Research Article Open Access

A Study on of the Engineering Properties of Self-Compacting Mass Concrete (SCMC)

Her-Yung Wang*, Yi-Fang Shih and Hen-Ching SuDepartment of Civil Engineering, National Kaohsiung University of Applied Sciences, 807, Taiwan, China

- *Corresponding Asuthor:

- Her-Yung Wang

Department of Civil Engineering

National Kaohsiung University Applied Sciences, 807, Taiwan, China

Tel: 886-7-3814526

E-mail: wangho@.kuas.edu.tw

Received date: September 22, 2015; Accepted date: October 07, 2015; Published date: October 14, 2015

Citation: Wang HY, Shih YF, Su HC (2015) A Study on of the Engineering Properties of Self-Compacting Mass Concrete (SCMC). J Archit Eng Tech 4:155. doi:10.4172/2168-9717.1000155

Copyright: © 2015 Wang HY, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Architectural Engineering Technology

Abstract

This study discusses the engineering properties of the self-compacting mass concrete mixed with plain cement and pozzolan. Two mix proportions of and three manufacturers are were used for quality control testing and drilling before the finished product pouring was poured, and the products are were tested to check determine whether they meet the performance standards of R1 self-compacting concrete. Including basic tests were performed for slump flow, flow time when with a slump flow is of 50 cm, flow time of in a V funnel, flow in a U-shaped channel (testing for possibility flow through obstacles) and filling height. The difference in workability is discussed by was investigated by using a Big U-shaped channel test to simulate the onsite structure prototype dimensions, and standard cylindrical specimens and model core-drilled specimens were made to determine the compressive strength of concrete and to check for non-uniformity, segregation and bleeding in the processes of transportation, pouring and squeezing lift-up. The temperature change during the hydration of the concrete material model was measured, and curing at the work site was carried out to simulate future field construction conditions. This made it possible to validate the temperature control effect of the self-compacting mass concrete with pozzolan, and the data can be used as a reference for selfcompacting concrete quality control in future construction projects. The findings show that self-compacting mass concrete with pozzolan can reduce the heat of hydration and provides other good engineering properties.

Keywords

Self-compacting mass concrete (SCMC); Pozzolan; Engineering properties; Hydration temperature

Introduction

The concrete work specifications for general construction contracts still often specify that plain cement should be used for the concrete mix, without any other minerals mixed in. However, concrete with high cement content develops micro-cracks, hydrates quickly and has poor workability control due to poor volume stability and an excessively high hydration temperature. Concrete that incorporates pozzolanic materials, such as slag and fly ash, has been widely used in various engineering applications [1-7]. The mix design strength (fc’=34.3 MPa) of concrete with pozzolanic admixture is suitable for early form removal, and the compressive strength is fc’=27.44 MPa, which provides excellent performance that is suitable for use in steel column grouting. However, in order for SCC (self-compacting concrete) to meet quality requirements, the mix proportions must be appropriate, and verification procedures must be used to ensure quality. SCC can enhance workability, but segregation and bleeding can occur when the process control is poor, so there must be constant testing and drilling to maintain SCC quality. The overall process enables owners, supervisors, construction workers and ready-mix plants to handle situations early and to build a basis for mutual trust. Self-compacting concrete (SCC) overcomes the common deficiencies of poor tamping, honeycomb formation and water leakage that occur in concrete by enhancing the concrete flow ability and improving its flow through obstacles. This results in concrete with good durability. Common pozzolanic materials (slag and fly ash) are easy to obtain, so the cost is relatively low, and their usage is quite common in Taiwan.

ACI 116R states that "any field cast mass concrete that is oversized must overcome the generated temperature or the volume change resulting from the hydration temperature and avoid cracks" [8]. According to ACI 301, “if the minimum size of a concrete section is larger than 75 cm or if the unit cement content exceeds 360 kg/m3, the hydration heat may be considered according to the engineering properties. Using pozzolanic material to partially replace the cement can reduce the excessive hydration heat” [9-11].

SCC has high flow and good template space-filling capacity. It is tamped by gravity without vibration, so it takes the form of its containing space as it fills. It can be used in construction sites with overly dense reinforcing steel bars, in sections that are too deep and narrow or in structures that are too complex. SCC is useful if an oversize pouring volume is required or if long-distance transport is required, but it is inapplicable to declivities [12,13]. Because it has sufficient consistency, it resists segregation during construction. The uniformity of the material is better than that of traditional concrete that has been compacted by vibration. To improve the flow ability and filling capacity, the amount of coarse aggregate added to the SCC is reduced to approximately 80% of the amount used in traditional concrete. The maximum size of the coarse aggregate particles is limited to less than the clearance between reinforcing steel bars. High-performance super plasticizer admixture is used, and water consumption is reduced, which helps to prevent the high flow rates that would lead to segregation [14]. If there are discrepancies between the specified values for the SCC mix proportions in the trial mix process and the workability inspection, the mix proportion is adjusted, mostly by changing the chemical usage and water consumption. After that, the sand-aggregate ratio or the addition of cementing material is adjusted. Variations in sandstone quality (gradation and grain shape) and in the moisture content of the sand during the adjustment of water consumption are widely regarded as important factors affecting SCC quality stability.

In recent years, a large amount of recycled materials, including mineral admixtures of fly ash, slag and silica fume, have been used in SCC to improve the specific gravity and consistency of the paste. This has made it possible to produce paste with enough suspension force to hold together coarse and fine aggregates so that the material will not segregate [15,16]. In addition, energy savings and carbon reductions are obtained by using green building materials.

Experimental Methods

Test materials and mixture design

Portland cement TYPE-I was used; it had a fineness of 389 m2/kg and conformed to ASTM C150. The fineness of the slag powder (Grade 100) was 400 m m2/kg /kg, and it conformed to CNS12549. The Class F fly ash was 290 m2/kg, and it conformed to ASTM C618. The aggregates were obtained locally. The specific gravity of the coarse aggregate was 2.66, and the specific gravity of the fine aggregate was 2.61, conforming to CNS1240. Carboxylic Type G admixture was used, with BUSUN SP- 150. The specific gravity was 1.042, and the pH was 5.01, conforming to ASTM C1017.

The SCC mix design compressive strength was 334.3 MPa. The selfcompacting performance rate was R1, and similar water-binder radio W/B (0.36-0.37) was used to design two mix proportions. The details are shown in Table 1.

| Mixture type | NO | Cement | Slag | Fly ash | Coarse aggregate | Sand | Water | SP | W/B | W/C | W/S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| O C | A | 528 | 0 | 0 | 771 | 858 | 185 | 6.34 | 0.36 | 0.36 | 0.089 |

| PMC | A | 230 | 90 | 130 | 823 | 896 | 159 | 6.3 | 0.37 | 0.72 | 0.076 |

| B | |||||||||||

| C |

unit: kg/m3

Table 1: Mixture proportion of SCMC.

Test items

The properties that were measured included onsite slump flow, flow time for a slump flow of 50 cm (CNS 14842), flow time in a V funnel (CNS 14841), flow in a U-shaped channel (through possible obstacles), filling height (CNS 14840), temperature, chloride ion content, compressive strength (CNS1232) and surface resistance. The standard compressive strength specimens were tested at 7 days, 14 days, 28 days and 56 days to compare the compressive strength, ultrasonic pulse velocity, electrical resistance (kΩ-cm) and strength efficiency of the cement.

Big U-shaped channel test and specimen production

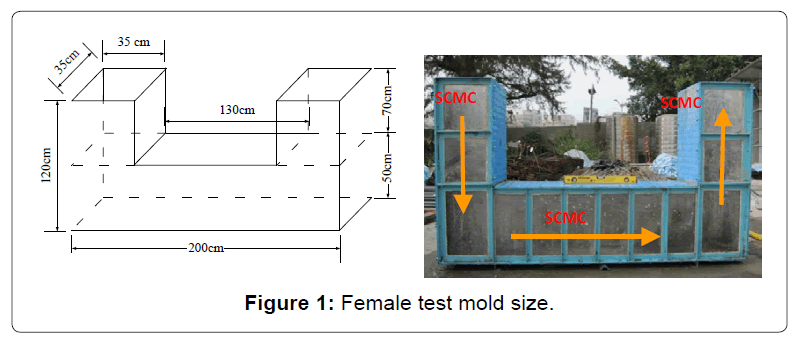

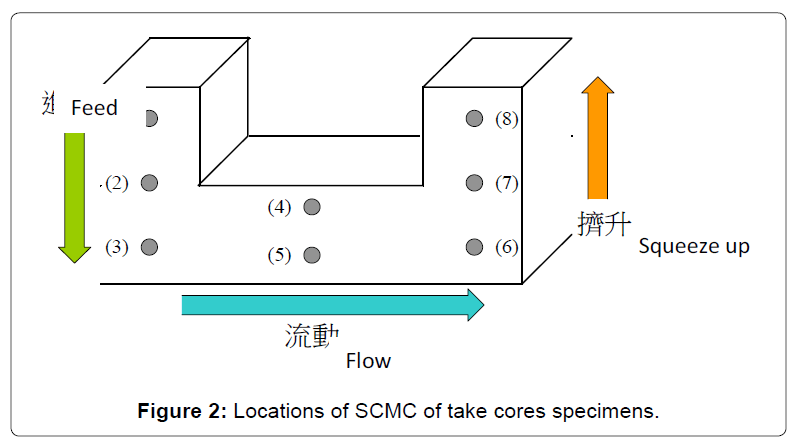

In terms of the flow behaviour of concrete, the actual flow and squeezing lift-up behaviours of SCMC can be observed through the Big U-shaped channel test, and the test can determine whether the mix proportion is uniform and whether segregation or bleeding may occur. The core specimens were drilled out of different positions of the specimen hardened by the Big U-shaped channel test, making it possible to determine the concrete strength and to determine whether the SCMC showed segregation, bleeding or material heterogeneity in the processes of transportation, pouring or squeezing lift-up. The corresponding size and test modes are shown in Figure 1. After the model forms were removed from the Big U-shaped channel test, eight specimens were drilled in the horizontal direction out of the feed channel; flow channel and squeezing lift-up channel (No. 1-8) (Figure 2).

Mock-up and temperature measurement configuration

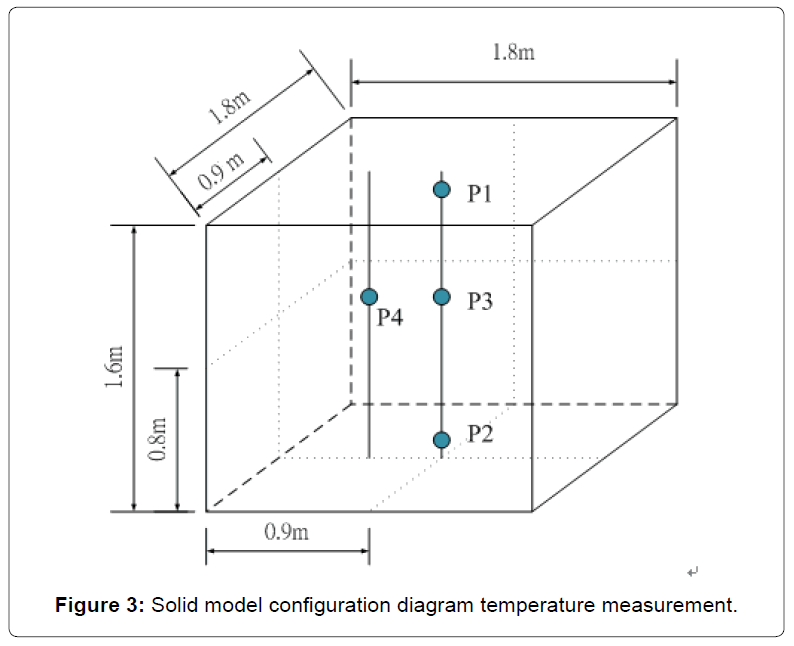

The onsite self-compacting mass concrete pouring thickness was simulated to determine the hydration temperature difference and the internal and external temperature differences between pozzolan concrete and straight cement concrete. The real specimen had the following dimensions: 1.8 m × 1.8 m × 1.6 m (LxWxH). The ordinary concrete mix (OC) and the pozzolan material concrete mix (PMC) were both poured. Figure 3 shows a diagram of the mock-up temperature measurement configuration.

A Japan KYOWA Model 20-PC was used as an automatic temperature acquisition device, and a computer was used for data output and recording. The temperature detection signal line was a K Type thermocouple wire.

Measuring point selection: #4 reinforcing steel bars (D13, diameter 12.7mm were embedded in the center of two models to fix the measurement points. Another in the air was used to measure the onsite atmospheric temperature. There were nine temperature-sensing wires connected to the data acquisition unit.

• One point was configured for top temperature measurement, numbered P1 (embedded in the center of the unit at a depth of 10 cm below the pouring top surface).

• One point was configured for bottom temperature measurement, numbered P2 (embedded in the center of the unit, at a depth of 10 cm from the bottom surface).

• One point was configured for center temperature measurement, numbered P3 (embedded in the center of a single block, at the center of thickness).

• One point was configured 45 cm away from the outer side and was used to measure the nearside surface layer temperature, which was numbered P4 (embedded in the center of thickness).

Temperature test procedure: The maximum initial temperature of concrete pouring should not exceed 32°C (onsite measurement). The fresh properties of the concrete must pass the test before concrete pouring.

Concrete surface: After the concrete surface is levelled off, the surface is watered and covered with non-moving fabric. Finally, the surface is covered with a waterproof plastic canvas, and an automatic temperature tester is switched on for recording at least once per hour. The temperatures of different parts of real samples on the first six days are recorded.

Results and Analysis

Fresh properties

Table 2 shows that the fresh properties of the pozzolan concrete meet the specified values. The slump flow of SCMC for various mix proportions is 665 mm-695 mm, which corresponds to Level 1 (650~750 mm) flow ability for self-compacting concrete. The flow time in the V funnel is 10-25 seconds. The flow time is 5.5-6.8 seconds when the slump flow is 50 cm, conforming to the standard for segregation resistance. The flow time is 5.4 seconds when the slump flow of the ordinary concrete (OC) is 50 cm, which meets the requirement. However, the flow time in the V funnel is only 6.4 seconds, which is shorter than 10 seconds, meaning that the concrete viscosity is insufficient and is likely to result in segregation.

| Item | OC | PMC | R1 | |||

|---|---|---|---|---|---|---|

| A | A | B | C | |||

| Mobility | Slump flow (mm) | 665 | 695 | 665 | 670 | 650~750 |

| Materials Analysis from resistance | V-funnel (sec) | 6.4 | 25 | 10.4 | 15.4 | 10~25 |

| T50 time (sec) | 5.4 | 5.5 | 6.8 | 6.8 | 5~20 | |

| T50 time (mm) | 320 | 325 | 340 | 338 | T50 time | |

| Concave test elevation difference * (mm) | 25 | 0 | 10 | 0 | --- | |

Note:* Concave elevation difference means SCC test surface and queered up mold surface height difference.

Table 2: Flow ability of SCMC.

The packing height is 320 mm-340 mm according to the box test R1 obstacle measurement. The unit water consumption of the OC mix is larger (185 kg/m3 > 159 kg/m3), but the PMC mix design has partial cement replaced by slag and fly ash; the cement content is only 43.5% of that of the OC mix design, and the hydration heat reaction can be slowed.

Compressive strength

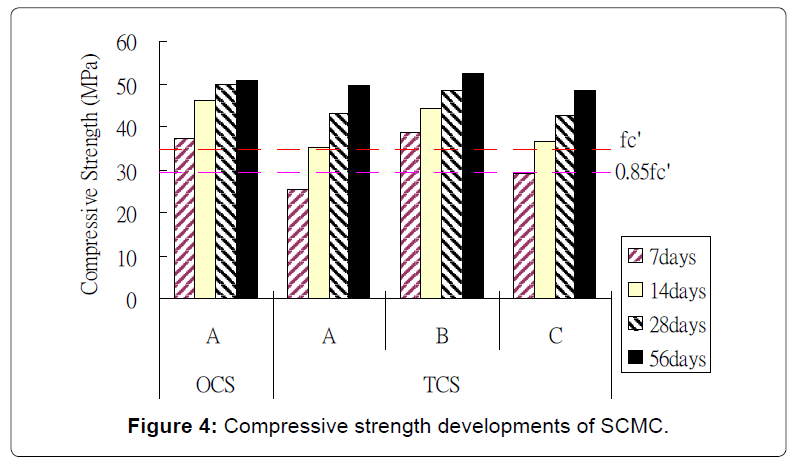

Table 3 and Figure 4 show that the compressive strengths of self-compacting concrete specimens with pozzolan (PMC) from manufacturers A, B and C are 43.02, 48.31 and 42.63 MPa, respectively, at the age of 28 days. These values are higher than the design strength of 34.33 MPa by approximately 25%, 41% and 24%, respectively. Thus, the strength of SCMC mixed with PMC meets the engineering requirement.

| OC | PMC | ||||

|---|---|---|---|---|---|

| Item | Age (days) | A | A | B | C |

| Compressive strength (MPa) |

7 | 37.24 | 25.28 | 38.71 | 29.01 |

| 14 | 46.26 | 35.18 | 44.30 | 36.55 | |

| 28 | 49.78 | 43.02 | 48.31 | 42.63 | |

| 56 | 50.57 | 49.49 | 52.33 | 48.41 | |

| Strength efficiency of cement (psi/kg/m3) |

7 | 10.3 | 16 | 24.5 | 18.4 |

| 14 | 12.8 | 22.3 | 28.1 | 23.2 | |

| 28 | 13.7 | 27.3 | 30.6 | 27 | |

| 56 | 14 | 31.4 | 33.2 | 30.7 | |

| Ultrasonic pulse velocity (m/s) |

7 | 3,927 | 3,921 | 3,928 | 3,977 |

| 14 | 4,147 | 4,057 | 4,056 | 4,109 | |

| 28 | 4,153 | 4,135 | 4,179 | 4,267 | |

| 56 | 4,307 | 4,300 | 4,283 | 4,285 | |

| Electrical resistance (kΩ-cm) |

7 | 4.9 | 3.4 | 9.9 | 8.4 |

| 14 | 7.2 | 6 | 13 | 16.3 | |

| 28 | 8.4 | 8.7 | 15.5 | 25 | |

| 56 | 9.3 | 14.5 | 19.3 | 43.3 | |

Table 3: Hardened property measurement of SCMC.

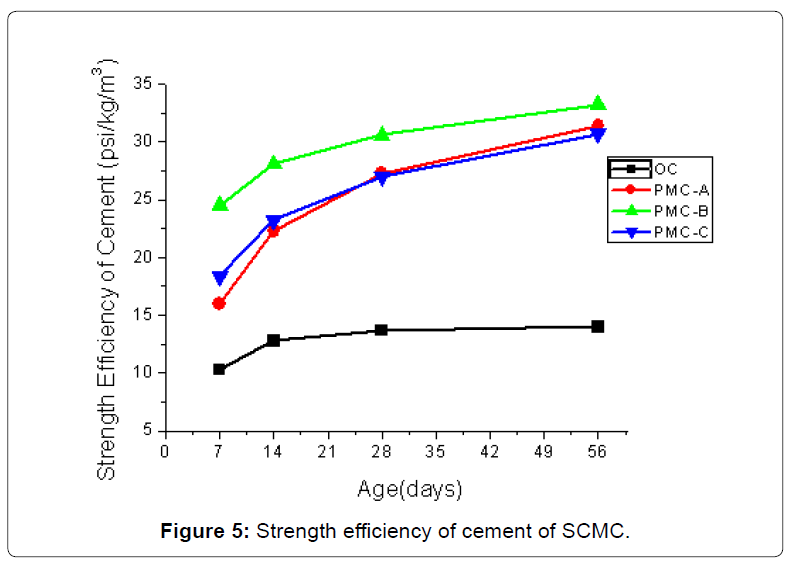

Strength efficiency of cement

Table 4 and Figure 5 show that the cement content of PMC is lower than that of the OC mix by 298 kg/m3. The PMC strength efficiency is 31.2-33.0 psi/kg/m3 on Day 56, which is more than twice the value for the OC mix. This means that the strength of the pozzolan mix meets the engineering requirement, and the cement has high strength efficiency. These are economical and environmentally friendly values.

| NO(type of SCC) | Specimens Number |

Compressive strength (MPa) | Core-drilled area | The regional average compressive strength(MPa) |

The total average compressive strength(MPa) |

The total average surface resistance value (kΩ-cm) |

|---|---|---|---|---|---|---|

| A | 1 | 29.01 | Feed channel | 29.20 | 31 | 96 |

| (PMC) | 2 | 29.40 | ||||

| 3 | 31.95 | Flow channel | 32.34 | |||

| 4 | 30.97 | |||||

| 5 | 33.52 | |||||

| 6 | 32.93 | |||||

| 7 | 29.60 | Rise channel | 29.74 | |||

| 8 | 29.89 | |||||

| B | 1 | 40.47 | Feed channel | 41.55 | 40 | 49 |

| (PMC) | 2 | 42.63 | ||||

| 3 | 43.32 | Flow channel | 39.89 | |||

| 4 | 35.97 | |||||

| 5 | 41.06 | |||||

| 6 | 39.20 | |||||

| 7 | 37.73 | Rise channel | 38.56 | |||

| 8 | 39.40 | |||||

| C | 1 | 41.16 | Feed channel | 42.14 | 41 | 65 |

| (PMC) | 2 | 43.12 | ||||

| 3 | 40.08 | Flow channel | 41.36 | |||

| 4 | 42.24 | |||||

| 5 | 41.94 | |||||

| 6 | 41.16 | |||||

| 7 | 39.79 | Rise channel | 38.51 | |||

| 8 | 37.24 | |||||

| A | 1 | 53.31 | Feed channel | 49.83 | 51 | 33 |

| (OC) | 2 | 46.35 | ||||

| 3 | 52.33 | Flow channel | 50.98 | |||

| 4 | 50.47 | |||||

| 5 | 51.35 | |||||

| 6 | 49.78 | |||||

| 7 | 51.84 | Rise channel | 50.42 | |||

| 8 | 49.00 |

Table 4: Compressive strength and resistivity for big U-shaped channel test of Core-drilled specimens (age of 28 days).

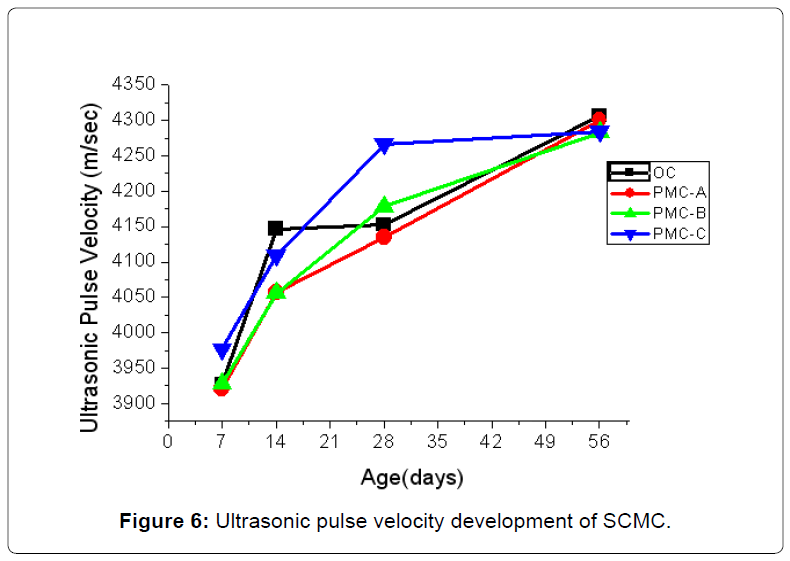

Ultrasonic pulse velocity

Table 5 and Figure 6 show that the ultrasonic pulse velocities of various SCMC groups are greater than 4,000 m/s at the age of 14 days. In addition, the constituents of concrete, listed in order of their contribution to the ultrasonic pulse velocity, are coarse aggregates, fine aggregates and cement paste. Although the OC mix has a lower W/C, its hydration is faster at an early age, and its ultrasonic pulse velocity is greater. However, the amount of aggregate in the PMC mix is greater than in the OC mix by 90 kg, and the pozzolanic reaction increases the internal compactness. The difference between the two ultrasonic pulse velocities is not apparent at 56 days.

| Ratio | Specimen size (m) | The maximum temperature measuring point (°C) | The maximum Temperature difference (°C) | |||

|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | |||

| OC | 1.8x1.8 | 57 | 60.1 | 76.2 | 72.3 | 24.4 |

| PMC | 57.1 | 53.3 | 65.7 | 61.5 | 19.1 | |

Table 5: Solid model -temperature measurements.

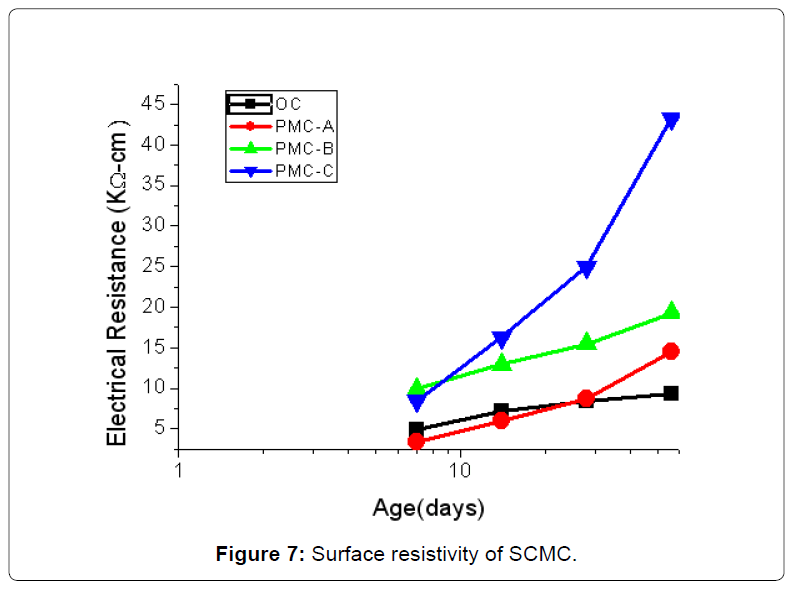

Electrical resistance

Table 3 and Figure 7 show that the electrical resistance of the PMC mix design of the manufacturer exceeded 20 kΩ-cm at the curing age of 56 days, meeting the standard of general corrosion resistant concrete. Although the electrical resistance of the PMC from manufacturers A and B did not meet the standard, according to the growth slope of the electrical resistance curve, the long-term electrical resistance of the concrete is supposed to meet the standard. In addition, the electrical resistance of the OC mix was only 9.3 kΩ-cm on Day 56, and the growth curve was smooth, meaning that micro-cracks are likely to occur inside the concrete if the concrete has high cement content and high water content. Therefore, the concrete has higher conductivity in the saturated surface dry state, meaning that the compactness and impermeability are worse. These changes negatively affect the durability.

Big U-shaped channel test

Filling capacity: Table 5 shows that the SCMC samples provided by various plants passed the Big U-shaped channel test. The aggregates can be suspended on the surface of the SCMC after transportation, pouring and squeezing lift-up. This means that the actual flow and squeezing lift-up are good, and it shows that there is no aggregate sedimentation or segregation. The height differences between the squeezing lift-up surfaces and the model top surfaces of the pozzolan SCMC samples from various plants were 0-10 mm in the Big U-shaped channel test, so the filling capacity was a little better than it was for the OC mix design (25 mm).

Analysis of core-drilled specimens: Table 4 shows that the aggregates in the core-drilled specimens from various parts of the SCMC samples of various manufacturers are distributed uniformly. The compressive strength and surface resistance of core-drilled specimens from various parts of the SCMC hardened concave specimens of various manufacturers were measured, making it possible to determine the internal structure quality after SCMC pouring and filling. The average compressive strengths of the core-drilled specimens from various core zones of the PMC mixes of manufacturers B and C and the OC of manufacturer A were higher than the design strength (fc’=34.3 MPa). Because the PMC mix from manufacturer A was tested in December and because the core-drilled specimens were cured in air, the hydration process and the pozzolanic reaction were slow. Therefore, the compressive strengths of the core-drilled specimens were only 29.2~32.34 MPa on Day 28. That result is still higher than the specified 0.85fc’ (29.16 MPa). Although the average compressive strength of the OC hardened concave specimens is higher than that of the PMC specimens, the electrical resistance on Day 28 was only 1/3~2/3 of that of PMC. It is obvious that the internal density of PMC is higher than that of OC, so PMC is more impermeable.

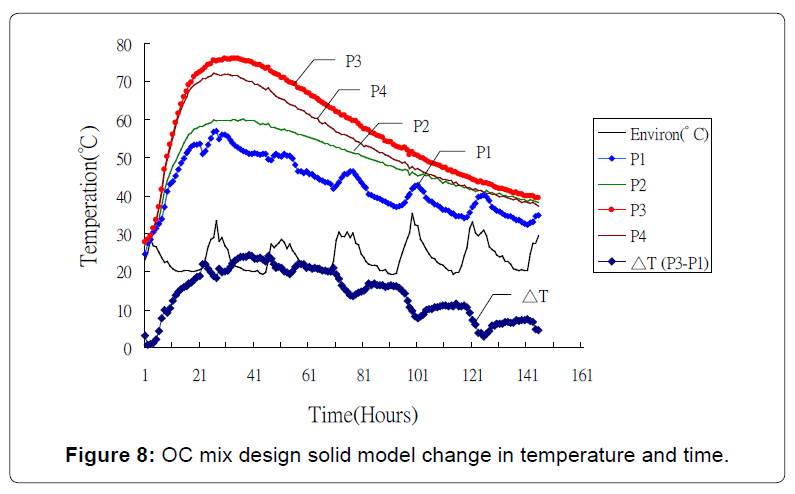

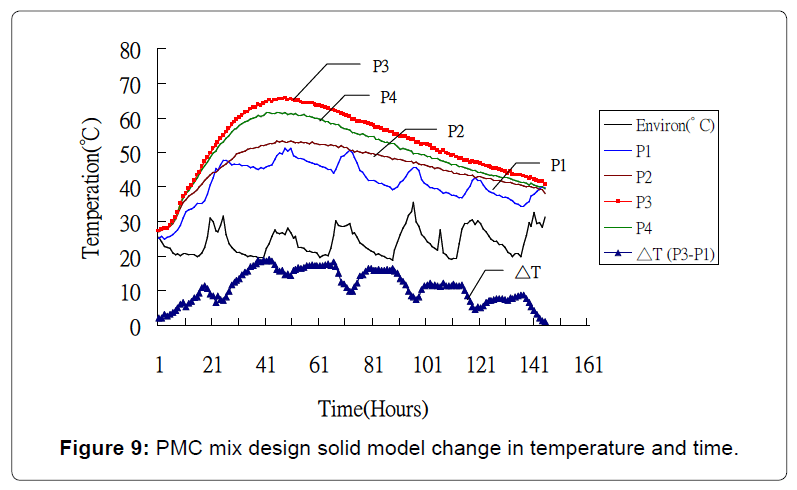

Mock-up hydration temperature

Table 5 and Figure 8 shows that the maximum temperature of the PMC mix (65.7°C) is lower than that of the OC mix (76.2°C) by 10.5°C, which means that the replacement of cement by pozzolanic material can actually reduce the hydration heat. The maximum temperature difference of PMC is lower than that of OC by 5.3°C, meaning that the replacement of cement by pozzolanic material can also reduce the mass concrete temperature difference.

Conclusion

• For a self-compacting mass concrete OC mix, when the cement content is high and the coarse aggregate is low and when a highperformance water-reducing agent is used, the flow time fails to meet the R1 requirement in a V funnel experiment, meaning that insufficient consistency is likely to cause segregation.

• The PMC mix replaces some of the cement with slag and fly ash. The resulting cement content is only 43.5% of that of the OC mix, but the compressive strength is 24%-40% greater, and the strength efficiency is more than twice as high (Figure 9).

• The ultrasonic pulse velocity reaches high quality above 4,000 m/s, meaning that the internal compactness is good.

• The electrical resistances of cylinder specimens are lower than 20 kΩ-cm at the age of 14 days, so the specimens do not meet the general corrosion resistance standard for concrete. However, the electrical resistance of the PMC mix is greater than that of OC, and it increases with age, so the durability is good.

• The replacement of cement by pozzolanic material can actually reduce the hydration heat and the mass concrete temperature difference.

• The disqualification of on-site fresh properties of SCMC usually occurs because the fine aggregate FM is relatively low and the moisture content in the aggregate is too high, so a correction has been made, and the mix proportion has been adjusted.

References

- Uysal M, YilmazK (2011) Effect of mineral admixtures on properties of self-compacting concrete. Cement & Concrete Composites 33: 771-776.

- Liu M (2010) Self-compacting concrete with different levels of pulverized fuel ash.Constr Build Mater 24: 1245-1252.

- Leemann A, Loser R, Munch B (2010) Influence of cement type on ITZ porosity and chloride resistance of self-compacting concrete. Cement and Concrete Composites 32: 116-120.

- Kou SC, Poon CS (2009) Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cement and Concrete Composites 31: 622-627.

- Filho FMA, Barragan BE, Casas JR. ALHC El Debs (2010) Hardened properties of self-compacting concrete - a statistical approach. Construction and Building Materials 24: 1608-1615.

- Boukendakdji O, Kenai S, Kadri EH, Rouis F (2009) Effect of slag on the rheology of fresh self-compacted concrete. Construction and Building Materials 23: 2593-2598.

- Craeye B, De Schutter G, Desmet B, Vantomme J, Heirman G, et al. (2010) Effect of mineral filler type on autogenously shrinkage of self-compacting concrete.Cement and Concrete Research 40: 908-913.

- Hills F (2000) ACI Committee 116: Cement and Concrete Terminology (ACI 116R-00). American Concrete Institute.

- Wang XY, Lee HS (2010) Modeling the hydration of concrete incorporating fly ash or slag. Cement and Concrete Research40: 984-996.

- Langan BW, Weng K, Ward MA (2002) Effect of silica fume and fly ash onheat of hydration of Portland cement. Cement and ConcreteResearch 32: 1045-1051.

- David G, Snelson Stan Wild, Martin O Farrell (2008) Heat of hydration of Portland Cement–Metakaolin–Fly ash(PC–MK–PFA) blends. Cement and Concrete Research 38:832-840.

- Mustafa S, Yaman IO, Mustafa T (2009) Transport and mechanical properties of self-consolidating concrete with highvolume fly ash. Cement & Concrete Composites 31: 99-106.

- Okamura H, Ouchi M (2003) Self-compacting Concrete. Journal of Advanced Concrete Technology Japan Concrete Institute 1: 5-15.

- Chou CJ (2009) Effects of fly ash and slag on compressive strength and toughness of high performance concrete. Institute of civil engineering,National Chung Hsing University for the degree of master of engineering.

- XieY, Liu B, Yin J, Zhou S (2002) Optimum Mix Parameters of High-Strength Self-Compacting Concrete with Ultra pulverized Fly Ash. Cement and Concrete Research32: 477-480.

- Bouzoubaa N, Lachemi M (2001) Self-Compacting Concrete Incorporating High Volumes of Class F Fly Ash: Preliminary Results. Cement and Concrete Research 31: 413-420.

Relevant Topics

- Architect

- Architectural Drawing

- Architectural Engineering

- Building design

- Building Information Modeling (BIM)

- Concrete

- Construction

- Construction Engineering

- Construction Estimating Software

- Engineering Drawing

- Fabric Formwork

- Interior Design

- Interior Designing

- Landscape Architecture

- Smart Buildings

- Sociology of Architecture

- Structural Analysis

- Sustainable Design

- Urban Design

- Urban Planner

Recommended Journals

Article Tools

Article Usage

- Total views: 15883

- [From(publication date):

October-2015 - Apr 21, 2025] - Breakdown by view type

- HTML page views : 11108

- PDF downloads : 4775