A Review on Some Physico-Chemical Compositions of Bread Wheat Determined By Using Destructive and Non-Destructive Methods

Received: 01-Jul-2024 / Manuscript No. acst-24-141034 / Editor assigned: 04-Jul-2024 / PreQC No. acst-24-141034 / Reviewed: 18-Jul-2024 / QC No. acst-24-141034 / Revised: 22-Jul-2024 / Manuscript No. acst-24-141034 / Published Date: 29-Jul-2024

Abstract

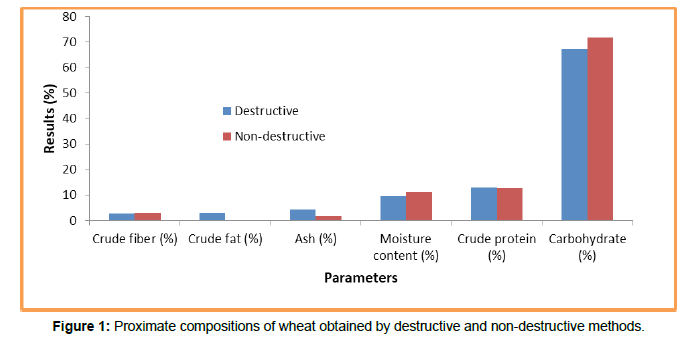

Some physico-chemical compositions of bread wheat (Triticum aestivum) were determined by using destructive and non-destructive methods. Standardized conventional method by Association of Official Analytical Chemists (AOAC) food analysis scheme was used for the destructive approach while near infrared spectrophotometer was used to measure some proximate compositions of wheat as a non-destructive method. Near infrared techniques for obtaining the proximate compositions in the bread wheat was found to be more economical and faster without destroying the actual proximate compositions of the grains. The proximate compositions of bread wheat determined by using nondestructive measurement were moisture content 11.07 ± 0.03%, crude fiber 3.00 ± 0.00% and carbohydrate 71.80 ± 0.35% and the proximate compositions of bread wheat determined by using the destructive measurement were 9.50 ± 0.10%, 2.67 ± 0.07% and 67.28 ± 0.39%, respectively. Statistical analysis showed that there was no significant difference between the values obtained by the destructive and non-destructive methods for the determination of the physico-chemical compositions of bread wheat samples .Therefore, non-destructive method is economical, fast and save time compared to the crushing of the sample and addition of chemical reagents in the samples.

keywords

Analytical method; Comparison; Composition; Destructive; Non-destructive

Introduction

Wheat (Triticum spp.) is the most important human food grain and ranks second in total production as a cereal crop behind maize, the third being rice (Adams et al., 2002). It is a staple food used to make flour for leavened, flat and steamed breads, cookies, cakes, pasta, spaghetti, macaroni, noodles, couscous and for fermentation to make alcoholic beverages (Adams et al., 2002). Wheat is an excellent health-building food and is considered to be good source of protein, minerals, B-group vitamins and dietary fiber. It has become the principal cereal, being more widely used for the making of bread than any other cereal because of the quality and quantity of its characteristic protein called gluten [1].

Wheat has several medicinal virtues, some of which include starch and gluten having the ability to provide heat and energy, the inner bran coats, phosphates and other mineral salts, the outer bran which is the much-needed roughage, is known to be indigestible portion that helps easy movement of bowels, the germ, vitamins B and E and protein of wheat help to build and repair muscular tissue. Gluten makes bread dough stick together and gives it the ability to retain gas. The wheat germ, which is removed in the process of refining, is also rich in essential vitamin E, the lack of which can lead to heart disease [2]. The loss of vitamins and minerals in the refined wheat flour has led to widespread prevalence of constipation and other digestive disturbances and nutritional disorders. The whole wheat, which includes bran and wheat germ, therefore, provides protection against diseases such as constipation, heart disease and disease of the colon called diverticulum, appendicitis, obesity and diabetes (Kumar et al., 2011) [3].

Wheat seeds consist of three parts namely the germ containing oil, the endosperm and the bran which is the protective covering containing fiber [4]. The amount of germ in cereal grains varies from less than 2% in wheat to more than 10% in corn and because of high oil content, the germ is often roasted and sold vacuum-packed to prevent its becoming rancid. The germ oil can be pressed out in the milling industries and sold as cooking oil (David et al., 2004). Foods containing cereal flours have been very important to human nutritional needs since ancient time. In developing countries, most cereal flours are enriched with Vitamin B1, Vitamin B2, niacin and iron. Vitamin D and calcium are also added to flours for use in areas where flour is a primary nutritional source [5].

Non-destructive testing (NDT) is a wide group of analytical techniques used in science and industry to evaluate the properties of a material, component or system without causing damage (Cartz, 1995). Non-destructive measurement refers to measurement performed using specialized equipment without causing any adverse effect or damage on the product on which the measurement is carried out. The terms Non-destructive examination (NDE), Non-destructive inspection (NDI) and Non-destructive evaluation (NDE) are also commonly used to describe this technology. NDT is a highly valuable technique that can save both money and time in product evaluation, troubleshooting and research. Common NDT methods include ultrasonic, magnetic particle, liquid penetrant, radiographic, spectrophotometer [Near Infrared (NIR), Mid-Infrared (MI) or Far-Infrared (FI) Spectroscopy], remote visual inspection (RVI), eddy current testing and low coherence interferometry (Losert, 2009). NDT is a commonly-used tool in agricultural engineering, forensic engineering, mechanical engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine and art (Cartz, 1995) [6,7].

Near infrared spectroscopy provides an alternative, non-destructive technology for measuring constituents of biological materials. Organic molecules have specific absorption patterns in the near infra-red region that can report the chemical composition of the material being analyzed (Williams and Norris, 2001). Near infra-red spectra can be collected either from the reflectance (NIR) of a sample or the transmittance (NIT) through a sample (Delwiche, 1995). Near Infrared Spectrophotometer (NIRS) is routinely used in agriculture for the analysis of food stuffs, drugs and many research analyses. The method has been broadly accepted and is widely used in quality assessment of foods, beverages and researches. The method is relatively inexpensive, rapid, preserves the sample and is able to measure several constituents concurrently. Current food and beverage applications of NIRS are dominated by proximate quality assessment and research focused on this aspect of near infrared analysis is very active. However, the use of NIRS as a tool for monitoring, ecological and physiological research remains underdeveloped. Research investigating its use in these and other microbiological monitoring functions is required and would provide a valuable, cost effective addition to proximate systems already in place within many food industry (Rolf, 2009) [8].

Determination of some physico-chemical compositions of bread wheat by using destructive and non-destructive methods.

Near infrared spectrophotometer was followed to carry out non-destructive measurements on the cereal grain to determine its proximate compositions. This involve measurement of about 20 to 30 g of the sample in the plate provided for the equipment, placing the sample container under the DA7200 NIR spectrophotometer and press the analyze button. The NIR ray scan through the sample as it rotates within it conferment and immediately, the result of the proximate compositions was displayed on the DA7000 screen less than 1 to 2 min. For the destructive approach, proximate compositions determination were assayed as described by association of official analytical chemists food analysis scheme for the determination of proximate compositions of cereal grains, all the reagents used for the laboratory analysis were all of analytical grade and most of the equipment used for the analysis are sophisticated, automated and are supplied by Foss Company (Sweden). Each analysis was carried out in triplicates.

As shown on Figure the level of significant in the values shows that there were no significant differences in the proximate compositions of bread wheat grain determined when both destructive and non-destructive approaches were applied (P < 0.05). This is an indication that non-destructive method is more advantageous over the destructive method in terms of economic issues and rapidity in physico-chemical content determination for cereal grains. The crude fat content obtained for wheat in this study was observed to be 3.11 ± 0.41% when destructive technique was used which indicate similar trend as observed with the findings by Adams et al. (2002) where the value for wheat obtained was 3.15 ± 0.40% for the production of noodles (Figure 1) [9].

The trend of the obtained results are low when compared with previous research for wheat 12.26 ± 0.00% as reported by Atwell (2001) and Alan et al. (2000). This could be as a result of varietal differences in the cultivar and environmental conditions which give wide variation in chemical characteristics observed within and among the grains. However, the results obtained in this work were observed to be higher than the reported values for wheat 1.28 ± 0.6%, necessary for the production of noodles (Akanbi et al., 2011). The implication of higher fiber content for the grains is to help the consumer to be healthier by keeping the bowels working and moving other foods quickly through the body for metabolic purposes. Ash content of wheat was significantly different (P < 0.05) for both the destructive and non- destructive measurements. For the destructive method, the ash content of wheat 4.41 ± 0.01% was significantly higher than the recorded value of wheat 1.71 ± 0.01% when non-destructive approach was applied. However, in the destructive measurement, the value was observed to be higher than the findings for wheat 2.25 ± 0.00% (Akanbi et al., 2011; Subramanium and Metta, 2000). But the ash content obtained from the non-destructive measurement was observed to be lower when compared with the reported value 2.25 ± 0.00% for wheat by the same researcher. This could be an indication that the pericarp and seeds vary substantially with respect to cereal grain constituent depending on the cultivar and environmental condition which could be the possible reason for the observed differences. Differences in bulk density and texture of the grains could be other possible reasons for the two significant sources of errors in NIR reflectance measurement. The carbohydrate content obtained in this work for wheat also indicates significant differences in the grain sample used for the analysis for both the destructive and non-destructive measurements when compared with each other. The non-destructive measurement quantified higher significant carbohydrate content for wheat 71.80 ± 0.35% over the recorded value of wheat 67.27 ± 0.39% when the destructive method was applied. However, this trend is in agreement with the reported range 65 to 75% necessary for the production of pastry products (Belderok et al., 2000) [10].

Conclusions

Compared to the destructive methods, the non-destructive methods is very important and is easily applicable for agricultural and industrial purposes. Therefore, the non-destructive method of proximate compositions determination can economically replace the conventional destructive method effectively without destroying the proximate compositions of the food products. Cereal grain industries, food processing industries and research institutes now have a tool for faster, economical and non-destructive means of proximate composition determination for their grains. Proximate compositions deserve to be adequately and economically determined. In view of this, technological advancement and utilization should address in food processing industries to ensure quick method of determining nutritional constituents in agricultural products by using non-destructive methods.

Recommendation

Compared to destructive methods, non-destructive methods are economical, fast and save time without destroying their corresponding qualities. Hence, for users it is better to use non-destructive methods than destructive methods.

References

- Adams ML, Lombis E, Zhao FJ, McGrath SP (2002) Evidence of low selenium concentrations in UK bread making wheat grain. J Sci Food Agric 82:1160-1165.

- Akanbi TO, Nazamid S, Adebowale AA, Farooq A, Olaoye AO, et al. (2011) Breadfruit, starch wheat, flour noodles. Preparation, proximate compositions and culinary properties. Int Food Res J 18:1283-1287.

- Belderok B, Mesdag H, Donner DA (2000) Bread-making quality of wheat. Acta Chimica Slovaca 2:115-138.

- Cartz L (1995) Non-destructive Testing. ASM International. ISBN: 9780871705174.

- David S, Gary M, Tom H, Kelvin M, Pamela C, et al. (2004) Department of Agriculture Market Access Programme (MAP). Grant made Available to Wheat Marking Centre, Inc Portland Oregon USA.

- Delwiche SR (1995) Single wheat kernel analysis by near infrared transmittance-protein content. J Cereal Chem 72:11-16.

- Kumar P, Yadava RK, Gollen B, Kumar S, Verma RK, et al. (2011) Nutritional contents and medical properties of wheat. Life Sci Med Res J 2:1-10.

- Rolf N (2009) Application of Near Infra-red Spectroscopic Analysis in the Food Industry and Research Food Safety Centre. Tasmanian Institute of Agricultural Research, University of Tasmania, Australia pp: 1 - 5.

- Subramanium V, Metta VC (2000) Sorghum Grain for Poultry in Technical and Institutional Options for Sorghum Grain Mold Management. Proceedings of an International Consultation, ICRISAT India 242 - 247.

- Williams PC, Norris K (2001) Near Infra-red Technology in Agricultural and Food Industries, Second Edition. American Association of Cereal Chemists. Incoorperation.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Abraha G (2024) A Review on Some Physico-Chemical Compositions ofBread Wheat Determined By Using Destructive and Non-Destructive Methods. AdvCrop Sci Tech 12: 714.

Copyright: © 2024 Abraha G. This is an open-access article distributed under theterms of the Creative Commons Attribution License, which permits unrestricteduse, distribution, and reproduction in any medium, provided the original author andsource are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 297

- [From(publication date): 0-2024 - Feb 23, 2025]

- Breakdown by view type

- HTML page views: 251

- PDF downloads: 46