Biogas Production from Poultry Faeces

Received: 28-Sep-2018 / Accepted Date: 12-Oct-2018 / Published Date: 16-Oct-2018 DOI: 10.4172/2576-1463.1000220

Abstract

Poultry faeces management is multidimensional, which involves in public health, waste management, utilization of fertilizing value and energy production issues. The paper attempts to depict the poultry faeces management by bioconversion technology. Biogas may be the tool of energy generation in rural/remote areas while appropriate technique of waste management in urban centers of developing countries. Biogas production from poultry faeces can prevent soil, ground water contamination, crop diseases, and public health resulting ameliorate environment. Three cycles of varying dose are conceded for searching optimum generation of biogas with modified Gobar Gas Company (GGC) 2047 model. The result has displayed as cumulative volume of produced gas.

Keywords: Biogas; Poultry faeces; Bioconversion

Introduction

During recent decades, the problem of efficient disposal and management of organic wastes has become more significant as of rapidly increasing population, urbanization and industrialization. Production of large quantities of organic waste all over the world poses major environmental (offensive odors, contamination of ground water and soil) and disposal problems [1]. Therefore, the disposal of different types of wastes has become very crucial issue for maintaining environmental health [2]. In this context, biogas production may be low-cost, viable and rapid technique/option for the efficient management of poultry wastes.

Fresh or semi-dried poultry faeces are allowed in agricultural land as fertilizer in low income areas. This may be contrast to developed areas as poultry droppings are used only after certain interval of discharge as after drying or provision of processing as composting. These scenarios are, however, unaffordable to most of the inhabitants of least developed countries. It is surprising as the absence or insufficiency of adequate poultry faeces management in many villages/towns of least developed countries, particularly in low income areas, increasing on leads to serious public health and environmental hazards. A chicken dropping is highly sensitive to public health, water resources pollution as well as aesthetic value of the acreage. Practically the nutrient available in chicken manure has not being fully utilized, resulting in loss of fertilizing values (such as Nitrogen, Phosphorus, Potassium, etc.). A number of plant pathogenic disease producing agents are also disseminated through untreated chicken manure and the economic losses accruing from these are enormous. Apart from the fact that fresh and semidried chicken droppings applied on the farm as fertilizer is a potential health hazard to grazing animals and leaching effect into the ground and sources of water also poses great threat to humans. Thus, proper management of chicken droppings is essential to utilize the nutrient value, to contribute energy demand and ultimately maintain sanitary condition of the community.

Biogas production has been proved to be a viable technology in the physical and socioeconomic conditions of Nepal [3]. This technology was first introduced in Nepal at St. Xavier’s School, Godawari by late Father BR. Saubolle in 1995. Thereafter, Government of Nepal started biogas programme in 1975. This programme took further momentum in the country from 1992 following the establishment of Biogas Support Programme (BSP) under the assistance of Netherlands Developments Organization. Biogas programme was established under the umbrella of Alternative Energy Promotion Centre (AEPC) of the Ministry of science and Technology in 1996. Biogas established till date have been using only cattle dung, in conjunction with or without human excreta as feedstock for the biogas plants. But little effort has been done so far to operate biogas plants with poultry faeces as an excellent raw material for biogas generation in terms of producing more per unit live weight than any other common animal waste [4]. Generating electricity is a much more efficient use of biogas than using it for gas light. From energy utilization point of view, it is more economical to use biogas to generate electricity for lighting. In this process, the gas consumption is about 0.75 m3 per KW hour with which 25 to 40 watt lamps can be lighted for one hour, whereas the same volume of biogas can serve only seven lamps for one hour [5].

Biogas is a clean burning fuel, generally used for heating and cooking. Biogas generally composes of methane 50% to 70%, carbon dioxide 30% to 40%, hydrogen 5% to 10%, nitrogen 0.3% and hydrogen sulphide in traces [6].

The overall aim of this research is to know the physiochemical parameters pH, temperature, moisture content, volatile solids and total organic carbon of poultry droppings before and after fermentation process. The specific objective is to optimize biogas production from poultry droppings by feeding appropriate dose.

Methodology

Conceptual framework

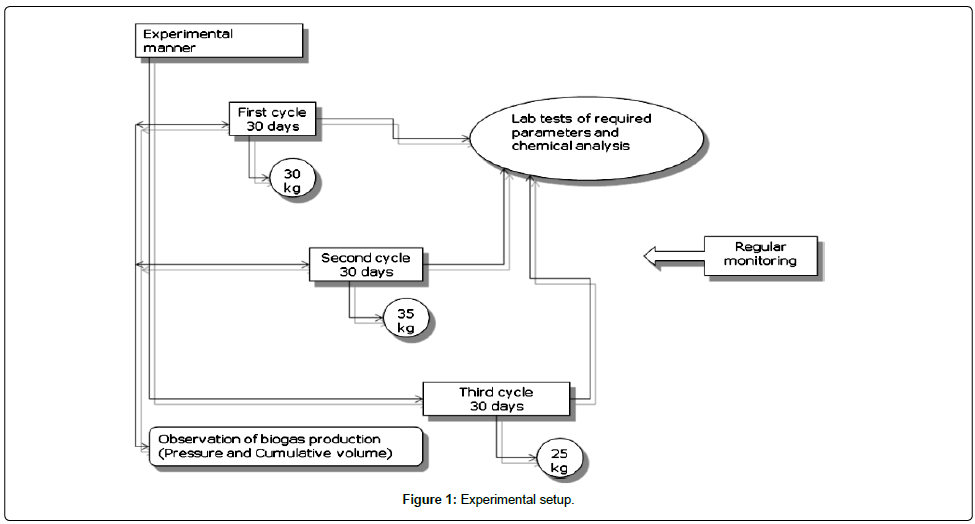

The study has conducted in three cycle includes each time period of thirty days. Quantity of gas production recorded as cumulative volume and all cycles are held continuously as one after another. Only poultry faeces were used as feedstock with a four days feeding frequency. Thirty kilograms feedstock was fed for first cycle (cycle I), Thirty-five kilograms for second (cycle II) and Twenty-five kilograms for third cycle (cycle III) as in batch basis. Before feeding the digester, the chicken droppings were mixed thoroughly with water. For proper solubilization of feedstock, the water solid ratio was about 1:1 on unit volume basis. Daily biogas production and cumulative volume was observed. In addition to this, various parameters as temperature, pH, moisture content, volatile solids and total organic carbon were recorded and analyzed during study. The experimental setup of the study in each of the cycle has shown in Figure 1.

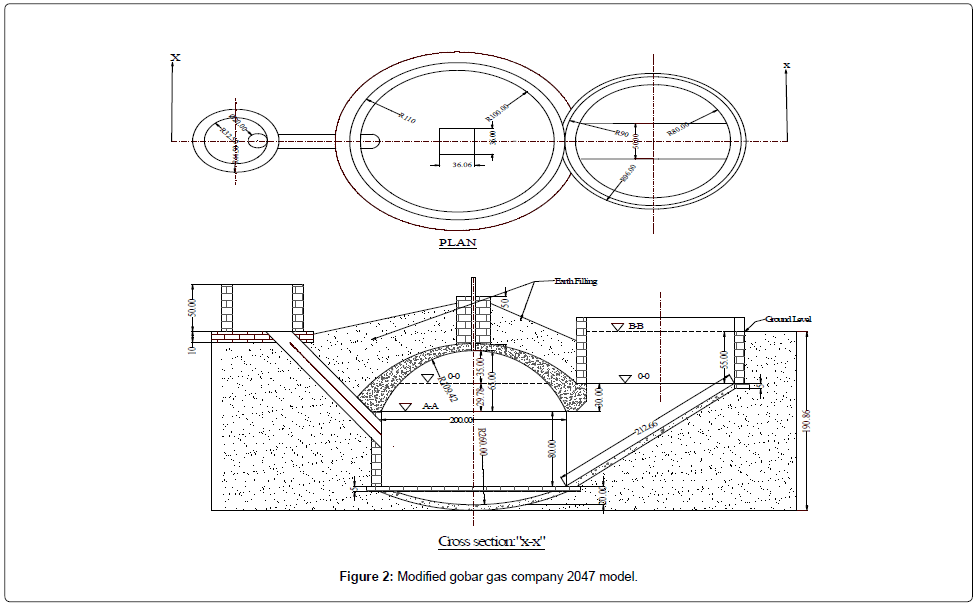

The model used for the study is fix dome bio digester having capacity of 4 m3 modified Gobar Gas Company (GGC) 2047 approved by Biogas Support Program (BSP) Nepal. The plan and section of modified Gobar Gas Company (GGC) 2047 digester (all dimensions are in centimeter) executed the study has shown in Figure 2.

Result and Discussion

The effect and interaction at the time of digestion in each cycle of various parameters as temperature, pH, moisture content, total volatile solids, and total organic carbon of fresh and digested poultry droppings were observed and analyzed. In addition to this, biogas production in cumulative basis has recorded and analyzed.

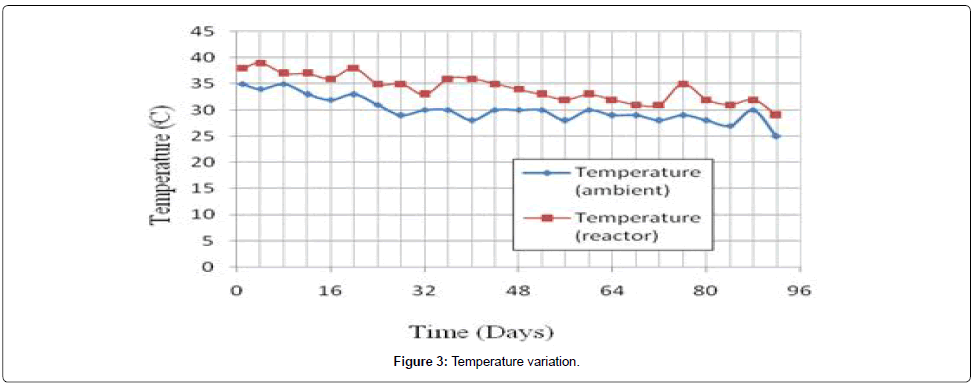

Temperature variation

Bacterial activity mainly depends upon temperature, which is critical factor for methane production. The methanogens are inactive in extreme high and low temperatures. Once metabolism occurs exothermic reaction is helpful for the methane production. Ambient temperature of the dome/digester was observed between 25ºC and 35ºC and inner temperature recorded between 29ºC and 38ºC in all three cycles during the study. Theoretically, heat is induced at the time of fermentation process. Graphical representation of temperature pattern inside/reactor and outside/ambient the digester has shown in Figure 3.

The lower marginal temperature for the methanogenesis is 15ºC. The outside as well as inside temperature of reactor recorded was above 25ºC. Thus, the temperature recorded during study was more than sufficient for the methanogenesis.

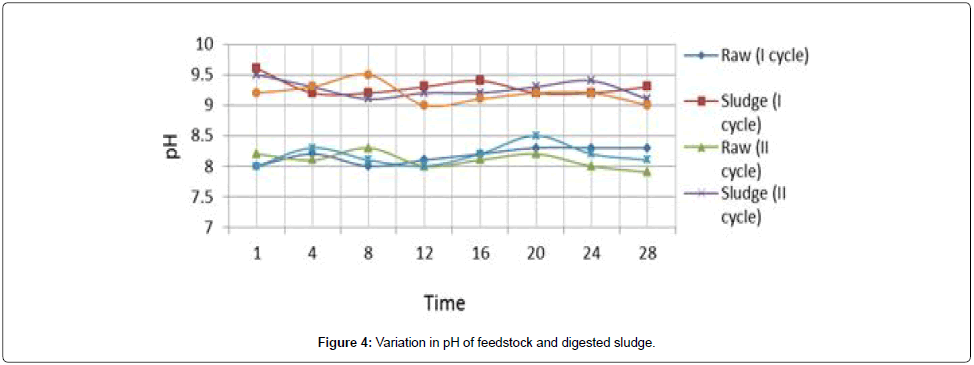

pH variation of feedstock and sludge

The variation in pH of feedstock and digested sludge in all cycles of each sample has shown in the Figure 4. pH in all cycles are in similar trend as slightly higher of digested sludge than feedstock.

Methanogenic bacteria are very sensitive with pH when its value decreases to below 6.5, they do not thrives, results in decrease in digestion/fermentation process. The pH value during the study period obtained was above 6.5. Thus, the methanogensis process has not presumed to be affected.

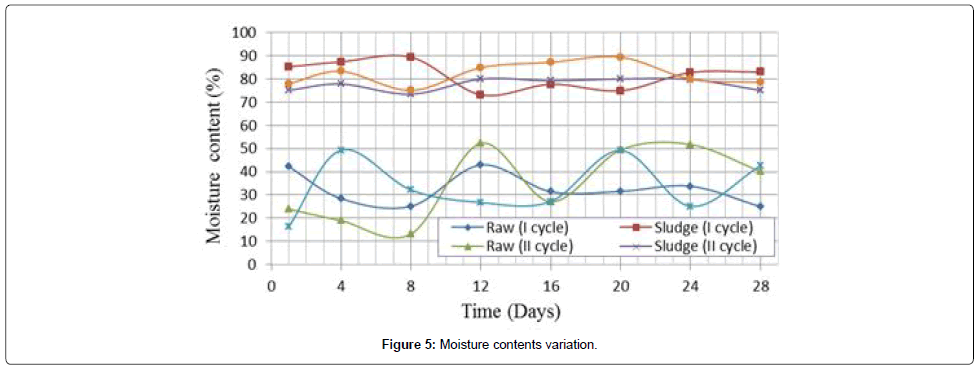

Moisture contents variation

The variation in moisture contents of both feedstock and sludge of all cycles has shown in the Figure 5. The variations of moisture contents in all cycle obtained between 75% to 90% in digested sludge whereas 15% to 50% in feedstock. In all cycles, the results obtained has similar trend, so that, the processes were held continuously and feedstock taken from same poultry farm.

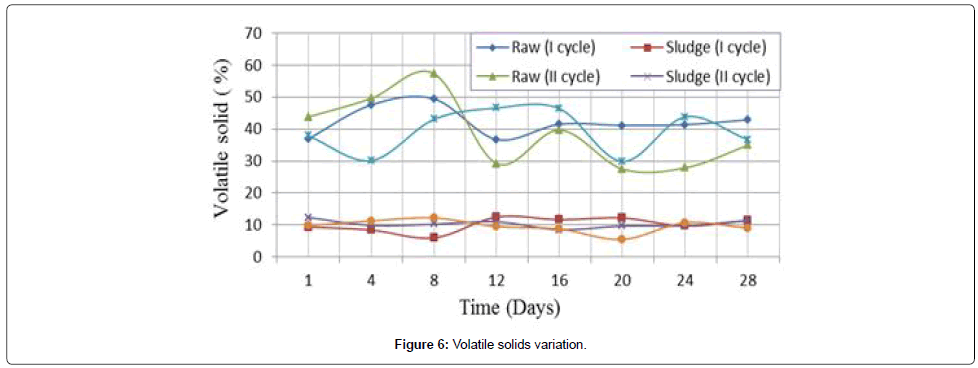

Variation in volatile solids

Contents of volatile solid of 29% to 59% have recorded in feedstock which is reduced to 8% to 12% in digested sludge. The volatile solid contents have significantly destroyed in all cycles. The volatile solids reduction in the fermentation process is due to the utilization by microorganisms for respiration and cell growth. The volatile solids representing the organics were in decreasing trend throughout the study period. This reduction is an indication of stabilization or fermentation. The volatile solids in all the cycles were reduced nearly about in similar trend. The pattern of data obtained during the study of volatile solids in all cycles of each sample has graphically represented in the Figure 6. It represents organic contents was steadily decomposed throughout the experimental period in all cycles.

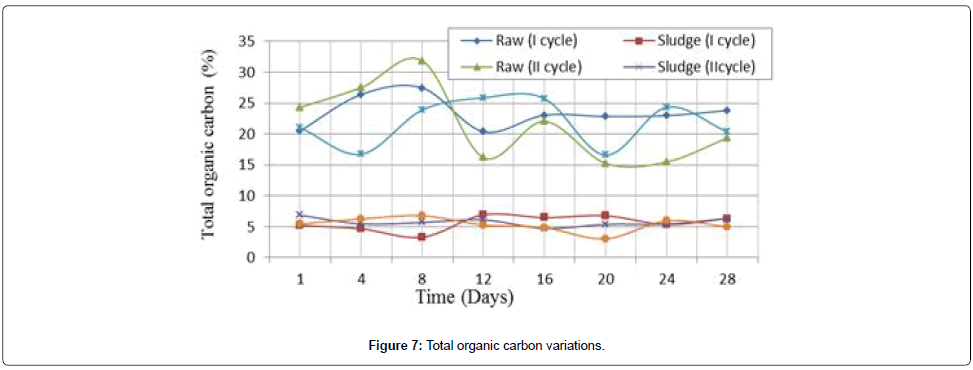

Total organic carbon variations

Total organic carbon is derived from the volatile solids from empirical formula by Gottas as stated by Bhandar [7]. Equation has related by dividing volatile solids by 1.8. The graphical representation of total organic carbon in the different cycles has shown in the Figure 7.

The carbon contents obtained was the range of 15% to 32% in feedstock and have been reduced to the range of 4% to 7% in digested sludge. The reduction in carbon contents is due to the combustion of carbon substances during the respiration, which indicate the active microbial activity in the anaerobic digestion. The carbon content reduction recorded more in third cycle to other two cycles. This presumes a greater mineralization rate in the anaerobic digestion process as of lower feeding rate. It indicates that the third cycle is efficient in the reduction of carbon content.

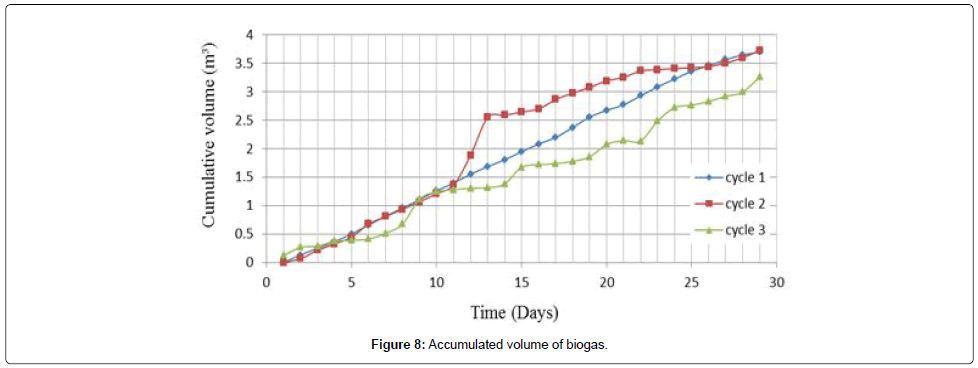

Biogas gas production

The gas production from anaerobic digestion was recorded by the flow meter during the period of study. Rate of biogas production has observed in second cycle is relatively more than rest of other two first and third cycle as of the higher feeding of poultry droppings. In second cycle, it has more volatile solids destruction relative to other two cycles which results of more gas production. The biogas produced in the second cycle has greater volume among three cycles due to more feeding rate. This study shows that biogas production from chicken droppings could be obtained efficiently by feeding around 8.5 kg per day. There was no insufficiency obtained during the study period as energy (gas) consumption for food preparation for 5 people. Gas requirement for cooking is 0.2 to 0.3 m3 per person [8]. From 50 kilograms of poultry waste 3 m3 of biogas per day per plant can be produced [9].

This study shows that digester could be operated by using around 2.5 quintal chicken droppings per month. The produced gas measured by flow meter on the basis of cumulative volume has presented in the Figure 8.

Gas production per kilograms of chicken dung is 0.065 to 0.116 m3 [6]. In the first cycle, dose of 30 kg mass has applied that produce 3.48 m3 gas theoretically and gas produced in the cycle is 3.925 m3. Similarly, second cycle 35 kg mass was fed which produce 4.06 m3 gases theoretically and gas produced in the cycle is 3.721 m3. In the third cycle, 25 kg mass was fed which produce 2.9 m3 gases theoretically and gas produced in the cycle is 3.255 m3 [10-12].

Conclusions

The study has demonstrated that it is feasible to use poultry droppings for production of biogas, and bioconversion is viable, user-friendly and eco-friendly technology for energy production in the scenario of energy crises period. Such a clean energy production technology may be appropriate option to reduce carbon emission resulting environmental impacts as global warming and climate change.

References

- Edwards CA, Bater JE (1992) The use of earthworms in environmental management. Soil Biol Biochem 24: 1683-1689.

- Senapati BK, Julka JM (1993) Selection of suitable vermicomposting species under Indian conditions. Earthworm resources and vermiculture, 113.

- FAO/CMS (1996) Food and Agriculture Organization of the United Nations, Support for Development of National Biogas Program (FAO/TCP/NEP/4451-T), Biogas technology: A training manual for extension, Consolidated Management Services Nepal (P) Ltd.

- Safely LM, Vetter RL, Smith D (1987) Operating a full-scale poultry manure anaerobic digester. Biol Wastes 19: 79-90.

- BRTC (1989) The Biogas Technology in China, Chengdu Biogas Research Institute, Agrictural Publishing House, Chegdu, China.

- Bhandari HS (2004) Survival growth and reproduction of eisenia fetida during degradation of dried human feces.

- Karki AB, Shrestha JN, Bajain S (2005) Biogas, A renewable source of energy in Nepal. Theory and Development, BSP-Nepal.

- Singh R, Karki AB, Shreshta JN (2004) Production of biogas from poultry waste in Kathmandu, MSREE, IOE Pulchowk-Nepal.

- Neupane SK (2015) Poultry faeces management by bioconversion technology with modified GGC 2047 model. J Adv Col Eng Manag 1: 107-117.

- http://www.journeytoforever.org/biofuel_library/MethaneDigesters/MD3.html

Citation: Neupane SK (2018) Biogas Production from Poultry Faeces. Innov Ener Res 7: 220. DOI: 10.4172/2576-1463.1000220

Copyright: © 2018 Neupane SK. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 6372

- [From(publication date): 0-2018 - Mar 29, 2025]

- Breakdown by view type

- HTML page views: 5406

- PDF downloads: 966