A Review on Energy Management in Textile Industry

Received: 12-Aug-2017 / Accepted Date: 29-Aug-2017 / Published Date: 06-Sep-2017 DOI: 10.4172/2576-1463.1000169

Abstract

In textile mill, electricity consumption is in increasing trend, due to modernized machines and continuous usage of the equipment’s in inefficient operating parameters. Textile sector may be considered as one of the largest industrial sector in India and at the same time it is also one of the oldest sectors in the country. Even after a lot of technological development globally, most of the mills are using the same old technology. The energy cost is around 15%-20% over the production cost and it stands next to raw material cost. Hence now a day’s area of focus is towards energy consumption at load end and by optimizing the efficiency of the motor. Although for the last few years process of modernization in textile industries are underway but still the pace is slow. So, in order to include major players of textile sector as well as other energy intensive industries for energy efficiency movement. In this paper, influence of various areas of energy consumption and process of optimisation in textile mill on energy conservation is discussed with practical data.

Keywords: Energy efficiency; Textile industry; Conservation; Management; Organizations.

23134Introduction

Textile Industry in India is one of the vital components of the Indian economy and contributing around 14%. of total industry production, about 4% of India’s Gross Domestic Product (GDP), about 17% of the gross export earnings and employing about 35 million people being the second largest provider of employment after agriculture. Taking the installed capacity of spinning machinery only, it ranks second (with 19.6% of total spindles globally), after China. In textile industry, electricity consumption and power cost is in increasing trend due to modernised machines and continuous usage of the machines in inefficient operating parameters [1].

Apart from the power cost, man power is also shortage in textile mills due to dusty environment inside the mill and heavy noise from the textile machines. Due to these reasons workers are not showing interest in working at textile mills, which compel mill management to deploy more automated machines. Hence, textile machinery manufacturers are integrating automation in the machines, indirectly requirement of power of the machines is increased.

The main objective of the textile mill is to produce yarn (thread) from the raw cotton which requires six stages of process. These are discussed briefly for readers understanding. The implementation of energy conservation programmes in spinning mills has gained wide acceptance in the back-ground of the rising cost of energy. With more and more utilisation of electrical energy and faster growth of industry, the impetus on energy conservation is increasing by leaps and bounds. The pressure of energy bill and pressure on the total available energy is very much needed for further development. The most important thing is conversion of electrical energy into mechanical energy. Normally the conversion efficiency is 85%. But even 1% increase in this figure will reduce the energy bill by millions of rupees. Today 85% of the industrial loads are driven by electric motors. Out of this induction motor itself constitutes 30% of the total drive system. So the thrust has been given on the loss minimization control of induction motor drives and energy saving to the maximum level possible extent in a spinning mill using systematic approach. The three major factors for energy conservation are high capacity utilisation, fine-tuning of equipment and technology upgradation.

The textile mill can be split into three systems namely, card sliver, combed sliver and ring spinning system. The card sliver system consists of blowroom and carding machine, which does the function of removing the foreign particle from the raw cotton and convert the same into thick yarn (sliver). The combed sliver system consists of draw frame and comber machines, the draw frame machine ensures the uniformity in thickness of the sliver and comber machine removes the unwanted short fibre in the sliver. Ring spinning system consists of Speed frame and Ring frame machine, which does the conversion of sliver (thick thread) into yarn (thin thread). Ring frame is the final product of the spinning mill.

Textile Processes

The textile industry has one of the most complicated industrial chains in the manufacturing industry. It is a fragmented and heterogeneous sector dominated by SMEs, with a demand mainly driven by three dominant end-uses: clothing, home furnishing and industrial use. Characterizing the textile manufacturing is complex because of the wide variety of substrates, processes, machinery and components used, and finishing steps undertaken. Different types of fibers or yarns, methods of fabric production, and finishing processes (preparation, printing, dyeing, chemical/mechanical finishing, and coating), all interrelate in producing a finished fabric. When one of these components is changed, the properties of the end product are affected. There are several properties that can be used to define a fabric. Some examples of fabric properties include weight, appearance, texture, strength, luster, flexibility, and affinity to dyestuff.

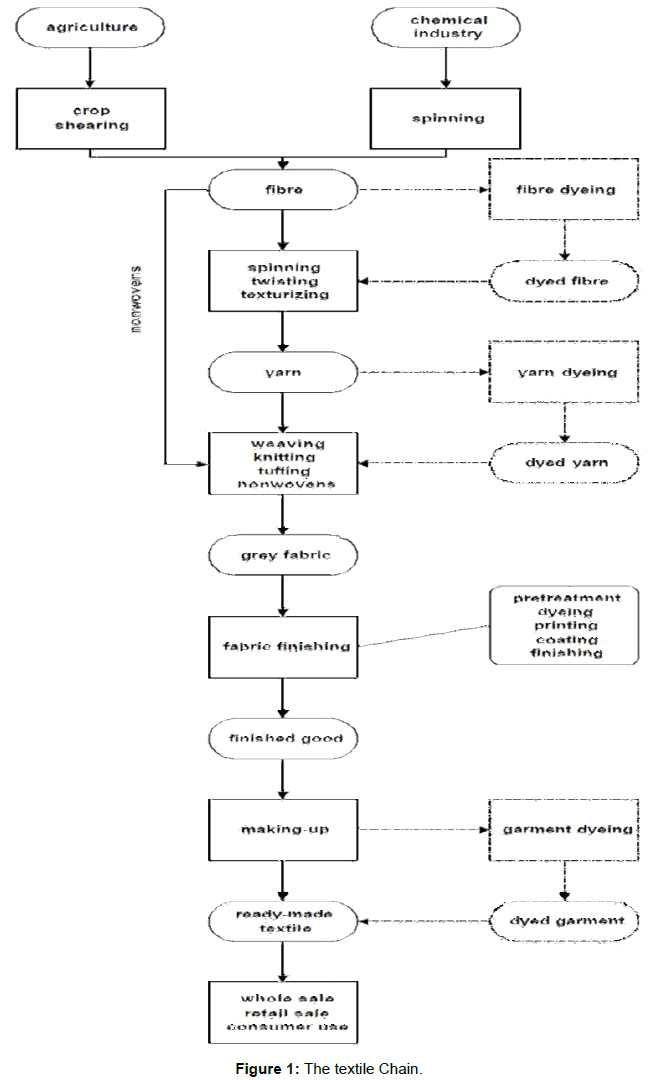

Figure 1 is a generalized flow diagram depicting the various textile processes that are involved in converting raw materials in to a finished product. All of these processes do not occur at a single facility, although there are some integrated plants that have several steps of the process all in one plant. There are also several niche areas and specialized products that have developed in the textile industry which may entail the use of special processing steps that are not shown in Figure 1.

Due to the variety of the processes involved in the textile industry, there are too many processes to be explained within the space constraints of this guidebook 7.

Energy Use In The Textile Industry

The textile industry, in general, is not considered an energyintensive industry. However, the textile industry comprises a large number of plants which all together consume a significant amount of energy. The share of total manufacturing energy consumed by the textile industry in a particular country depends upon the structure of the manufacturing sector in that country. For instance, the textile industry accounts for about 4% of the final energy use in manufacturing in China [2] while this share is less than 2% in the US. The share of the total product cost expended on energy in the textile industry also varies by country. Table 1 shows general shares of cost factors for 20 Tex combed cotton yarn in several countries. Energy cost is often the third or fourth highest share of total product cost [3].

| Cost factors | Brazil | China | India | Italy | Korea | Turkey | USA |

|---|---|---|---|---|---|---|---|

| Raw material | 50% | 61% | 51% | 40% | 53% | 49% | 44% |

| Waste | 7% | 11% | 7% | 6% | 8% | 8% | 6% |

| Labor | 2% | 2% | 2% | 24% | 8% | 4% | 19% |

| Energy | 5% | 8% | 12% | 10% | 6% | 9% | 6% |

| Auxiliary | 4% | 4% | 5% | 3% | 4% | 4% | 4% |

| Capital | 32% | 14% | 23% | 17% | 21% | 26% | 21% |

| Total | 100% | 100% | 100% | 100% | 100% | 100% | 100% |

Table 1: Share of manufacturing cost factors for 20 Tex combed cotton yarn in several countries in 2003.

The textile industry uses large quantities of both electricity and fuels. The share of electricity and fuels within the total final energy use of any one country’s textile sector depends on the structure of the textile industry in that country. For instance, in spun yarn spinning, electricity is the dominant energy source, whereas in wet-processing the major energy source is fuels. From Table 1 it can see that share of energy in manufacturing cost is day by day increasing and in india in 2003 it was 12% but nowdays it has gone upto 18-20%.

Breakdown of energy use by end-use

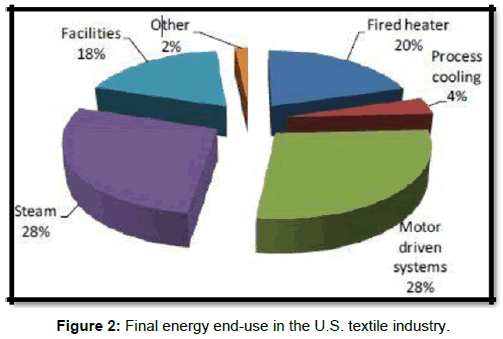

In a textile plant, energy is used in different end-uses for different purposes. Figure 2 shows the Breakdown of final energy use by end use in the U.S. textile industry [4]. Although the percentages shown in the graph can vary from one country to another, this figure gives an indication of final energy end-use in the textile industry. However, it should be noted that it is more likely that the textile industry in the U.S. does not include as many labor-intensive processes (e.g. spinning and weaving) as it does in some developing countries like China and India where the cost of labor is lower. As is shown in the figure below, in the U.S. textile industry steam and motor-driven systems (pumps, fans, compressed air, material handling material processing, etc.) have the highest share of the end-use energy use and each accounts for 28% of total final energy use in the U.S. textile industry.

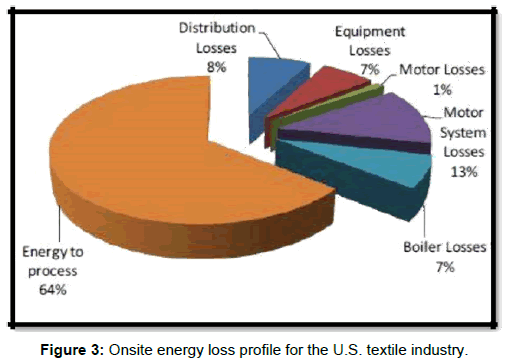

As indicated, there are significant losses of energy within textile plants. Figure 3 below shows the onsite energy loss profile for the U.S. textile industry [4]. Around 36% of the energy input to the U.S. textile industry is lost onsite. Motor driven systems have the highest share of onsite energy waste (13%) followed by distribution 4 and boiler losses (8% and 7% respectively). The share of losses could vary for the textile industry in other countries depending on the structure of the industry in those countries. However, the figure below gives an illustration of where the losses happen and the relative importance of each loss in the U.S. textile industry.

As shown above, motor driven systems are one of the major enduse energy wasters in the textile industry.

Koc and Kaplan calculated the energy consumption for spinning different types and counts of yarn and the results are shown in Table 2 [3]. For all types of fibers, finer yarn spinning consumes more energy. That said, yarns used for weaving involves more twisting than yarns used for knitting. Also, production speed is low for weaving yarn compared to that of knitting yarn. As a result, with the same yarn count, more energy is consumed for weaving yarn. Also, for the same yarn count, the energy consumption for combed yarn is higher because of the additional production step (combing).

| Yarn count (Tex) | Combed yarn | Carded yarn | ||

|---|---|---|---|---|

| Knitting | Weaving | Knitting | Weaving | |

| 37 | 138 | 163 | 134 | 162 |

| 33 | 158 | 188 | 154 | 186 |

| 30 | 179 | 212 | 173 | 209 |

| 25 | 219 | 260 | 211 | 255 |

| 20 | 306 | 364 | 296 | 357 |

| 17 | 389 | 462 | 374 | 453 |

| 15 | 442 | 525 | 423 | 512 |

Table 2: Typical specific energy consumption (kWh/kg) for yarns with different yarn counts and final use (Weaving vs. Knitting).

Improvement opportunities

The common measures for the energy conservation and energy efficiency in the textile industries are high capacity utilization, fine tuning of equipment’s and technology up gradation and other kind of re-engineering initiatives. Apart from this following are few important energy efficiency measures which is specific for subgroups and are in very much practice in Indian textile industries (Table 3).

| Spinning |

|

| Weaving |

|

| Processing |

|

Table 3: Innovative projects for different processes.

Higher spindle speeds and increased electrical utility rates have signicantly increased the energy costs of textile mills in India. Ring frames account for 75-80% of the energy consumption. Using a ring frame with a 30 mm tin roller pulley shaft and with light weight drum pulleys acheived significant savings. Using an invertor drive permited higher spindle speeds and productivity without additional energy consumption.

Energy-efficiency improvement opportunities in the textile industry

This analysis of energy-efficiency improvement opportunities in the textile industry includes both opportunities for retrofit/process optimization as well as the complete replacement of the current machinery with state-of-the-art new technology. However, special attention is paid to retrofit measures since state-of-the-art new technologies have high upfront capital costs, and therefore the energy savings which result from the replacement of current equipment with new equipment alone in many cases may not justify the cost. However, if all the benefits received from the installation of the new technologies, such as water savings, material saving, less waste, less waste water, less redoing, higher product quality, etc. are taken into account, the new technologies are more justifiable economically [5].

Energy Conservation Management Technologies

Since energy management is relevant to a wide range of departments within a company, it is necessary to enhance the awareness, improve the knowledge and obtain the participation and cooperation of everybody involved in the production process.

Improving efficiency of electricity use

Lighting: Due to its nature of operations, the share of lighting in electricity use is relatively high. It is important to re- examine whether the light source is utilized in the most efficient way and take electricity saving measures.

Electric motor: The textile industry uses a vast number of relatively small electric motors. While a conventional machine was driven by a single motor with the generated mechanical power transmitted to various parts of the machine in a collective manner, many modern machines utilize multiple motors with a control board controlling the movement of each motor, which is directly coupled to a machine part to drive it independently from others.

Electric heating: In the textile industry, electric heating has largely been replaced by other methods (steam, gas heating, or direct or indirect fired heating) for some time in order to achieve cost reductions

Improvements in efficient fuel use

Selection of fuel: In selecting fuels, those with good flue gas characteristics in addition to high calorific value and ease of combustion are desired, so that air pollution can be prevented as much as possible.

Selection of boiler: Boilers used in the textile industry have experienced a change from Lancastrian- or Scotch-type tubular or smoke tube to water-tube boilers, As a result, boiler efficiency has improved.

Improvement in efficient use of steam

Piping: The amount of steam in the textile industry involved is not so large but the locations where steam is required are widespread so that steam losses due to heat radiation from steam transportation pipes and pressure drops are considerable. For steam transportation over long distances, high pressure and small-diameter rather than low pressure and large diameter piping is desired.

Steam accumulators: A steam accumulator can be installed midway through the heat transporting pipe, between the boiler and the heat consuming load, in order to store excess steam when the load is light by transforming it to heated water

Utilization of heat exchanger

In each production process of the textile industry, the heating and cooling of gases and liquids as media of heat are frequently required. This is done through heat exchange between different fluids, and in order to avoid contamination or chemical reaction due to their direct contact, heat exchangers are used to carry out indirect heating and cooling.

Non-conventional sources of energy

The different alternative renewable sources of energy are biomass, tidal energy, geothermal energy, solar energy and wind energy. The technology is easy and straightforward to control, with nearly very little maintenance cost. There will not be any drawback of air pollution. It means that nothing is wasted and there is no effluent.

Energy Audit

An energy audit is a survey, inspection and analysis of energy flows for energy conservation in an industry to reduce the amount of energy input into the system without negatively affecting the output [6-13].

Areas of energy audit

In the study of Energy audit of the running equipment, see the visible abnormal symptoms in the inefficient transfer of energy in the system.

Lighting: Sparks, in case of contactor switching, loose joints etc.

Heating: In motors, other load equipment coupled to motor Due to Friction, metal-to-metal touch, poor lubrication, misalignment.

Summary and Conclusion

Energy is one of the main cost factors in the textile industry. Especially in times of high energy price volatility, improving energy efficiency should be one of the main concerns of textile plants. There are various energy-efficiency opportunities in textile plants, many of which are cost-effective. However, even cost-effective options often are not implemented in textile plants due mainly to limited information on how to implement energy-efficiency measures, especially given the fact that the majority of textile plants are categorized as SMEs. These plants in particular have limited resources to acquire this information. Know-how regarding energyefficiency technologies and practices should, therefore, be prepared and disseminated to textile plants.

References

- New Energy and Industrial Technology Development Organization (2009) A report on national survey on implementation of energy efficiency improvement technologies in textile sector.

- Koc E, Kaplan E (2007) An investigation on energy consumption in yarn production with special reference to ring spinning. Fibres Text East Eur 15: 63.

- United States Department of Energy (US DOE) (2004) Energy use, loss and opportunities analysis: U.S. manufacturing and mining.

- Sharma S (2014) Energy management in textile industry. Int J Pow Sys Oper En Manag 2: 45-49.

- Dhayaneswaran Y, Ashokkumar L (2013) A study on energy conservation in textile industry. J Inst Eng India Ser B 94: 53-60.

- Bhaskar MS, Verma P, Kumar A (2013) Indian textile industries towards energy efficiency movement. Int J Envir Sci Deve Mon (IJESDM) 4: 36-39.

- Worrell E, Bode JW, De Beer JG (1997) Energy-efficient technologies in industry. ATLAS project for the European Commission, Netherlands.

- Hasanbeigi A (2010) Energy-efficiency improvement opportunities for the textile industry, Ernest orlando lawrence berkeley national laboratory.

- http://www.emt-india.net/eca2006/Award2006_CD/32Textile/GrasimIndustriesLtdStapleFibreDivisionNagda.pdf

- Abdel-Dayem AM, Mohamad MA (2001) Potential of solar energy utilization in the textile industry-a case study. Renewable Energy 23: 685-694.

- Goyal S (2011) Energy conservation in textile industry. Lambert Academic Publishing.

Citation: Khude P (2017) A Review on Energy Management in Textile Industry. Innov Ener Res 6: 169. DOI: 10.4172/2576-1463.1000169

Copyright: ©2017 Khude P. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 14694

- [From(publication date): 0-2017 - Nov 21, 2024]

- Breakdown by view type

- HTML page views: 13310

- PDF downloads: 1384