ATP Measurement in the Last Rinse Water of Automated Washer-Disinfectors: The Added Value of Every Load Monitoring

Received: 28-Jul-2016 / Accepted Date: 12-Aug-2016 / Published Date: 16-Aug-2016 DOI: 10.4172/2476-213X.1000109

Abstract

Objective: To assess whether monitoring every loads of automated washer-disinfectors (AWDs) by testing the last rinse water with Adenosine Triphosphate (ATP) would have an added value to document effective and reproducible AWD processes.

Methods: Every load monitoring (ELM) of the last rinse water with ATP was performed on three AWDs at the sterilization department of a 329 acute-bed hospital in Italy. No change were made in the routine procedures, except the last rinse water of a process was collected with a water sampler and tested on ATP. Data from negative controls and empty cycles were also obtained for comparison. ATP values were analysed according to AWD, load, and process characteristics.

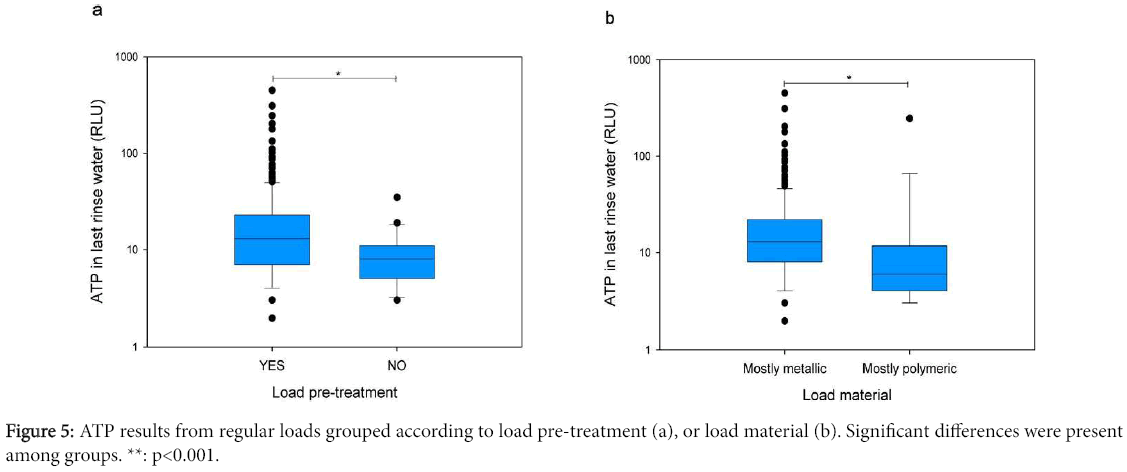

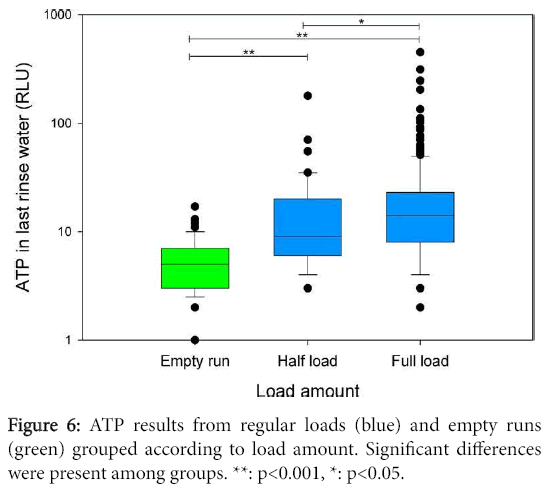

Results: A total of 435 ATP tests were performed, including 74 negative, 74 empty runs and 287 regular load tests. ATP values from regular loads ranged between 2 and 452 RLUs and 1.3%, 0.7%, 0.3% out of the 287 measurements was above 200, 300, and 400 RLUs, respectively. ATP values from negative tests and empty runs differed significantly (p<0.001) from the regular loads with a median value [I quartile; III quartile] of 4[2;5], 5[3;7], and 12[7;22] RLU, respectively. Analysis of ATP values from regular loads grouped by load pre-treatment, AWD washing program, load material or load amount showed significant differences between groups. No significant differences in ATP data were found among AWDs.

Conclusion: The measurement of ATP in the last rinse water of AWDs showed that characteristics and quantities of the load relate to the ATP readings. The test is advised as an informative additional test to visual inspection for monitoring every load of an AWD.

Keywords: ATP; Medical device; Automated washer-disinfector; Every load monitoring; Decontamination; Cleaning; Disinfection

97474Introduction

Cleaning and disinfection are essential steps in the reprocessing of medical devices. Automated Washer-Disinfectors (AWDs) are widely used in healthcare settings to obtain both clean and disinfected medical devices. The use of AWD is advocated in literature [1] and in standards [2,3] for minimizing processing variability and infective risk for the staff of the central sterile supply department (CSSD).

According to the European Medical Devices Directive 93/42/EEC and subsequent amendments by 2007/47/EC a claim made on a product or procedure has to be proven. Therefore the person responsible for the AWD production should document that processed devices are washed and disinfected according to minimal requirements. In Europe, the easiest way to meet these minimal requirements is by complying with the European harmonised standards ISO 15883-1 [2] and 15883-2 [3]. When current standards are met, an AWD process has to be monitored with physical parameters, such as water pressure, flow, flow velocity, temperature, water pH and conductivity. These parameters may provide information on the mechanical functioning of an AWD and on the presence of inorganic material in the water. Nevertheless, no relevant information on the presence of organic matter is obtained, e.g., tissue residuals or microbial burden.

In the ISO 15883-5 [4] test-soils are specified to mimic contamination on medical devices. Alfa reported that 9/11 (82%) of the proposed test soils are based on human observation, such as colour interpretation [1]. Human observation and interpretation make these tests subjective. Often these test do not provide quantitative results and most of them are not easy to implement in the daily practice of the CSSD. Additionally, the labour that comes with some of these tests makes them impractical for every load monitoring.

Recently, a new test protocol, based on the measurement of Adenosine TriphosPhate (ATP) in the last rinse water of AWDs has been proposed [5]. An inventory study showed high variability in the ATP values and indicated that monitoring of every AWD load should be considered and quantitative, non-subjective, practical tests should be designed to check the effectiveness and reproducibility of the AWD process [5]. Based on this, our observational study verifies the technical and practical feasibility of monitoring every AWD load in a hospital CSSD by measuring the ATP in the last rinse water and evaluates whether the test has an added value in reporting about the AWD process.

Materials and Methods

Setting

The study was conducted at the CSSD of the Santa Maria del Carmine Hospital in Rovereto, Italy. The hospital is a medium-sized public healthcare structure with 329 acute beds, where about 15600 hospitalizations and 7200 surgical interventions per year in the fields of orthopaedics, traumatology, gynaecology, general surgery, otorhinolaryngology, dermatology, ophthalmology, vascular surgery and urology are performed. The CSSD produces approximately 92000 units of single-packed devices and accessories, 15000 small dimension kits for single patient use, and 22300 surgical kits are processed per year. In the reprocessing activity, three AWDs are used. These AWDs are the subject of our observational study.

ATP protocol

Monitoring was performed in only one AWD at a time but in every process run of that AWD, so called Every Load Monitoring (ELM). No change in the routine procedure of using an AWD was introduced. Only the measurement of ATP in the last rinse water was added. One week before the start of the study, the staff involved was trained on sampling the last rinse water and performing the ATP measurement.

The ATP protocol was adopted from the literature [5]. Shortly, before an AWD cycle was started, an empty Water Sampler (WS; Valimed AB, Umea, Sweden), composed out of a special funnel and a beaker [5], was placed in the load of the AWD. The location was the lowest available shelf of the loading tray, close to the front-right side of the unloading door. After a full AWD cycle, the funnel was removed and a sampling stick (Clean-Trace™ ATP Water Test, 3M, St Paul, MN, USA) was dipped in the collected last rinse water sample. The stick was then positioned back in its sleeve, activated and shaken for 10 s. Next, the activated test stick was placed inside its associated luminometer (Clean-Trace NGi, 3M) and the displayed relative light unit (RLU) value was registered. Between each process, the WS was emptied.

The protocol also required a negative control and an empty process run of the AWD at the beginning of each production day. The negative control was performed by the activation of a test stick without sampling. A value<15 RLU at negative control was considered a pass result for using the ATP measuring system that day. An empty process run was a run with only a WS as load in the AWD.

All ATP test results were recorded in a data sheet together with additional data describing the AWD, the load, and the process characteristics, including load pre-treatment, AWD program, load amount, load type, load material, loading tray type and, load visual inspection after the AWD process (see first column of Table 1).

| Grouping criterion | Regular loads | Empty runs | ||

|---|---|---|---|---|

| Loads number | ATP (RLUs)* | Runs number | ATP (RLUs)* |

|

| AWD id | ||||

| #1 | 99 | 12[7;25] | 23 | 5[3;6] |

| #2 | 91 | 10[7;20] | 26 | 4[4;6] |

| #3 | 97 | 14[8;21] | 25 | 6[4;8] |

| Loading tray type | ||||

| For surgical instrument | 153 | 15[9;30] | 34 | 5[3;7] |

| For cannulated devices | 126 | 10[6;18] | 24 | 5[4;6] |

| For anestesia sets | 8 | 4[4;5] | 16 | 6[4;7] |

| AWD program | ||||

| Long, with pre-rinsing | 206 | 14[9;25] | 40 | 4[3;7] |

| Short, without pre-rinsing | 81 | 8[5;17] | 34 | 5[3;7] |

| Load pre-treatment before AWD | ||||

| YES: manual pre-cleaning and/or brushing and/or ultrasound plus soaking | 266 | 13[7;23] | - | - |

| NO: only soaking | 21 | 8[5;11] | - | - |

| Load amount | ||||

| Empty run (0%) | - | - | 74 | 5[3;7] |

| Half load (50%) | 51 | 9[6;19] | - | - |

| Full load (100%) | 236 | 14[8;23] | - | - |

| Load type | ||||

| Non hollow | 133 | 13[8;22] | - | - |

| Lumened | 36 | 13[7;21] | - | - |

| Mixed | 118 | 11[7;22] | - | - |

| Load material | ||||

| Mostly metallic | 269 | 13[8;22] | - | - |

| Mostly polymeric | 18 | 6[4;10] | - | - |

| Load visual inspection after AWD process | ||||

| Passed | 285 | 12[7;22] | - | - |

| Failed | 2 | Values were 51; 91 RLUs | - | - |

*Values are expressed as median [I quartile; III quartile] of the value distribution; AWD: Automated Washer-Disinfector

Table 1: Result summary for the ATP test on last rinse water. Load number and their ATP values are grouped by AWD or load characteristics. Empty run number and their ATP values are grouped by AWD characteristics.

The monitored AWDs were recently validated according to current standards [2-5]. All equipment was used according to the manufacturers’ instructions.

Statistical analysis

ATP values obtained from regular loads, empty runs and negative controls were considered for analysing the data. Normality of data was assessed by Shapiro-wilk test. Variables that did not have a normal distribution were presented as median and quartiles interval. An unvaried analysis was performed on ATP values from both regular loads and empty runs grouped according to the individual AWD (AWD id), loading tray type and AWD program. ATP values from regular loads were also studied after grouping according to the following load-related characteristics: load pre-treatment before AWD, load amount, load type, load material. The Mann–Whitney U test was used to compare two groups. The non-parametric Kruskal–Wallis test was used to compare three groups. If a significant difference was found with the Kruskal–Wallis test, then a Mann–Whitney U test was used to compare each pair of groups followed by a Bonferroni-Holms post-hoc correction [6]. All analyses used two-sided tests with a significance level of p<0.05. The STATA version 13.0 for Windows (STATACorp. College Station, TX, USA) was used for data analyses.

Results

During the period of ELM there was no need to modify the water sampling procedure, the ATP measurement protocol or further retraining of the staff. A total number of 435 ATP tests were performed, including 74 negative control, 74 empty run and 287 regular load tests.

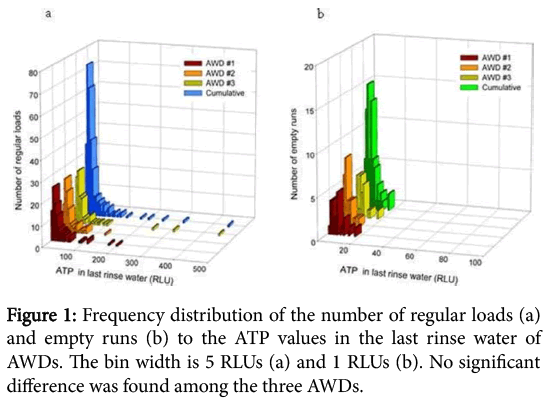

ATP values from regular loads ranged between 2 and 452 RLUs, with a median value [I quartile; III quartile] of 12[7;22] RLUs. The frequency distribution histograms of the whole regular load dataset and of each single AWD are shown in Figure 1a. The non-normal distribution of data is obvious and was confirmed by Shapiro-wilk test showing non-normality for both ATP (p<0.001) and logATP values (p<0.001). Half of the ATP values was between 7 and 22 RLUs, nevertheless 9 (3.1%), 4 (1.3%), 2 (0.7%), and 1 (0.3%) out of the 287 measurements performed on regular loads were above 100, 200, 300, and 400 RLUs, respectively.

No significant difference among the three AWDs was found for ATP of regular loads (Figure 1a) and empty runs (Figure 1b). In a summary, Figure 1 and Table 1 demonstrated that the ATP values of the three AWDs were comparable.

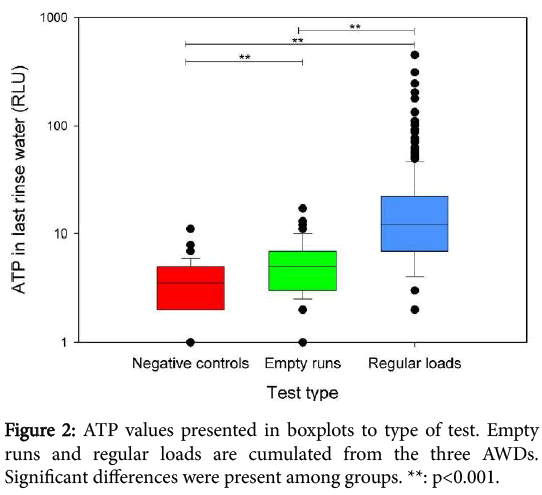

Considering that no significant difference was obtained among the three AWDs, collected data were accumulated and then compared according to test type. ATP values from negative controls and empty runs showed a median value [I quartile; III quartile] of 4[2;5] RLUs and 5[3;7] RLUs, respectively. When compared to regular loads, ATP values from negative tests and empty runs differed significantly (p<0.001) (Figure 2).

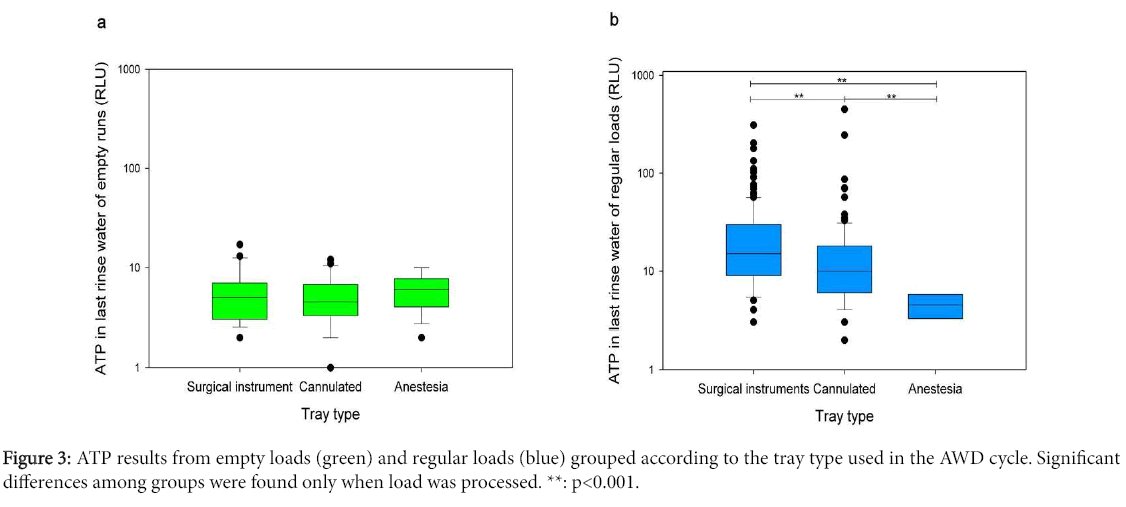

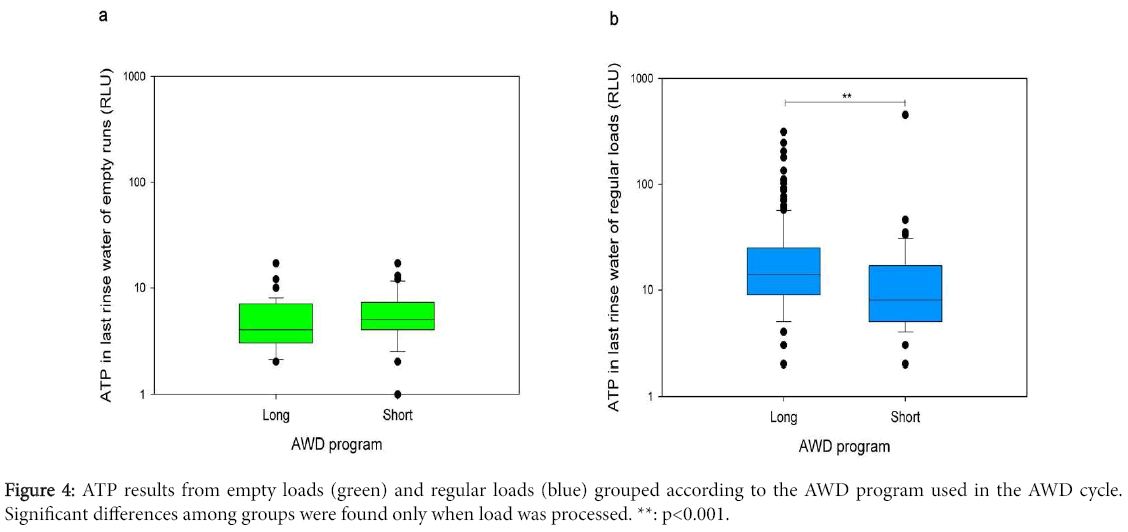

The use of different loading trays (Figure 3a) or different AWD programs (Figure 4a) during empty runs did not determine different ATP results (Table 1). However, grouping ATP values from regular loads according to the loading tray (Figure 3b) or to the AWD program (Figure 4b) resulted in significant differences.

In Figure 5, the results of load pre-treatment or not, and the kind of material processed are presented. The significant differences between groups demonstrate a trend that the higher the initial contamination (i.e., instruments needing for pre-treatment) the higher the ATP results (Figure 5a). The results in Figure 5b indicate that the metallic devices generated significantly higher ATP values than polymeric devices (Figure 5b). By considering the amount of load processed by the AWD, a trend can be recognized that the more load the higher the ATP results (Figure 6).

The Table 1 also indicates that two out of 287 (0.7%) regular loads failed the visual inspection after AWD process and devices were reprocessed a second time. ATP values measured in the last rinse water of these two runs were 51 and 91 RLU. Due to the low number of loads that failed the visual inspection, the statistical analysis of ATP data grouped by load visual inspection after AWD process was not feasible.

Discussion

Differences in ATP values between regular loads and empty runs are in agreement with previous reported findings [5]. Also, the range of ATP measurements in the last rinse water fits the purpose of the measuring instrumentation (ranging from 1 to 1000000 RLU) that was able to quantify ATP in all the water samples from both regular loads and empty runs.

Inspection of the Table 1 and Figure 1 indicates that the three AWDs generated comparable results in terms of ATP value of empty runs and regular loads. This made it possible to accumulate the result of the three AWD and to analyse if the kind of load and the loading method influenced the ATP readings. Figure 3b indicates that surgical instruments were associated to the highest ATP levels and the anaesthesia devices to the lowest. Generally, the biological load on an instrument used for surgery is higher than the contamination on the anaesthesia equipment. The cannulated instruments generated values in between the surgical and anaesthesia loads. The inner surface of these devices cannot be easily assessed by visual inspection or tested. Consequently more information of inner surfaces has to be acquired.

A closer inspection of the accumulated results in Figure 5a indicates that instruments with a pre-treatment before processing in an AWD have higher ATP value then not pre-treated instruments. This might be caused by the fact that these instruments contain more bioburden than the normal contaminated instruments. Therefore these instruments are pre-treated before being processed in an AWD. A similar tendency is recognized between the long process (for dirty instrument) and the short process cycle (Figure 4b). The amount of ATP appears also to be influenced by the amount of load: the more load, the higher the ATP value (Figure 6). This could have potential application for defining the optimal load amount into the AWD, having a quantitative indicator to avoid overloading of the machine. Material of instruments seems to influence the ATP value as well. Loads containing more of polymeric than metallic (stainless steel) instruments show lower ATP readings (Figure 5b). Micromorphology and chemistry at the device surface may play a role on this. To find a correlation on this topic, a study is necessary in which the surface is investigated more in detail. Indeed, a limitation of the study is the absence of randomization in assigning the loads to the various subgroups. According to the observational design of the study, the choice of applying or not a pre-treatment to the load and the selection of the AWD washing protocol was related to the device to be processed (protocols were designed according to indications of the device manufacturers and were already established before data collection) and to the experience of the CSSD operators in evaluating the difficulty in cleaning and disinfecting the specific load. In the end, the selected cleaning and disinfection protocol was actually reflecting the perceived complexity of the device.

In this study, two regular loads failed the visual inspection after AWD processing. In the first load, three devices for traumatology showed chalk residuals, but no blood or bone debris. ATP measured in the last rinse water of this load was 51 RLUs. In the second load, visual inspection revealed bone and soft tissue debris on a femoral rasp for hip arthroplasty. An ATP value of 91 RLUs was measured in the last rinse water. On the opposite, 10 out of 287 regular loads showed ATP values higher than 91 RLUs, but passed visual inspection. These findings support the need of monitoring every load and integrating visual inspection with additional tests.

ATP test is largely used in food processing and in hospital setting for the evaluation of the cleanliness of environmental surfaces by swabbing the area of interest [3]. The testing method proposed here makes use of a last rinse WS. This procedure reduces sampling complexity and sample variability since the water is sampled by simply dipping the specific stick into the beaker of the WS. Different maximum ATP levels have been proposed in literature for interpreting the ATP values in a pass/fail mode [7]. Griffith et al. [8] indicated that 500 RLUs was a realistic value for the routine monitoring of surfaces in a general surgery ward. Some years later, the same research group proposed a revised stricter pass/fail value of 250 RLUs, showing the importance of linking benchmarking to incremental quality improvements [9]. Fushimi et al. showed that ATP values from gastrointestinal endoscope reliably reflected the microbiological load and defined that allowable ATP levels after manual cleaning in their institution were 169 RLUs and 407 RLUs for external endoscope surfaces and channel results respectively [10]. Alfa et al. validated an ATP water test method for monitoring manual cleaning of flexible endoscopes and reported that the average protein, haemoglobin, and bioburden benchmarks were achieved if<200 RLU were detected in water samples flushed through endoscope channels [11]. The application of these criteria to our dataset elicits that a non-negligible number of loads would fail the ATP test (E.g., 4 loads out of 287 (1.4%) monitored loads showed ATP test>200 RLUs). Interestingly, all this loads passed the visual inspection, suggesting low sensitivity of the visual assessment for checking load after AWD process. Although currently available data may not be sufficient to properly define a maximum level of ATP to release the load, a value out of the literature may be set as warning level, e.g., 200 RLU [11].

ATP data here presented are in agreement with a previously reported multicentre study [5] and confirm that practices and performance of the local CSSD are comparable with similar structures within Europe. The presence of relatively high values of ATP in a fraction of the observed load cannot be neglected and confirms the need for ELM of AWDs.

Conclusion

Overall it can be concluded that ELM by WS and ATP delivers valuable added information next to visual inspection of every processed load. It is advised to use ELM for both monitoring and optimizing the procedures for reprocessing medical devices with AWDs.

Acknowledgments

The authors wish to thank the staff of the Sterilization Department of the Santa Maria del Carmine Hospital (Rovereto, Italy) for their cooperation in data acquisition, constructive input and feedback.

ATP sticks and the luminometer used in the study were provided by 3M Italy.

Financial Support

This work was partially supported by the Healthcare Research and Innovation Program (IRCS-PAT), Autonomous Province of Trento, Italy.

Potential Conflicts of Interest

All authors report no conflicts of interest relevant to this article.

References

- Alfa MJ (2013) Monitoring and improving the effectiveness of cleaning medical and surgical devices. Am J of Infect Control 41: S56–S59.

- International Organization for Standardization (2006) ISO 15883 Washer-disinfectors Part 1: General requirements, terms and definitions and tests. ISO standard.

- International Organization for Standardization (2006) ISO 15883 Washer-disinfectors Part 2: Requirements and tests for washer-disinfectors employing thermal disinfection for surgical instruments, anesthetic equipment, bowls, dishes, receivers, utensils, glassware, etc. ISO standard.

- International Organization for Standardization (2006) ISO 15883 Washer disinfectors Part 5: Test soils and methods for demonstrating clearing efficacy. ISO standard.

- van Doornmalen Gomez Hoyos JPCM, van Wezel RA, Tessarolo F (2015) Variability of ATP amount in last rinse water of automated washer-disinfectors demands monitoring of every load. J Hosp Infect 91: 87-89.

- Holm S (1979) A simple sequentially rejective multiple test procedure. Scand J Statist 2: 65-70.

- Amodio E, Dino C (2014) Use of ATP bioluminescence for assessing the cleanliness of hospital surfaces: a review of the published literature (1990-2012). J Infect Public Health 7: 92-98.

- Griffith CJ, Cooper RA, Gilmore J, Davies C, Lewis M (2000) An evaluation of hospital cleaning regimes and standards. J Hosp Infect 45: 19-28.

- Lewis T, Griffith C, Gallo M, Weinbren M. (2008) A modified ATP benchmark for evaluating the cleaning of some hospital environmental surfaces. J Hosp Infect 69: 156-163.

- Fushimi RMT, Takashina M, Yoshikawa H, Kobayashi H, Okubo T, et al (2013) Comparison of adenosine triphosphate, microbiological load, and residual protein as indicators for assessing the cleanliness of flexible gastrointestinal endoscopes. Am J Infect Control 41: 161-164.

- Alfa MJ, Fatima I, and Olson N (2013) Validation of adenosine triphosphate to audit manual cleaning of flexible endoscope channels. Am J Infect Control 41: 245–248.

Citation: Tessarolo F, Valentinotti L, Mariotti G, Ziglio A, Rigoni M, et al. (2016) ATP Measurement in the Last Rinse Water of Automated Washer-Disinfectors: The Added Value of Every Load Monitoring. J Clin Infect Dis Pract 1: 109. DOI: 10.4172/2476-213X.1000109

Copyright: © 2016 Tessarolo F, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Open Access Journals

Article Tools

Article Usage

- Total views: 16362

- [From(publication date): 9-2016 - Apr 03, 2025]

- Breakdown by view type

- HTML page views: 15420

- PDF downloads: 942