Research Article Open Access

Analytical Framework for the Assessment of Crop Production Technology

Janusz Gołaszewski1*, Dariusz Załuski1 and Krystyna Żuk-Gołaszewska21Department of Plant Breeding and Seed Production, University of Warmia and Mazury in Olsztyn, Poland

2Department of Agrotechnology, University of Warmia and Mazury in Olsztyn, Poland

- *Corresponding Author:

- Janusz Gołaszewski

Department of Plant Breeding and Seed Production

University of Warmia and Mazury in Olsztyn

Plac Łódzki 310-724 Olsztyn, Poland

Tel: +48895234805

E-mail: janusz.golaszewski@uwm.edu.pl

Received date: February 01, 2017; Accepted date: February 20, 2017; Published date: February 27, 2017

Citation: Gołaszewski J, Załuski D, Żuk-Gołaszewska K (2017) Analytical Framework for the Assessment of Crop Production Technology. Adv Crop Sci Tech 5:257. doi: 10.4172/2329-8863.1000257

Copyright: © 2017 Gołaszewski J, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Advances in Crop Science and Technology

Abstract

The objective of the study was to compile a methodical approach for a time-and-cost-efficient test of a crop production technology. The two or three-year procedure consisted of: (i) a survey among farmers on the technological state-of-the-art, (ii) screening the selected agro-technical factors with the use of factorial (FD) and/or fractional factorial design (FFD), (iii) a series of on-farm FD and FFD experiments and estimation of the total and individual contribution of the factors into costs and profitability of production. The test crop for verification of the procedure was pea (Pisum spp.). The approach is illustrated by empirical data obtained from the implementation of the procedure for testing of a green pea production technology in north-eastern Poland. The statistical efficiency and economic profitability of agrotechnical factors in the tested technology were given.

Keywords

Smart agriculture; Agricultural experimentation; Survey in agriculture; Factorial and fractional designs; On-farm experiment

Introduction

There is an ongoing process in agriculture to bring the growing demand for higher yields and changing preferences for agricultural products together with improved efficiency of crop production [1,2]. Any modification of the crop production technology involves testing a set of agro-technical factors in a given local habitat and for environmental conditions. It suggests that changes in agro-technical factors, such as machinery, cultivars, fertilizers, pesticides, etc. should be validated with a cost-and-time-efficient empirical testing procedure. There is no prompt methodical approach for screening the interaction between specific agro-technical factors in order to design a new technological process and implement it into agricultural practice. Instead, there is a common practice to conduct single or two-factor field experiments in research stations or to compare the reduced number of technologies, e.g., “traditional” and “new” ones, in a single replicated on-farm comparative field demonstration.

The initial problem in validation of new crop production technology is associated with the selection of key factors responsible for an anticipated level and/or quality of yield and testing them under farm conditions. Useful tools in solving these problems are factorial designs (FD) of type sk (k factors on s levels) or fractional factorial designs (FFD) of type sk-p (p is a fraction of sk) Box and Hunter, Za┼?uski and Go┼?aszewski, Za┼?uski et al. [3-5] and on-farm experiments e.g., On-Farm Trials - Some Biometric Guidelines [6], Blaise et al., Gomez and Gomez, Byerlee, Amir and Knipscheer, Liu et al., Barlow et al. [7-12].

Certain methodological and economical considerations limit the broad application of FDs in agricultural experiments. The higher the number of factors and their levels in an experiment, the higher the number of treatments to be tested and the greater influence of soil variability on the experimental results. At the same time, the cost of the experiment rises.

On-farm experiments include methods, tools and techniques which may be easily applied in the environmental and organizational conditions of a given farm [7,8]. Hence, methodical assumptions of on-farm research should be applied to the production activity of a given farm and consideration given to the self-evident prerequisites of such activity, including the interest of farmers and available farm machinery. In substance, an initial prerequisite for on-farm research related to plant production technology is verification of a given technology in agricultural practice [9]. In such cases the methodical approach is substantially different than in classic field experimentation. Excluding tested factors, all the remaining factors should be taken at the levels of present farm technology - which means the traditional crop production technology at the farm level.

An indispensable part of the on-farm experimentation methodology is the calculation of technology modification costs. Several authors Amir and Knipscheer; Liu et al.; Barlow et al. [10-12] have discussed some practical issues in improving the economic impact of farming system research with respect to three stages: the ex-ante stage - securing representativeness of the target area, the ongoing stage - using suitable partial budgeting techniques, ex-post stage - an assessment of the wider technological and economic effects together with the identification of enabling and constraining factors in the technological progress.

It is presupposed that the number of treatments and replications of on-farm experiments should be at a minimum. An extreme case is when only two technologies are compared, which results in a relatively low research utility because the main function of such an experiment is a demonstration of new technology.

The objective of this study was to present a methodical approach for testing new crop production technology. The test crop was pea (Pisum spp.). The consecutive stages of the procedure assume: 1) detection of the key technology factors on the basis of the results from on-farm survey and FFD field experiments. 2) implementation of the key factors into a series of FD and FDD on-farm experiments 3) calculation of the contribution of the individual agro-technical factors and profitability of the new technology.

Materials and Methods

The results of a questionnaire survey and field experiments according to FFD illustrate an approach in detection of the key factors of technology.

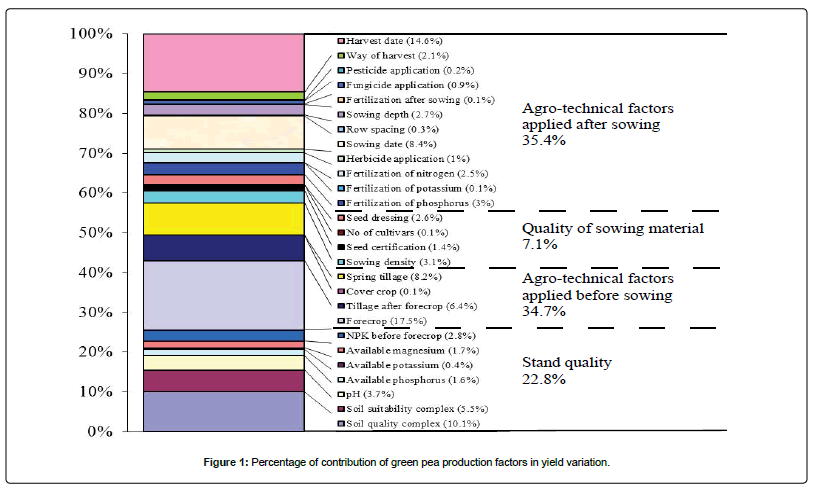

The survey data on pea production technology was collected in the north-eastern part of Poland (2006). It was carried out on 243 farms with a total area 3896 ha and an average yield of 6.20 t ha-1 (SE=0.124). Only pea crops produced for consumption and contracted by the local processing industry were considered. This type of production was represented by 75% of farms and accounted for 86% of the surveyed area at the average yield 6.73 t ha-1 (SE=0.104). The other surveyed plantings produced fodder pea as dry seeds. The survey questionnaire addressed 27 production factors assigned into four groups: stand quality, agro-technical factors applied before sowing, quality of sowing material, and agro-technical factors associated with sowing and chemical application(s) after sowing (Figure 1). The on-research-station study is represented by data obtained from two-single-replicated factorial experiments of type 35-1 arranged in completely randomized designs. These experiments were carried out in 2003 and 2004 at the Tomaszkowo Experimental Station (53°42’N, 20°26’E). In the experiments, five experimental factors had 3 variants: A - cultivars (Kos, Stig, Set), B - phosphorus and potassium fertilization doses (natural fertility, 70 kg P·ha-1 and 100 kg K·ha-1, and 100 kg P·ha-1 and 130 kg K·ha-1), C - sowing dates (the earliest possible, 10, and 20 days after the first date, respectively), D - sowing densities (70, 100, 130 kg·ha-1), and E - chemical protection (without protection, seed chemical protection, seed and plant chemical protection).

The factors responsible for a high variability of pea yield were selected for testing in on-farm experiments (2007). It was planned that a distributed system of on-farm experiments would be built on the basis of the FD of type 23 and FFDs of type 23-p and located at different farms while taking into account the organizational customizability of a given farm. The farms were typified in cooperation with the Warmian Fruit and Vegetable Processing Company, Ltd. in Kwidzyn, Poland. Three factors (A, B, C) were selected for testing in on-farm experiments on the basis of generalized results from the survey and research-station FFD experiments (Table 1):

| Experiment* | Factor-treatment | A-t | A-t | A-n | A-n |

|---|---|---|---|---|---|

| B-t | B-n | B-t | B-n | ||

| xE2 (4 sites) (nnn, ttt) |

C-t | ttt | - | - | - |

| C-n | - | - | - | nnn | |

| xE5 (1 site) (nnn, nnt, ntn, tnn, ttt) |

C-t | ttt | - | - | nnt |

| C-n | - | tnn | ntn | nnn | |

| xE8 (1 site) (nnn, nnt, ntn, tnn, ttn, tnt, ntt, ttt) |

C-t | ttt | tnt | ntt | nnt |

| C-n | ttn | tnn | ntn | nnn |

*xE2 â┬?┬? symbol x means the number of farms, E2 means the experiment with 2 treatments. As an example, treatment â┬?┬?tntâ┬?┬Ł for factors A,B,C means technology where factor A is at the level â┬?┬?traditionalâ┬?┬Ł (t), B â┬?┬? â┬?┬?newâ┬?┬Ł (n), and C â┬?┬? â┬?┬?traditionalâ┬?┬Ł (t).

Table 1: The scheme of six on-farm experiments with 2-, 5-, and 8-treatments.

Fertilization of P and K: “t” - average level of fertilization in farms; “n” – doses of P and K per hectare were increased by 25 kg of P and 20 kg of K, N was fixed - 50 kg.

Sowing date: “t” - the earliest possible, “n” - 10 days after the first date.

Plant protection: “t” - traditional farm approach, “n” full protection (seed dressing, herbicide, fungicide).

At each farm the experiments were replicated in the 2 fields.

Statistical analyses

In the survey analysis, the total variability of yield was fractionated into the contributions of production factors by the use of General Linear Model (GLM). The efficiency of parameter estimation was maximized by using the weighted least squares method with hectares as weights [13]. The sums of Type-III squares in the ANOVA model and those coefficients η2 (eta square) displaying the relative contribution of a given factor were calculated according to (1) [14].

(1)

(1)

where: SSEffect is the sum of squares of a given effect, and SSModel is the sum of squares. The statistical analyses were supported by STATISTICA v. 9.1 (StatSoft, Inc.).

Results

Survey

All the studied factors of the green pea production technology contributed 40.1% to the yield variation. The further decomposition of this variation showed that factors associated with stand quality, agricultural activities before sowing, quality of sowing material, and application after sowing contributed in 22.8, 34.7, 7.1, and 35.4 percent, respectively (Figure 1).

The soil gradation and the complex of agricultural suitability had the highest impact on yield variation and its suitability for pea production (stand quality). This was followed by forecrop and tillage after forecrop harvesting (before sowing), seed dressing, sowing density, fertilization of phosphorus, dates of sowing and harvest (seed quality and treatments after sowing).

FFDs

The on-research-station studies on the key agro-technical factors of green pea production are represented by data from the two-year series (E03, E04) of two 35-1 FFD experiments.

On-farm research

The treatment means from experiments fluctuated greatly between the very high yield of 8.30 t ha-1 in 1E2 and the very low yield of 1.69 t ha-1 in 5E5 (Table 2). In general, yields in experiments E5 and E8 were significantly lower than in experiments with two treatments but the difference between yields of traditional (T) and new (N) technology (technology difference N-T) was nearly at the same level. The only exception was experiment 1E2 where the difference N-T exceeded the others by about twice the amount.

| Experiment | Mean | Treatments | Technology difference | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| nnn | nnt | ntn | ntt | tnn | tnt | ttn | ttt | nnn-ttt | ||

| 1E2 | 7.58 | 8.30 | - | - | - | - | - | - | 6.85 | 1.45 |

| 2E2 | 7.00 | 7.38 | - | - | - | - | - | - | 6.62 | 0.77 |

| 3E2 | 5.82 | 6.14 | - | - | - | - | - | - | 5.50 | 0.65 |

| 4E2 | 4.61 | 4.97 | - | - | - | - | - | - | 4.24 | 0.73 |

| 5E5 | 2.09 | 2.45 | 2.13 | 2.15 | - | 2.03 | - | - | 1.69 | 0.76 |

| 6E8 | 2.13 | 2.50 | 2.15 | 1.94 | 2.44 | 1.90 | 2.11 | 2.09 | 1.88 | 0.63 |

| Average | 4.87 | 5.29 | 2.14 | 2.04 | 2.44 | 1.97 | 2.11 | 2.09 | 4.46 | 0.83 |

Table 2: Mean yields and technology difference in on-farm experiments.

The main and interactional effects estimated for experiments E5 and E8 (Table 3) were the basis for the calculation of the contribution of each factor to the technology. This was then used to assess the relative costs of modifying the technology. The contribution of factors and their interactions (experiments E5 and E8) to N-T technology differences was measured with estimates of main and interaction effects. Fertilization (A, 33%) had the highest contribution, followed by sowing date (B, 15%) and chemical protection (C, 9%). Among the interactions, fertilization × sowing date × chemical protection (ABC, 28%) and sowing date × chemical protection (BC, 13%) also had significant contributions.

| Effect | 5E5 | 6E8 | Average mean and interaction effects | Adjusted average mean and interaction effects* |

|---|---|---|---|---|

| A | 0.275 | 0.265 | 0.270 | 0.273 |

| B | 0.160 | 0.080 | 0.120 | 0.121 |

| C | 0.180 | -0.035 | 0.072 | 0.073 |

| AB | 0.058 | 0.057 | 0.058 | |

| AC | 0.038 | -0.038 | -0.038 | |

| BC | 0.108 | 0.108 | 0.109 | |

| ABC | 0.145 | 0.315 | 0.230 | 0.233 |

| Sum of average contribution of main and interaction effects into the difference N-T | 0.82 | 0.83 | ||

*Average effects from experiments were adjusted to the average difference N-T (0.83)

Table 3: Main and interaction effects in on-farm experiments.

Extra fertilization which involved costs of fertilizers and their application was done at the average cost €9, 82 ha-1 (recalculated from 39.29PLN - Polish zloty) (Table 4). Sowing date was a non-cost factor. Decisively, the highest costs were of intensified chemical protection, i.e., fungicides and their application; on average €43.75 ha-1. The total additional costs in new technology accounted for €53.57 ha-1.

| Rates of return of additional costs on new technology, rates of return of additional costs on new technology per test factor | ||||||||||||

| Experiment | Technological difference N-T (t ha-1) |

Sale price â┬?¬ t-1 |

Added return â┬?¬ t-1 |

Added profit â┬?¬ t-1 |

Marginal benefit-cost ratio | |||||||

| 1E2 | 1.45 | 160 | 232 | 178 | 4.33 | |||||||

| 2E2 | 0.77 | 160 | 122 | 69 | 2.29 | |||||||

| 3E2 | 0.65 | 165 | 106 | 53 | 1.99 | |||||||

| 4E2 | 0.73 | 165 | 120 | 67 | 2.25 | |||||||

| 5E5 | 0.76 | 163 | 124 | 70 | 2.31 | |||||||

| 6E8 | 0.63 | 163 | 102 | 48 | 1.90 | |||||||

| Mean | 0.83 | 163 | 134 | 81 | 2.51 | |||||||

| Rates of return of additional costs on new technology per test factor | ||||||||||||

| Experiment | Added return | Added profit | Marginal benefit-cost ratio | |||||||||

| A | B | C | A | B | C | A | B | C | ||||

| 5E5 | 44.69 | 26.00 | 29.25 | 34.88 | 26.00 | -14.50 | 4.56 | 0.00 | 0.67 | |||

| 6E8 | 43.06 | 13.00 | -5.69 | 33.26 | 13.00 | -49.44 | 4.39 | 0.00 | -0.13 | |||

| Mean | 43.88 | 19.50 | 11.78 | 34.07 | 19.50 | -31.97 | 4.47 | 0.00 | 0.27 | |||

| Adj. factor* | 1.79 | 3.74 | 0.53 | |||||||||

| Adj. mean | 78.46 | 34.87 | 21.07 | 127.50 | 72.98 | -119.64 | 2.37 | 0.00 | 0.14 | |||

*adjusting factor results from division of mean added return, added profit and marginal rate by the relevant sum of mean effects for factors A, B, and C, i.e., for added return: 134.39/(43.88+19.50+11.78)=1.79

Table 4: Summary of economic outputs.

The individual contributions of tested factors were estimated using the results from FD and FFD on-farm experiments. In the analysis of added return for each factor in experiment E8, there are noticeable negative values for added return, added profit and marginal ratio for chemical protection (C). The low economic effect stems from the fact that yields in this FD experiment were relatively low and did not compensate for the high costs of fungicides. In addition, as mentioned, interactions BC and ABC had a relatively high share in yield variation, which could have diminished the main effect of C and may indicate the necessity of an analysis of interactions with other factors. The marginal benefit-cost ratio for fertilization was 2.00 and for chemical protection 0.12.

At an average technological difference of 0.83 t ha-1, the average added return and added profit were €134 t-1 and €81 t-1, respectively. The marginal rate across the experiments was 2.51, which means that each €1 invested in new technology gave €2.51 in return.

Discussion

This paper presents a methodical procedure for engineering crop production technology in a two-stage process, which consists of detecting key agro-technical factors of a given technology which contributes the most to yield variation and verifying them in the conditions of agricultural practice. The procedure is composed o fthree consecutive research methods: a survey of the state of the art of technology and/or on-research-station factorial experiments at the first stage, and a system of on-farm factorial experiments at the second stage. The information provided by these methods is complementary but the crucial stage of this approach is associated with on-farm research.

The use of on-farm field experiments in agricultural experimentation is considered a very useful tool at any stage of research. However, it also underlines the difficulty of testing crop production technology within differentiated farm conditions [2,15-18]. Some of the technologies developed by agricultural scientists in the conditions of experimental stations do not work in practice and some of them may be unique to a specific location of the station and have to be (re)developed from the beginning [19-21].

In this paper, the developed system of various full and fractional factorial designs for testing crop production technology in on-farm experiments was based on the results of a thorough survey study and fractional factorial experiments at a plot scale. A similar compilation of different research methods for an integrated agricultural technology developed system was proposed by Biggs [22], who combined exploratory surveys, diagnosis of farmers’ problems, on-farm experiments and development feedback systems. Byerlee et al. [9] distinguished the two main objectives of on-farm research; increasing the body of knowledge and solving specific problems in the farming systems. These authors argued that location-specific research with a short-term objective of developing improved technologies for a target group of farmers and research conducted over a longer time (to overcome major, widespread constraints in farming systems) are part of an integrated research system in which area-specific research provides the basis for defining longer-term research priorities. Another model for generating an acceptable agricultural technology was developed by Rhoades and Booths [23] and stresses that applied research must begin and end with the farmer.

In our studies the test crop was Pisum sativum L. sensu lato cultivated for food use. The study was conducted in the north-eastern part of Poland and covered farms which contracted their production to the local vegetable processing company. The results of the studies from the survey and field plot experiments enabled the identification of key factors responsible for high yields, construction of factorial experimental designs, and eventual implementation of the system of experiments on farms. The system is composed of factorial and fractional designs based on a plan of full factorial design 23. Such a systemic approach was advantageous both from the point of view of organization of the research, as well from the point of view of farms where the experiments were located. It was done in an attempt to improve the efficiency of on-farm experiments by implementation of covariates associated with spatial variation of soil properties into statistical analysis. However, the results were not satisfactory. A possible reason for this was the number of on-farm experiments and replications per experiment was too small to prove the effects of spatial covariates because of the small number of degrees of freedom for experimental error.

Field experiments conducted on farms are not common practice in Poland. In general, demonstration experiments involving only two or three treatments without replications or with quasi-replications is rather easily accepted by farmers. However, in the case of most advanced designs requiring some extra organizational activities, and usually extra expenditures, the motivation for experimentation is relatively low. In the current study, only two advanced experiments (E5 and E8) were established on farms. Despite this, the data from the experiments enabled estimation of significant sources and their contribution to yield variation. The farmers’ participation in the experiment was crucial for the successful introduction of the proposed experimental system. Some authors report that this is generally advantageous because the farmers’ participation in on-farm experiments requires fewer resources and less time than on-research-station or diagnostic survey research [24].

Conclusions

On the basis of the results presented in this paper some methodical conclusions may be drawn.

Survey studies and on-research station multifactorial experiments are effective tools in screening agro-technical factors in the context of crop production technology and detection of key factors responsible for high yield variation. Both the research methods are confirmative and validate each-other.

ANOVA of data from the survey, together with eta-square estimates enables the fractionation of production factors and reveals the structure of their contribution into yield variation.

Single two-treatment experiments with alternative technologies (traditional, new) should be established at as many sites as possible because they are the basis of overall information on the technology gap. In addition, they are the reference point for correction of a single contribution of factors and their interactions to the gap.

The system of FD and FDD on-farm experiments is universal and scalable for a higher number of factors.

The system of on-farm experiments enables flexible organization of experiments, depending not only on the interests of farmers and organizational capacity of farms, but also on the methodical assumptions of research and available funds.

The efficiency of the system is high because the experiments may be analyzed in multiple ways: as a single realization or configured in different sets of experiments (i.e., at the local administration level, for different soils, etc.). It is worth noting that the efficiency of the system and its information provided will be higher, together with the higher number of farms engaged in on-farm experimentation.

The proposed procedure may be adopted by processing companies which contract feedstock from farmers. This is because, for a given feedstock the crop production technology at the contracted farms is common and uniform and any innovative changes in production factors may be quickly and efficiently verified, e.g., when a new production factor should be tested.

Acknowledgements

Funding for this research was provided by the Ministry of Science and Higher Education, Grant No. MSzWiN 529-108-0913. This paper benefited from the discussions and assistance of the representatives of Warmian Fruit and Vegetable Processing Company, Ltd. in Kwidzyn and associated farmers. The authors would like to express special acknowledgements to PhD Student Anna Zar─?ba and the farmers: Arkadiusz Piskorski (Kwidzyn), Lucjan Kossobudzki (Jazowa), Wies┼?aw Szpura (Królewo), and Leszek Grenda (Stare Pole).

References

- Clay DE, Shanahan JF (2011) GIS Applications in Agriculture. Volume II: Nutrient Management for Energy Efficiency. CRC Press, Taylor & Francis Group.

- Golaszewski J, Zaluski D, Zuk-Golaszewska K, Grzela K (2013) Geostatistical methods as auxiliary tools in field plot experimentation. In: Stafford JV (ed.), Precision Agriculture â┬?┬?13. Wageningen Academic Publishers, pp: 499-506.

- Box GEP, Hunter JS (1961) The 2k-p Fractional Factorial Designs Part I. Technometrics 3: 311-351.

- Zaluski D, Golaszewski J (2006) Efficiency of 35-p fractional factorial designs determined using additional information on the spatial variability of the experimental field. Journal of Agronomy and Crop Science 192: 303-309.

- Zaluski D, Golaszewski J, Stawiana-Kosiorek A, Zareba A (2006) Full and fractional design in the practice of field experimentation. Advances in Agricultural Sciences 1: 39-47.

- Zaluski D, Golaszewski J (2006) Efficiency of 35-p fractional factorial designs determined using additional information on the spatial variability of the experimental field. Journal of Agronomy and Crop Science 192: 303-309.

- Blaise D, Majumdar G, Tekale KU (2005) On-farm evaluation of fertilizer application and conservation tillage on productivity of cotton+pigeon pea strip intercropping on rainfed Vertisols of central India. Soil and Tillage Research 84: 108-117.

- On-Farm Trials - Some Biometric Guidelines (1998) Statistical Services Centre, University of Reading, UK, p: 16.

- On-farm evaluation of fertilizer application and conservation tillage on productivity of cotton+pigeon pea strip intercropping on rainfed Vertisols of central India. Soil and Tillage Research 84: 108-117.

- Gomez AG, Gomez AA (1984) Statistical procedures for agricultural research. John Wiley and Sons Inc.

- Byerlee D, Harrington L, Winkelmann D (1982) Farming system research: Issues in research strategy and technology design. American Journal of Agricultural Economics 65: 897-904.

- Amir P, Knipscheer HC (1989) Conducting on-farm animal research: procedures and economic analysis. Winrock International Institute for Agricultural Development, Morrilton, USA. International Development Research Centre, Ottawa, Canada.

- Liu Y, Swinton SM, Miller NR (2006) Is Site-Specific Yield Response Consistent over Time? Does It Pay? American Journal of Agricultural Economics 88: 471-483.

- Barlow C, Jayasuriya SK, Price E, Maranan C, Roxas N (1986) Improving the economic impact of farming systems research. Agricultural Systems 22: 109-125.

- Carroll RJ, Ruppert D (1988) Transformation and Weighting in Regression. Chapman and Hall, New York, USA.

- Greenacre M, Blasius J (2006) Multiple correspondence analysis and related methods. Chapman & Hall/CRC, Taylor & Francis Group, Boca Raton, London, New York.

- Farrington J (1988) Farmer participatory research. Editorial introduction. Experimental Agriculture 24: 269-279.

- Hildebrand PE, Poey F (1985) On-farm agronomic trials in farming systems research and extension. Lynne Rienner Publishers Inc., Boulder, CO, USA, p: 162.

- Scherr SJ (1991) On-farm research: the challenges of agroforestry. Agroforestry Systems 15: 95-110.

- Golaszewski J, Voort MVD, Meyer AA, Baptista F, Balafoutis A, et al. (2014) Comparative analysis of energy efficiency in wheat production in different climate conditions of Europe. Journal of Agricultural Science and Technology B 4: 632-640.

- Sumberg J, Okali C (1988) Farmers, on-farm research and the development of new technology. Experimental Agriculture 24: 333-342.

- Matlon P, Cantrell R, King D, Benoit-Cattin M (1984) Coming full circle: Farmersâ┬?┬? participation in the development of technology. IDRC-189e, Ottawa, Canada.

- Stroud A (1993) Conducting on-farm experiments. CIAT Public, No 228.

- Biggs SD (1980) On-farm research in an integrated agricultural technology developed system: Case study of triticale for the Himalayan hills. Agricultural Administration 7: 133-145.

Relevant Topics

- Agricultural science

- Agronomy

- Climate impact on crops

- Crop Productivity

- Crop Sciences

- Crop Technology

- Field Crops Research

- Hybrid Seed Technology

- Irrigation Technology

- Organic Cover Crops

- Organic Crops

- Pest Management

- Plant Genetics

- Plant Breeding

- Plant Nutrition

- Seed Production

- Seed Science and Technology

- Soil Fertility

- Weed Control

Recommended Journals

Article Tools

Article Usage

- Total views: 3876

- [From(publication date):

February-2017 - Apr 04, 2025] - Breakdown by view type

- HTML page views : 2999

- PDF downloads : 877