 0.677 ± 0.0014 | 0.790 ± 0.002 |

| 6. | 100 | 0.672 ± 0.015 | 0.151 ± 0.015 |

| 7. | 120 | 0.532 ± 0.116 | 0.004 ± 0.000 |

| 8. | 140 | 0.412 ± 0.197 | 0.180 ± 0.000 |

| 9. | 160 | 0.310 ± 0.277 | 0.008 ± 0.000 |

| 10. | 180 | 0.195 ± 0.245 | 0.004 ± 0.000 |

| 11. | 200 | 0.184 ± 0.059 | 0.008 ± 0.000 |

Table 5: Effect of temperature on pigment stability at 80°C.

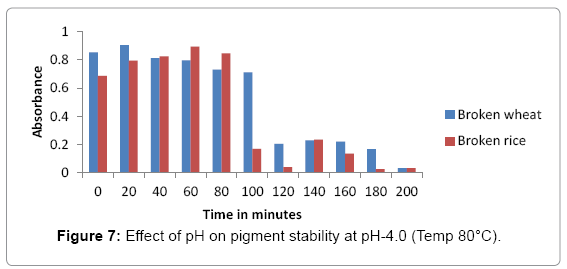

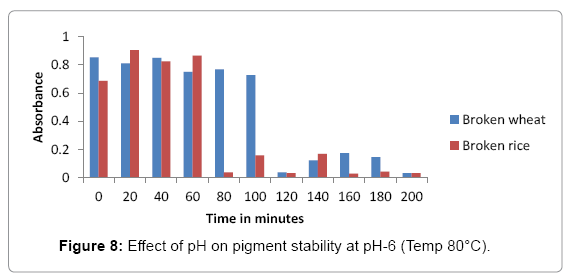

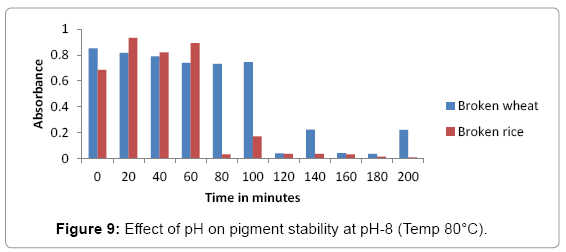

Effect of pH: To check the optimum pH for the stability of pigments, pigment solutions were incubated for different pH as 4.0, 6.0 and 8.0 from 0 to 200 min at 80°C.Pigments showed high stability at pH values (6.0-8.0) when compared to that at acidic pH values (4.0-5.0) (Table 6 and Figures 7-9).

| S. No. | Time (min) | pH-4.0 | pH-6.0 | pH-8.0 | |||

|---|---|---|---|---|---|---|---|

| ABS (BW) | ABS (BR) | ABS (BW) | ABS (BR) | ABS (BW) | ABS (BR) | ||

| 1. | 0 | 0.852 | 0.686 | 0.852 | 0.686 | 0.852 | 0.686 |

| 2. | 20 | 0.903 | 0.793 | 0.810 | 0.903 | 0.818 | 0.933 |

| 3. | 40 | 0.810 | 0.824 | 0.848 | 0.824 | 0.790 | 0.820 |

| 4. | 60 | 0.795 | 0.892 | 0.750 | 0.864 | 0.740 | 0.892 |

| 5. | 80 | 0.730 | 0.845 | 0.767 | 0.038 | 0.733 | 0.030 |

| 6. | 100 | 0.710 | 0.170 | 0.727 | 0.159 | 0.746 | 0.170 |

| 7. | 120 | 0.206 | 0.041 | 0.038 | 0.034 | 0.038 | 0.034 |

| 8. | 140 | 0.230 | 0.235 | 0.123 | 0.170 | 0.223 | 0.034 |

| 9. | 160 | 0.222 | 0.136 | 0.275 | 0.030 | 0.041 | 0.003 |

| 10. | 180 | 0.168 | 0.027 | 0.179 | 0.043 | 0.035 | 0.013 |

| 11. | 200 | 0.034 | 0.034 | 0.034 | 0.034 | 0.222 | 0.007 |

Table 6: Effect of pH on pigment stability at different pH level.

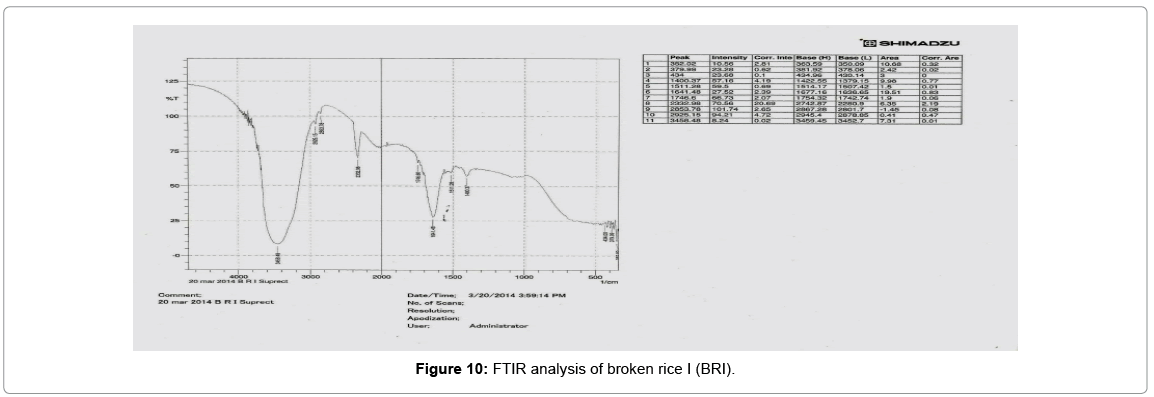

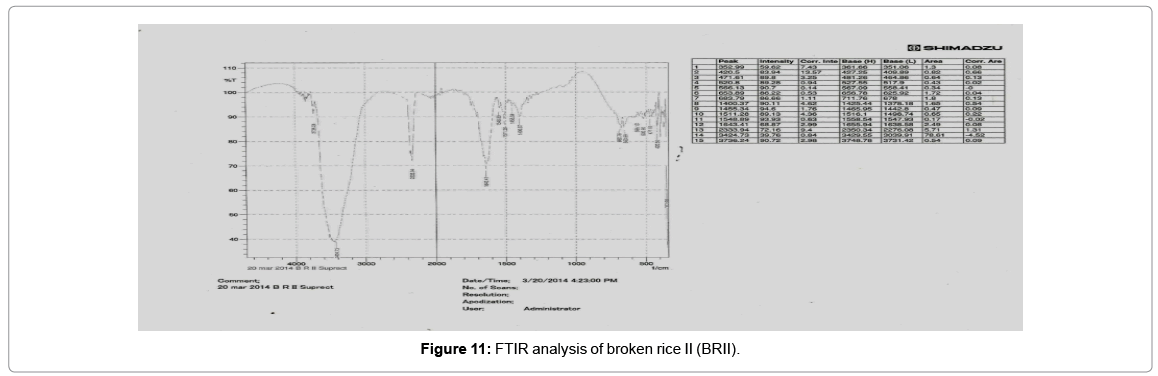

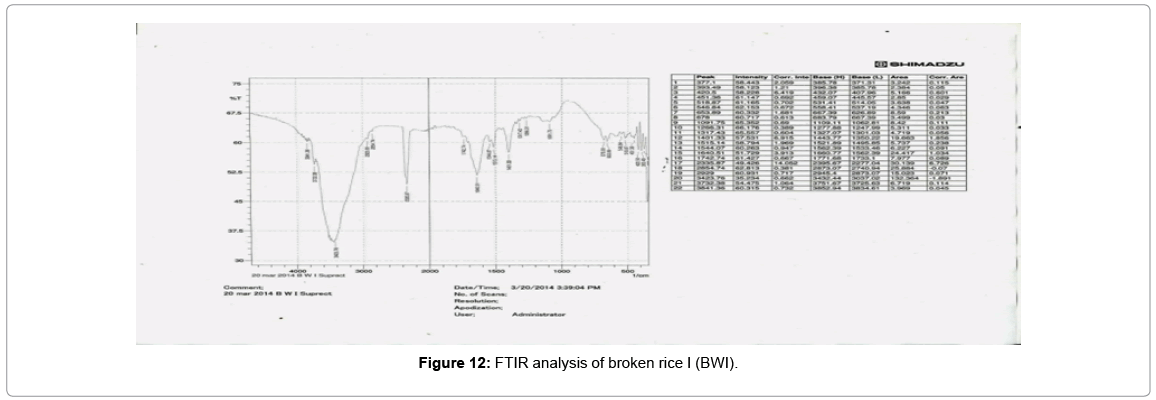

FTIR analysis

FTIR analysis was performed to determine the chemical bonds in a molecule by producing infrared absorption spectra of Pigments. The measurements were carried out at infra-red spectra between 500-4,000 nm.

The IR spectrum of pigment extracted from Pencillium sp. in case of broken rice (I) showed broad O-H stretching at 3458.48 cm-1 (Figure 10) functional group of alcohol and phenols. In the IR spectrum stretching frequency also observed at 1641.48 cm-1 and 1400.37 cm-1 assignable to ̶ C=C ̶ stretching and C-C stretching functional group of alkenes and aromatic rings. Geweely also reported IR stretching frequency at 3450 cm-1 for the pigment extracted from P. pupurogenum [16]. In the IR spectrum stretching frequency were also observed at 1,620 and 1,350 cm-1 (Figure 11) assignable to C=C and C-H functional groups of the aromatic ring, respectively.

In case of broken wheat (I) showed strong O-H stretching and H-bonding at 3423.76 cm-1 functional group of alcohol and phenols (Figure 12). In the IR spectrum stretching frequency also observed at 1640.51 cm-1 and 1401.33 cm-1 assignable to ̶ C=C ̶ stretching and C-C stretching functional group of alkenes and aromatic rings. It was also showed asymmetric stretching N-O at 1515.14 cm-1 functional group of nitro compounds.

Conclusion

Research on carotenoids has included all branches of natural sciences has led the way to pure natural food colouring matters. I believe that pure synthetic carotenoids will gradually replace by natural extracts. Production of colors by fermentation has a number of advantages; cheaper production, possibly easier extraction, higher yields, no lack of raw material and no seasonal variation.

In the present study, it was concluded that the specific culture of Pencillium sp. was used for the production of pigments via solid state production by using agricultural wastes. Out of these agricultural wastes broken wheat (0.996 OD) was best for the pigment production. The maximum pigment yield (137.8 U/g) was seen at 12th day. The study revealed that the addition of nitrogen source improves the metabolic activity of the organism. Various parameters were optimized to check the pigment stability. Pigments showed high stability at low temperatures (30-60°C) and become low at high temperature (above 60°C) and high stability at near-neutrality pH values (8.0) when compared to acidic pH values (4.0–6.0).

FTIR analysis was performed to determine the chemical bonds in a molecule by infrared absorption spectra of Pigments. IR indicated that it is an phenolic compound and has broad stretching OH, C=C and C-H groups of the aromatic ring. It can be concluded that the microbial pigment produced can find application in the areas of textile, pharmaceuticals and food industries because of its antibacterial and antifungal properties.

According to the American Heart Association, due to elevated level of cholesterol more than one million die each year because of cardiovascular disease. Medications available are very expensive posing side effects ,where Red yeast rice is a natural colourant, containing naturally produced monacolins which has the ability to reduce LDLcholesterol and increase HDL-cholesterol thus improving heart health, besides a food colourant.

References

- Laurent D (2005) Microbial production of food grade pigments. Food Technol Biotechnol 44: 313-321.

- Subhasree RS, Babu D, Vidyalakshmi R, Mohan VC (2011) Effect of carbon and nitrogen sources on stimulation of pigment production by Monascus purpureus on jackfruit seeds. Intl J Microbiol Res 2: 184-187.

- Julio CC, Oishi OB, Adenise LA, Ashok P, Babitha S, Soccol CR (2006) Effect of substrates on the production of Monascus biopigments by solid-state fermentation and pigment extraction using different solvents. Ind J Biotechnol 6: 194-199.

- Gunasekaran S, Poorniammal S (2008) Optimization of fermentation conditions for red pigment production from Penicillium sp. under submerged cultivation. Afr J Biotechnol 7: 1894-1898.

- Joshi VK, Devender A, Anju B, Shashi B (2003) Microbial pigments. Ind J Biotechnol 2: 362-369.

- Wong HC, Koehler PE (1981) Production and isolation of an antibiotic from Monascus purpureus and its relationship to pigment production. J Food Sci 46: 589–592.

- Su YC, Wang JJ, Lin TT, Pan TM (2003) Production of the secondary metabolites gamma-aminobutyric acid and monacolin K by Monascus. J Ind Microbiol Biotechnol 30: 41-46.

- Aniya Y, Ohtani II, Higa T, Miyagi C, Gibo H, et al. (2000) Dimerumic acid as an antioxidant of the mold, Monascus anka. Free Radic Biol Med 28: 999-1004.

- Wu G, Wu X (2000) Screening DPPH radical scavengers from Monascus sp. J Bioequi Bioavai 40: 394-399.

- Blanc PJ, Laussac JP, Le Bars J, Le Bars P, Loret MO, et al. (1995) Characterization of monascidin A from Monascus as citrinin. Int J Food Microbiol 27: 201-213.

- Vidyalakshmi R, Paranthaman R, Murugesh S, Singaravadivel K (2009) Microbial bioconversion of rice broken to food grade pigments. Glob J Biotechnol Biochem 4: 84-87.

- Silvana TS, Daniel JD, Voltaire SA, Brandelli A (2011) Stability modeling of red pigments produced by Monascus purpureus in submerged cultivations with sugarcane bagasse. Food Bioprocess Technol 6: 1007-1014.

- Neveen SG (2011) Investigation of the optimum condition and antimicrobial activities of pigments from four potent pigment-producing fungal species. J Life Sci 5: 697-711.

Relevant Topics

- Agricultural biotechnology

- Animal biotechnology

- Applied Biotechnology

- Biocatalysis

- Biofabrication

- Biomaterial implants

- Biomaterial-Based Drug Delivery Systems

- Bioprinting of Tissue Constructs

- Biotechnology applications

- Cardiovascular biomaterials

- CRISPR-Cas9 in Biotechnology

- Nano biotechnology

- Smart Biomaterials

- White/industrial biotechnology

Recommended Journals

Article Tools

Article Usage

- Total views: 4340

- [From(publication date):

June-2017 - Jul 06, 2025] - Breakdown by view type

- HTML page views : 3281

- PDF downloads : 1059