A sustainable Avenue of Desertization Renovation and Silicate Industry: Removing Desert Sand to Manufacture Inorganic Materials

Received: 16-Feb-2022 / Manuscript No. jescc-22-54886 / Editor assigned: 18-Feb-2022 / PreQC No. jescc-22-54886 (PQ) / Reviewed: 04-Mar-2022 / QC No. jescc-22-54886 / Revised: 10-Mar-2022 / Manuscript No. jescc-22-54886(R) / Accepted Date: 10-Mar-2022 / Published Date: 17-Mar-2022 DOI: 10.4172/2157-7617.1000608

Abstract

Deserts exert a great influence on human activities and global environment trend. On the other hand, the sharp conflict between the increasing use of inorganic products and the decrease in mineral resources will deepen in the coming decades due to advancements in human activities. This obliges us to seek alternative raw materials for sustainable development. This paper proposes an excellent practical framework of using idle desert sand as a raw-material resource to manufacture engineering materials such as paving materials, concretes, cement clinkers, glasses, ceramics, bulk materials, and high-purity (hydr-)oxide powders. This framework well connects the low-cost manufacturing, curing desertization, saving mineral and earth resources, and social and economic developments. Therefore, the present study elaborated the necessity, possibility, and significance of the project in terms of desertization curing, raw-material and earth resources, characters of desert sand, available products, and the social and economic efficiency. In addition, the progress in research and application of desert sand for engineering materials are summarized. Finally, issues and prospect facing the desert-sand-based materials, product execution, and industrial applications are pointed out. It is expected that this information would help in the research, development, and production of new inorganic materials as well as in desert-environment curing and the sustainable management of mineral and earth resources.

Keywords

Sustainability; Desert sand; Silicate materials; Resource economization; Ecological environment

Removing Desert Sand to Manufacture Engineering Materials is one of the Promising Alternatives for Curing Desertization

A desert refers to an area where the land mass is covered by sand beaches or dunes and lacks water and plants. Deserts mainly distribute in 13 regions of the world in terms of geographic location [1]. Of the 162 million square kilometers of land area on the Earth, ~30% is occupied by deserts and another 43% is currently threatened by desertization. Deserts pose great hazards to the biological environment, farmlands, infrastructures, and human health. Much effort has been made to control and cure desertization by the cultivation of psammophytes and protection of existing vegetation in many countries, especially in China and India. China has planted billions of trees on the past decades, mostly in the northwest region. The trees have held back the moving desert dunes and desertification. China has also succeeded in planting commercial crops such as vegetables, fruits, and herbs over large sand beaches; moreover, developing solar energy, wind energy, heat energy, sports, and tourism in desert areas helps in promoting the local economy and consequently, the quality of life [2-5]. However, the renovation of desertization is not an easy goal as deserts span across very large areas. Mostly in remote corners of the world with limited access to roads, water, and electricity, which is quite difficult and requires extreme amount of human resource, financial, water, and growth-suitable plants. Moreover, some scientists worry about the planting worsening water scarcity as many of the trees are not native to the regions and they use a lot of water despite they are planted in areas that are experiencing less rainfall.

To avoid such difficulties in curing desertization, it is suggested that industrial route, as a supplemental alternative, should be considered to convert idle desert sand into valuable products. If the sand dines or beaches in deserts are removed, the flat lands could be (re)produced, which are more beneficial for agriculture, forestry, and infrastructure activities. In the same time, the desertization area could be reduced and so improve desert ecological environment. This will show enormous social and economic benefits.

Conflict Between the Increasing use of Inorganic Products and the Decrease in Mineral Resources Highlights the Need for Desert-Sand Raw Materials

Inorganic minerals are tremendously used in road pavement, building, metallurgy, chemicals, mechanical engineering, and environment protection, as well as daily necessities [6, 7]. Construction industry is the biggest customer for consumption of mineral resources [8], which involve various shapes of crushed and well-graded sand/ gravel aggregates required for asphalt, concrete, and polymer, as well as clay powders for cement clinker in contrast. the nonconstruction materials include chemicals, glass, ceramic, refractory, and bulk materials; their raw materials cover more than fifty species of minerals such as quartz, alumina, magnesia, kaolin, talc, bentonite, montmorillonite, feldspar, bauxite, dolomite, and fluorspar, etc, many of which contain a large amount of SiO2 composition [6, 9-10].

Industrialization practice in major countries shows that when GDP increases to a certain level, the consumption of non-metallic minerals is significantly higher than that of metallic minerals. Some experts even take the proportion of the output value of non-metallic and metallic minerals to predict the industrialization degree of a country.

To cope with the increasing demand for inorganic products, exploitation for a variety of mineral resources has also grown, especially in recent decades, which consumes a tremendous amount of mineral resources. For instances, clay and shale are produced in 42 states in the United States, with ordinary clay producing the most, it peaked at 26,200 kt in 1996, decreased to 23,000 kt in 2003, merely with an average annual trend of -1.7%, and rebounded to 24,600 kt in 2004. As of 2007, there are 200 companies operating 800 mines and quarries for the minerals; this economic activity created great wealth for the United States. The sand, gravel and soil mineral resources are also abutment in China; there are more than 180 deposits only for ceramic clays. By the end of 2012, the total identified reserves were estimated to be about 347.4 billion tons and the total retained reserves were about 257.3 billion tons. With the acceleration of urbanization construction, the demand for the raw materials is rapidly increased. In order to adapt to the new environmental protection policy of China, the output of clay-brick products was decreased to 2.5 million tons (by 10.84%) in 2018. The limitation to mineral exploitation leads to a severe scarcity in supply and increase of their price; this inevitably influences the fundamental construction and other relates fields.

Furthermore, some resources are locally spatialized in some countries or even deposited in areas where are high geopolitical instability as 61% of the world’s resources come from the politicallyunstable countries. This strongly impacts their supply in international markets. Therefore, the availability of resources for use in current and future generations should be considered as a strategic issue. In this situation, seeking for other raw materials such as idle desert sand and developing desert-sand based new-type materials are one of the avenues to relieve the conflict in desert-sand available countries.

Removing Desert Sand to Manufacture Engineering Materials Connects Low-Cost Manufacturing, Mineral and Earth Economization, Desertization Renovation, and the Social and Economic Developments

The natural minerals were almost created by sedimentary rocks, principally in the Post-Devonian age and are non-regeneration substances. For instance, the sand and gravel aggregates, dolomite, and ball clays were estimated, at 2014, to be respectively depleted in 12, 15, and 4 years in Poland. Although the considerable resources have been identified, they may be not currently extracted because the extraction of the mineral deposits is restrained by the actual or planned land use, land property ownership, environment protection exigencies, and social opposition.

The development of mineral industry likewise arises a series of problems such as environmental pollution and cultivated land destruction. According to the statistical data of the Ministry of Land and Resources of China, the total number of cultivated land was reduced to less than 1.2 million km2 by the end of 2010, one of the main reasons is also ascribed to the cultivated land destruction caused by sand and gravel mining.

To ensure sustainable development in mineral resources, environment, economics, and society, many countries have taken measures to regulate the business behaviors in mineral resource exploitation and use. Earlier in 1996, an applied geological mapping study of the Wigan Metropolitan Borough was completed by the British Geological Survey to provide a geoscience basis for planning and development decisions of users of planners, developers, engineers, and conservationists. The Federal Minister for Economics and Labor of Austrian Parliament compiled mineral resource maps in 2001, in which the deposits of needed minerals of metallic ores, industrial minerals, and construction materials, crushed stoned, and clay, etc in Austria were documented; an Austrian Minerals Resources Plan for permitting future exploitation was established to protect land use. As in other European countries, Romania adopted the standards, laws, norms, and settlements concerning environment management to unify and introduce the concept of environmental management for the exploitation of clays in ceramic industry to minimize the impact on environment, human, and social activities. However, the protection of natural mineral and earth resources depends on the reasonable use and management; the environment management is just for understanding the complex actions between the present earth surface and the control of production in the extractive field.

In such situations, there is no doubt that it is just a matter of time before the huge potential of idle desert sand as a raw-material resource for inorganic products is disclosed except the presently-available wastes and low-value substances such as fly ash, metallurgical slag, coal gangue, and exhausted quartz sand in foundries as well as the beach and river sands.

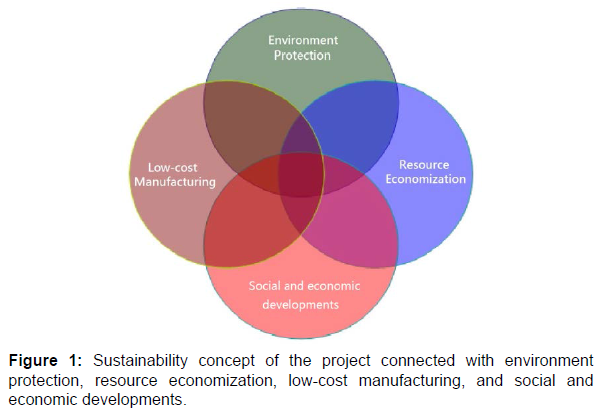

Removing desert sand to manufacture engineering materials is a brand-new project with sustainability, which aims at establishing desert-industry chain different from the present agriculture and forestry systems. It will connect the low-cost manufacturing, resource and earth economization, environment protection, and social and economic developments (Figure 1), illustrating a great industrial potential.

In the same time, this project helps change the traditional production manner of using quartz sand and clay as raw materials and derive new-type materials based on desert sand, avoiding high production cost, exploitation of minerals, and occupation of land. Moreover, this project will transfer the silicate industrial center to the undeveloped regions near deserts, which helps in employment of local residents and so their living standard, beneficial of the balanced development of society.

Industrial Application Avenues of Desert Sand

Desert sands are quite different in chemical composition, granularity, and microstructure from pure quartz and clays. They generally contain granules with a size range of tens to hundreds micrometers and a nominal chemical composition of 60-80 wt% SiO2 and rest of Al2O3, CaO, Fe2O3, TiO2, Na2O, MgO, and K2O dependent on the desert geographic locations, which is a valuable resource for manufacturing silicate materials and products, The mystical nature created the desert sands with various sizes, shapes, and microstructures; the sand particles are composed of SiO2, feldspar, and (Ti-Fe)xOy phases.

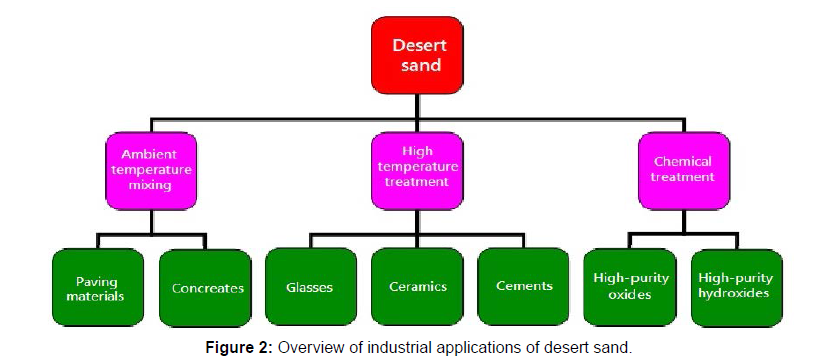

Desert sand can be feasibly used to prepare various silicatebased inorganic materials by tailoring individual or a part of the characteristics. For instances, by tailoring the granularity, it can be used as aggregates of clay, concrete, and polymer for large-scale construction in pavements of roads, highways, bridges, channels, and buildings, as well as functional bulk-materials at ambient temperatures; by tailoring the chemical composition, desert sand can be batched with other auxiliary substances to synthesize cement clinker, glass, and ceramics through high-temperature treatments; moreover, by tailoring the abutment chemical composition of Si, Al, Ca, Fe, Mg, Ti, the highpurity hydroxides and oxides can be extracted as high-quality powders (Figure 2). All of these are important raw materials in many industry fields. The eight application routes are described as follows.

Paving materials

Desert sands are early used in road engineering as aggregates of paving materials in desert area where the raw materials are not sufficient and transportation is difficult. Engineers had to use local sand as the aggregates to reduce the cost. Paving materials containing 25 wt% desert sand was confirmed to be no notable influence on the quality of roads. To overcome the shortages of small granularity and poor gradation, several techniques were used to enhance the properties of various roads; for examples, the optimization of processing parameters for compacting Aeolian sand from the Ulan Buh desert, China and use of foaming agent for sand from the Indian desert. Moreover, artificial additives and industrial wastes such as synthetic resins, chemical accelerators, sulfur and bitumen mixtures, cement, incinerator ash, and cement by-pass dusts, were introduced in the sands, respectively in the deserts of Inner Mongolia, China, Yazd and Mahshahr, Iran, and Oman and Saudi Arabia. The polymer-concrete composites were also synthesized in the Libyan Desert and western Rajasthan desert, India. In order to avoid road blocking due to sand storm and vehicle fault derived from the surface wear between rotating metal assemblies, local desert-sand bags were installed beside roads during highway construction. These measures largely reduce the difficulties and construction costs, utilize the industrial wastes in the area, and ensure long-range transportation.

Concretes

Concrete is another huge consumption for aggregates in construction field, which requires 60–80% sand aggregates with various size and shape to achieve a stable structure. The strength of concretes made from desert sands in the Kharga Oasis (Egypt), central Australia, and Sharkiya Sands (Oman), was confirmed to be 16% lower of that of standard concrete; however, such loss in strength is still acceptable from an economic perspective, except in certain cases. To improve the mechanical properties of the concretes, many techniques were adopted for engineered cementitious composite (ECC) and selfcompacting concrete (SCC), such as optimization of the composition of full aggregates with desert sand, additions of reinforcements such as fly ash, PVA, steel-PVA hybrid-fiber. chlorobutyryl chloride (CBC) or carboxymethyl starch (CMS), and use of larger sand particles developed through a fine desert-sand sintering process. As the infrastructures are still not sufficiently, especially in developing countries where the situations are more complex, the research and development on desert sand aggregates still have a long way to go.

Cement clinkers

The cement clinker, as the raw materials of concrete, contains 20–23 wt% SiO2 that is supplied with the high-quality clay. Using desert sand to replace the clay is quite significant in terms of the mineral resource and economics. An ecological cement clinker was innovated in 1999, which used desert sand from the Ulan Buh desert in northwesten China and coal gangue to replace clay. By calcining the mixed raw material powders at high temperatures, the cement paste exhibited strengths that met the cement specification. However, there still remain some practical problems such as powder preparation and calcination time to affect the manufacturing.

Desert-sand-reinforced polymers

Polymer has become a popular construction material, which is always reinforced by adding hard particles. For examples, the coreinforced epoxy composite containing glass fibers and the nanosized sand particles that were milled using dune sand from the Thal desert in Pakistan; the fly-ash-based geopolymer mortar added with dune sand (Australia desert) was used in arid and hot regions, such as North African and Middle Eastern countries.

Glasses and glass ceramics

All of the buildings use glass as windows, in which SiO2 takes over 50 wt% percentage. It is very interesting that there are the natural glass substances, named as Libyan Desert Glass (LDG), along the southwestern margin of the Great Sand Sea in western Egypt. This region was thought to be the result of a comet impacting sands in this area in the “Fission-Track Age”, 28.5 million years ago.

Glass can also be fabricated through an industrial route using desert sand, quartz sand, and clays as raw materials. For instances, the silicate glass (CaO-MgO-Al2O3-SiO2-Fe2O3-K2O) was manufactured by melting desert sand from the Middle East and clays. Moreover, glass ceramics with Nano sized quartz and cordierite crystals were respectively synthesized using the Hopq desert sand (China) and auxiliaries of feldspar, kaolin, magnesia, and alumina as raw materials; the glass ceramics possessed higher strengths and hardness and therefore can be used for decorating buildings and other important industrial assemblies.

Ceramics

Silicate ceramics are substantially used in construction decorating, industrial fields, and commodities due to their high hardness, strength, and resistance to corrosion, heat, and wear, dependent on their chemical composition and density. As a substitution, desert sand can be used to fabricate silicate ceramics with a variety of phases such as the quartz (SiO2), forsterite (2MgO·SiO2), mullite (3Al2O3·2SiO2), sapphire (4MgO·5Al2O3·2SiO2), and cordierite (2MgO·2Al2O3·5SiO2), By using granular stacking and sintering routes, desert sand granules can be directly prepared into porous ceramics, which no longer use organic/ inorganic pore-formers that can discharge harmful gases to pollute the ambient environment during sintering. The silicon oxynitride (Si2N2O) ceramics were synthesized using the Egyptian desert sand and reclaimed Si, which exhibited much higher hardness and strength, as well as the excellent resistance to high-temperature oxidation and corrosion than the ordinary ceramics. In addition, the desert-sand based composite ceramics can be fabricated by adding reinforcing particles of super-hard SiC or ZrO2; while the quartz-anorthite (SiO2- CaAl2Si2O8) composite ceramics are excellent candidates for lightweight bricks, tiles, and insulation/filling materials when combining desert sand and coal fly-ash.

Bulk materials

Desert sand is also a promising thermal-energy-storage material in solar-wind energy fields and waste-heat recovery system as it exhibits physical properties of high thermal-storage temperature, naturally-good fluidity, large specific-surface area, and non-corrosion. These features increase the power-cycle efficiency and decrease heatstorage costs. It was reported that desert sand from the United Arab Emirates has an average heat capacity of 926 J/kg∙K in the range of 150–1100 °C and is thermally stable between 650–1000 °C. However, the transformation of calcium carbonate into calcium oxide, sand agglomeration, and change in color from lighter to whiter tones at high temperatures have a negative impact on its solar-absorption capacity. As a practical example, a sand-air solar-power station was built at edge of the Tenger desert, China, where it is rich in solar energy, the heat exchanger was full of local desert sand with a proper granularity range. This station provided enough heat to local residents every day and has become a model to promote the utilization of solar energy and local economics in desert areas.

The HCl-washed sands (Hopq desert) were confirmed the good electrochemical-activation, lithium-storage capacity, and cycle properties. A desert sand layer with a definite granularity range was developed for separation of water-in-oil emulsions; this helps get rid of the expensive fluorosilane super-hydrophobic materials used in this area.

Social and Economic Benefits of the Project

Silicate materials account for a huge proportion of inorganic materials, not all of which require high-quality quartz sand or minerals containing SiO2 as the raw materials. By establishing industrialization systems near desert areas to ensure electric power, natural gas, transportation, water, and human resources, large quantities of valueless desert sand can be removed and transform into high-value industrial products as mentioned above. This realizes the low-cost manufacturing of inorganic products and is more economically valuable than the agricultural and forestrial systems. Taking annual production of 2,000,000 tons of cement clinker as an example (large-scale), replacing the 20% clay could remove 500,000 mm3 of desert sand, which is roughly equivalent to the area of 12 football fields (80×100 mm2) piled up with sand done of 5.0 m in height, saving clay cost of 40.0 million USD. Taking another example of annual production of 100,000 tons of ceramic products as an example (medium-scale), replacing 100 % of quartz sand and clay could remove 230,000 mm3 of desert sand, which is roughly equivalent to the area of 6 football fields piled up with sand of 5.0 m in height, saving quartz sand and minerals of 7.9 million USD approximately.

On the other hand, by removing the nearest desert sand to human’s active area, local residents, farmlands, and infrastructures no longer suffer from attacking of the moving desert dunes, sand storm, and always-bad weather. The (re)produced flat land areas are more beneficial of agriculture and forestry activities and the infrastructure constructions such as road paving, transportation, communication, and electricity supply. As a result, the desertization area could be reduced and so improving the desert ecological environment.

Construction and silicate industries are foundations of human’s civilizations, which own huge numbers even in the countries with desert. Thus, this project would bring about enormous economic and social benefits due to the cost economization and flatted desert areas.

Issues and challenges in the applications of desert sand The research and development on desert-sand based materials and techniques provide a broad prospect for us to utilize the idle desert resource. However, there is still hard work to be done. First, the chemical compositions of desert sands are greatly influenced by their geographical location. For examples, Australian deserts are predominantly reddish because of the higher content of iron oxide than that in the Earth’s crust in the Northern Hemisphere; in contrast, the Saharan desert sands are more yellow. Soluble salts were found in the aeolian sands of the Taklamakan and Badanjilin deserts in China. Unfortunately, the desert sands in the Abu Dob and Um Ara areas in the Southeastern desert of Egyptians cannot be exploited for this project as the radioactive U and The-rich sands were found in them, which are highly hazardous to human health. Moreover, the granularity and chemical composition are also different at different exploitation locations and sampling points around an exploitation location even in a same desert. Therefore, it is essential to deeply investigate detailed information about the local desert sand and the corresponding processing technique and production categories. Second, the physical and chemical properties of desert sands do not completely meet specifications of the raw materials for manufacturing silicate materials. For instances,

1) Desert sand can only substitute a fraction of aggregates for concretes and hardly improves their strength;

2) Desert sand granules, used in the composites and bulk materials, are easy to be cracked when subjected to force, high temperature, thermal cycle, chemical corrosion, and electric fields in service;

3) High-content impurities in desert sands influence the properties of the products, especially the refractority, thermal conductivity and resistance to wear and corrosion;

4) The synthesis principle, processing, and material’s properties have not yet significantly disclosed;

5) The industrial tests for the new-type materials of glass, ceramics, and bulk materials have not been sufficiently conducted in practice. Ultimately, the issues such as the exploitation of desert sand, production execution, desert management, and assessment of desert environment have not been paid great attentions.

All of these remain a lot of theoretical and practical issues in the industrial utilization, which pose challenges for us in the subsequent research, development, utilization, and management of the project.

Outlook

The rigorous desertization trend and the deepening conflict between the increasing use of inorganic products and the decrease in mineral resources provide the necessity, the present studies and a part of industrial applications of the desert-sand based materials and techniques provide the possibility, and the combination of all of these illustrates a promising prospect for us to use idle desert sand to manufacture engineering materials and products.

As an implementing scheme, producers should investigate the characters of local desert sand, market requirement, and local basic conditions, ascertain the production category that may be within the scope of the aggregates of clay, concrete, and polymer, bulk material, cement clinker, glass, ceramic, high-purity hydroxides and oxides or others, accomplish a concrete execution scheme that particularly involves with the desert ecology environment, and obtain a permission of local administration departments.

However, facing the practical issues in materials research and development, production execution, and management and monitoring of desert environment, mineral and earth resources, it is essential to establish a multidisciplinary team that integrates scientists, engineers, managers, and officers, respectively majoring in aspects of materials and manufacturing science, geology, ecology, resource, environment, management, policy, etc. to participate in this project together. It is also desirable to further strengthening in the research, development, and utilization of new techniques and materials based on desert sand.

We believe that, though the continuous efforts, the silicateindustry centers based on desert resource can be firstly launched in a country and then, extended to more and more countries where the desert conditions are permitted. If it is done, a brand-new sustainable development model can be established, demonstrating a perfect integration of the low-cost manufacturing, economization resource, desert ecological environment improvement, and social and economic developments.

Acknowledgment

This work was supported by the major project of Science & Technology in Inner Mongolia, China

References

- William GM, Bram JG, Patricia P (1968) Deserts of the World; an Appraisal of Research into Their Physical and Biological Environments. Univ Arizona Press.

- Chi C, Taejin P, Xuhui W, Shilong P, Baodong X, et al. (2019) China and India lead in greening of the world through land-use management. Nat Sustain 122-129.

- Huang L, Zhang ZS (2015) The Stability of revegetated ecosystems in sandy areas. An assessment and prediction index. Water 1969-1990.

- Zastrow M (2019) China's tree-planting drive could falter in a warming world. Nature 474-475.

- Brett A. B, Lei G, Yanqiong Y, Xiufeng S, Jeffery DC, et al. (2018) China's response to a national land-system sustainability emergency. Nature 193-204.

- George M, Thomas C, Hart J, LeRoy DB, Kenneth A (1987) Annual ceramic mineral resources review. Amer Ceram Soc Bull 753-778.

- Michel P, Jean-Y T (1988) Industrial minerals in Canada Development trends and recent initiatives at energy, mines and resources. CIM Bull 64-69.

- Xudong S, Ying L, Shan G, Yang W, Bo Z (2021) Interregional supply chains of Chinese mineral resource requirements. J Cleaner Product 123-514.

- Ja MG (2017) Mineral resources of Novokuznetsk administrative district of Kemerovo region (metallic and non-metallic minerals). OP Conf Ser Earth Environ Sci 84-96.

- Albina I. O, Michael O (2019) Ceramic mineral waste-forms for nuclear waste immobilization. Mater 26-38.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at,, Google Scholar, Crossref

Citation: SHI Z (2022) A Sustainable Avenue of Desertization Renovation and Silicate Industry: Removing Desert Sand to Manufacture Inorganic Materials. J Earth Sci Clim Change, 13: 608. DOI: 10.4172/2157-7617.1000608

Copyright: © 2022 SHI Z. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 2399

- [From(publication date): 0-2022 - Apr 03, 2025]

- Breakdown by view type

- HTML page views: 1905

- PDF downloads: 494