Carbon Flow and CO2 Emission in Induction Furnace Steelmaking

Received: 02-Sep-2024 / Manuscript No. jpmm-24-141695 / Editor assigned: 04-Sep-2024 / PreQC No. jpmm-24-141695 (PQ) / Reviewed: 18-Sep-2024 / QC No. jpmm-24-141695 / Revised: 23-Sep-2024 / Manuscript No. jpmm-24-141695(R) / Published Date: 30-Sep-2024

Abstract

Since last few years study of CO2 emission in every sector has become very important due to severe global climatic changes. Steel sector contributes to about 7.2% of global CO2 emission. Across the world steel is manufactured through BF-BOF route and Electric furnace route. Further, electric steelmaking is divided in electric arc furnace steelmaking and induction furnace steelmaking. Ample data is available for BF-BOF and EAF route, but for induction furnace steelmaking available data is very less. Induction furnace steelmaking is a unique way of steel production. The route is very much popular in Asian countries. Induction furnace uses steel scrap for steelmaking. Considering these factors, the purpose of present study is to generate the data of CO2 emission for induction furnace steelmaking. It was observed that at steel melting shop CO2 emission for induction furnace is only 3-5 kg CO2 /ton of steel. Comparison of induction furnace data is also done with the arc furnace steelmaking and BF-BOF steelmaking which have high amount of CO2 emission per ton of steelmaking.

Keywords

Steelmaking; Induction Furnace; CO2 Emission; Carbon Flow

Introduction

Since last few years, the global climate change has become a widely discussed issue. This severe climate change is caused by emission of CO2 in the atmosphere. It is the need of time to reduce these global Green House Gas (GHG) emissions which can be possible by decarbonizing various sectors. Carbon dioxide is naturally present in the earth’s atmosphere in the form of carbon cycle. The carbon cycle is nothing but natural circulation of carbon among the atmosphere, solid, and animals, plants and oceans. There are natural sources of CO2 generation and CO2 sinks. However, various human activities disturb these entities by influencing high generation of CO2, at the same time reduce natural sinks by cutting forests.

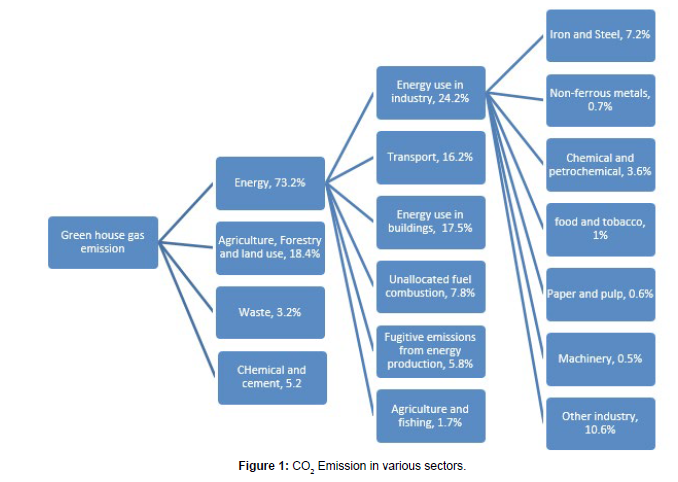

Human interference with CO2 generation has been increased since industrial revolution [1]. Large amount of CO2 generation comes from the combustion of fossil fuel. The increased use of fossil fuel is attributed to population growth, changes in seasonal temperatures, economic growth, increase in fuel prices, evolution of newer technologies, etc. Intergovernmental Panel on Climate Change (IPCC) [2] presented a comprehensive report on GHG emissions by various sectors. As per the report, the sectors which emit GHG are energy sector, agriculture, forestry, transport, industry, etc. The report further discusses about direct and indirect emissions of various sectors. Out of total GHG emissions, energy use in industry contributes to about 24%. In this regime iron and steel industry has a share of 7.2% for GHG emissions at a global level. The same is depicted in Figure 1 in the form of a chart. Across the globe presently, there are two prominent steelmaking routes; namely, blast furnace with basic oxygen furnace (BF-BOF) route of steelmaking and electric route of steelmaking. Electric route can further be divided as steelmaking in an electric arc furnace (EAF) and steelmaking in an induction furnace (IF) (Figure 1A).

India is the second largest steel producer in the world with the production of about 125 million tons in the year 2022 [3]. Indian steel industry is divided in three major steelmaking routes namely: BF-BOF steelmaking, EAF steelmaking and induction furnace steelmaking [4]. Out of these three routes induction furnace steelmaking contributes to about 1/3rd of the India’s steel production. Presently, India is producing about 40 million T steel per annum through induction furnace route, which is highest for any country across the world.

Other than India, various countries in Indian sub-continent such as Pakistan, Bangladesh, Nepal and Sri Lanka produce steel mainly with induction furnace route. There are many African countries where induction furnace steelmaking is the only route of steel production. Across the globe for mini steel mills induction furnace steelmaking route is widely getting popular for its simplicity in installation, less infrastructure and mainly, low capital investment compared to EAF and BF-BOF routes. Additionally, the countries where iron ore and coal/coke are not available but steel scrap is available, induction furnace becomes the natural choice of steelmaking. As this route is getting worldwide acceptance, it becomes equally important to study carbon emission in induction furnace steelmaking. The explicit study of carbon emission for induction furnace steelmaking is difficult to find in the literature, hence, the purpose of present work is to develop the data of carbon emission for induction furnace. The data of induction furnace steelmaking is also compared with arc furnace steelmaking. In addition to use of steel scrap, both, EAF and IF use direct reduced iron (DRI) as the basic raw material for steelmaking; but the present study is restricted to the production of steel using steel scrap only.

Basic Data

Carbon dioxide is one of the major ingredients which steel plants emit. In the year 2019 total CO2 emission by steel industry was about 3.7 Gt across the world [5]. The data were further divided to CO2 generation by BF-BOF route and EAF route, which was about 3.16 Gt and 0.51 Gt, respectively. Carbon dioxide emission for BF-BOF and EAF route have been discussed in various literatures [6-12]. A large variation was observed in the data. This variation may be attributed to different measuring techniques, calculation algorithms, size ranges of various furnaces, quality of various raw materials, variation in the chemical composition of various raw materials used in steel making, etc. Moreover, efficiency of the furnace is also one of the important parameters. Over the years operating efficiencies of the furnaces have been improved due to technological innovations, which may also lead to variation in the CO2 generation per ton of the steel produced. From these literatures illustrative number for CO2 emission may be considered as 2000-2500 kg / T of steel produced for BF-BOF route; and 60-100 kg/T of steel produced for EAF steelmaking route. The values are depicted in (Table 1).

| BF – BOF steelmaking | EAF steelmaking |

|---|---|

| CO2 kg/T liquid steel | CO2 kg/T liquid steel |

| 2000-2500 | 60-100 |

Table 1: Table 1 CO2 emission in BF-BOF route and EAF route of steelmaking.

It can be observed that CO2 generation in BF-BOF route is much higher compared to EAF route. The obvious reason for the vast difference is attributed to large amount of carbon combustion, mainly, in blast furnace and basic oxygen furnace. The process involves ironmaking prior to steelmaking. Where as in EAF, steel scrap is the major input raw material. The steelmaking involves melting of scrap as well as carbon combustion.

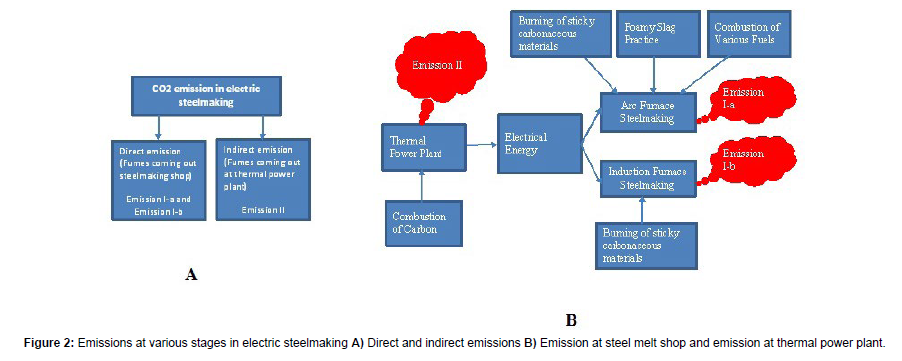

Electric Furnace Steelmaking and Emissions

In electric steelmaking, the main raw material is steel scrap and the main source of heating is electrical energy. Various emissions taking place at electric steelmaking have been depicted in Figure 2. In electric steelmaking two types of emissions have been observed [12] 1. Direct emission 2. Indirect emission. The emissions are depicted in Figure 2A. The emission taking place at steel melt shop during steelmaking is considered as direct emission. The electricity used by electric furnaces is generated at thermal power plants by combustion of carbon; hence, the emission at power plant is termed as indirect emission. Figure 2B depicts direct emission as Emission I-a and Emission I-b for electric arc furnace and electric induction furnace, respectively. Indirect emission is shown as Emission II. For electric furnaces, the scrap may be sourced from automobile waste, various machine parts, refinery scrap, mining industry scrap, etc. Some amount of oil, grease or sticky carbonaceous materials are attached to the surface of these scraps. At the time of melting, these carbonaceous materials get burned and produce fumes which mainly contain carbon dioxide. These fumes are processed, the dust is removed, cleaned and emitted into the atmosphere. This type of CO2 emission is common for both electric arc furnace and electric induction furnace.

At arc furnace steel melt shop, in addition to electrical energy, the furnace also uses chemical energy for steelmaking. Chemical energy is obtained by combustion of various carbon bearing fuels. The fuels can be in the form of liquid, gas or solid. Combustion of these fuels generate CO2. In arc furnace, chemical energy is mainly used to reduce electricity consumption. As depicted in Figure 2B, two types of chemical energies are used in arc furnace, 1. Foamy slag practice and 2. Combustion of fuels. In foamy slag practice solid carbon is combusted along with oxygen. Additionally, solid/liquid fuels are also combusted as a supplement of heat source. The ratio of electrical energy to chemical energy in the operation of EAF is also decided by demand and supply chain of these fuels and economics of steelmaking. Thus, emission at arc furnace steel melt shop is attributed to electrical and chemical energies. The emission is denoted by Emission I-a in Figure 2B.

Electric Furnace Steelmaking and Emissions

Induction furnace steelmaking is another type of electric route of steelmaking. The operation is quite different than electric arc furnace. Unlike arc furnace, no chemical energy is used for induction steelmaking. The fume generation at furnace is only due to burning of sticky carbonaceous materials attached to steel scrap as explained earlier. Hence, direct CO2 emission in induction furnace steelmaking is very less compared to arc furnace steel melt shop. The same is presented as Emission I-b Figure 2B.

Induction Furnace Steelmaking, Carbon Flow and Co2 Emission

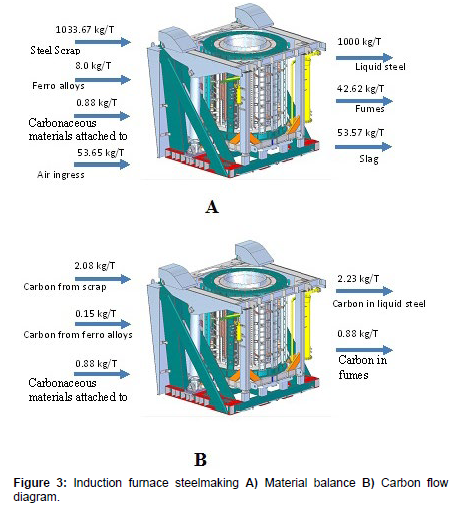

One of the ways to understand CO2 emission for steelmaking is to study the carbon flow diagram using material flow analysis. Material flow analysis is an organised representation of the flow of the quantities of various materials within a system. The outcome can be measured by connecting the sources and flow patterns with various transitional and final products. It is one type of depiction of law of conservation of mass. Figure 3 depicts material balance and carbon balance diagram of induction furnace steelmaking. Figure 3A presents material balance of induction furnace steelmaking for the production of 1 ton of liquid steel. Steel scrap and ferro alloys are the main input materials for induction furnace, while liquid steel, fumes and slag are output. Scrap also brings in some carbonaceous materials in the systems that are stuck to it. As the furnace is open from the top, the scrap is always in the contact with ambient air. The oxygen of air oxidizes the scrap which forms slag. It is important to note that slag is a mixture of oxides, even though there is no oxide in the input raw materials. At the same time sticky or oily carbonaceous materials get burnt by the atmospheric oxygen to form carbon dioxide. The balance nitrogen of the air goes out of the system as flue gas. Therefore flue gas mainly contains carbon dioxide and nitrogen. Thus, even though air is not charged along with input raw materials, it plays a role in slag formation and in flue gas formation. The same concept of ingress of air is also considered during the calculation of material balance in electric arc furnace [13]. Based on the above phenomena calculation of material balance is carried out in induction furnace which is depicted in Figure 3A. Considering the weight of liquid metal and slag formation, The calculation of yield of steel scrap is carried out. The amount of ingress air is calculated based on oxide formation i.e. slag and flue gas generation. The air is basically calculated stoichiometrically in the material balance.

Material balance calculation is the key factor for carbon balance; hence, it is very important to carryout material balance prior to carbon balance. Figure 3B depicts carbon balance in induction furnace. Left hand side in the Figure 3B depicts the sources of input carbon. These sources are carbon from steel scrap and carbon from ferro alloys. In addition to that whenever scrap is added into the furnace for steelmaking it also brings in some carbonaceous material into the system. As the scrap is sourced from various chemical industries, automobile industries, mining plants, etc. It is very common that carbonaceous materials are attached to it. These materials could be oil, grease or some hydrocarbons. Such materials become input source of carbon in the induction furnace. Throughout melting of the scrap, the sticky oily or carbonaceous materials get combusted and form fumes. This is the only source of flue gas generation in the induction furnace. The carbon present within the steel scrap or ferro alloy as chemical composition contributes to the carbon content of steel that is produced. The right hand side depicts the output carbon as carbon content in steel and carbon present in the flue gas. Slag is a mixture of oxides and does not contain any carbon. The numbers are presented per 1000 kg of steel production where 0.88 kg carbon is responsible for CO2 generation in the furnace, which is 3.2 kg/T steel. Depending on the scrap yield, the slag weight and flue gas generation vary. Depending on sticky carbonaceous materials attached to the scrap, CO2 emission is estimated to be 3-5 kg CO2 per ton of steel produced. Accordingly, the values of CO2 emission for all the steelmaking routes can be rewritten as depicted in Table 2.

| BF – BOF steelmaking | EAF steelmaking | Induction furnace steelmaking |

|---|---|---|

| CO2 kg/T liquid steel | CO2 kg/T liquid steel | CO2 kg/T liquid steel |

| 2000-2500 | 60-100 | 3-5 |

Table 2: Comparison of CO2 emission per ton of steel produced for various routes.

For electric furnaces, electricity is generated at thermal power plants by the combustion of fossil carbon which Emit CO2. Modern EAFs consume about 380-600 kWh/t electrical units [14-16], while induction furnace consumes about 500-530 kWh/t on liquid steel production [17] using scrap. It is important to consider auxiliary loads for both EAF and IF. The major components for auxiliary load are air pollution control system, water cooling pump house, overhead cranes and continuous casting machines. Considering foamy slag practice and deliberate combustion of fuel for chemical energy, EAF pollution control system is heavier compared to induction furnace. The plant data suggests, EAF consumes about 80 kWh/t as an auxiliary load while IF consumes about 40 kWh/t. Thus, for EAF plants total electricity consumption is about 460 kWh/t, while for IF plants electricity consumption is about 550 kWh/t. the same is presented in Table 3. As discussed previously, electricity is generated in thermal power plants which emits carbon dioxide for the generation of electricity. Generation of carbon dioxide for the generation of one electrical unit is different for different countries [18]. In the present studies, average value of 0.8 kg CO2 for the production of 1 kWh of electrical unit is considered. With these numbers, CO2 generation for EAF and IF can be calculated as depicted in Table 3. Table 3 compares CO2 generation in arc furnace and induction furnace. For both the steelmaking processes total electrical units have been calculated and converted them to CO2 emission which indirect emission. Another CO2 emission is at SMS which is direct emission. Total of direct and indirect CO2 emission also calculated and depicted in Table 3.

| EAF steelmaking | |

|---|---|

| Electrical unit consumption for melting 100% scrap | : 380 kWh/t |

| Auxiliary units | : 80 kWh/t |

| Total electrical units | : 460 kWh/t |

| CO2 generated for the production of 1 electrical unit | : 0.8 kg CO2/kWh |

| CO2 generation due to electricity | : 368 kg CO2/t |

| CO2 emission at EAF steel melt shop due to chemical energy | : 100 kgCO2/t |

| Total CO2 emission by EAF steelmaking | : 468 kg CO2/t |

| IF steelmaking | |

| Electrical unit consumption for melting 100% scrap | : 510kWh/t |

| Auxiliary units | : 40 kWh/t |

| Total electrical units | : 550 kWh/t |

| CO2 generated for the production of 1 electrical unit | : 0.8 kg CO2/kWh |

| CO2 generation due to electricity | : 440 kg CO2/t |

| CO2 emission at IF steel melt shop due to burning of sticky oily materials | : 3 kgCO2/t |

| Total CO2 emission by IF steelmaking | : 443 kg CO2/t |

| EAF steelmaking |

Table 3: Direct and indirect CO2 emission in electric steelmaking.

Conclusion

Electric steelmaking is one of the very important routes of steelmaking across the world. All the operating parameters such as energy requirement, material balance, CO2 emissions, etc. have to be calculated separately for EAF and IF. EAF uses both, chemical energy and electrical energy for steelmaking; while IF uses only electrical energy. Considering operating practices, direct emission i.e. CO2 emission at melt shop for induction furnace is much less compared to arc furnace. Carbon emission for each route is normally studied by The carbon flow diagram. For induction furnace steelmaking, carbon flow has been presented for the first time. It has been observed that direct CO2 emission in induction furnace steelmaking is mainly because of the burning of sticky carbonaceous materials attached to the scrap. Carbon dioxide emission for IF steelmaking varies from 3-5 kg CO2/T of steel; while for arc furnace direct CO2 emission is about 60-100 kg CO2/T. For both the electric furnaces direct and indirect emissions have been defined and calculated in the present studies. Although present work considers use of steel scrap as the main input raw material, it is equally important to study carbon emission when directly reduced iron is used in electric furnaces. The scope of study of DRI melting in induction furnace concerning to carbon emission has been reserved for the future studies.

Conflict Of Interest

The author declares that he has no conflicts of interest.

References

- Ritche H, Rosor M, Rosado P (2020) CO2 and greenhouse gas emissions”, Our world in data

- Edenhofer O, Pichs-Madruga R, Sokona Y (2014) Climate change 2014: Mitigation of Climate Change”, Working group III Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA

- December 2023 crude steel production and 2023 global crude steel production totals, World Steel Association, (2023)

- Ministry of Steel, Government of India, Annual Report, 2022-23

- Swalec C (2021) The iron and steel industry is responsible for 11% of global carbon dioxide (CO2) emissions and will need to change rapidly to align with the world’s climate goals,

- Yinjiao L, Wenqing X, Tingyu Z, Feng Q, Tiebing X, et al. (2012) CO2 emissions from BF-BOF and EAF steelmaking based on material flow analysis, Adv Mater Res 518-523.

- Hasanbeigi A, Carlos J, Cardenas R, Price L, Triolo R, et al. (2015), Comparison of Energy-Related Carbon Dioxide Emissions Intensity of the International Iron and Steel Industry: Case Studies from China, Germany, Mexico, and the United States. LBNL-1004069

- Price L, Phylipsen D, Worrell E (2001) Energy Use and Carbon Dioxide Emissions in the Steel Sector in Key Developing Countries, Energy Analysis Department, Environmental Energy Technologies Division, LBNL-46987.

- Huachun H, Hongjun G, Xiang Z, Haiyu L (2017) Assessment on the energy flow and carbon emissions of integrated steelmaking plants. Ener Rep 3: 29–36.

- Echterhof T, (2021), Review on the Use of Alternative Carbon Sources in EAF Steelmaking, Metals 11: 222

- Sakamoto Y, Tonooka Y (2000) Estimation of CO2 emission for each process in the Japanese steel industry: a process analysis, Int J Energy Res 24: 625-632.

- Demus T, Reichel T, Echterhof T, Pfeifer H (2014) Biochar usage in EAF steelmaking potential and feasibility, in Conference: 1st ESTAD & 31st JSI 7-8 April.

- Hay T, Visuri V, Aula M, Etcherhof T (2021) A Review of Mathematical Process Models for the Electric Arc Furnace Process, Steel Res Int 92: 2000395.

- Carlsson L, Peter B, Samuelsson P, Jönsson P (2019) Predicting the Electrical Energy Consumption of Electric Arc Furnaces Using Statistical Modeling. Metals 9: 959.

- Kirchen M, Badr K, Pfeifer H Influence of direct reduced iron on the energy balance of the electric arc furnace in steel industry. Energy 36: 6145-6155.

- Shanmugam S, Viswanathan N, Manjini S, Chandra S, Holappa L (2021) Challenges and Outlines of Steelmaking toward the Year 2030 and Beyond Indian Perspective, Metals 11: 1654.

- Bedarkar S, Dalal N (2020), Energy balance in induction furnace and arc furnace steelmaking, International Journal of Energy Research 10: 57–61.

- Ministry of Power (2018) CO2 Baseline Database for the Indian Power Sector, Government of India, CEA

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Swaren SB (2024) Carbon Flow and CO2 Emission in Induction Furnace Steelmaking. J Powder Metall Min 13: 434.

Copyright: © 2024 Swaren SB. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 234

- [From(publication date): 0-2024 - Feb 04, 2025]

- Breakdown by view type

- HTML page views: 181

- PDF downloads: 53