Research Article Open Access

An IoT-Based Solution for Control and Monitoring of Additive Manufacturing Processes

Barbosa GF* and Aroca RVDepartment of Mechanical Engineering, Federal University of Sao Carlos, Brazil Washington Luis road, 310, São Carlos – SP, Brazil

- *Corresponding Author:

- Barbosa GF

Department of Mechanical Engineering

Federal University of Sao Carlos, Brazil Washington Luis road

310, São Carlos – SP, Brazil

Tel: (16) 3306-6426

E-mail: gustavofb@ufscar.br

Received date: February 13, 2017; Accepted date: March 06, 2017; Published date: March 16, 2017

Citation: Barbosa GF, Aroca RV (2017) An IoT-Based Solution for Control and Monitoring of Additive Manufacturing Processes. J Powder Metall Min 6:158. doi:10.4172/2168-9806.1000158

Copyright: © 2017 Barbosa GF, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

Day-by-day, industries are looking for digitizing their manufacturing processes, as well as introducing control and monitoring systems along the shop floor. Internet functionalities and data-based services have been introduced on processes in order to innovate the production based on the Industry 4.0 paradigm. This new concept, also named advanced manufacturing, digital factory or industrial Internet brings benefits for production processes and machines towards a complete value chain transformation with all, or most, information stored on cloud based services. This work presents a proof of concept system additive manufacturing machines management, where an Internet integration of beacon technology on manufacturing environment allows the communication of production data extracted from the machines with mobile devices in a fast and intuitive way. Information can be obtained through applications installed on mobile devices, providing real time indexes of productivity to managers or operators when they simply approach to the machines. The proposed solution aims to show the application of this technology in the manufacturing environment, where IoT (Internet of Things) linked to systems integration and cloud architecture, presents the benefits of the Industry 4.0 concepts. Finally, the gains in productivity and innovation obtained with the concepts of advanced manufacturing have been presented, to add value in term of growth and competitiveness for the companies in their manufacturing processes.

Keywords

Additive manufacturing; IoT; Manufacturing; Beacon; Bluetooth

Introduction

In the last ten years, a relevant transformation in our daily lives has been witnessed through the emergence of information and communication technologies. The computers are getting so small that they seem to disappear inside almost all our technical devices. In fact, it is known that more than 90% processors in the world are in embedded systems, such as machines or dedicated appliances. In addition to all that, things communicate on a worldwide network: the Internet. This trend has certainly also found way into industrial production, which has benefited more and more from advances in information technology. In Germany, this trend is called the 4th Industrial Revolution, in shorthand, Industry 4.0 [1].

This concept of Industry 4.0 is synonymous for the transformation of today’s factories into intelligent factories, which are designed to meet and exceed the current challenges of shorter product life cycles, highly customized products and tough global competition [2]. High product variability and the reduction of product life cycles require a flexible and agile production structure that can be quickly reconfigured to meet the new product demands. This degree of flexibility cannot be achieved by traditional automation. Instead, modular plant structures composed by intelligent devices, the so-called Cyber Systems (CPS), which are networked via the Internet of Things (IoT), are key elements to overcome the currently rigid planning and production processes [3].

In the scope of Industry 4.0, shop floor devices, machines, production modules and products are understood as CPS, which exchange information autonomously, triggering actions and controlling each other independently. Faced to this scenario, factories are developing into smart manufacturing environments, where the gap between the real world of the factory and the digital world are getting smaller and smaller. Thus, manufacturing systems are integrating intelligent processes that provide the ability to respond with flexibility, monitor interruptions and failures and generate indicators for production management.

On this way, the present research work presents a solution for the management of additive manufacturing processes, where the integration of the beacon technology in the productive environment, allows the communication of production data extracted from the machines through mobile devices, in a fast and intuitive way, allowing the monitoring of the production processes on real time. The integrated beacon technology solution with systems and devices, as well as cloud data storage, brings the benefits to the manufacturing environment in the ways of Industry 4.0. Moreover, the proposed system can be used also as a Human-Machine-Interface (HMI), where the machines don’t need to have physical HMIs, but only Internet connectivity. In that way, when the user approaches a machine, he can monitor its operation, but also change parameters, execute a STOP or HALT function, start a process or perform other actions.

Literature Review

Manufacturing is continually improving in the development of concepts for methods, processes and tools available for the production of consumer goods or sales. Currently, manufacturing is considered an integrated concept at all levels, from machines to production systems, reaching the global level of the operation [4].

In the post-World War II period, the growth of consumer demands has resulted in improvement of quality and best practices in operation management [5].

At the end of the 20th century, competition growth and the diversity of consumer demands due to globalization resulted in manufacturing processes managed according to indicators of quality, cost, delivery, flexibility, speed and reliability [6].

Industry 4.0

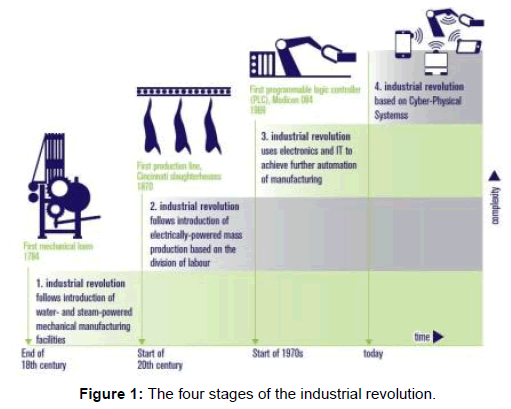

Industrialization began with the introduction of mechanical manufacturing equipment at the end of the 18th century, when machines like the mechanical loom revolutionized the way goods were made (Figure 1). Figure 1 shows the evolution of the industry along the time.

This 1st industrial revolution was followed by a 2nd one that began around the turn of the 20th century and involved electrically-powered mass production of goods based on the division of labor. This was in turn superseded by the 3rd industrial revolution that started during the early 1970s and has continued right up to the present day. This 3rd revolution employed electronics and information technology (IT) to achieve increased automation of manufacturing processes, as machines took over not only a substantial proportion of the “manual labor” but also some of the “brainwork”. Germany needs to draw on its strengths as the world’s leading manufacturing equipment supplier and in the field of embedded systems by harnessing the spread of the Internet of Things and Services into the manufacturing environment so that it can lead the way towards the 4th stage of industrialization, named Industry 4.0.

In an Industry 4.0 factory, machines are connected as a collaborative community. Such evolution requires the utilization of advanced prediction tools, so that data can be systematically processed into information to explain uncertainties, and thereby make more “informed” decisions. Cyber-Physical System-based manufacturing and service innovations are two inevitable trends and challenges for manufacturing industries [7].

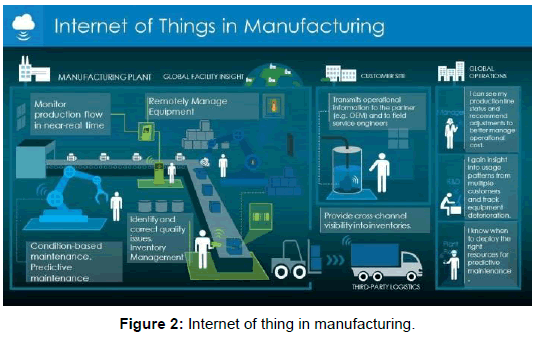

Inside this context, the Internet of Things and Services makes it possible to create networks incorporating the entire manufacturing process that convert factories into a smart environment. Cyber- Physical Production Systems comprise smart machines, warehousing systems and production facilities that have been developed digitally and feature end-to-end ICT-based integration, from inbound logistics to production, marketing, outbound logistics and service. This not only allows production to be configured more flexibly but also taps into the opportunities offered by much more differentiated management and control processes. In addition to optimizing existing IT-based processes, Industry 4.0 will therefore also unlock the potential of even more differentiated tracking of both detailed processes and overall effects at a global scale which it was previously impossible to record. It will also involve closer cooperation between business partners (e.g., suppliers and customers) and between employees, providing new opportunities for mutual benefit [8] (Figure 2). Figure 2 represents the application of IoT in manufacturing environment.

The trends in IoT technology impact the company at various levels of integration on manufacturing. In view of these trends, an evolution of industrial production systems brings some expected benefits [9,10]:

• Costs reduction energy saving

• Increase of security

• Environmental conservation reduction of errors

• End of waste

• Transparency in business increase in quality of life

• Customization and unprecedented scale.

The basic technology responsible for this concept of Industry 4.0 is the IoT (Internet of Things) that makes the logical connection of all the devices and means related to the productive environment, sensors, transmitters, computers, production cells, production planning system, strategic industry guidelines, government information, climate, suppliers, everything being recorded and analyzed in a database [11]. It should be noted, however, that the emergence of these connected machines raise serious security concerns that are clearly neglected today. In our experiments, it has been tested an industry leading CNC machine, that comes with Internet connectivity. The machine, by default can be remotely operated from anywhere on the Internet and comes without password.

With the solution proposed herein, machines can only be operated and monitored remotely with safe passwords. However, for daily use convenience, it has proposed the use of beacon technology that will allow control of monitoring of users that are considerably near the machine.

Beacon technology

Beacon is inside the scope of IoT. Beacon is hardware that uses Bluetooth Low Energy standard, with low power consumption with battery to transmit messages and information directly to a smartphone, tablet, device or another machine. It is small enough to be attached to a wall or countertop and is being used by stores and businesses that want to talk to consumers and their target audience as they go through the store. Apple is spreading this technology with the creation of iBeacon, which communicates with its devices from the iOS operating system. However, there are also many other manufacturers who have built beacons that can send messages to both Apple devices and other operating systems, such as Android [12-18].

In this concept, the signal is picked up by smartphones near places where the hardware is installed and using Bluetooth Low Energy (BLE) technology. When the mobile device detects the signal, it reads the ID number, calculates distance and, based on that data triggers an action in a mobile application compatible with the system. In addition, beacon technology also has the potential to send reminders and other fast communications to an organization’s employees as well as to industrial automation. In the direction of the Internet of Things (IoT), the beacon technology can be integrated into systems to monitors entertainment units, security systems, appliances, thermostats, accessories, surveillance cameras and more through smartphones. This exemplifies that the Internet of things is fast and enables the integration of the digital and physical worlds everywhere [19,20]. One beacon based application gaining much interest is the estimate of distance from beacons to devices. This is done by measuring the Received Signal Strength Indicator (RSSI) of each beacon near the user device.

Beacons are Bluetooth devices installed in strategic locations, with no need for power point or Internet access. Each beacon has a unique identifier (ID) that it transmits via Bluetooth. Mobile apps can receive this identifier and send it to the platform the data in cloud via 3G or Wi-Fi. The platform identifies what content is associated with that ID and user and returns the content to the user. This content can be available anywhere on cloud services, or directly on the machine itself. In that way, a beacon can have and directly provide information, or just provide a pointer to where information or control is available, such as a URL (Universal Resource Locator) (Figure 3). Figure 2 shows below how a beacon works.

The frequency of beacon transmission depends on your configuration, which can be changed depending on each specific device. The settings can influence the battery life.

Additive manufacturing

The rapid prototyping technologies increasingly as interesting technology in the additive manufacturing, since they use the technique of adding layers. These have major advantages over other processing methods due to the versatility in the production of free and complex shapes, by computer aided CAD/CAM.

With the progress of rapid prototyping, other names emerged to better express the technology that developers and users have thought better express it, translating succinctly all the capability required. They are: 3D printing, layer fabrication, manufacturing by layers, manufacturing of free forms and solid free training..

Considering the rapid prototyping nomenclature, a limited term, a technical committee formed by the body of the ASTM (American Society for Testing and Materials) agreed on a new technical term to be adopted, called Additive Manufacturing (AM). The purpose of this new nomenclature is clear that some machines with this technology can build final objects from part models generated in CAD without the need for further planning. Moreover, the problem of mentioning basic construction technique of this technology (overlapping layers) was resolved with the use of the new term.

In the manufacturing of a part held by additive manufacturing each technology shares the same technical guidelines: the computer analyzes a solid modeled on virtual environment (CAD) and it defines the manufacturing of the object through layer. These layers are systematically recreated and combined to form a 3D object.

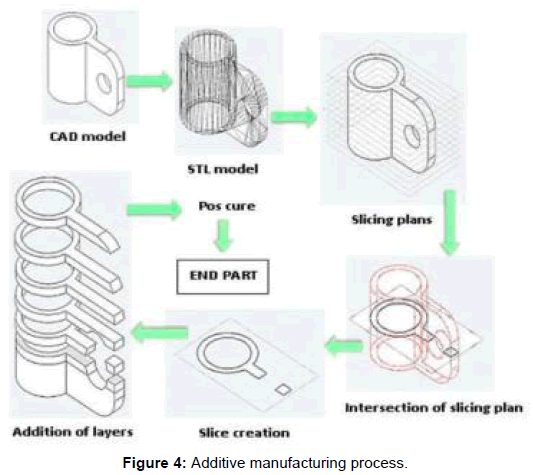

According to Busato [16], some stages of the process by addition of materials have been determined:

• Modeling for obtaining the 3D model on CAD system

• CAD models conversion to “STL” format (surface tessellation language or standard tessellation language); Check if no error occurred in the conversion

• Creation of fixtures

• Orientation to manufacturing (vertical/horizontal)

• Slicing and preparation for manufacturing (construction parameters and numerical control program); Manufacturing (model execution in machine)

• Post-processing (removal of fixtures and resin excess, postcuring and finishing of surface).

Additive manufacturing enables the fast, flexible and cost-efficient production of parts directly from 3D CAD data, a technology that helps you to perform your tasks in an innovative way (Figure 4). Figure 4 illustrates the steps of adding layers’ process from the design to the final part (end item):

All additive manufacturing equipment sold today is based on the concept “layer by layer” and the material to be processed is what makes these devices different. However, the additive manufacturing using metal alloys is still restricted to few components. Although media likes to use the term “3D Printing” as a synonym for all additive manufacturing processes, there are lots of individual processes which vary in their method of layer manufacturing. Individual processes will differ depending on the material and machine technology used. Hence, in 2010, the American Society for Testing and Materials (ASTM) group “ASTM F42 – Additive Manufacturing”, formulated a set of standards that classify the range of Additive.

Manufacturing processes into 7 categories [21].

VAT photo polymerization: Uses a vat of liquid photopolymer resin, out of which the model is constructed layer-by-layer.

Material jetting: Creates objects in a similar method to a twodimensional ink jet printer. Material is jetted onto a build platform using either a continuous or Drop on Demand (DOD) approach.

Binder jetting: Uses two materials: a powder based material and a binder. The binder is usually in liquid form and the build material in powder form. A print head moves horizontally along the x and y axes of the machine and deposits alternating layers of the build material and the binding material.

Material extrusion: Fuse deposition modelling (FDM) is a common material extrusion process and is trademarked by the company Stratasys. Material is drawn through a nozzle, where it is heated and is then deposited layer by layer. The nozzle can move horizontally and a platform moves up and down vertically after each new layer is deposited.

Powder bed fusion: Includes the following commonly used printing techniques: Direct metal Laser Sintering (DMLS), Electron Beam Melting (EBM), Selective Heat Sintering (SHS), Selective Laser Melting (SLM) and Selective Laser Sintering (SLS).

Sheet lamination: Includes ultrasonic additive manufacturing (UAM) and laminated object manufacturing (LOM). The Ultrasonic Additive Manufacturing process uses sheets or ribbons of metal, which are bound together using ultrasonic welding.

Directed energy deposition: covers a range of terminology: ‘Laser engineered net shaping, directed light fabrication, direct metal deposition, 3D laser cladding’ It is a more complex printing process commonly used to repair or add additional material to existing components.

Novel and Motivation

The proposed work has been motivated by the application of the beacon technology on manufacturing environment. Novelty can be the link of IoT (Internet of Things) to systems integration and cloud based on Industry 4.0 for a specific application to monitoring of additive manufacturing processes. It should be noted that many 3D printer equipment has no HMI or very limited HMIs, however, any operator usually has a tablet or smartphone that can be used as the machine’s HMI.

Contribution Proposed

The proposed work presents a new integrated concept for the management of additive manufacturing machines, where the application of beacon technology in the factory environment allows the communication of production indexes extracted from the machines via mobile devices. Processes data can be obtained by users through specific applications installed on mobile devices, providing production indicators on real time, as users approach to the machines with beacon installed. Each machine or object of interest receives a beacon. To implement the proposed application in this work, the concept of Physical Web was used, allowing users to have information at their fingertips. In addition to several IOT (Internet of Things) features, it was also designed for industry applications. One of the examples of the creators of the technology is “An industrial robot could display diagnostic information” [22].

Case study

The proposed system architecture was created and tested on a real environment with several possible situations. All systems rely on web interfaces that can be embedded on the machines, or available using an intermediate cloud service. The possible situations which are:

1. Manager/operator far from the machine can monitor and control the machine from a web interface using mobile devices or any computer, but with strong authentication mechanism;

2. Manager/operator can directly control and monitor machines by simply approaching the machine with a mobile device.

For the situation 2, there are two possible technical solutions. Both solutions are activated when a configured RSSI threshold level is detected, which maps to a certain distance. In that way, the system can be configurated to be activated in a certain range: from a few centimeters to some meters. When the configured threshold is detected, a background Android service, automatically launches the web browser, with a key to access the monitoring or control web interface, without password.

Here, two types of beacons can be used. Some beacons can broadcast an entire URL, such as the beacons that follow the Eddystone-URL or Ephemeral URL standards. These beacons can directly send the machine HMI Internet Address.

However, many other types of beacons can only broadcast an identified (ID). For such beacons, we have prepared an intermediate web service that acts as a “phone list directory” that maps beacons IDs to machine control URLs. In that way, when a beacon is detected, its ID is looked up in a database on the cloud that will provide the machine control and monitoring address.

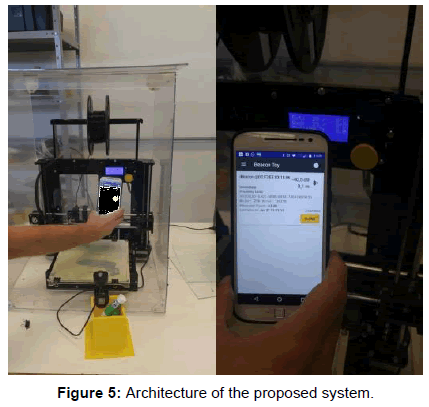

In order to validate the proposed concept, the beacon technology was integrated into an additive manufacturing process, with the objective of monitoring the variables of the FDM and VAT 3D printing processes.

The architecture shown in Figure 5 represents the integration of beacon technology with 3D printers on Wi-Fi and cloud, so that process monitoring can be performed on real time by users via mobile devices (Figure 5).

By setting the transmission power of the beacon, it is possible to set the reading distance from less than one centimeter up to several meters. This is an important security measure, since the low power ensures that only the proximity of a few centimeters makes the URL available, which defines the web address of monitoring and control. In any case, it is recommended to use a password on the web page, as it was used in the developed prototype.

Figure 6 illustrates the installation of beacon on a 3D printer as showed below, branded Sethi3D model AiP, as well as its communication with the smartphone when it approaches.

Each printer was equipped with a beacon (yellow circular device glued to the printer), which in turn continuously transmits the web address where information on use, diagnosis and even control of that machine is made available (Figure 6).

When approaching a mobile device (smartphone or tablet) that has “Physical Web” software installed, the device automatically detects the presence of the beacon and opens the webpage that provides the informative data and controls of the machine associated with the beacon.

Figure 5 shows the screen of the remote control and monitoring App for 3D printers, the Repetier Server (Figure 7).

For additive manufacturing processes, the monitoring software allows users to monitor some parameters, as follows:

• Estimated printing time

• ETE % of printing volume

• Heated bed temperature

• Current layer being printed Number of layers

• X, Y and Position Nozzle temperature Speed

• Cost of the part Volume

• Real time visualization of the process using a webcam

Furthermore, the user can also send commands to 3D printer by mobile device. Some of main commands are:

• Stop and start the printing process; Pause the process

• Modify bed or extruder temperature

• X, Y and Z position

• Go to home position

• Speed multiplier

• Flow multiplier

• Cooling multiplier.

Some of the mentioned commands are important to make quick adjustments during the printing process. In fact, it is common for an operator to notice some unwanted result in the printing process, and he may want to make a quick modification in the material flow rate, temperature or speed to improve the process quality, for example.

Frequently, the operator does not have a computer at that time, so he can approach a mobile device to the printer and make the needed adjustments quickly.

To implement a solution, some assumptions are necessary: the specification of Physical Web does not allow us to use beacons for unsafe web addresses. On this way, devices, machines and other devices must have a secure connection using SSL (Secure Socket Layer).

In addition, during the tests it was observed that some commercial beacons, of low cost, do not allow to make the broadcast of the web address. It was noted that the compatible beacons with Eddystone [23] are the most recommended for this type of application. In the unavailability of beacons, it can be used the “Beacon Toys” application for smartphone, which simulates beacons, allowing to perform proofs-of-concept without using real beacons. In addition to the “Beacon Toys” application, the Physical Web application was also used to detect the beacons and to open the control and monitoring web page associated with this beacon.

Also, the possibility of using non-compatible beacons with Eddystone was trialed, which proved possible, but with the need for an intermediate server. Because generic beacons do not store URLs, it is possible to use the beacons code and associate them with the machine’s web address through a relationship table that must be on a cloud server.

Finally, in order for the beacon to be detected and to lead to the page of interest, it was necessary to develop a specific application, which consults the mentioned database via Internet. Although not be a standard and not compliant with the standard, it is a viable solution due to lower cost, since generic beacons can be purchased at a lower cost than the Eddystone Beacons.

In order to progress these development, some trials have been started on others additive manufacturing machines as showed below in Figures 8 and 9.

It’s important to note that machines use a FDM and VAT processes respectively (Figures 8 and 9).

Regarding the data collection from the 3D printers, open architectures such as printers based on the Repetier Server system, allows full access to any printing parameter for the proposed system. Proprietary printers, such as the ones shown on Figures 8 and 9, have proprietary internal architecture, which does not allow direct access to printing parameters for the monitoring process.

On this way, a possible solution that has been evaluated is to install external sensors to infer the machine status and printing process. One example is the use of an electrical power sensor to monitor when the printing process starts and ends. Such sensor can also estimate power usage and electricity costs, and can be integrated in the proposed system, allowing it to be automatically shown on the mobile device’s screen when it approaches the machine that has the beacon installed.

Conclusion

The new era of Industry 4.0 is demanding new tools and technologies to allow operators, managers and engineers to have a better control and monitoring of the new processes that are becoming available every day. The Internet of Things comes as a solution to integrate and provide a better use of the resources on shop floor. Moreover, industrial machines typically have limited human machine interfaces (HMI), which area not standardized.

As a possible solution, this article proposes the usage of Bluetooth Low Energy Beacons, to allow mobile devices to automatically discover nearby machines and allow the user to monitor and control the machine from its own mobile device. The proposed system has been tested on open architecture 3D printers using Repetier Server software and a BLE Beacon.

By collecting data from the shop floor (processes, machines, etc.) and providing them to decision-makers on real time and at any place (by mobile devices), the manufacturing processes can be improved as exemplified in the case study.

Finally, it can be concluded that the concepts of Industry 4.0 can contribute significantly to assist the new manufacturing processes in several sectors of the industry, besides promoting gains such as productivity, standardization, ergonomics, flexibility, maintenance, labor and innovation mentioned in this research work, based on IoT that connects the digital and real worlds.

Acknowledgements

We would like to acknowledge the supports of Prof. Dr. Jonas de Carvalho (EESC – USP) in this research.

References

- Kagermann H, Wahlster W, Helbig J (2013) Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. Final Report of the Industrie 4.0 Working Group. Forschungsunion im Stifterverband für die Deutsche Wirtschaft e.V., Berlin

- Weyer S, Schmitt M, Ohmer M, Gorecky D (2015) Towards Industry 4.0 - Standardization as the crucial challenge for highly modular, multi-vendor production systems. Elsevier, IFAC-PapersOnLine 48: 579-584.

- Broy M, Kargermann H, Achatz R (2010) Agenda Cyber Physical Systems: Outlines of a new Research Domain. acatech, Berlin, Germany.

- Esmaeiliana B, Behdadb S, Wangc B (2016) The evolution and future of manufacturing: A review. Journal of Manufacturing Systems 39: 79-100.

- Voss CA, Tsikiktsis N, Frohlich M (2002) Case research in operations management. Int J Oper Prod Manag 22: 195e219

- Chowdary BV, George D (2012) Improvement of manufacturing operations at a pharmaceutical company: a lean manufacturing approach. J Manuf Technol Manag 23: 56e75.

- Lee J, Kao HA, Yang S (2014) Service innovation and smart analytics for Industry 4.0 and big data environment. Proceedings of the 6th CIRP Conference on Industrial Product-Service Systems

- Spur G (1997) The highest level of computerized factory organization is characterized by a strategy for integrating the individual subsystems. Optionen zukünftiger Produktionssysteme, Berlin, Akademie Verlag 23.

- Lasi H, Peter Fettke, Feld T, Hoffmann M (2014) Industry 4.0. Business & Information Systems Engineering pp: 239-242.

- Griffin T (2016) MW Smart Factory Information Technology Integration with Manufacturing.

- Venturelli M (2014) Indústria 4.0: Uma Visão da Automação Industrial. Automação Industrial. Controle de Processo. Acessado em

- Shishkovsky I (2001) Synthesis of functional gradient parts via RP methods. Rapid Prototyping Journal. 7, issue 4: 207-211.

- Tay BY, Evans JRG, Edirisinghe MJ (2003) Solid freeform fabrication of ceramics. International Materials Reviews 48: 341-370.

- Gibson I, Rosen DW, Stucker B (2010) Additive Manufacturing Technologies – Rapid Prototyping to Direct Digital Manufacturing. New York, Springer.

- Wohlers T (2008) Wohlers report 2008. Fort Collins, Colorado: Wohlers Associates.

- Busato FA (2004) Parâmetro de moldagem por injeção de termoplásticos em moldes fabricado por estereolitografia com resina Somos 7110. Universidade Federal de Santa Catarina, tese de mestrado, Florianópolis.

- EOS (2014) Additive Manufacturing.

- Rockheine (2016) Conheça o sistema beacon e saiba como ele entrará em sua casa. Disponível em

- Beekme (2016)

- Multibase (2016) Build better applications.

- ASTM F2792-12a (2012) Standard Terminology for Additive Manufacturing Technologies. ASTM International, West Conshohocken, PA.

- Physical Web (2016).

- Eddystone (2016) Specification for Eddystone, an open beacon format from Google.

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 7800

- [From(publication date):

April-2017 - Apr 21, 2025] - Breakdown by view type

- HTML page views : 6543

- PDF downloads : 1257