Assessing Off-Site Readiness in Construction Organisations from the Contractors' Perspective: A Case Study from India

Received: 18-Oct-2021 / Accepted Date: 01-Nov-2021 / Published Date: 08-Nov-2021 DOI: 10.4172/2168-9717.1000250

Abstract

This paper intends to present Indian construction organisations' present factors in adopting Off-Site Construction (OSC) methods from the contractors’ perspective. An existing readiness maturity model has been used to assess a large organisation in India. A case study methodology has been adopted in this paper to highlight critical issues in OSC adoption in India. This paper presents an off-site readiness framework and a case study and concludes the Indian construction sectors readiness to adopt the OSC methods. Through the case study, different issues related to the adoption of OSC have been identified and highlighted for the Indian construction sector. Through the case study, several barriers related to OSC methods have been identified and highlighted within the Indian construction sector. Although the model has been applied to the Indian construction sector, it can easily be modified to fit into other areas with similar industry dynamics and business conditions. Practitioners in India can utilise the proposed OSC readiness maturity model as a structured process to guide and assess their OSC readiness in the market, enabling construction practitioners the tools to evaluate and benchmark their operations through the strategic and operational phases. This research shall add to the existing knowledge of OSC in India by mapping issues relevant to India's construction industry. Drivers and barriers affecting the implementation of OSC techniques in the Indian construction industry; the research has provided background on the status of OSC. This research study focuses on assessing and developing an OSC readiness framework for an Indian construction organisation. Scope and population for data collection within this research are limited to large construction organisations in India only.

Keywords: Off-site construction; Construction industry; Housing; Modular Construction; Indian construction; Readiness maturity model

Introduction

Slow adoption of new and innovative technologies is one of the significant reasons that the construction sector usually lags behind other industries to take full advantage of innovations [1,2]. However, this trend has been changing over recent years, especially regarding Off-Site Construction (OSC) awareness and its importance. OSC has received broader acceptance in many countries; however, it is still a comparatively recent phenomenon and yet to gain momentum in India [3]. India has started to consider using OSC practices in recent years. Innovation in the construction industry has often been observed as slow-moving; in India's case, the technological 'conservatism' further hinders the shift towards new methods and innovative practices [4].

Sustainability was not the top priority in India; however, the construction sector is slowly becoming sustainable; the past decade has witnessed massive growth in this area, becoming one of the top issues in the sustainable development program 2030 and the exploration and innovation of the construction industry [5-7]. However, the most significant barrier is the increasing need for infrastructure and housing in India. Other factors and the construction sector face include delays in completion, low quality, high demand, and lack of project management skills, which hinder the construction industry's consistency and growth [8].

More construction organisations have recently started expressing interest in OSC; however, they are usually discouraged by the current confusion, lack of awareness, and available guidelines [9]. One of the most significant barriers is the organisation's scepticism about their ability to integrate OSC practices into their current construction activities, and they usually lack appropriate resources to facilitate and satisfy market needs if extensive off-site procedures are implemented in the industry [10,11]. Therefore, this paper aims to fill this gap (of assessment and ability check) in the literature by assessing and validating an OSC readiness maturity model using a real-life case study from India, looking at these factors from a contractor's perspective. OSC readiness can be defined as a measure of the degree to which the organisation may be ready, prepared, or willing to obtain benefits that arise from the OSC practices. The maturity model in this paper aims to examine how ready the organisation is in adopting the OSC practices.

This paper presents a case study of a Construction Company in India, detailing practices that can help the adoption of OSC. The following section includes a literature review and discusses a framework to assess the processes that impact the OSC adoption and methodology. The paper then discusses the case study from a contractor's perspective. The last section summarised the findings and concluding remarks of the cases.

Materials and Methods

OSC has gained significant attention in major recommendations obtaining greater productivity and pace in construction. Many authors are even calling it the construction industry's future to increase the standardisation and reduce cost and time [12-15]. Several authors, have looked at the drivers and challenges faced by the OSC in India and how to mitigate them [3,16, 17]. They have highlighted several issues and solutions and stressed the need to investigate further the aspects that affect people, processes, and organisations. Recent studies in India reported a lack of international exposure to construction activities, especially in large scale projects and physical infrastructure development [18]. Other points include the dominance of traditional practices that are highly labour-intensive and uncertainty in cost and time schedules [19,20]. Therefore, it is critical to address the high demand for housing, infrastructure, global knowledge transfer and a sustainable built environment in India.

The literature review highlighted the significance and benefits of employing OSC methods; however, the current uptake of OSC is low in India but is gradually increasing. The literature review also suggests no clear evidence of successful OSC implementation in the Indian context because it is highly competitive. Companies only search for proven technologies to gain a competitive advantage [21]. Things have been changing for the last few years. Some organisations have started considering OSC as an alternate and innovative technique. However, issues such as lack of guidelines, awareness, and resources to implement it efficiently. Hence, there is a need for tangible evidence of the advantages of using different OSC techniques levels. Researchers from other practising nations such as the UK, USA, Australia, China and Malaysia have documented the experiences and lessons regarding OSC in the literature. Still, there is a strong need for tangible research [22].

Many researchers have looked at the OSC adoption in different developed countries; some highlighted the critical role of strategy in implementing OSC. The project strategy is essential to changing the project process from 'traditional construction' to 'manufacturing and installation' [23]. Some authors have suggested that the lack of feasible business process models can be a significant barrier in OSC implementation [24]. Emphasised the necessity for kick-starting projects to generate more prospects and spilling out the effect on the entire industry whereas, revealed that evaluating the degree of industrialisation of a component or building system production in offsite construction is inadequate in the construction industry [25]. They also stressed the need for holistic and systematic assessments of these solutions' applicability and overall benefit.

Further, stressed the need to investigate an appropriate prefabricated building system to fulfil the present context's housing shortage [26]. All these authors have pointed out the drivers and barriers at different stages; however, there is minimal discussion at the organisation's process level and self-assessment. Further, there is no holistic study on the impacts of OSC in Indian construction. Recently, many Indian construction companies have started experimenting with OSC. However, lack of awareness and confusion has discouraged any intensive implementation of OSC, and the Organisations are sceptical about their capabilities of integrating OSC practices in their construction activities[27-29].

This research developed an OSC readiness framework for Indian construction organisations. It is critical to compare and test the current practices in an organisation before introducing any new techniques. Therefore, this investigation of the current state and knowledge of OSC practices was undertaken in India. This research adopted the OSC readiness developed which can assess the maturity level of a construction organisation in India; this mechanism of an 'off-site construction readiness framework' has similarities with Capability Maturity Models (CMMs), which are used to guide organisations on defining processes. CMMs assist in determining what activities must be performed to meet specific criteria. By exercising through the off-site readiness framework, the organisations would gain knowledge on OSC and know their capability for adopting OSC in construction projects. The model dictates the capacity of the organisation to implement OSC in certain construction activities. Thus, the organisation’s maturity level and characteristics can be studied based on the OSC readiness model results. In addition to the OSC readiness framework, the research proposes a strategy for the extensive implementation of off-site practices in India.

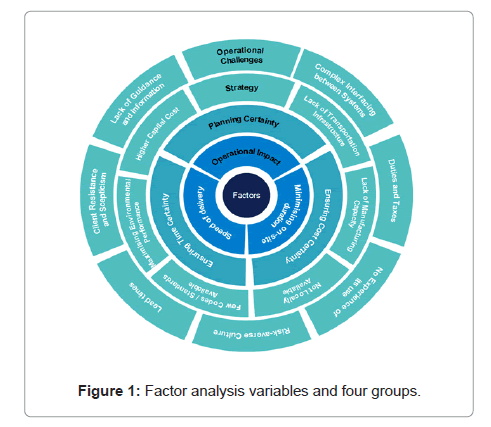

Four crucial factors discussed in Figure 1 illustrates possible routes for OSC's future uptake. However, presented these variables in isolation; several others have endeavoured to examine the fundamental aspects of People, Process and Technology (including OSC roadmaps), Platform, Process and Product integration platforms and OSC's Future Landscapes [3]. Whilst all these efforts provide points for discussion and further development, the primary objective prevails, how do organisations prepare themselves for OSC transformation? At an organisational level, where OSC uptake occurs, needs addressing; this is where the level of 'readiness' and organisational maturity is so important.

Level 1 (No Clear Application) presents organisations with issues they need to re-visit regarding their existing procedures and any inevitable restructuring to improve efficiency/readiness. Level 2 (Frequent Application, but Lack of Standard Practice) highlights the frequency of application lack of policy issues, including the need to significantly repeat and standardise processes in line with clear strategy/ policy directions. Level 3 (Clear Established Practices and Procedures) focuses on the need to establish clear OSC policies. This includes a full evaluation of existing operations with clear project strategies to deliver best practice, recording experiences from previous projects and best in class provision offered by other companies and documenting lessons learned (as part of their organisational learning strategy. This paper uses the framework described and documented in Table 1, developed to present three case studies of large construction consultancies in India. As the companies have a presence throughout India, which helped to understand the local challenges as well that are peculiar to certain areas only.

Methodology

The readiness framework shown in Table 1 was validated and applied to a real-life case study from India to assess its readiness to adopt OSC. A case study can be defined as a process or strategy to perform research that involves an empirical investigation of a phenomenon within its real life context, primarily when the boundaries between the phenomenon being studied and the context within which it is being studied are not clearly evident [30]. The case study method is particularly useful in validating and testing the theoretical models by implementing them in real-life situations and organisations. The data collection for this research was performed via semi-structured interviews to deliver a variety between the structured and unstructured extremes [31,32]. Interviews can also provide a more holistic picture, and broader details about non-verbal communication such as body language have also impacted the answers.

For this research, a large construction organisation was approached that has been practising OSC methods for a long time in India and agreed to participate. Ten (10) people were interviewed from this organisation positioned at different geographical locations in India. The respondents included architects, designers, project managers, HR managers, Quality managers and technical staff. All the participants possessed more than 10 years in construction and at least 5 years in OSC. The interviews were organised in each employee's office, and every interview lasted around 1 hour. These participants were chosen based on their seniority, experience, geographical location and experience in the OSC projects. In the first phase, the respondents were provided with the necessary information about the research and the purpose of the research was explained to all the participants.

Additionally, the participants were also asked about the level of maturity of each factor and sub-factor mentioned in Table 1, and they were also provided with these tables and figures in advance so that the respondents can put their thoughts in the context of the maturity model. Maximum flexibility aFnd anonymity were ensured during the interviews so that the participants can answer all the questions without any restriction and hesitation. This helped them explain their company's systems and procedures in detail regarding OSC and highlighted issues with IT systems, procurement methods, internal processes, and market challenges.

| Factors | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| No clear application | Frequent application. Lack of standard practice | Established operating procedure | |

| The organisation may / may not practice the critical steps for effective implementation of Offsite techniques. Organisations at this level need to revisit their existing operations and restructure their team to improve efficiency/readiness. | This level represents the frequency of application. At this level, the organisation significantly repeats a series of critical techniques. However, it will have scope for improvement in processes and need to define the standard practice. | At this level, the organisation has clear standard practice about Offsite Construction methods. It continually reviews the existing operations and plans the project strategies to increase efficiency-the organisations at this level. Document best procedures through recording experiences and lessons from the previous projects. | |

| F1.Operational challenges | |||

| F1. 1. Complex Interfacing between the systems: How does the organisation respond to the challenges in assembling individual systems:products of a complex nature? | Is the workforce aware of the assembling techniques and interfacing of different products? | Does the organisation demonstrate how to assemble new, complex structures before erecting them onsite? | Does the organisation expedite the learning curve from one offsite project to another project, through integrating training programs in the strategy? Also, does the organisation prioritise capacity building in the policy? |

| F1.2. Duties and taxes: How does the organisation consider the leviability of duties and taxes on the Offsite products? | Does the organisation identify the potential challenges associated with the duties and taxes on the Offsite products? | Does the material procurement strategy of the organisation consider both imported and domestic Offsite products? Also, does the organisation maintain any records to monitor the duties and taxes payable / already paid? | Does the organisation achieve optimal utilisation of imported and domestic products? Does it always prioritise the Offsite products entitled to incentives or exemptions from the taxes? |

| F1.3. Level of experience in Offsite constnuctIon: How many offsite projects have been handled? What is the level of expertise of the organisation? | Are the design and project development teams aware of the techniques and methods involved in offsite construction practices? | Do all the senior management. Project teams. construction workforce has significant experience in handling offsite construction projects? | Does the organisation maintain a structure with a dedicated project team and workforce that are specialised in offsite construction operations? |

| F1.4. Promoting the advantages of offsite Construction Technique: How does the organisation handle the existing negative image (Goodie( & Gibb, 2007: Arif er al.. 2012) on offsite construction methods? Does it promote the advantages associated with the OSC method? | Does the organisation promote the potential benefits from offsite construction methods? Also, does the organisation conduct any enlightenment programsr one to one session with the potential clients to clarify their concerns? | Does the organisation maintain a calendar of awareness workshops? Also, does it brief the potential clients about the nature of worlc, application methods and achievable benefits before starting the project? | Does the organisation extensively promote the benefits of OSC products by showcasing successful projects. Value proposition and product samples? Also, does it include the promotional activities in the strategy? |

Table 1: Ofsite construction readiness maturity model.

Case study

The company mentioned in this study will be called Organisation X that was founded in 1978. The organisation works in industrial buildings, commercial buildings, housing, IT parks and stadiums and is spread throughout India. In the recent five years, they have constructed administration and accommodation complexes for various academic institutions across India and have employed OSC successfully in these projects.

Factor 1. operational challenges

The project lead mentioned, "Recently, we have identified a foreign product for one of the projects. In the initial assessment, the technology appeared to be handy. Nevertheless, our project team found it difficult to work and co-ordinate with all our vendors. We had to halt the project and arrange a three-week training for all the workforce and special interaction with the vendors." It was noticed that the organisation monitors the project performance and responds with immediate control measures wherever required. According to the project team (Manager and Mechanical consultant), the organisation has provided training for the workforce. However, due to a lack of familiarity with the new product, the staff could not work with ease. The project team also shared that the three-week training in erection and assembly, hands- on training on a mock unit have immensely helped the workforce. Some demonstration images and photographs of on-site erection were also found during the site visit. It is noticed that the project team was divided into four groups for the training purpose. The observational evidence also provides similar inference. During the interactions, it was found that all the technical staff was comfortable working with the new technology, and one of the workers called it 'readymade construction.' The project lead expressed that 'our organisation may plan for a standard training protocol for future projects. However, the success of the on- going project will decide'. Based on all the evidence, it can be said that the organisation is currently practising group training and one to one training sessions on the new techniques. However, the organisation lacks a standard training protocol for various OSC projects. Therefore, organisation X achieved level two in terms of "complex interfacing between the systems" in the OSC readiness framework.

Factor 1.2. duties and taxes

Organisation X predominantly used locally available material and systems in the past. However, for an on-going infrastructure project, they used imported technology. During the interview, it was observed that organisation X had conducted an initial assessment and feasibility before finalising the product. The interaction with the project accountant revealed that the organisation has considered several local and imported products. The decision-making process included the components of tax and customs duties the said technology may attract. "This product is quicker and better in quality. There is no huge price difference, so the management decided to try." the project lead mentioned. The senior manager shared that they did not inquire about incentives or tax benefits concerning the foreign product. The authors could not gather any documental evidence since the cash flows and purchase orders are confidential documents. The interview reveals that the organisation practices a robust decision-making process. There are designated people to handle the Letter of Credit (LC) purchases involved in Imports. The on-going project's procurement and purchase strategy indicate that the organisation frequently uses local and foreign products. However, it lacks a standard practice concerning duties and taxes. Based on this, the researcher assigned level two to the organisation.

Factor 1.3. level of experience in off-site construction methods

The HR manager was also interviewed during the research. The information on the organisation's careers page and the team profile reflects its strategic recruitment policy. In the interview, the HR manager stated that the organisation formulates the project team according to the project's nature and requirements. The HR team follows a directive while constituting teams and assigning roles and responsibilities. The organisation X chart of one of their on-going projects presents the design and project execution staff profiles. It indicates that all the senior management of the project execution staff have more than five years of experience in OSC projects. During the site visit, a quality manager shared his experiences from the previous projects. He was trained to assess OSC products' quality aspects and alert the procurement team and management wherever required. The evidence from the interviews and site visits indicates that the organisation has a clear strategy for formulating teams and assigning responsibilities. All the OSC projects have experienced or specialised senior management. Hence, it can be understood that the organisation achieved level three in terms of "Level of experience in off-site construction methods."

Factor 1.4. promoting the advantages of off-site construction techniques

Organisation X has a clear strategy for marketing; it considers the promotion of OSC methods as part of its brand-building exercise. They largely publicised one of their completed projects, an international cricket stadium. This project holds a significant share of the implementation of OSC methods in construction. Thus, by publicising the project, the organisation has also projected OSC as an appropriate solution to achieve construction speed. In addition to this, the organisation also participates in national and international exhibitions in real estate and construction. Photographs of their exhibition stalls present evidence, including a display of mock units, products, and videos of their landmark projects. OSC is referred to as 'modern, sophisticated construction equipment and machinery in the corporate brochures and other organisation literature. The authors also noticed two articles focused on modern construction methods, written by the organisation's Chief Operating Officer. In the interview, the senior level management shared their interest to capture a significant share in the current market for OSC in India. Based on the evidence, the researcher assigned level three in the area "Promoting advantages of off-site construction techniques."

Factor 1.5. lead times

The authors' opinions include one senior project manager, a project co-ordinator, and two contractors during the research. One of the project co-ordinators shared the experiences of the on-going project. The project team plans all the events in alignment with the delivery schedules. The team prepared a detail list of quantities, estimation and delivery schedules. The organisation released purchase orders in advance and assigned a team to co-ordinate with the procurement and delivery. As a significant portion of the project depends on the imported products, the organisation paid great attention to the shipping and delivery of the products to ensure smooth operations. According to the senior manager, all the project schedules are prepared in consultation with the manufacturers and logistics.During the interview, the senior manager shared, "The board may consider a collaboration with the foreign vendors. The on-going project may be seen as a pilot project to test the vendor's operations and credibility. We better own an in- house facility as we plan for similar projects in the future."However, the existing documents or literature do not indicate any collaborations with foreign or local vendors. From the evidence, it can be said that organisation X works in close coordination with the suppliers but with no standard practice. Hence, it is at level two in terms of "Lead times."

Factor 1.6. client's resistance and skepticism

During the interviews, it was noticed that organisation X is yet to face any significant resistance from its clients. According to the project manager, the client approached the organisation with a prior decision on the implementation of OSC. The on-going project has clear timelines and completion targets at the project briefing and initial discussion stages. So, the selection of OSC methods was encouraged by the client. One of the senior managers expressed a similar opinion about the stadium project. Organisation X maintains documentation of the project all through the phases. It was noticed that the documentation of the critical benefits of OSC was performed in various projects. However, it was difficult to assess the organisation's readiness against the construct, "resistance and scepticism" only based on the on-going projects. Hence, the authors explored the documented and archival evidence. On several occasions, the organisation details the success stories of previous projects to their extensive client base.The organisation encourages clients to participate in vigorous brainstorming and all critical decision-making events. Therefore, it can be said that organisation X reached level three of the OSC readiness in terms of "Client's Resistance and Scepticism."

Factor 1.7. guidance and information

Different learning materials were identified along with the know- how, guidance charts on display in the site office and other construction site locations. According to the project manager and an HR manager, the organisation encourages the manufacturers/vendors to train their workforce. However, there is no standard practice or setup for training, unlike some other case studies. The project manager expressed his opinion that providing an in-house instructor or trainer would enhance construction performance and speed. According to him, this was already put up to HR and management. The HR manager shared that the organisation is considering addressing this in their annual plan for the next financial year. From the above interview and observations, it can be concluded that organisation X is currently at level two concerning 'guidance and information that fosters readiness in adopting OSC methods.

Factor 2. broad execution strategy

Factor 2.1. transportation infrastructure: According to the operations managers and senior project managers, the management acknowledges the significance of transportation infrastructure. In the interview, all the participants expressed that the project team evaluates the available infrastructure during the project feasibility analysis. It is one of the critical components of technical feasibility. Such an initial analysis provides the necessary information on the existing transportation infrastructure. The operations manager pointed out that all the OSC intense projects are located in prime locations with adequate infrastructure. She further highlighted that a detailed route plan and schedule would be prepared twenty days before the products' arrival. As discussed in the earlier section (Factor 1.2.), the organisation has a dedicated team to plan the operations and logistics. This team handles all the critical decision making and liaising with various agencies and stakeholders. Based on these findings, the researcher assigned level three to the organisation in terms of "Transportation Infrastructure."

Facror 2.2. manufacturing capacity: In the interviews, all the participants stated that they finalise the product selection and prepare all the estimation documents at the project's early stages. The procurement and logistics team prepare a critical evaluation report at the early stages. It was observed that the project teams approach the OSC intense projects with an appropriate supply chain and timescale.

This entire process is treated as an integral part of the design and construction phases. In the senior operations manager's words, "we select supply chain with right skills and experience." Organisation X visited the manufacturing units in China before the selection. The interviews revealed that the organisation only works with vendors who express willingness to abide by a legal contract. Therefore, level two is assigned to the organisation in terms of "Manufacturing Facility."

Factor 2.3. shortage in availability: According to the senior project manager, the organisation acknowledges the shortage of suppliers and prefab solutions manufacturers. In his words, "It is high time for the company to begin an in-house facility. The future of housing is prefab. If the management aspires to capture the market, we must invest our money in wise infrastructure." From the interview findings, it can be concluded that the current organisation lacks an in-house manufacturing facility. It imports materials and products for large scale projects. Therefore, organisation X can be assigned level one for this factor.

Factor 2.4. availability of codes/standards: According to the senior management, the architects and design team provide requirements and standards (as per the local legislation and building codes) to the manufacturers. The manufacturers share the product plan, features, and material specifications. In the interview, the project manager commented, "The imported products generally present detailed guidelines and standards. At present, there are no restrictions or standards specified for prefab construction. The government may think about this". The evidence of detailed guidelines and codes of practice were observed during the site visit. Hence, organisation X is at level three in the readiness to adopt OSC in the area "Availability of Codes and Standards."

Factor 2.5. maximising environmental performance in the life cycle: Most of the participants acknowledged that off-site products possess efficient, environmentally friendly features. The architects mentioned a different, perhaps a contrary opinion. A few architects from the design team commented, "There is no product in the market that says unsustainable. Sustainability is linked to the process of construction and life cycle of the building". During the interviews, the author collected a mixed response to the sustainability aspect. However, all the participants (design and execution) expressed that the organisation follows a clear waste minimisation strategy. Based on the pieces of evidence, it can be stated that the organisation attained level two in the area of "Maximising Environmental Performance in the Lifecycle."

Factor 2.6. capital cost: The senior project manager and HR manager conveyed that organisation X is considering upskilling the workforce. HR also mentioned that the management is committed to additional budget allocation under the training and learning overhead. However, the researcher could not access more data on the cash flows since the financial documents are treated as confidential and sensitive documents. The operations manager hinted on the future expansion, in-house facility, and other collaborations with Asia's manufacturers. However, this is unclear as a committed expenditure is not observed. According to the findings, it can be understood that the organisation is at level one in terms of the "Capital Cost" factor.

Factor 3. certainty in planning

Factor 3.1. cost certainty: The interviewed participants expressed that the QS team prepares detailed estimates and quantities for all the initial phase projects. As the authors could not interview the organisation's finance managers, the manager operations shared moderate information on the organisation's finance and cost planning. According to him, the finance managers work in coordination with various teams of different projects. The finance managers monitor and document the general administrative expenses, contract-related costs, project cost, financing-related costs (cost of capital), and internal accounting. The project manager shared that a weekly accounting review and financial reporting are practised in the on-going project. He shared, "This helps us in keeping track of all expenses and projected costs, payments, and in mitigating risks if any". Based on the findings, the researcher assigned level two against the "cost certainty" factor.

Factor 3.2. time certainty: The senior project manager stated that the project planning team prepares the project schedule in consultation with the manufacturers, vendors, and suppliers; organisation X has an established protocol for all the OSC intense projects. In such projects, the project team pays attention to the critical activities and time-cost trade-offs. All the project teams work in synchronisation. The evidence from the site visit and documents such as minutes of the meetings and review reports indicate that the project manager closely monitors the execution and delivery processes. As discussed, according to the operations manager, an in-house facility will enhance their current operations in terms of prompt delivery and speed in construction. Based on the interactions, it can be said that though the organisation lacks on other fronts such as in-house manufacturing facilities and collaborations with suppliers, it can be concluded that the organisation X achieved level three in terms of "Time Certainty" due to the implementation of a standard protocol for OSC projects.

Factor 4. operational efficiency

Factor 4.1. minimising on-site duration: As discussed in the "Time certainty" factor, the evidence indicates that the standard protocol encourages the workforce to streamline the off-site activities. During the site visit, it was noticed that the project schedule indicates the nature of the work package, resources required and pre-requisites. This provides clarity on the off-site activities and prepares the project team and vendors accordingly. The weekly review meetings monitor the compliance of the project schedule. However, the organisation does not have a similar protocol for on-site activities. Based on the findings, the researcher assigned level two against the organisation's OSC readiness in the area of "Minimising On-Site Duration."

Factor 4.2. prompt delivery: The organisation does not have an in-house facility or established collaborations with local or overseas vendors. However, according to the project manager, the QS and purchase departments communicate detailed specifications and time schedules to all the vendors at the pre-construction phase. This early communication provides sufficient time for the vendors. The operations manager also mentioned that the tendering process acknowledges the reputation and experience of the vendors. In the on-going project, the QS and purchase teams considered the manufacturers' experience, resources, and infrastructure capacity. This further ensured a smooth purchase and efficient delivery during the construction phase. Based on the collected evidence, level two is assigned against the "prompt delivery" factor.

Discussion

The purpose of this research work was to present the validation of the Off-Site Construction readiness framework. The case study was analysed to validate the framework and test its applicability in practice. This task has been carried out on real life construction organisation. The validation procedures were carried out using interviews, document analysis, and other observable pieces of evidence. In this case, the organisation had used both OSC practices and the traditional construction methods and demonstrated that the proposed OSC Readiness framework was able to assess the organisations' level of OSC readiness.

Organisation X has reached level two in terms of "Duties and taxes"; hence, it can be said that all the organisation has considered the maintenance of records and monitoring the tax and duty payments as part of the material procurement strategy. Import duties and taxes are among the most significant barriers to the uptake of OSC; therefore, the organisations should look for domestic products or produce themselves where possible [33,13]. It has also established a standard procedure in most of its operations. This reflected in the organisation's practice in working with complex OSC products, recruiting an experienced workforce, addressing the clients' scepticism, and providing training sessions and guidance to the staff. However, it is yet to establish a standard operating procedure to achieve optimum advantage from the OSC techniques.Stated that the design and illustration of products must be documented systematically to ensure process standardisation is achieved during installation and construction phases [24]. The need for standardisation in design and project function was emphasised by several researchers [13, 34-36].

Results against the broad execution strategy have revealed exciting findings; all three organisations' representatives shared minimal to no knowledge about "capital cost". This could be due to the sensitive nature of the data related to cost and finance. Transportation infrastructure is seen as a critical contributor in OSC uptake, and problems here can have serious consequences, especially for the smaller projects [37]. Therefore, end-to-end transportation should be assessed during the project planning stage. The OSC readiness framework assessed the organisations in certainty planning and operational efficiency factors. It was evident that the entire organisation X has attained maturity beyond the first level. Organisation A had a straightforward practice of applying standardised cost and planning methods. However, it lacked a strategic approach in this area. The organisation needs to adopt a strategic approach to ensure cost certainty and planning because it is a fundamental pre-requisite for both contractors and clients [38].

Similarly, organisation X has demonstrated precise application in both minimising on-site duration and prompt delivery. It has crossed level one and achieved level two maturities in performing fast delivery, showing that the organisations have embraced a strategic approach to apply standard procedure in delivery methods and performance. This framework provides a formal process to be used by construction organisations in India to assess their readiness before adopting the OSC method and asserts the scope for upgrading within an organisation's processes. The organisation's planning efficiency assessment revealed that organisation X had reached level two of the OSC readiness in time planning and level three in cost planning. Organisation X can further develop their capacity in the efficient execution strategy as the OSC can help reduce the CO2 emissions whilst also contributing to reduced waste outputs and fewer resource requirements. The environmental impact of construction activity needs to be carefully controlled, from landfill, through to transportation [39-41]. Organisation X reached level 1 in Capital Cost, which is usually one of the most significant barriers to OSC as it tends to require higher up-front costs for the purchase of materials at the beginning of a project (Mtech, 2009). Once this initial investment has been absorbed into organisational business models, organisations should look for other available opportunities and joint ventures to achieve the economies of scale [17]. The OSC readiness framework was applied carefully in organisation X to evaluate operational efficiency. The findings demonstrated that all organisations X had achieved level two of OSC readiness in "Prompt delivery" [42- 47].

Conclusion

Current research and literature on OSC do not adequately assess the OSC readiness of construction organisations in India. Successful implementation of OSC highly depends on the organisation's readiness, and the organisations must be aware of their current strengths and weaknesses. Previously, there was no formal assessment method to evaluate the OSC readiness of the company at an organisation level. Although there were several maturity models, they could not help organisations level up and enhance their OSC readiness and implementation. The appropriation of maturity levels provides clear guidance and direction into the practical stages and issues needed for construction entities to maximise their OSC engagement within the Indian market. This also provides suitable direction and measures for evaluating and benchmarking their processes (strategic and operational) against core phases. The corollary enables organisations to evaluate their OSC 'preparedness' or readiness for engaging in the OSC market. Therefore, exercising this research has helped fill the gaps identified in India's literature and the OSC section.Hence; an OSC readiness maturity model would be influential for the initial assessment of India's construction organisations' OSC preparedness. This maturity model will serve as a guide for OSC practitioners, policymakers and other key stakeholders involved in improving the construction industry's quality in any country with similar demographics and conditions. The research has made a significant contribution to two aspects of current knowledge. The study primarily established a set of 4 key areas that need to be considered at the organisational level while implementing OSC. Secondly, the research developed the OSC readiness maturity model to assess India's construction organisations' readiness status. The research will add to the existing body of knowledge on OSC by mapping issues relevant to India's construction industry.

Acknowledgements

The authors would like to personally thank all participants for their engagement, support and insight used in the development and assessment of this Offsite Construction Readiness Maturity Model.

References

- Ahuja V, Yang J, Shankar R (2009) Study of ICT adoption for building project management in the Indian construction industry. Autom Constr 18: 415-423.

- Herr CM, Fischer T (2019) ‘BIM adoption across the Chinese AEC industries: An extended BIM adoption model’. J Comput Des Eng 6:173-178.

- Bendi D, Qasim RM, Arif M, Goulding J, Kaushik A (2020) Understanding off-site readiness in Indian construction organisations. Constr Innov 21:1-21

- Luthra S, Garg D, Haleem A (2016) ‘The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry’. J Clean Prod 121:142-158 .

- Arif M, Egbu C, Alshawi M, Srinivas S, Tariq M (2010) Promoting green construction in India through industry-academia collaboration.J PROF ISS ENG ED PR 136: 128-133.

- Scheyvens R, Banks GA, Hughes E (2016) ‘The Private Sector and the SDGs: The Need to Move Beyond “Business as Usual’. Sustain Dev 24:371-382.

- Mensah J (2019) ‘Sustainable development: Meaning, history, principles, pillars, and implications for human action: Literature review’. Cogent Soc Sci 5:1-21.

- Shrivastava S, Chini A (2011) ‘Construction Materials and C&D Waste in India.’ in Lifecycle Design of Buildings, Systems and Materials.

- Wuni IY, Shen GQ, Hwang BG (2020) ‘Risks of modular integrated construction: A review and future research directions’.Front Eng Manag 7:63-80.

- El-Abidi KMA, Ofori G, Zakaria SAS, Abdul-Aziz AR (2019) Using Prefabricated Building to Address Housing Needs in Libya: A Study based on Local Expert Perspectives. Arab J Sci Eng 44:1-19.

- Edialeyoung B, Seidu RD, kubi JA (2020) Modular Construction Innovation in the UK : The Case of Residential Buildings. Proc Int Conf Ind Eng Oper Manag 2022:806–816.

- Goodier C, Gibb A (2007)‘Future opportunities for off-site in the UK’, Constr Manag Econ 25:585-595.

- Pan W, Gibb AF, Dainty ARJ (2007) ‘Perspective of UK housebuilders on the use of off-site modern methods of construction’. Constr Manag Econ 25: 183-194.

- Blismas N, Wakefield R (2009) Drivers, constraints and the future of off-site manufacture in Australia. Constr Innov 9 :72-83.

- Arif M, Egbu C (2010) Making a case for off-site construction in China. Eng Constr Archit17:536-548.

- Goulding J, Nadim W, Petridis P, Alshawi M (2012) ‘Construction industry off-site production: A virtual reality interactive training environment prototype’ Adv Eng Inform26:103-116.

- Arif M, Bendi D, Sawhney A, Iyer KC(2012) State of off-site construction in India-Drivers and barriers. J Phys Conf Ser 364:1-9.

- Jha KN, Devaya MN (2008) ‘Modelling the risks faced by Indian construction companies assessing international projects’.Constr Manag Econ 26:337-348.

- Tiwari P (2001) ‘Energy efficiency and building construction in India’. Build Environ 36:1127-1135.

- Auti A, Skitmore M (2008) Construction Project Management in India. Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Int J Constr Manag 8:65-77.

- Yang LR, O’Connor JT, Chen JH(2007) ‘Assessment of automation and integration technology’s impacts on project stakeholder success’. Autom Constr 16:725-733.

- NadimW, Goulding JS (2011) ‘Off-site production: A model for building down barriers A European construction industry perspective’. Eng Constr Archit 18:82-101.

- Durdyev S, Ismail S (2019) Off-site Manufacturing in the Construction Industry for Productivity Improvement. Eng Manag J 27:1-14.

- Kamar KM, Alshawi M, Hamid ZA (2009) ‘Barriers to Industrialized Building System (IBS): The Case of Malaysia’,in Built and Human Environment 9th International Postgraduate Research Confrence (IPGCR 2009).

- Blismas N, Pasquire C, Gibb A(2006) Benefit evaluation for off-site production in construction. Constr Manag Econ 24:121-130.

- Smith R, Narayanamurthy S(2008) Prefabrication in Developing Countries: A Case Study of India.

- Goodier C, Gibb A (2005) ‘Barriers and Opportunities for Offsite in the UK’, Abdul Samed Kazi,ed. Systematic Innovation in the Management of Project and Processes, 11th Joint CIB International Symposium, 13-16 June 2005, pp. 148–158.

- PanW, Gibb AG, Dainty AR (2008) ‘Leading UK housebuilders ’ utilisation of off-site modern methods of construction’. Build Res Inf 36:56-67.

- Zhai X, Reed R, Mills A (2014) ‘Factors impeding the off-site production of housing construction in China: An investigation of current practice’. Constr Manag Econ 32:40-52.

- Yin RK (2018) Case Study Research and Applications, Case Study Research and Applications: Design and Methods.

- Fellows R (2009) Advanced Research Methods in the Built Environment. Constr Manag Econ 27: 605-609.

- Buchanan C, Gardner L (2019) Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng Struct 180:332-348.

- Rahman MM (2013) ‘Barriers of Implementing Modern Methods of Construction’. J MANAGE ENG 30:69-77.

- Gibb A, Isack F (2003) ‘Re-engineering through pre-assembly: Client expectations and drivers.Build Res Inf 31:146-160.

- Tam VWY,Tam CM, Zeng SX , Ng WCY(2007) ‘Towards adoption of prefabrication in construction’. Build Environ42:3642-3654.

- Azman MNA, Ahamad MSS, Majid TA, Hanafi MH (2010) The common approach in off-site construction industry. Aust J Basic & Appl Sci 4: 4478-4482.

- Zhang W, Lee MW, Jaillon L, Poon CS (2018) ‘The hindrance to using prefabrication in Hong Kong’s building industry.J Clean Prod 204:70-81.

- Xiao H, Proverbs DG(2003) ‘Cost Certainty and Time Certainty: an International Investigation’Association of Researchers in Construction Management, 1(September), pp. 3–5. Â

- Jaillon L, Poon CS, Chiang YH (2009) ‘Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong’.J Waste Manag 29:309-320.

- Gong P, Teng Y, Li X, Luo L (2019)‘Modeling constraints for the on-site assembly process of prefabrication housing production: A social network analysis’.Sustainability (Switzerland)11:1-20.

- Mtech Consult Limited (Mtech) (2009) Offsite and MMC in affordable housing. Shrewsbury, U.K.

- Badir Y, Kadir MRA,Hashim AH(2002) Industrialised building systems construction in Malaysia. J Archit Eng 8:1-6.

- Deepthi B, Rana MQ, Arif M, Goulding J, Sawhney A (2020) An off-site construction readiness maturity model for the Indian construction sector. Constr Innov 21:123-142.

- Friedman K (2003) Theory construction in design research Criteria: Approaches, and methods. Des Stud 24: 507-522 .

- YinRK (2013) ‘Applications of case study research’, Applied Social Research Methods Series.Â

- Building Research Establishment (BRE) (2007) Modern methods of construction (MMC) in housing: Parts I-IV. Watford, U.K.

Citation: Rana MQ, Bendi D, Arif M, Oladinrin O, Kaushik A (2021) Assessing Off- site Readiness in Construction Organisations from the Contractors' Perspective: A Case Study from India. J Archit Eng Tech 10: 250. DOI: 10.4172/2168-9717.1000250

Copyright: © 2021 Rana MQ, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 1803

- [From(publication date): 0-2021 - Nov 21, 2024]

- Breakdown by view type

- HTML page views: 1358

- PDF downloads: 445