Research Article Open Access

Calculation and Assessing the EEDI Index in the Field of Ship Energy Efficiency for M/V Jules Garnier

Tien Anh Tran*

School of Energy and Power Engineering, Wuhan University of Technology, Vietnam Maritime University, 484 Lach Tray, Ngo Quyen, Hai Phong, Vietnam

- *Corresponding Author:

- Tien Anh Tran

PhD Researcher, Lecturer

School of Energy and Power Engineering

Wuhan University of Technology

Vietnam Maritime University, 484 Lach Tray, Ngo Quyen

Hai Phong, Vietnam

Tel: +8613986027618

E-mail: trantienanhvimaru@gmail.com

Received date: September 14, 2016; Accepted date: October 17, 2016; Published date: October 26, 2016

Citation: Tran TA (2016) Calculation and Assessing the EEDI Index in the Field of Ship Energy Efficiency for M/V Jules Garnier. J Marine Sci Res Dev 6: 212. doi: 10.4172/2155-9910.1000212

Copyright: © 2016 Tran TA. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Marine Science: Research & Development

Abstract

The “International Convention for the Prevention of Pollution from Ships (MARPOL 73/78)” keeps the important role in controlling the harmful gasses emissions to the environment from navigation activities. It was adopted in July 2011 and added a new Chapter 4 with Regulations on Energy Efficiency for ships to MARPOL Annex VI through the “Energy Efficiency Design Index (EEDI) for new ships”, and “the Ship EnergyEfficiency Management Plan (SEEMP) for all ships”. On the other hand, Annex VI (MARPOL 73/78) also added the new definitions and the requirements for survey and validated of the formats for “the International Energy Efficiency (IEE) Certificate”. Furthermore, the role of new ships energy efficiency managements is very significant so contributing to the later ships operation through EEDI index. In this aim, the articles has presented the definitions, regulations following MARPOL Convention as well as calculate the EEDI index and assess this working of energy efficiency managements for new ship M/V Jules garnier.

Keywords

Energy efficiency; EEDI; MARPOL convention; SEEMP

Introduction

Nowadays, the environmental pollution is the big problem that affects harmfully to the life environment and humans in the earth. The effects have been causing like as acid rain and global warming.

In the field of shipping transportation, IMO “International Maritime Organization” has a mandatory of ensuring the green shipping with reducing fuel consumption on ships and greenhouse gas (GHG) emission, under Annex VI of the harmful gas pollution prevention in “International Convention for the Prevention of Pollution from Ships (MARPOL 73/78)”.

According to the “International Maritime Organization’s (IMO)” (2010), second greenhouse gas (GHG) study, shipping emitted 1046 million tonnes of CO2 in 2007; about 3.3% of global emissions. For many existing ships, reducing fuel consumption to reduce these types of emissions involves applying operational measures rather than adopting an alternative technology because of the long payback periods associated with new investment [1].

MEPC 67 (Marine Environmental Protection Committee) approved the Regulations of IMO in 2014, providing the updated emission estimated for greenhouse gasses from ships. Following of the statistics source of CO2 gas emission in the international shipping, there are about 796 million tonnes of CO2 gas emission in 2012, 2.2% of the total global CO2 emissions for that year. In contrast, this figure has been declining slightly. In 2007 before, the international shipping was given out approximately 885 million tonnes of CO2, the proportion of 2.8% of the total CO2 emissions for that year [1-5].

The “International Convention for the Prevention of Pollution from Ships”, MARPOL 73/78 gradually applies effectively from then Annex VI with a new Chapter 4 concerns about the ship energy efficiency management for all types of ship includes Bulk Carrier, Gas Carrier, Tanker, Container ship, General Cargo ship, Refrigerated Cargo Carrier, Ro-Ro cargo ship, etc. by providing with the energy efficiency measures: EEDI for new ships and SEEMP for all ships 400 gross tonnages and above.

It is cleared that the calculation and assessment of the ship energy efficiency management play an important role following the MARPOL Convention Annex VI, especially this working is applied to new ships with over 400 gross tonnages. The certain calculation objective is on Bulk Carrier with ship name M/V Jules garnier due to NAIKAI ZOSEN CORPORATION Design department machinery design section, Hiroshima, Japan.

This article is divided into these sections: Section 1, Introduction; Section 2, Enhancement of Ship Energy Efficiency Regulations; Section 3, Sea trial experimental data on M/V Jules garnier; Section 4, Results and section 5, Conclusion.

Enhancement of Ship Energy Efficiency Regulations

EEDI

Concept and formula: “EEDI – The Energy Efficiency Design Index” is an energy efficiency measure tool that applies in the field of shipping transportation with the aim of measuring and evaluating of CO2 gas emission reduction from operation activities on ships such as equipment, engines, and humans. Aslo, it is an index to assess the effectively equipment using through its value calculation.

On the other hand, International Maritime Organization has also established a series of regulations about managing of ship energy efficiency through EEDI for new ships design, “EEOI (Energy Efficiency Operational Indicator)” for the existing ships operate, and “SEEMP (Ship Energy Efficiency Management Plan)” for all ship with 400 gross tonnages above.

However, the earth’s climate changes rapidly from the development of industries on shore and at sea. CO2 emission control is to be tightened every five years through the MARPOL Regulations in Annex VI, Chapter 4. In the future, EEDI will be expected with the innovation and development of all the components in the field of ship energy efficiency.

An amount of CO2 gas emission per ship’s capacity mile needs as small as possible. It leads to the EEDI declining to the significant value, so creating more energy efficient ships [1-5].

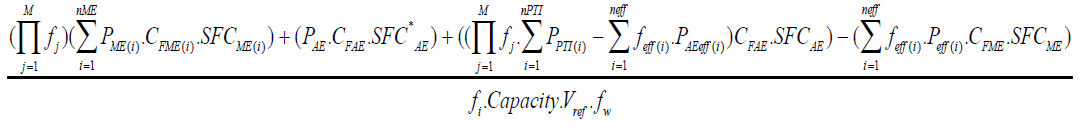

The general formula for EEDI calculation is indicated below:

EEDI=CO2 Emissions/Transport Work (1)

Broadly then, EEDI is mainly an amount of CO2 gas emissions from new ships divided by its cargo capacity carrying.

Formula 1 can be expressed following that:

EDDI=Engine Power.SFC.CF/dwt. Speed (g CO2/ton-mile) (2)

In where: SFC – Specific fuel consumption (g/kWh), represents an amount of fuel used for engines in an hour. The measured value is recorded in NOx Technical file, it is a part of NOx certification;

CF - Carbon factor, It is an amount of CO2 generated per mass of fuel burned. The type of fuel used is corresponding to the NOx Certification (NOx Technical file) and determines the value of the CF conversion factor. Table 1 shows the diversity of fuels corresponding to the difference CF (t-CO2/t-Fuel);

| Type of fuel | Reference | Carbon Content | CF (t-CO2/t-Fuel) |

|---|---|---|---|

| Diesel/Gasoil | ISO 8217 Grades DMX through DMB | 0.8744 | 3.206 |

| Light Fuel Oil (LFO) | ISO 8217 Grades RMA through RMD | 0.8594 | 3.151 |

| Heavy Fuel Oil (HFO) | ISO 8217 Grades RME through RMK | 0.8493 | 3.114 |

| Liquefied Petroleum Gas (LPG) | Propane | 0.8182 | 3.000 |

| Butane | 0.8264 | 3.030 | |

| Liquefied Natural Gas (LNG) | 0.7500 | 2.750 | |

| Methanol | 0.3750 | 1.375 | |

| Ethanol | 0.5217 | 1.913 |

Table 1: The CF (t-CO2/t-Fuel) certain value at each type of fuels.

DWT – Dead Weight Tonnage, It is a capacity of vessel that carries full load, Following EEDI formula, with respect of 100% DWT for all ships but container ship is 70% DWT (Table 1).

Note: Reprinted from Module 2 - Ship Energy Efficiency Regulations and Related Guidelines, IMO, retrieved

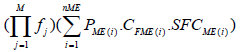

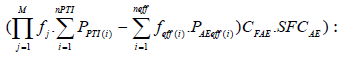

The formula (3) is described and divided into parts separately for the (1), in detail:

: Main Engines Emissions

: Main Engines Emissions

): Auxiliary Engines Emissions

): Auxiliary Engines Emissions

:Shaft Generators/ Motors Emissions

:Shaft Generators/ Motors Emissions

fi Capacity .Vref fw: Efficiency Technologies

fi Capacity .Vref fw:Transport work

EEDI = (CO2 from Propulsion system + CO2 from Auxiliary – CO2 emission reduction)/ DWT. Speed

In where:

PME: Main Engine Power (kW);

PAE: Auxiliary Engine Power (kW);

SFC: Specific fuel consumption (g/kW);

C: Fuel to CO2 factor (g CO2/ g Fuel) (nearly 3);

Capacity: for Cargo ships DWT, for Passenger ships GT;

Vref: Reference speed (nm/hour);

fi: Correction factor for capacity;

fw: Correction factor for performance in real weather;

fi: Correction factor for efficiency.

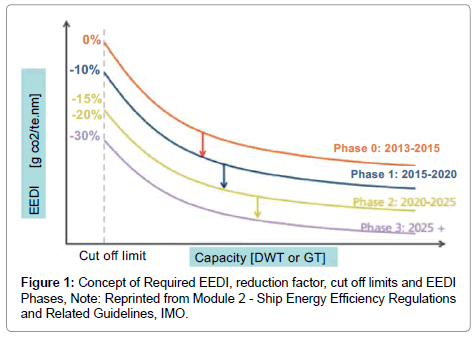

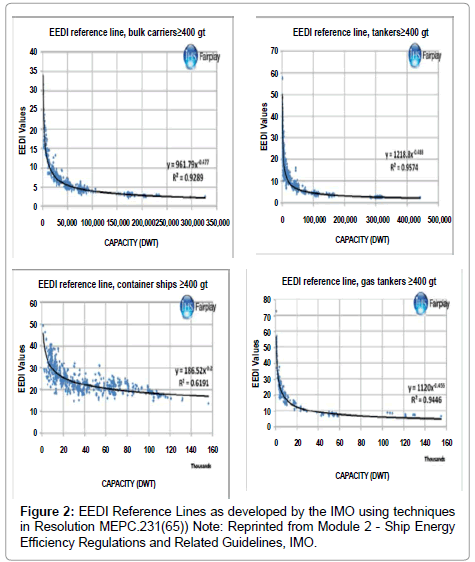

i. EEDI reference line: “The EEDI Reference line (EEDI Baseline) for each type of ship is defined as a curve representing an average index value fitted on a set of individual index values for a defined group of ships”. Its curve is described in Figures 1 and 2.

Each Reference EEDI line was drawn by collecting the different sources of data, data quality checks, a number and type of ships selected, year of ship built, etc. All of them are described in relevant IMO Guidelines (Resolution MEPC.231(65) and MEPC.233(65)). In then, Reference EEDI formula is detail described below:

Reference EEDI = a*b-c (4)

Where: a, b and c are constant determined from the Table 2.

| Ship type defined in Regulation 2 | a | b | c |

|---|---|---|---|

| Bulk Carrier | 961.79 | DWT | 0.477 |

| Gas Carrier | 1120.00 | DWT | 0.456 |

| Tanker | 1218.80 | DWT | 0.488 |

| Container ship | 174.22 | DWT | 0.201 |

| General cargo ship | 107.48 | DWT | 0.216 |

| Refrigerated cargo carrier | 227.01 | DWT | 0.244 |

| Combination carrier | 1219.00 | DWT | 0.488 |

| Ro-Ro cargo ship (vehicle carrier) | (DWT/GT)-0.7x780.36 where DWT/GT <0.3 | DWT | 0.471 |

| 1812.63 where DWT/GT³0.3 | |||

| Ro-Ro cargo ship | 1405.15 | DWT | 0.498 |

| Ro-Ro passenger ship | 752.16 | DWT | 0.381 |

| LNG carrier | 2253.7 | DWT | 0.474 |

| Cruise passenger ship having non-conventional propulsion | 170.84 | DWT | 0.214 |

Table 2: Parameters for determination of EEDI Reference value [Resolutions MEPC.203(62) and MEPC. 251(66)].

ii. EEDI reduction factor (X): It presents the percentage of EEDI reduction relative to EEDI baseline. The value of “reduction factor” is decided by International Maritime Organization (IMO). Its certain value is indicated in Table 3.

| Ship Type | Size | Phase 0 | Phase 1 | Phase 2 | Phase 3 |

|---|---|---|---|---|---|

| 1Jan 2013- 31 Dec 2014 | 1 Jan 2015 – 31 Dec 2019 | 1 Jan 2020 – 31 Dec 2024 | 1 Jan 2025 and onwards | ||

| Bulk carrier | 20,000 DWT and above | 0 | 10 | 20 | 30 |

| 10,000 DWT and above | n/a | 0-10* | 0-20* | 0-30* | |

| Gas carrier | 10,000 DWT and above | 0 | 10 | 20 | 30 |

| 2,000-10,000DWT | n/a | 0-10* | 0-20* | 0-30* | |

| Tanker | 20,000 DWT and above | 0 | 10 | 20 | 30 |

| 4,000 – 20,000 DWT | n/a | 0-10* | 0-20* | 0-30* | |

| Container ship | 15,000 DWT and above | 0 | 10 | 20 | 30 |

| 10,000 – 15,000 DWT | n/a | 0-10* | 0-20* | 0-30* | |

| General Cargo ships | 15,000 DWT and above | 0 | 10 | 15 | 30 |

| 3,000-15,000DWT | n/a | 0-10* | 0-15* | 0-30* | |

| Refrigerated cargo carrier | 5,000 DWT and above | 0 | 10 | 15 | 30 |

| 3,000-5,000 DWT | n/a | 0-10* | 0-15* | 0-30* | |

| Combination carrier | 20,000 DWT and above | 0 | 10 | 20 | 30 |

| 4,000-20,000DWT | n/a | 0-10* | 0-20* | 0-30* | |

| LNG carrier*** | 10,000 DWT and above | n/a | 10** | 20 | 30 |

| Ro-Ro cargo ship (vehicle carrier)*** | 10,000 DWT and above | n/a | 5** | 15 | 30 |

| Ro-Ro cargo ship*** | 2,000 DWT and above | n/a | 5** | 20 | 30 |

| 1,000-2,000 DWT | n/a | 0-5*, ** | 0-20* | 0-30* | |

| Ro-Ro passenger ship*** | 1000 DWT and above | n/a | 5** | 20 | 30 |

| 250-1,000 DWT | n/a | 0-5*, ** | 0-20* | 0-30* | |

| Cruise passenger ship*** having non-conventional propulsion | 85,000 GT and above | n/a | 5** | 20 | 30 |

| 25,000-85,000 GT | n/a | 0-5*, ** | 0-20* | 0-30* |

Table 3: EEDI reduction factors, cut off limits and implementation phases [Resolutions MEPC.203(62) and MEPC.251(66)].Note: Reprinted from Module 2 – Ship Energy Efficiency Regulations and Related Guidelines, IMO.

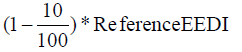

iii. Required EEDI calculation formula: The Required EEDI is identified base on the reduction factor X for the ship that depends on year of ship built (Table 3) and value of Reference EEDI in formula (4). So, the relationship between these parameters will determine the Required EEDI value through formula (5):

Required EEDI = (1-X/100)* (Reference EEDI) (5)

In where:

X: Reduction rate;

Required EEDI: The EEDI limit value for each ship, in fact the Attained EEDI must be smaller than Required EEDI.

Attained EEDI ≤ Required EEDI

In where:

Attained EEDI, This value is determined by calculation and then ship has just newly built. Moreover, the Regulations also added for the Required EEDI following:

• “If the design of a ship allows it to fall into more than one of the above ship type definitions, the required EEDI for the ship shall be the most stringent (the lowest) required EEDI”.

• “For each ship to which this regulation applies, the installed propulsion power shall not be less than the propulsion power needed to maintain the maneuverability of the ship under adverse conditions as defined in the guidelines to be developed by the Organization”.

• “At the beginning of Phase 1 and at the midpoint of Phase 2, the IMO shall review the status of technological developments and, if proven necessary, amend the time periods, the EEDI reference line parameters for relevant ship types and reduction rates set out in this regulation” [6,7].

a. SEEMP: “SEEMP - The Ship Energy Efficiency Management Plan” is given out by IMO in aims with energy efficiency management for all ships 400 gross tonnages above. Its function is absolutely useful for assessing and improving the existing ships that is operating on international shipping. After finishing the Kyoto conference in 1997, “SEEMP” and “EEOI” are standard component for managing the ships on the international routes that observe the Regulations related to the environmental protection.

Moreover, “The Marine Environment Protection Committee” was held on March, February, 2012, adopted the guidelines in aims with implemetation for “the Energy Efficiency Design Index – EEDI” and “ the Ship Energy Efficiency Management Plan - SEEMP” component.

The guidelines are adopted the following as:

• “Guidelines for the calculation of the Attained EEDI for new ships”

• “Guidelines for the development of a Ship Energy Efficiency Management Plan (SEEMP)”

• “Guidelines on survey and certification of the Energy Efficiency Design Index (EEDI)”

• “Guidelines for calculation of reference lines for use with the Energy Efficiency Design Index (EEDI)”

b. Changes to the MARPOl annex VI regulations: In July 2011, IMO has debated for changing the Regulations on ship energy efficiency management. At conference, the delegates have been agreed and decided to the regulations implementation. In particular, the changes were indicated in Table 4.

| Resolution MEPC.176(58) | Resolutions MEPC.203(62)&MEPC251(66),… |

|---|---|

| Chapter I Reg.1 Application Reg.2 Definitions Reg.3 Exceptions and Exemptions Reg.4 Equivalents |

Chapter I Reg.1 Application Reg.2 Definitions Reg.3 Exceptions and Exemptions Reg.4 Equivalents |

| Chapter II Reg.5 Surveys Reg.6 Issue or endorsement of a Certificate Reg.7 Issue of a Certificate by another Party Reg.8 Form of Certificate Reg.9 Duration and Validity of Certificate Reg.10 Port State Control on Operational Requirements Reg.11 Detection of Violations and Enforcements |

Chapter II Reg.5 Surveys Reg.6 Issue or endorsement of a Certificate Reg.7 Issue of a Certificate by another Party Reg.8 Form of Certificate Reg.9 Duration and Validity of Certificate Reg.10 Port State Control on Operational Requirements Reg.11 Detection of Violations and Enforcements |

Table 4: “Summarizes the existing regulations in Chapters 1 and 2 of MARPOL Annex VI and the ones that were changed (in red color) to accommodate the energy efficiency regulations”.

Regulation 2: “The amendments mainly include definitions for “new ship” as applicable to various phases of EEDI regulations, “major conversion” and “ship types” for which EEDI regulations apply”.

Since EEDI only applies to new ships and those ships that undergo major conversions beyond 1 January 2013, the exact definition of the above terms was required. Additionally, terms such as “Attained EEDI” and “Required EEDI” have been defined [3].

Regulation 5: “The requirement for surveys including an initial for newly built ships, a full or partial survey in case of major conversion of existing ships, survey for SEEMP to verify its existence on board ship, etc. are specified in this regulation. This regulation states that EEDI survey and verification shall be carried out according to relevant IMO guidelines”.

Regulations 7 and 8: “The changes to these regulations deal with energy efficiency certification, making it mandatory for ships to have an International Energy Efficiency (IEE) Certificate; also emphasizing the responsibility of flag State Administration”.

“An International Energy Efficiency Certificate for the ship shall be issued after a survey in accordance with the provisions of regulation 5.4 to any ship of 400 gross tonnages and above, before that ship may engage in voyages to ports or offshore terminals under the jurisdiction of other Parties.

The certificate shall be issued or endorsed either by the Administration or any organization duly authorized by it. In every case, the Administration assumes full responsibility for the certificate.” [MEPC Resolution 203(62)]

Regulation 9: “This regulation defines the validity aspects of the IEE certificate. It will be valid for the life of the ship unless otherwise invalidated by a major conversion or change of flag or ship withdrawal for service”.

“The International Energy Efficiency Certificate shall be valid throughout the life of the ship subject to the provisions of paragraph.

An International Energy Efficiency Certificate issued under this Annex shall cease to be valid in any of the following cases if the ship is withdrawn from service or if a new certificate is issued following major conversion of the ship; or upon transfer of the ship to the flag of another State…”[MEPC Resolution 203(62)].

Regulation 10: “This regulation specifies the requirement for Port State Control (PSC) for energy efficiency. Accordingly, the IEE certificate is the starting point for any PSC inspection”.

“In relation to chapter 4, any port State inspection shall be limited to verifying, when appropriate, that there is a valid International Energy Efficiency Certificate on board, in accordance with article 5 of the MARPOL Convention.” [MEPC Resolution 203(62)]

Sea Trial Experimental Data on M/V Jules Garnier

The EEDI Calculation plays a crucial role in assessing the new ship in the greenhouse gas emission (GHG) into the environment. Especially, the IMO Regulations must adopt these Regulations with the aim of Energy Efficiency measures.

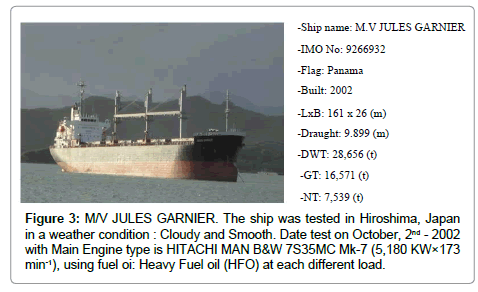

The target ship is chosen for the researching with ship name: M/V Jules garnier, it was built in Naikai Zosen Corporation, Hiroshima, Japan (Figures 3 and 4).

The sea trial parameters have been conducted under the calm weather condition on the open-sea environment in Hiroshima, Japan. In particular, they are indicated in Table 5.

| Load | Measure times | M/E Output (kW) | SFC (g/kW.h) | CF | DWT | Ship Speed (knots) |

|---|---|---|---|---|---|---|

| 1/2 | M-1 | 2,750 | 182.5 | 3.114 | 28, 656 | 12.845 |

| M-2 | 2,720 | 180.6 | 12.589 | |||

| 3/4 | M-3 | 4,170 | 179.2 | 3.114 | 28, 656 | 14.410 |

| M-4 | 4,070 | 179.4 | 13.948 | |||

| C.S.O | M-5 | 4,760 | 177.3 | 3.114 | 28, 656 | 14.846 |

| M-6 | 4,620 | 180.4 | 14.574 | |||

| M.C.O | M-7 | 5,490 | 181.6 | 3.114 | 28, 656 | 15.252 |

| M-8 | 5,430 | 181.8 | 15.386 |

Table 5: The sea trial parameters on M/V JULES GARNIER In where: C.S.O = Continuous Service Output; M.C.O = Maximum Continuous Output.

Calculation of EEDI index on M/V Jules Garnier

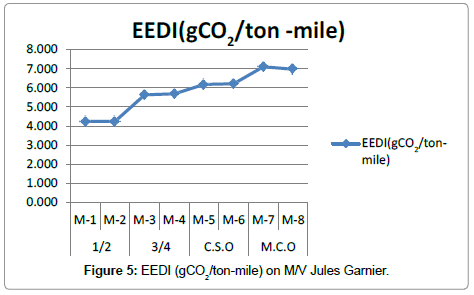

The calculation of EEDI index is very important with aim to assess the CO2 emission from ship to sea environment and energy efficiency measure on ship. This working is carried out following the EEDI index determination (includes on Attained EEDI and Required EEDI) (Figure 5).

a. Calculation of attained EEDI: Each ship has the diversity of EEDI index so to compute the EEDI with the sea trial parameter in Table 5 after new ship building.

Attained EEDI at certain loads is described in Table 6 after applying the above formula (2) with the sea trial parameters on M/V Jules garnier.

| Load | 1/2 | 3/4 | C.S.O | M.C.O | ||||

|---|---|---|---|---|---|---|---|---|

| Measure times | M-1 | M-2 | M-3 | M-4 | M-5 | M-6 | M-7 | M-8 |

| EEDI(gCO2/ton-mile) | 4.246 | 4.240 | 5.635 | 5.689 | 6.177 | 6.214 | 7.103 | 6.972 |

Table 6: EEDI (gCO2/ton-mile) at each different load.

This EEDI (gCO2/ton-mile) is computed with the certain detail parameters in Table 6. On the other hand, this trend describes the variable EEDI at each load presents on Figure 5.

b. Calculation of required EEDI: Each ship has a certain EEDI index, the different types of ship and dead weight will decide the diversity EEDI index, following the above calculation of Attained EEDI at each load, to determine the certain value in Table 6 and the variable trend in Figure 5 on M/V Jules garnier.

Furthermore, the calculation of Required EEDI needs to conduct depend on the 2.1.4 item. However, Required EEDI can obey following the built year of ship, It is very important because of amending the Regulations at International Maritime Organization (IMO), in particular MARPOL Convention, Annex VI, Chapter 4.

Following the Figure 1, Required EEDI is different depend on built year of ship. So, the calculation of Required EEDI index is divided into the Phase:

- Phase 0: (2013-2015)

Required EEDI=Reference EEDI

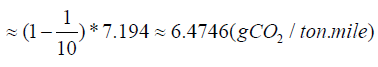

Applying the Formula (4) to compute the Reference EEDI value and Table 2 with parameters for determination of EEDI Reference. It will have a certain value of Reference EEDI, Also it is the value of Required EEDI for phase 0 that applied for ships from 2013 to 2015. The calculated parameters are chosen and applied for Bulk Carrier type (M/V Jules garnier).

RequireEEDI=ReferenceEEDI=a*b–c=961.79*28,656- 0.4777≈7.194(gCO2/ton.mile)--- -- - Phase 1: (2015-2020)

This calculation working is depended on year of ship built. From the beginning of Phase 1 from 2015 to 2020, the Required EEDI value will be supervised strictly following the new changes of IMO Regulations for MEPC (Marine Environment Protection Committee).

Following the above formula 5 to calculate the Required EEDI for ships and also the item 2.13 to determine the EEDI Reduction factor X in Table 3, the Required EEDI value for Bulk Carrier is calculated below under the constant value of the above Reference EEDI:

RequiredEEDI

Results

The calculation of Attained EEDI and Required EEDI is necessary for assessing and operating the most effective. One side, it determines not only a mass of CO2 gas emission to the environment but also the energy efficiency management on ships. Regulations for the prevention of air pollution from ships (MARPOL 73/78) with adding the new Chapter 4, Annex VI makes a mandatory the Energy Efficiency Design Index (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) for all ships.

One another side, The above calculations for Attained EEDI and Required EEDI for M/V Jules garnier that has been built in Hiroshima, Japan indicates that the results for assessing of a mass of CO2 emission following the Regulations are assured inquires: Attained EEDI ≤ Required EEDI at that time of built ship. However, for the present, Attained EEDI gets exceed the limit of EEDI regulation.

One another side, The above calculations for Attained EEDI and Required EEDI for M/V Jules garnier that has been built in Hiroshima, Japan indicates that the results for assessing of a mass of CO2 emission following the Regulations are assured inquires: Attained EEDI ≤ Required EEDI at that time of built ship. However, for the present, Attained EEDI gets exceed the limit of EEDI regulation.

Ship energy efficiency plays a significant role in field of creating the green shipping now-a-days, especially the world is facing the great problems about the climate changes from enhancement of economics and industrials in parallel with the population explosion.

The reduction of CO2 gas emissions also EEDI index is a great issue that needs to solve from ships. In recent years, the marine industry is gradually developed both the quantity and quality by applying the modern science and technology into the field of ship building and operating. Marine Environment Protection Committee (MEPC) is also given the amendment about Regulations with desire of the climate changes reduction.

The calculation and assessment of EEDI index for new ship are necessary working to respond the IMO’s regulations for bulk carrier in general and in particular for M/V Jules Garnier.

Acknowledgement

The author wants to give an acknowledgement to Reliability Engineering Institute, School of Energy and Power Engineering, Wuhan University of Technology, 430063 Wuhan, PR China.

References

- IMO (2010) “Module 2 - Ship Energy Efficiency Regulations and Related Guidelines”, IMO Train the Trainer (TTT) Course on Energy Efficient Ship Operation.

- IMO (2014) “2014 Guidelines on the method of calculation of the Attained Energy Efficiency Design Index (EEDI) for new ships”, MEPC 66/21/Add.1 p: 1.

- IMO (2010) “Preventions of Air Pollution from Ships”, Marine Environment Protection Committee, 59th Session, Agenda item 4.

- FaiC (2011) “IMO Technical Measures in Reducing Greenhouse Gas Emissions from ships: A Lloyd’s Register Perspective”,Lloyd’s Register Approach to IMO Technical Measures in Reducing Greenhouse Gas Emissions from Ships.

- Haakont (2011) “Development of small versus large hydropower in Norway-comparision of environmental impacts”, Energy Procedia 20: 185-199.

- ICCT (2011) “The Energy Efficiency Design Index (EEDI) for New Ships”, Policy Update 15, October 3-2011.

- deLarruceaJR (2012) “Energy Efficiency Design Index (EEDI) Marpol Annex VI: Legal Framework and Regulatory problems”, Technical University of Catalonia (UPC-Barcelona Tech).

Relevant Topics

- Algal Blooms

- Blue Carbon Sequestration

- Brackish Water

- Catfish

- Coral Bleaching

- Coral Reefs

- Deep Sea Fish

- Deep Sea Mining

- Ichthyoplankton

- Mangrove Ecosystem

- Marine Engineering

- Marine Fisheries

- Marine Mammal Research

- Marine Microbiome Analysis

- Marine Pollution

- Marine Reptiles

- Marine Science

- Ocean Currents

- Photoendosymbiosis

- Reef Biology

- Sea Food

- Sea Grass

- Sea Transportation

- Seaweed

Recommended Journals

Article Tools

Article Usage

- Total views: 43112

- [From(publication date):

December-2016 - Jul 18, 2025] - Breakdown by view type

- HTML page views : 41244

- PDF downloads : 1868