Air CO2 for the Manufacture of the Commodity Fuels

Received: 25-Apr-2022 / Manuscript No. OGR-22-61758 / Editor assigned: 27-May-2022 / PreQC No. OGR-22-61758(PQ) / Reviewed: 25-May-2022 / QC No. OGR-22-61758 / Revised: 31-May-2022 / Manuscript No. OGR-22-61758(R) / Accepted Date: 02-Jun-2022 / Published Date: 03-Jun-2022 DOI: 10.4172/2472-0518.1000243

Abstract

Carbon negative fuel isobutanol as the gasoline replacement has been described and the gas mileage was provided for the two cars: the 2020 Toyota Camry and the 2020 Porshe Cayenne Coupe Turbo. In addition, the gasoline replacement by carbon negative fuel diacetyl alcohol was tested. Upon reaching 20,000 miles for both said cars, the cars were examined by the independent mechanics from Toyota dealership and from the Porshe dealership. The same has been done on the similar cars the 2020 Toyota Camry and the 2020 Porshe Cayenne Turbo fed with the gasoline replacement diacetyl alcohol. The fifth corporate car 2020 Shevrolet Silverado 1500 was used to test the carbon negative diesel fuel replacement diacetyl alcohol for 10,000 miles. Diesel fuel replacement was made by condensing two acetone molecules into diacetyl alcohol used to replace diesel fuel. 2020 Shevrolet Silverado 1500 was tested by the Shevrolet mechanic. The mechanics did not identify any problems in said new engines of all the cars tested. Set of two additional cars Toyota Camry 2020 and Porshe CVayenne Coupe Turbo has been used to tested diacetyl alcohol as the gasoline replacement for the testing distance of 20,0000. The similar testing bu the certified mechanics was done for these two cars as well. Therefore, we offer diacetyl alcohol as the replacement for gasoline and the diesel fuel, which will resolve the existing currently the price challenge at the gas stations after the major political decisions of the elected country management in 2022.

Keywords: Carbon negative economy; carbon negative fuels; diacetyl alcohol from acetone made from the air CO2 as gasoline or diesel fuel; fuel isobutanol from the air CO2 as gasoline replacement replacement; replacement of current economy based on exhaustion of petroleum reserves

Keywords

Carbon negative economy; carbon negative fuels; diacetyl alcohol from acetone made from the airCO2 as gasoline or diesel fuel; fuel isobutanol from the airCO2 as gasoline replacement replacement; replacement of current economy based on exhaustion of petroleum reserves

Introduction

Major concerns of the environmental nature have been bothering Dr. Michael V. Tyurin since the year 2001 when he started working at Celanese Chemicals and became involved into the molecular biology and microbiology of Acetogens, the major lungs of Earth consuming annually tremendous amount of airCO2 in billion tons in the coastal areas of the Ocean where fresh water of rivers comes to contact with the salty sea water of the Ocean. The Author sincerely desires to resolve the catastrophic ecological problem Earth started experiencing lately after the intensified use of the combustion engines, requiring petroleum originated fuels, by the replacing of the petroleum as the feedstock for the gasoline or diesel fuel production by the airCO2 as the feedstock for the same purpose. Instead of gasoline from the petroleum the author has designed the proprietary procedure to manufacture the gasoline replacement fuel isobutanol from the airCO2. The manufacturing process is simple, environmentally friendly and may be located anywhere in the world with the preference the Author has given to the subtropical areas of the USA where the Sun gives enough free Sun light to power the solar panels to make the manufacture free or independent from the electric energy grid. As you know, at the Equator area of our planet Sun gives for free up to 1,330 W/h/m2 of the solar panels, assembled and arranged properly. The solution of that problem will be the relocation of the overcrowded Earth population reaching by 2050, 15 billion people to other planets similar to Earth by the temperature and the atmosphere composition or the dramatic reduction of the Earth population [1]. The last solution is immoral as therefore is not acceptable. The problem with the Earth overpopulation is that the people breath producing airCO2 and they burn gasoline and diesel fuel for the transportation needs, which produces enormous amounts of the airCO2 [1]. Following the concerns of Dr. Tyurin in 2000-2001, in 2010 HASA has bombarded the Moon surface (220000 miles from Earth) and found a lot of ice on its dark side [1]. The Moon worked as the fresh water trap in the Space vacuum collecting the water vapors flying around Earth. The environmental concern of Dr. Tyurin is the shortness of the fresh water on Earth because of its loss to the outer Space as depicted in Figure 1 below. The relocation of the overcrowded Earth population is desirable but not practically achievable since of the lack of the contemporary technology level and engineering knowledge preventing from the development of the efficient and fast enough spacecrafts. The Author has suggested the ultimate solution to the depicted environmental problem consisting in the replacement of the technology to manufacture of the existing fuels from distillation of petroleum to get the petroleum gasoline (C7 – C9 carbohydrates) and diesel fuel (C10-C12) fractions of petroleum by the technology to manufacture said gasoline and diesel fuel from the airCO2 [1] since NASA has called in 2010 the airCO2 content as the “Point of No Return” after discovering the airCO2 content above 400 ppm [1].

What is a fuel? A fuel is defined as a material that stores potential energy that, if released, can be used as the heat energy [2]. A fuel can be stored as a form of chemical energy which is released through combustion, or the nuclear energy which is the source of heat energy, and at times, chemical energy that is released through oxidation with or without combustion. Chemical fuels can be categorized into common solid fuels, liquid fuels and gaseous fuels, along with biofuels and fossil fuels. Furthermore, these fuels can be divided on the basis of their occurrence; primary – which is natural, and secondary – which is artificial. For example, coal, petroleum and natural gas are primary types of chemical fuels while charcoal, ethanol and propane are secondary types of chemical fuels [1, 2].

Alcohol is a liquid form of chemical fuel with the general formula of CnH2n+1OH and it includes common types such as methanol, ethanol, propanol and butanol isomers [3]. A significance of these four stated substances, known as the first four aliphatic alcohols [3], is that they can be synthesized both chemically and biologically, all have high octane ratings which increase the fuel efficiency, and exhibit/have properties that allow the fuels to be used in internal combustion engines [1, 4]. As stated, a form of liquid chemical alcohol fuel is butanol.

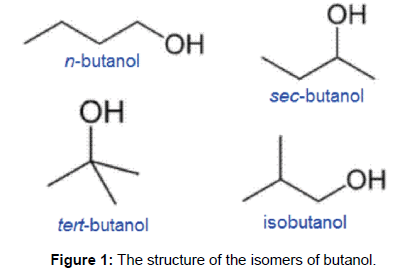

Butanol is a 4-carbon, flammable liquid (at times solid under negative temperatures) alcohol which has 4 possible isomers, n-butanol, secbutanol, isobutanol and tert-butanol [1, 4]. Its four link hydrocarbon chain is long, and as such, it is fairly non-polar [5]. Without any differences in chemical properties, it may be produced from both biomass, which it is known as ‘biobutanol’, and fossil fuels, becoming ‘petrobutanol’. A common method of production is, like ethanol, fermentation, and uses the bacterium Clostridium acetobutylicum to ferment the feedstock which may include sugar beet, sugar cane, wheat, and straw [1, 6]. Alternately, it’s isomers are industrially produced from propylene which undergoes the oxo process in presence of rhodium-based homogeneous catalysts, changing it to butyraldehyde and then hydrogenated to produce n-butanol; the hydration of either 1-butene or 2-butene to form 2-butanol; or deriving as a coproduct of propylene oxide production via isobutane, by the catalytic hydration of isobutylene and from a Grignard reaction of acetone and methylmagnesium to get the tert-butanol [1].

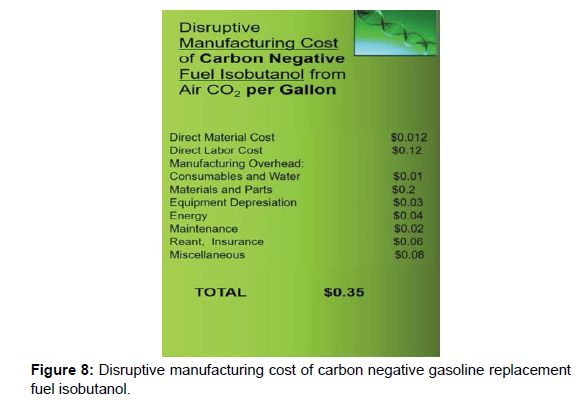

We herein describe the production and the use of fuel isobutanol or the fuel diacetyl alcohol from the concentrated t0 20% airCO2 (the balance is Hydrogen produced by the sea water electrolysis using energy from the solar panels). The manufacturing cost of fuel isobutanol as we have estimated that factor was $0.35 per gallon of the fuel isobutanol vs. over $1.70 all major petroleum corporations spend. However, they are much into the petroleum reselling business buying petroleum in Saudi Arabia for $20 per barrel and then selling it in the USA for $150 per barrel. They also have invested a lot into the refineries businesses. To build one refinery it costs over $500 millions (data of 2016) and every five years over $250 millions for the operation of the refinery [1]. All refineries produceCO2 during said petroleum distillation process coming to the air. Therefore, making fuel isobutanol from the airCO2 does not fit much the established economics of the modern petroleum businesses like SHELL, BP, etc.

The chemical structures of the butanol isomers follow a four chain structure as seen below, each showing different placement of the hydrocarbon (Figure 1).

The combustion energy of fuel butanol is represented by the following numbers for the isomers of butanol shown below as indicated in [1, 7]:

1-butanol: −2671 kJ/mol,

2-butanol: −2661.1 kJ/mol,

Isobutanol: −2662.6 kJ/mol,

Tert-butyl alcohol: −2644.8 kJ/mol

. The combustion energy of gasoline is slightly higher. It is around -3200kJ/mol [1].

The octane number of the most prosperous fuel isobutanol is 98 [1, 7].

Therefore, we have decided to sacrifice four corporate cars for the test driving them on the highway and in the city of Brownsville, TEXAS, to see if any damage could possibly happen to the cars, and especially their engines operated with the fuel isobutanol or the fuel diacetyl alcohol as the gasoline replacement herein.

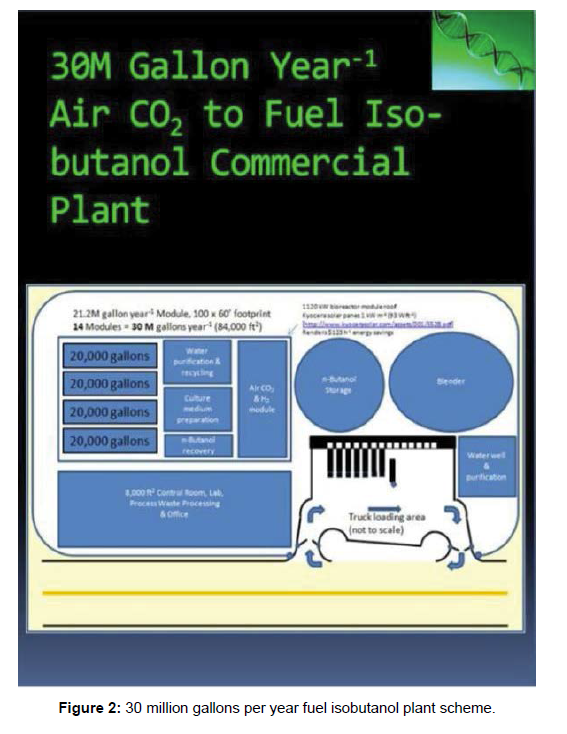

The scheme of the proposed CLONABLE fuel isobutanol manufacturing plant, producing 30 million gallons of fuel isobutanol yearly is shown in Figure. 2.

The manufacturing price of the acetone manufactured from the airCO2 is approximately $0.0.34-35 per gallon [8]. The condensation of the two acetone molecules over the alkaline catalyst per gives fuel diacetyl alcohol at the manufacturing cost of $0.01-0.02 per gallon [9]. The combustion energy of the diacetyl alcohol is approximately – 3473 kJ/Mol as compared to the combustion energy of the diesel fuel of -808 kJ/Mol which substantially exceeds the typical for the diesel fuel combustion engine energy release as the mechanical energy of driving and corresponds to the higher engine power under the given engine mechanical dimensions, probably because of the increase of the combustion mixture explosive pressure. However, we are not the explosion experts to discuss this herein. We have just sacrificed the new diesel engine of the 2020 corporate truck Shevrolet Silverado 1500 to investigate the damaging effects of diacetyl alcohol use instead of the use of the diesel fuel manufactured solely from the petroleum with the substantial airCO2 emissions during such manufacture as it is known [1].

Diesel engines are wide spread and used for the cargo transportation on land and in the sea. Special ind of the Diesel fuel is the fuel for the turbines of the aircraft engines. If the Gasoline market is currently only over $1 trillion, the diesel fuel market is projected by the major petroleum corporations to reach over $1.7 trillion by 2020 and this is growing above that [1]. Combustion of fuels for the energy production and breathing of people both produce airCO2 (the major mechanisms of the airCO2 production). It is important, that the urban green spaces of our cities help to maintain the distorted now balance of the airCO2 content. To the airCO2 content, please, add theCO2 exhaust of the petroleum refineries, performing petroleum distillation on its fractions including gasoline (C7-C9 petroleum fractions) and diesel fuel (C10-C15 petroleum fractions). Only in the Continental USA there are 80 refineries. The airCO2 has reached the point of No Return already in 2010, when NASA has discovered plenty of ice on the dark (Space cold, -293 oC) side of the Earth satellite Moon, located 220,000 miles away from the Earth surface. NASA has attributed said ice to the evaporation of the fresh water vapors from the Earth atmosphere to the outer Space vacuum, where Moon worked as the cold trap for said evaporating fresh water vapors from Earth [1, 7]. In about 10-20 years from now or later (we are not the Mediums to predict) the fresh water shortage is anticipated on the Earth. The fresh water shortage means the shortage of the manufacture of the crops and of the livestock, meaning the coming at said time global shortage of food supplies. Besides the projects on the gasoline and diesel fuel manufacture from the airCO2 we are very much interested also in developing of the technologies of the food manufacture from the airCO2 with the use of the genetically engineered organisms [1].

This article is devoted to our first experience with the diesel fuel or gasoline replacement diacetyl alcohol manufactured from the aceton made solely from the airCO2 and the use of said new diesel fuel or the gasoline replacement to power the diesel engine of the light truck 2020 Chevrolet Silverado 1500 ofr the gas engines of Toyota Camry / Porshe Cayenne Coupe Turbo, the property of our corporation which we have decided to sacrifice for that really profitable purpose (look at the dynamics of the diesel fuel market above). The truck has been used with its diesel fuel tank filled with our replacement of the diesel fuel diactetyl alcohol manufactured from acetone, produced from the airCO2. The production of the acetone from the airCO2 then was followed by the condensation of the acetone molecules over the alkaline catalyst to form the diacetyl alcohol, which has been used to replace the diesel fuel in out truck Shevrolet Silverado 1500 to test its use, the fuel efficiency and other parameters for as long as we have decided to sacrifice this truck for this corporate experiment. It is all somewhat related to the positive functioning of the urban green spaces. Urban green spaces, such as parks, forests, green roofs, streams, and community gardens provide critical ecosystem services beneficial to the humankind. Green spaces also promote physical activity, psychological well-being, and the general public health of the urban residents. The direct connection of the described technology based on the use of carbon negative fuels for the diesel fuel or gasoline replacement manufacture from the airCO2 and the extensive use of urban green spaces as the eventual and health promoting activity.

There is the picture of the fresh water reserves our planet has. This is the public domain and we encourage the readers to read that as well in addition to this article reading (Figure 3).

As you can see the fresh water amount is very small. But we know that the crops manufacture and the livestock manufacture depends solely on that negligible fresh water amount as shown in the picture above.

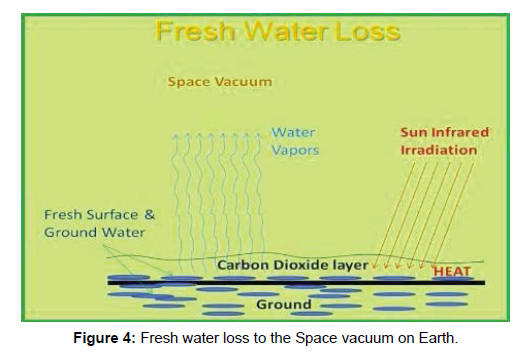

As we stated at our corporate website [1], there will be a certain shortage of the fresh water on our planet more or less soon. We are not the Mediums to tell when exactly, but that might happen in the next 10-20 years. At that time we do anticipate the Global starvation: people will kill for a glass of fresh water and hamburger at that time. The major problem with the airCO2 accumulation is that under the no wind conditions the air gas mix is separated, letting the heaviest gasses in the air blend to go down to the Earth surface by the natural gravity force. There is also the influence of the greenhouse effect on this process [1]. The natural gravity force has been stably maintained for the last several million years, since that was the time of the steady Earth mass maintenance. However, the recent developments of the carbohydrates produced by the petroleum refineries in the form of gasoline and diesel fuel have resulted in enormous already airCO2 concentrations (see above). The airCO2 is one of the heaviest gases in the air gas blend with the density of 1.997 g/m3, along with the inert gases (trace amounts) but the airCO2 concentration has exceeded 400 ppm in 2010 (NASA reports) [1] and now it is above 450 ppm and is constantly growing. Please, compare these numbers to the era prior to the petroleum use in the year of 1900. The airCO2 is the heaviest gas (1.997 g/m3) in the air gas blend and it tends to cover the Earth Ground under the constant gravity force. The airCO2 as anyCO2 selectively absorbs Solar infrared energy, heating Ground covered with the airCO2. The ground is known as the major fresh water refuge after rains, snow / ice melting, etc. In the United States, most of the Southern States allow the ground with the trapped fresh water covered by the airCO2 to boil under the normal pressure. NASA has bombarded the Moon for the investigation of the resulted debris for its chemical composition. NASA has found a lot of ice on the Moon surface working as the cold trap for the Earth fresh water vapors in the Space vacuum [2, 6] as NASA has discovered in 2010 [1]. This process was summarized in the picture we offer below (Figure 4).

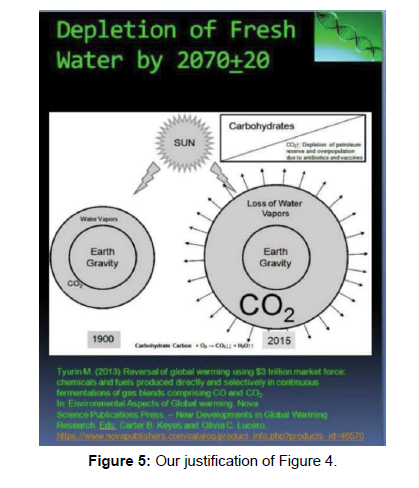

So, we have identified the major environmental problem Earth might have now. We have done that in 2000-2001, and NASA has confirmed our observations in 2010 [1]. Let’s think of the best ways to resolve that problem besides the already proposed radical solutions, which are of course valuable and exist as the solutions. The radical solutions mean the search or the extraterrestrial planets, similar to Earth by the climate and the atmosphere composition, etc. Below we try to add the material to the material shown in Figure 4 (Figure 5).

That requires the enormous investments of the private capital and/ or the governmental / international efforts. We are working in the same direction, but try to offer one of the natural and free ways to resolve the same environmental problem as that was already identified above. If the petroleum combustion on Earth will be cut down and the fuels will be produced from the airCO2 that will eventually work well on our planet even without the relocation of the overcrowded Earth population to the other newly discovered planets.

What waste of fresh water vapors to the Space vacuum means? We have discussed already the fresh water shortage due to its waste to the Space vacuum. The absence of fresh water on Earth means the time of long term starvation of the humankind. People at said time will kill for a glass of water and hamburger. NASA stated in 2010 that planet Earth has passed the Point of NO RETURN because of the increasing airCO2 concentration. In 2010 it was 400 ppm. Today it exceeds 450 ppm and grows up.

The solution would be the replacement of the existing fuels and chemicals by the carbon negative fuels and chemicals. Dr. Tyurin already has created carbon negative gasoline and diesel fuel manufacturing technologies [10, 11]. The solution to the fresh water loss to the outer Space also exists. Dr. Tyurin wants to get the investor’s money to organize the World’s Empire of Fresh Water. The best resolution for free Solar energy extraction with the use of modern solar panels is the Equator area of Earth. It is 11,000 miles long on the Equator perimeter, and at the Equator area it is possible to extract with solar panels as much as 1,330 Wt/m2 of solar panel each and every hour (1,330 W/ m2/h) and use said free electric energy to distill the sea water to make fresh distilled water, which has to be packed immediately in the plastic bottles, manufactured at the same inflatable boats-plants. For the high time operations (24/7/365) we have to have the sets of alakaline batteries from the destroyed at the military shipyards submarines, connected in series to have the power water distillers heaters voltages.

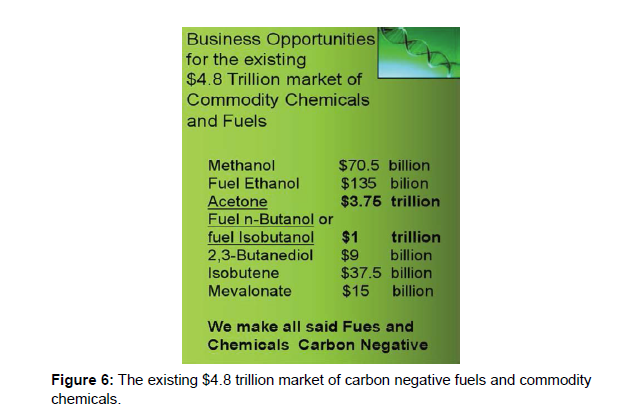

The future of the carbon negative businesses development is very encouraging but already not normal (see Declarations section) (Figure 6).

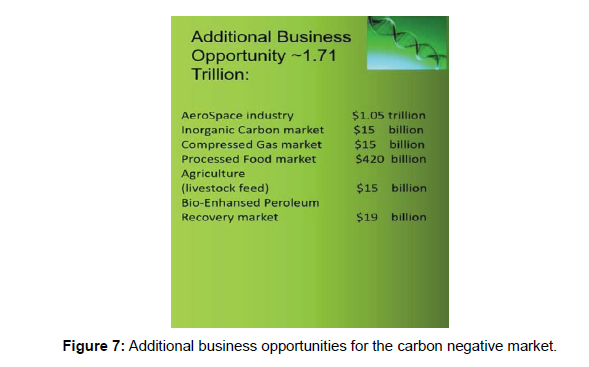

There are certain additional business opportunities (Figure 7)

The manufacturing cost structure for the carbon negative gasoline fuel replacement fuel isobutanol is shown below (Figure 8).

Materials and Methods

We have used the other two cars, 2020 Toyota Camry ($30,000) and Porshe Cayenne Turbo (>$300,000), to test our gasoline replacement fuel isobutanol for the corporate needs on the highway and in the city of Brownsville, TX. The diesel fuel replacement diacetyl alcohol was used at the same location in the truck 2020 Shevrolet Silverado 1500. We always placed the spare fuel tanks in the trunks of all said vehicles to ensure that only fuel isobutanol and diacetyl alcohol would be used to refill the respective gas tanks. The use of the Porshe was dictated by the fact that the small portion of the US population uses only the luxuries cars for any their needs. The runs of the Toyota Camry and the Porshe Cayenne Turbo were for 20,000 miles. The run of the Shevrolet Silverado 1500 was for 10,000 miles. Upon reaching said mileage points the cars were examined by the certified mechanics provided by the respective dealerships and transported to test said cars to the corporate location.

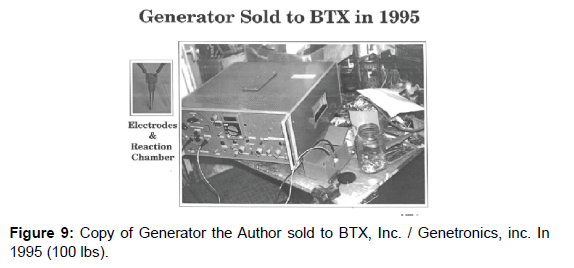

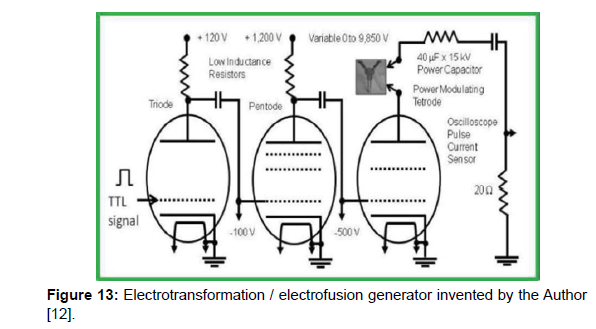

Said literally fantastic progress in commercial biocatalyst development was because the Author had the access to the copy of his, we would say perfect, electrotransformation Generator [12]. Brief history: After getting the Russian Patent 2-005776 Dr. Tyurin started looking for the potential consumers for his electrotransformation technology [12]. In 1995 he got the communication with the BTX, Inc. / Genetronics, Inc. per said electrotransformation Generator. Said company was very interested in getting a copy and ordered one. The intent of said company was to try this Generator for the therapy of the Head and Neck Cancers with the toxic chimiotherapeutic antibiotics and chimiopreparations, supposedly easily entering the tumor cells after treatment with series of similar to electrotransformation high voltage pulses. So, that company has ordered the copy of said Generator. There was certain delay in the communication related to the total pricing. The Author has made friends with the Third Secretary of the US Embassy in Moscow, the Russian Federation, Mr. James Winkelam and promptly characterized to him his problem. Mr. Winkelman was very kind and offered help to the Author and the Author got the funds from the company essential for the UPS transportation of the copy of said Generator from Moscow to San-Diego, CA. In 1999 the Author has requested the CEO of BTX. Inc. / Genegetronics, Inc. if the Author might purchase said copy of his Generator for spare parts. In response he has received the fax from Ms. Joany Kerr, the International Sales Director, that now the Generator becomes the property of the Author. Therefore, the Author was able to do his Acetogens strains biocatalysts development using his electrotransformation Generator [12]. The original generator sold to the BTX, Inc. / Gnetronics, Inc. In 1995 is shown in Figure 9.

The fax from Ms. Kerr is shown in Figure 10.

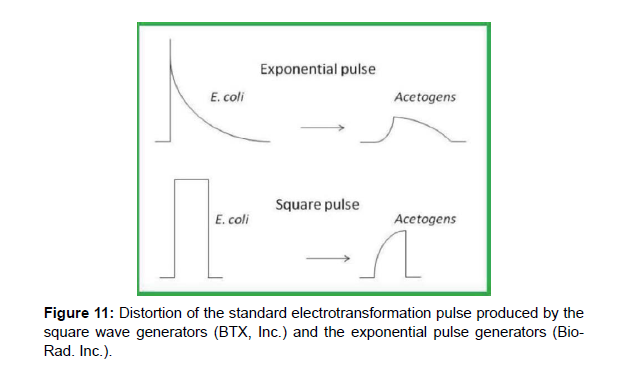

The essential need for said Generator was determined by the observations, that Acetoigen cells posses enorrnously high internal cell capacitance. For example, the strandard 50 microliters cell sample of the Acetogen cell suspension had the electric capacitance of about 8 micro Farads vs. standard E. coli 50 micreolioters cell sample having the electric capacitance of 50 nano Farads. The design of the electric circuit of the Author’s electrotransformation Generator allowed the cell samples with very high internal capacitance, like in the case of Acetogens, as shown in Figure 11.

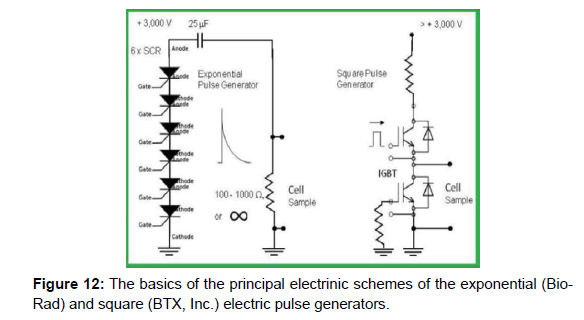

The basics of the principal electronic schemes of both types of the square or exponential pulse generators are given in Figure 12.

The principal electric scheme of the Author’s electrotransformation Generator is show in Figure 13.

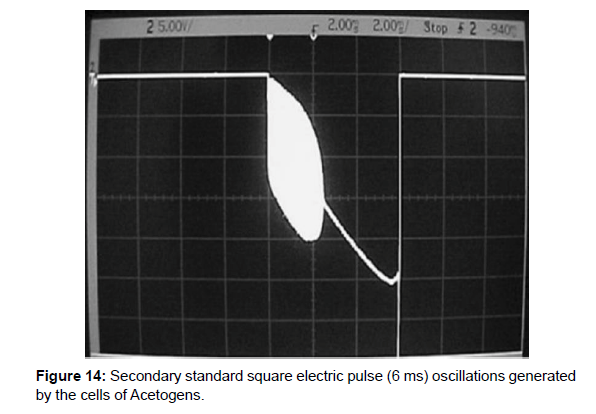

It is extremely important, that the design of the electronic scheme shown in Figure 13, allowed the generation of the secondary oscillations by the to be elctrotransformed cells of Acetogens duirng the standard high voltage electrotransformation electric pulse generation by said generator, as clearly shown in Figure 14.

The frequency of said secondary oscillations varied depending on the Acetogen strain used from 23 to 26 MHz.

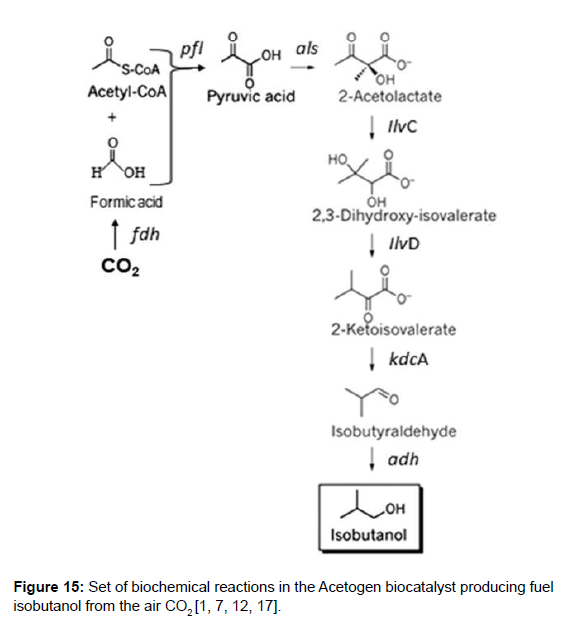

Due to the use of said electrotransformation / electrofusion Generator [12], we were able to create the commercial biocatalyst capable of production of fuel isobutanol from airCO2 via the set of biochemical reactions show below in Figure 15.

Results

The certified mechanics from the respective car dealerships tested the respective cars meticulously to reveal any damages caused by the replacement of the gasoline with the fuel isobutanol and the diesel fuel replacement with the diacetyl alcohol. The cars were placed on the treadmill with the device to check the engine emissions. Then the mechanics made the test drives of the each said vehicle. No any mechanical or any other damages to the engines of the all said cars were ever revealed upon said thorough testing. Test drives of each said vehicle by the certified mechanics did not reveal any abnormal driving behavior in any of the said cars. The mechanics still did not make any further recommendations on the following use of the gasoline and the diesel fuel replacements leaving the Author the pioneerignship of reporting this very good news to the public. The mileage of the cars used to test fuel isobutanol replacement of gasoline were 36 mpg on the highway and 29 mpg in the city of Brownsville. You can easily calculate the average gas mileage from said numbers. But the overall picture looks to us very promising since the mileage even slightly exceeded the gasoline use mileage in Toyota Camry and Porshe Cayenne Turbo. Due to the limited number of the tested cars we cannot make any predictions for the other car makes and the cars made before the year of 2020. This will become the risk of the future car owners, who will decide to replace their gasoline with the produced from the airCO2 fuel isobutanol. If you remember our corporate goal is to replace all the petroleum use by the use of the air CO2, initially to resolve the issue of the transportation problems, making the airCO2 and the airCO2 accumulation.

For the use of diacetyl alcohol as the diesel fuel replacement for over the 10,000 miles runs, the 10,000 miles old 2020 Shevrolet Silverado 1500 truck mileage was achieved on the highway at the average mileage

~35 mpg, and at ~24 mpg driving in the city. The calculated the combined driving efficiency was about ~29 mpg. The Author does not take any risk in forecasting the mileage behavior of the other diesel cars/trucks makes and per the mileage forecasting for the diesel cars/ trucks make older than the year of 2020.

Discussion

As we have discussed earlier, the disruptive and equal cost of the gasoline and diesel fuel replacement fuel diacetyl alcohol at our gas stations will disrupt the fuel market regardless of our desire to influence the fuel market. Therefore, the war has already started between our businesses and the major petroleum corporations initially NATIONWIDE, but then WORLDWIDE. That war has started from the desire of SHELL Petroleum International Corporation to kill the Author after he offered to SHELL his proprietary carbon negative technology of the gasoline manufacture fuel isobutanol for commercialization [6]. Now the Author offers his disruptive carbon negative gasoline replacement fuel diacetyl alcohol sales at his own gas stations. What that means? The started war will become more and more intensive. Now the Author can walk anywhere outside of his business site only in the presence of the well trained SECURITY OFFICERS. Now the Author cannot go himself anywhere like he liked visiting the Mediterranean food restaurant Dimassi’s in Houston TEXAS Medical Center area, or may be invite someone on a date coming to any restaurant in the neighborhood. He has to always have SEVERAL SECURITY PEOPLE accompanying him at any time the Author is outside of his well-protected by the microwave radar detectors/killers corporate compartment. Good buy FREE LIFE for the Author, now everything has to be done only in the presence of the well trained SECURITY to protect the Author and serve as the immediate witnesses if something still happens. The war has started and it will not be over until the Author is alive. His ancestors will also have to have the same well trained Security Teams. That is the today’s price now the Author has to pay for his scientific discoveries. No more any travel to any World’s scientific conference or symposium, no more purely public speaking and appearance along. This is the price Dr. Tyurin has to pay for his scientific discoveries, aimed at helping the environment of our planet Earth.

The Author’s notes on his success in the biocatalyst development is due to his access to his electrotransformation/electrofusion Generator the Author has made in 1995 for sale to the US corporation BTX, Inc / Genenetronics, Inc. Said corporation has used said Generator for the experimental approval of its recommendations to cure face and neck cancers in human beings. It is well known that anti-tumor antibiotics and other preparations used for cancer chemotherapy are extremely toxic. There was the belief in the BTX, Inc. / Genetronics, Inc. Management that the use of electrotransformation for the intracellular delivery of said anti-tumor antibiotics and other anti-tumor agents will substantially decrease the toxic affect noted herein. For aid application the Author has designed and built himself at Rice University in 1999 from the scratch the TTL generator used in combination with

The Author was really inspired by the cars testing results reported herein by the the use of both the gasoline and the diesel fuel replacements fuel isobutanol and diacetyl alcohol Nationwide/Worldwide. The owners of the vehicles who decide to use the replacements of the gasoline and the diesel fuel are still under their own risk of getting their car damages since we have tested said cars for the relatively low quantity of miles to make the conclusions on the safety of said fuels for the engines.

As you now, there are no scientists in the World except the Author who can electrotransform cells of Acetogens which the Author used as the specially engineered strains-biocatalysts capable of converting the gas mixture ofCO2, N2 andH2 to fuel isobutanol or fuel aceton, the predecessor of fuel diacetyl alcohol. Acetogens as microorganism have certain very unique characteristics. For instance they possess very high electric capacitance. The 50 microliter sample of the suspension of the Acetogen cells in the cuvette for the electrotransformation (500 mkl microcentirfuge tube) posses electric capacitance of eight micro Farads. Said capacitance of the electrotransformation cuvette with loaded cells of Acetogens irreversibly distortes the shape of square or exponential pulses produced by the standard electroporation equipment available on the market for scientists. Dr. Tyurin’s Generator (Russian patent 2-005776) is also available for the scientific consumption but its cost is not comparable with the cost of the electroporation generators World-wide. It is above $2,000,000, each. There are no Federal grants providing such amounts of cash to purchase the equipment.

The Power Tetrode in the Generator the Author used allowed the secondary oscillations happen during the electrotransfromation square pulse applications as shown in Figure 14. The Author has discovered these secondary ocsillations generated only by the certain target cell types during the electric membrane breakdown in the target cells during his work as the Visiting Professor at Dartmouth College working with Costridium thermocellum [13] and reaching the stage of the biological fathership of the fuel cellulosic ethanol. However, at the cellulosic biomass treating technologies prior to inoculation of genetically modified strain of Clostridium thermocellum (as in [13]) are way too expensive making the price of 1 gallon of fuel ethanol as expensive as $5 dollars (price of 2006).

The only drawback of the fuel isobutanol is the increase of its viscosity in the fuel line at low surrounding air temperatures. To overcome this shortcoming of the fuel isobutanol for its use at the low temperatures, we offer it not in the pure form as it has been suggested before [14], but as the mixture with the gasoline at the ratio 80% fuel isobutanol and 20% of gasoline. Of course, in the Southern States of the USA the 100% fuel isobutanol should be used with no problems due to its higher viscosity at the low temperatures almost around the year long: from March through November. During short winter time we offer for sale the gasoline fuel isobutanol/gasoline mixture as described above. If the diacetyl alcohol is used to replace gasoline from petroleum, there is no such problem. Just watch your cear engine gaskets thoroughly since the combustion energy of the fuel diacetyl alcohol is higher than that of gasoline (you will get more engine power at the moment and the purchasing price and longer drives in general).

The Author describes herein the results of his personal use of the fuel diacetyl alcohol solely in his corporate 2020 Shevrolet Silverado 1500 truck with no attempts to convey said personal experience on the other makes of the diesel fuel trucks and other diesel fuel engines. Over the 10,000 miles run, the 2020 Shevrolet Silverado 1500 truck mileage was achieved on the highway at the average mileage ~35 mpg, and at ~24 mpg driving in the city. That was the new 2020 corporate Shevrolet Silverado 1500 truck with the diesel engine. With the older models of the diesel trucks these numbers will be most likely lower. We did not notice no side effect of using the diacetyl alcohol instead of the regular diesel fuel as the diesel truck engine and the truck was checked by the Chevrolet mechanic, with the only exception that we had to keep in memory the need to feel the truck with the fuel only at the corporate territory, not at the regular gas station. Probably, at this point we will offer the fuel diacetyl alcohol to the local gas stations as the fuel for the diesel engines. However, they will have to test all the safety parameters of storage of this fuel on the station and the details of its use by the customers if anything unusual comes up. If we are successful in all said tests, the satisfactory results will go for the National/World’s implementation of our new diesel fuel and to the new gasoline stations, selling only diacetyl alcohol to customers as the diesel fuel at the same sales cost, as there is no our intent to disrupt the fuel market by the sudden decrease of the fuel prices. Our major concern herein is related to the use of our gasoline and the diesel fuel replacements to help the air jet aviation to help to fight the airCO2 production.

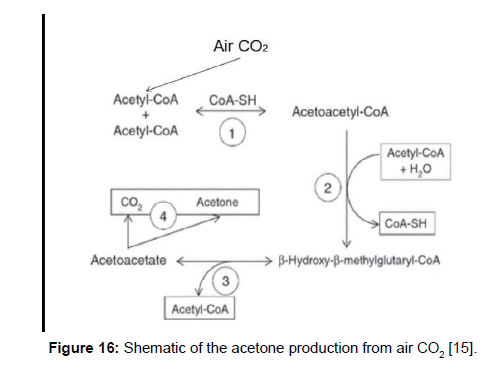

Writing about that, the Author must note, that the final products of any of the said replacements are the water and theCO2. However, please, remember, that all said replacements of the gasoline and the diesel fuel were made from the airCO2 used as the feedstock for the processes of said fuels manufacture. So, the calculations will show that our replacements of gasoline and of the diesel fuel are carbon negative. Herein we have to remind you how the diactetyl alcohol was made. Several words on the acetone manufacture from the airCO2 [15]. The overall schematic diagram of the process we used is shown below in Figure 16.

The following chemical reaction allows us make certain calculations per the Acetone yield [15]:

12 O2 + 56H2 = 3.6 Acetone + 0.06 Cell Carbon

Again, we have to note, that our manufacturing facility is the gridindependent, getting all the electric energy solely from the solar panels covering all the area over our bioreactors. We used our original not having any World’s analogs gas blend horizontal fermentation vessels [1, 7, 8, 15]. The bottom of each vessel was covered with the gas Pall spargers providing the size of gas blend bells of around 0.5 micrometers. The overall fermentation work went extremely well with the high microbial densities of the genetically engineered strains of Clostridium sp. MT896 and of Clostridium sp. MAceT113 [15]. When the acetone reached the concentration of about 8 - 9 g/l in each fermentation block of our fermentation plant, the fermentation was deceased and the acetone was collected from the fermentation fluid. Evaporated acetone was collected and then subjected to the treatment under the alkaline catalyst per the US Patent 1550792A [16] to reach the production of the diacetyl alcohol. At the concentration of the diacetyl alcohol 97% it was collected, dehydrated from the trace amounts of water and used as the diesel or gasoline engine fuel. So, now we are ready to offer to the customers the replacement of the diesel fuel or gasoline, manufactured in the US solely from the airCO2. The combustion energy of the diacetyl alcohol is approximately – 3473 kJ/Mol as compared to the combustion energy of the diesel fuel of -808 kJ/Mol which substantially exceeds the combustion engine energy release as the mechanical energy of driving and corresponds to the higher engine power under the given engine mechanical dimensions, probably because of the increase of the combustion mixture explosive pressure. However, we are not the explosion experts to discuss this herein. We have just sacrificed the new diesel engine of the 2020 corporate truck Chevy 1500 to investigate the damaging effects of diacetyl alcohol use instead of the use of the diesel fuel manufactured solely from the petroleum with the substantial airCO2 emissions during such manufacture as it is known [1].

Several notes per the commercial air transportation. We would like to offer both, our gasoline replacement fuel isobutanol and the diesel fuel replacement diacetyl alcohol for the testing at the aircraft manufacturing facilities. The growing air transportation produces the enormous amounts of the airCO2. If there is still any risk of replacing of the air jet fuel with any of our carbon negative compounds, that will be really great. However, the testing has to be done thoroughly since the life of the passengers, life of cargo on the transport jets, will be in stake. There are the justified reports on the use of fuel isobutanol as the additive for the air jet fuel [17].

Again, several notes of the Author per the possible easing of the grand ecological problem our planet has now encountered due to the near exhaustion of the petroleum reserves. We must note that that took the Nature over 3 million years to make said petroleum, while the Humankind used almost all of it in just about 200 years. The ways to preserve fresh water on Earth would be to decrease the airCO2 content. The common ways to do so are the lack of petroleum-based transportation and the substantial decrease of the Earth population since everybody breath producing the airCO2. The last way is immoral and will never exist in the Nature. The solution of finding a new planet similar to Earth are very slim at least now due to the natural weakness of the planet’s Earth engineering knowledge and skills. In the year of 2000 Dr. Michael Tyurin has predicted ways before NASA observation of 2010 the ecological catastrophe on the Earth and started developing new technologies of manufacturing carbon negative fuels from the airCO2. We describe herein our progress after that about 22 years of our being concerned about the airCO2 accumulation problem and its consequences.

Herein we present our practical data on the manufacture of the gasoline replacement fuel isobutanol and diesel fuel replacement diacetyl alcohol both manufactured from the airCO2. Our data are supported by our personal results of the combustion engines operations for over 10,000 miles for the diesel engine and over 20,000 miles for the gasoline engines. We have sacrificed out corporate vehicles diesel engine-based 2020 Shevrolet Silverado 1500 and gasoline engine based cars and SUV 2020 Toyota Camry and 2020 Porshe Cayenne Coupe Turbo in our reasonable anticipation that our taken with this article risks will be well compensated in the near future of our corporate developments.

The identical pair of cars was used to test the gasoline replacement fuel diacetyl alcohol in regular gasoline engines. After the runs of 20,000 miles, the set of Toyota Camry and Porshe Cayene Coupe Turbo has been evaluated by the invited specifically for that purpose certified mechanics of Toyota and Porshe. Said mechanics did not find any engines mechanical damages, changes of the engines performance and anticipations of shortening of the engines use life duration. Therefore,we are herein proclaiming that the fuels diacetyl alcohol is suitable fuelfor both types of the engines we have tested: for the diesel engines and for the gasoline engines. However, we should not dismiss our intents to use fuel isobutanol as the gasoline engine fuel. But technically, it is always beneficial to pour the same fuel to the gasoline pumps and the diesel fuel pumps. There will be the war with the international petroleum corporations on the pricing since we are going to compete at all on the sales of gasoline and diesel fuel replacements. We will have to write another article on what was the outcome of our natural intent to set up the sets of gas stations for the diesel fuel sales and for the gasoline sales Nationwide. The article will be published only if the Author would be still alive. Thank you for your attention.

The Author trusts that he would be able to locate the Houston law firm to sue the offender who caused the Author’s corporate website premature death [1]. Her name is Levy, the same family which owns the grocery stores Fiesta in Houston TEXAS. So far the Author was unable to find a lawyer in Houston TEXAS, to treat said offender under the US Federal law (Theft of the Author’s name and the Author’s businesses names and identities, Federal felony B with the Federal jail time for the offender and the monetary compensation for the Author). The offender is the attorney from the Houston law firm Hirsch and Westheimer, and she delicately indicated in the legal paperwork for the Harris County Civil Court that she had accessed without the Authors knowledge and without the Author’s authorization to do so, of course, the Author’s corporate computers and she apparently knew all his passwords, including the one the Author used for the access to his corporate website (http://syngasbiofuelsenergy.com) at the yahoo small business website. As that seems to the Author, said lawyer has changed the number/or the expiration date on the Author’s credit card and his corporate website (http://syngasbiofuelsenergy.com).

The (http://syngasbiofuelsenergy.com) immediately died as the result of said action. This is the Federal Felony B theft of the Author and his TEXAS businesses names and identities with the Federal jail time for said lawyer and $trillions of compensation from the lawyer’s law firm and from the family of said lawyer (the owners of the Fiesta food stores in Houston, TX). They all do not have that much, so they will owe to the Author for the rest of their lives and pass that to their inherits, they will owe to the Author and his ancestors by the Federal Court order, unless its judge was already bribed there, like the one who was bribed by the defendants lawyers from the Harris County, TX. The Authors hides this story of his attempted murder since there was no any proper FBI investigation of the absence of the due diligence in TEXAS, avoiding paying Federal taxes for the money bribery of Judges and the felony bribery in the Justice System of the Harris County, TX. The Judge Ward of the Harris County Civil Court #234 is still intact, and the Author has brought to that Court his legitimate lawsuit against Citibank, NA for the credit card fraud, theft of cash from the Author’s personal and business checking accounts for over 35,000 with the Bank of America, NA, and physical theft of $10,000 from the Author’s safe deposit box performed by the employees of the Capital One, NA bank at its Briar Forest location in Houston, TEXAS. The Author does not believe there is any Federal law followed in Houston, TEXAS at all. By that time the Author intends to have the complete FBI investigation of said the Author’s attempted murder with the punishment of the international petroleum corporation SHELL the Author has visited in Houston, TEXAS and the Houston Toyota Tundra truck drivers involved into said Author’s attempted murder, having their insurance company Farmers to pay trillions of $dollars to the suffered Author of this article and their driver’s licenses terminated in TEXAS per said car totaling and the attempted Author’s murder, if there is still any law in TX and the State of TX is still the part of the USA. The war with the major petroleum/ gasoline/ diesel fuel manufacturers has started and it will continue until the Author wins it with the replacement of the petroleum use by the use of the airCO2 as the feedstock for the carbon negative fuels manufacture on our planet. Said war will take another 70 years or so and will continue after the Author’s natural death by his ancestors.

Declarations

Ethical Approval and Consent to Participate: This article does not contain any section, requiring Ethical Approval. The only Author is complied with the Consent to Participate.

Consent to Participate: The Author complied with the consent to publish this article.

Consent to Publish: The Author complied with the Consent to publish this original article.

Authors Contribution: Dr. Michael V. Tyurin has planned all the experimental work, conducted all the experiments, analyzed the experimental data, wrote this original manuscript, edited ot as appropriate and submitted for this publication the edited original manuscript.

Funding: Funding was done by the private investors, who declined to provide their names and their business affiliations. The investors noted, the author should decline any source of funding.

Competing Interests: The Author does not have any competing interests with any third party. The author declares his personal conflict of interests with the law firm in Houston, TX Hirsch and Westheimer, which has destroyed his corporate website (http://syngasbiofuelsenergy. com), and with the major petroleum and gasoline/diesel fuel companies in Houston (TX), with the Houston Police (City of Houston) and with the Houston FBI ignoring the Author’s concern about his attempted murder committed by SHELL after the Author has presented to SHELL his proprietary technology for gasoline manufacture from the airCO2, not from petroleum [6]. The attempted murder is of no interest for the corrupt by the major petroleum corporations in Houston, TX Houston FBI. The Author has no intent to file the lawsuit against the Houston FBI at any point, but he is inclined to make this case the public domain. Houston FBI does not follow the established in the USA Federal Laws.

Availability of data and materials: All the data and materials are available if necessary from the Author of this manuscript.

Authors’ information: The Author is the owner of his mentioned TEXAS businesses Microbial Biocatalyst International, Inc. and Inorgcarbdiesel, Inc. The work has been done at the corporate site with the USPS address P. O. Box 300230, Houston, TX 77230.

References

- http://syngasbiofuelsenergy.com

- Morrison RT, Boyd RN (1992) Organic Chemistry (6th ed.). Prentice Hall, New Jersey, USA.

- Adam Hill (2013) What is Butanol?.

- (1994) Chemicals in the Environment: 1-butanol. Office of Pollution Prevention and Toxics U.S. Environmental Protection Agency, USA.

- Dr Brown P (n.d.) Alcohols, Ethanol, Properties, Reactions and Uses, Biofuels.

- Tyurin MV, Padda R, Huang KX, Wardwell S, Caprette D, et al. (2000) Electrotransformation of Clostridium acetobutylicum ATCC 824 using high-voltage radio frequency modulated square pulses. J Appl Microbiol 88: 220-227.

- Kiriukhin M, Tyurin M, Gak E (2014) Genome tailoring powered production of isobutanol in continuous CO2/H2 blend fermentation using engineered acetogen biocatalyst. J Ind Microbiol Biotechnol 41: 763-781.

- Berzin V, Kiriukhin M, Tyurin M (2012) Selective production of acetone during continuous synthesis gas fermentation by engineered biocatalyst Clostridium sp. MAceT113. Lett Appl Microbiol 55: 149-154.

- US Patent US1550792A

- Tyurin MV (2021) Gasoline Replacement Fuel Diacetyl Alcohol. Int J Automot Technol 23: 23-46.

- Tyurin MV (2021) Diacetone Alcohol as the Diesel. Energy Efficiency. Energy Efficiency. Ed.: Dr. Muhammad Wakil Shahzad. IntechOpen. Rijeka: Janeza Trdine 9, 51000 Rijeka, Croatia. London: 5 Princess Gate Court, London, SW7 2QJ, UK. ISBN 978-1-83969-828-6.

- Tyurin MV (1992) Russian Patent 2-005776.

- Tyurin MV, Sullivan RS, Lynd LR (2005) Role of Spontaneous Current Oscillations during High-Efficiency Electrotransformation of Thermophilic Anaerobes. Appl Envir Micribol 71: 8069-8076.

- Gak E, Tyurin M, Kiriukhin M (2014) Genome tailoring powered production of isobutanol in continuous CO2/H2 blend fermentation using engineered acetogen biocatalyst. J Ind Microbiol Biotechnol 41: 763-781.

- Fenkl M, Pechout M, Vojtisek M (2016) N-butanol and isobutanol as alternatives to gasoline: Comparison of port fuel injector characteristics. EPJ Web Conf 114: 02021.

- Johnston G, Vice President Regulatory Affairs, Gevo Inc (2017) ICAO Seminar on Alternative Fuels. ICAO Headquaters, Montreal, Canada.

- Tyurin M (2013) Gene replacement and elimination using λRed- and FLP-based tool to re-direct carbon flux in acetogen biocatalyst during continuous CO₂/H₂ blend fermentation. J Ind Microbiol Biotechnol 40: 749-758.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Tyurin MV (2022) Air CO2 for the Manufacture of the Commodity Fuels. Oil Gas Res 8: 243. DOI: 10.4172/2472-0518.1000243

Copyright: © 2022 Tyurin MV. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 1602

- [From(publication date): 0-2022 - Mar 31, 2025]

- Breakdown by view type

- HTML page views: 1121

- PDF downloads: 481