Research Article Open Access

A Framework for Mitigating Respiratory Diseases in Underground Coal Mining by Emphasizing on Precautionary Measures

Satar Mahdevari* and Kourosh Shahriar

Department of Mining and Metallurgical Engineering, Amirkabir University of Technology, Tehran, Iran

- Corresponding Author:

- Mahdevari S

Department of Mining and Metallurgical Engineering

Amirkabir University of Technology, Tehran, Iran

Tel: +98 21 64542972

Fax: +98 21 66405846

E-mail: satar.mahdevari@aut.ac.ir

Received date: June 01, 2016; Accepted date: June 13, 2016; Published date: June 20, 2016

Citation: Mahdevari S, Shahriar K (2016) A Framework for Mitigating Respiratory Diseases in Underground Coal Mining by Emphasizing on Precautionary Measures. Occup Med Health Aff 4:239. doi:10.4172/2329-6879.1000239

Copyright: © 2016 Mahdevari S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Occupational Medicine & Health Affairs

Abstract

Background: By increasing the depth and extent of the underground mines, coal miners are at risk of developing lung diseases especially pneumoconiosis because of their regular exposure to airborne dusts and toxic gases. Mechanization results in accelerative production of higher dust levels and worst working conditions.

Aim of the study: Annual statistics show that most of the underground coal miners in Iran, with experience more than five years, are suffering from lung diseases. Due to that, this research was conducted in order to investigate the risk of exposure to coal dust at Kerman coalfield, Iran.

Participants and methods: A cross sectional study was carried out over 556 coal miners from three coal mines. Among them 460 persons directly worked at the coalface for at least five years. Spirometry tests were also done in order to determine the parameters of FEV1, FEV1/FVC and . Z-test with overall error set at 0.01 was used for comparison of the results.

Results: Differences between the results of the spirometry measurements for face and non-face miners were meaningful indicating the more vulnerability of the face miners to the disease. In addition, the results showed a nonlinear decline in FEV1 over the first five years of employment, with a sharp decrease in the first two years. According to the results, the face miners are more prone to respiratory diseases, however all miners are at risk.

Conclusion: Direct measurements showed that the dust levels in the coalfaces are high and exceed the recommended exposure limit of 1mg/m . Remedial and precautionary measures were found to be the most appropriate solution to mitigate the development of such tormented diseases. Therefore, a framework composed of the three major levels: precautionary measures, medical surveillance and remedial management was proposed by focus on the precautionary measures as the best solutions.

Keywords

Coal workers’ pneumoconiosis; Dust control; Precautionary measures; Respiratory diseases; Silicosis; Underground coal mining

Introduction

Coal mining has many hazards that make it unique in the field of occupational health and safety [1]. The hazardous nature of coal mine operations can be deduced from the statistics of mine accidents and injuries. Based on Bureau of Labor Statistics [2] underground coal mining is a relatively dangerous industry and the miners are more likely to be fatal or to incur a non-fatal injury or illness. Nevertheless, coal is an important global commodity and it will remain the largest energy source for the near future.

Approximately 60% of the world steel production and 40% of the current electricity production is powered by coal. The total known mineable coal deposits are sufficient for at least 300 years of use, the time when is approximately fivefold of known natural gas and tenfold of known crude oil. Coal has also played a significant role in the advancement of civilization, and it will continue to be a major fuel source in developing countries for at least the next quarter century.

Coal consumption has steadily increased since 2000 due to increased demand in China, the USA and India. Coal mining therefore remains an important growth industry worldwide, however it is still perceived to be a dangerous occupation, particularly for underground mining. Although underground coal mining is a mature endeavor, new information is still emerging on its health and safety consequences. Despite improvements in exposure assessment and ventilation controls as well as the existence of protective governmental regulations, coal miners are still at risk for respiratory diseases caused by coal dusts and their associated morbidity and mortality [3].

It has long been recognized that inhalation of harmful dusts and gases generated during mine extraction is associated with a lung disease unique to coal mining. In fact, there are wide varieties of respiratory disorders that can result from the inhalation of dusts, toxic gases, fumes and particles. In a general point of view, the diseases of respiratory system are usually appeared due to the inhalation of dusts and particles with aerodynamic diameters less than 10 microns.

The more common disorders usually observed in coal miners include pneumoconiosis, lung cancer, chronic obstructive pulmonary, asthma, chronic cough and bronchitis, reactive airways dysfunction syndrome, hypersensitivity pneumonitis, acute inhalational lung injury, benign pleural, mesothelioma, and respiratory infections, such as tuberculosis [4].

Now-a-days, by increasing the depth and extent of the underground mines, coal miners are at risk of developing lung diseases especially pneumoconiosis because of their regular exposure to airborne dusts and toxic gases. Thus, a contribution between mining engineers and clinicians should be prepared to diagnose these diseases and present applicable precautionary measures to prevent or control such diseases in underground coal mining. For this purpose, some remedial and precautionary measures are presented in this research in order to provide a better understanding of the disease and its incurable consequences.

Coal mining-related respiratory diseases

Mining-related diseases may be defined as the illnesses caused by physical, chemical and biological hazards or even psychological trauma which results from working in mines. Chemical hazards in underground mines that are mainly airborne are resulted from inhalation of coal dusts, particulates, naturally occurring gases, engine exhaust, chemical vapors etc. Amongst them coal dusts are the most important airborne hazard and are the main cause of the incidence of respiratory diseases.

Respiratory diseases are lung diseases resulted from inhalation of coal dust in a mining face during coal extraction. Lung disease associated with coal dust exposure was first reported in 1822 as “miner’s asthma” [5]. Coal mining-related respiratory diseases can affect the gas exchanging tissues of the lungs. The diseases can also affect the lung passages called airways that carry air back and forth during breathing. Essential function of the lung tissues is to absorb O2 from atmosphere, transfer it to haemoglobin, and eliminate CO2 from blood. The lungs are unable to excrete the inhaled dusts.

Mechanization with the introduction of plow or shearer and continuous miner machines into the coal mines lead to produce higher dust levels and worst working conditions at underground. As a result, pneumoconiosis, which is caused by long exposure to coal dusts, appears to be a widespread disease in coal miners throughout the world. In general, pneumoconiosis is a disease caused by the presence of a large amount of dust in the lungs. Pneumoconiosis also refers to fibrotic (scarring) disease of the lung tissue caused by inhalation of respirable mineral dusts. The two main pneumoconiosis that affect miners’ health are Coal Workers’ Pneumoconiosis (CWP) and silicosis, which are caused by inhalation of coal and silica dusts, respectively. Prolonged exposure to large amounts of coal dust can result in serious forms of the disease like Progressive Massive Fibrosis (PMF).

CWP that is nearly similar to black lung disease is associated with underground coal mining, but silicosis can affect workers in many types of mines and quarries, including coal mines. CWP is characterized by dust-induced lesions in the gas exchange regions of the lung [6], and is a debilitating respiratory disease resulting in diminished ability to exchange oxygen. Silicosis is caused by inhaling respirable crystalline silica (silicon dioxide, SiO2). Quartz as a major component of the roof and floor rock strata in coal mines, is a type of crystalline silica that causes silicosis.

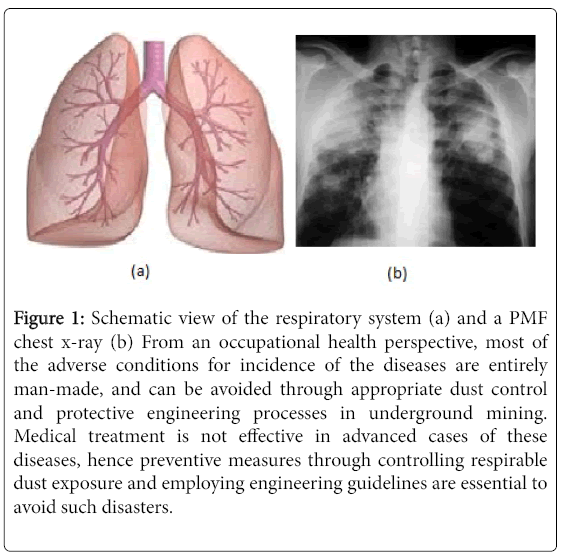

Both CWP and silicosis diseases which are distinguished by pathology, have similar radiographic findings, with milder forms characterized by small (<1 cm) rounded opacities found more in the upper lung zones. A more severe form called PMF is characterized by coalescence of small opacities into large ones (≥1 cm) [3]. The respiratory system of body and an example of chest x-ray showing a PMF that produces shrinkage of adjacent lung with hyper-expansion of lower lobes are presented in Figure 1.

Figure 1: Schematic view of the respiratory system (a) and a PMF chest x-ray (b) From an occupational health perspective, most of the adverse conditions for incidence of the diseases are entirely man-made, and can be avoided through appropriate dust control and protective engineering processes in underground mining. Medical treatment is not effective in advanced cases of these diseases, hence preventive measures through controlling respirable dust exposure and employing engineering guidelines are essential to avoid such disasters.

The pneumoconiosis diseases usually take many years to develop and be manifested, depended on the working conditions and intensity of exposure. The severe state develops after the initial, milder form of the disease known as anthracosis. This is often asymptomatic and is found to at least some extent in all urban dwellers due to air pollution. In severe cases, the pneumoconiosis often lead to lung impairment, disability, and finally premature death.

Methods

Based on the informal information, more than 20% of the underground coal miners in Iran, with experience more than five years, are suffering from lung diseases and waited for time of their death at home. Due to that, a research program is conducted by the authors in order to investigate the risk of exposure to coal dust at Kerman coalfield, Iran.

For this purpose, a cross sectional study was designed to study 556 coal miners from three coal mines namely Babnizu, Hashouni and Hojedk. Among them 460 persons has directly been worked at the coalface for at least five years.

Table 1 shows the general characteristics of the face miners (directly related to extraction) and non-face miners (not at the face area) in the investigated mines. The examined miners are all male. The other properties such as marital status and smoking are not considered in our study.

| Variable | Unit | Face miners (N=460) | Non-face miners (N=96) | ||

|---|---|---|---|---|---|

| Ave. | SD | Ave. | SD | ||

| Height | (cm) | 168.7 | 6.9 | 168.1 | 8 |

| Weight | (kg) | 64.8 | 10.3 | 65.9 | 17.2 |

| Age | (Year) | 37.2 | 8.3 | 40.1 | 8.6 |

| Experience | (Year) | 10.8 | 4.9 | 14.9 | 3.6 |

Table 1: General characteristics of the miners.

Apart from what is in the inhaled coal dust and the affected part of the lung, coal miners at this region suffer from lung disease resulted from several different types of respiratory diseases.

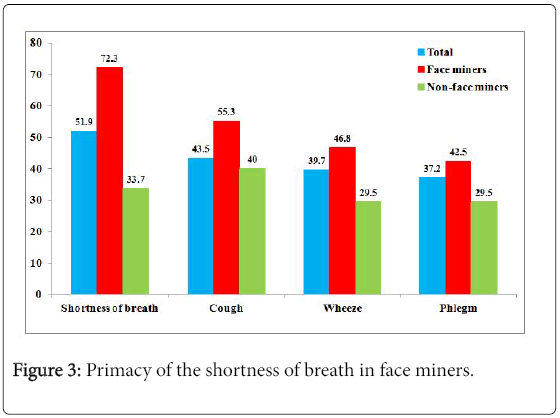

For this purpose, a field study is scheduled to investigate the causes and consequences of respirable dusts and toxic gases. The results of the examination for four common disorders at the investigated mines are summarized in Table 2.

| Respiratory disorder | Total | Face miners | Non-face miners |

|---|---|---|---|

| Cough | 43.5 | 55.3 | 40 |

| Phlegm | 37.2 | 42.5 | 29.5 |

| Shortness of breath | 51.9 | 72.3 | 33.7 |

| Wheeze | 39.7 | 46.8 | 29.5 |

Table 2: Relative percentages of the incidence of four common disorders.

As shown, the differences between face miners and non-face miners are meaningful indicating the more vulnerability of the face miners to the disease. Spirometry tests are also done in order to determine the parameters of Forced Expiratory Volume at the first second (FEV1), Forced Expiratory Ratio (FEV1/FVC) and Forced Expiratory Flow (FEF25-75).

Z-test with overall α error set at 0.01 (2-tailed) is used for comparison of the results. The results of the spirometry measurements for face miners in comparison with non-face miners are summarized in Table 3. In this table, the subscripts m and n are for results of measurement and natural values, respectively.

| Spirometry ratios (%) | Face miners | Non-face miners | ||

|---|---|---|---|---|

| Ave. | SD | Ave. | SD | |

|

79.02 | 12.38 | 76.51 | 13.87 |

|

93.01 | 14.66 | 95.24 | 13.64 |

|

87.16 | 32.34 | 84.52 | 33.96 |

Table 3: Spirometry results for face miners in comparison with nonface miners.

According to the results of spirometry tests, the face miners are more prone to respiratory diseases, however all miners are at risk. In addition, the results show an early decline in FEV1. Decline over the first five years of employment was nonlinear, with a sharp decrease in the first two years.

Direct measurements show that the dust levels in the coalfaces are high and exceed the NIOSH recommended exposure limit of 1 mg/m3 [7]. Although the permissible exposure limit for respirable coal dust can be up to 2 mg/m3, the dusts monitored in the mines are more than 3 and in some cases about 4 mg/m3.

Thus, we scheduled a new program to investigate the mines by paying a more attention on miners’ occupational health. According to the findings, we concluded that instead of looking for suitable medical treatment, the most essential task is to prevent such diseases through precautionary measures.

Since there is no specific certain treatment for CWP and silicosis diseases, one of the most duties of the mining engineers is to provide a safe working environment by monitoring the pollutants and presenting reliable solutions. Therefore, a framework for some remedial and precautionary measures is presented in this research in order to cope with development of such agonized diseases.

Remedial and precautionary measures

Coal is not a pure mineral. It is a mixture of mainly carbon, oxygen, nitrogen and crystalline silica and some trace elements. The examples of trace elements are boron, barium, cadmium, arsenic, mercury, nickel, iron, antimony, lead, zinc, aluminum, graphite, kaolin, mica and talc.

Coal also contains low levels of uranium, thorium and other naturally occurring radioactive isotopes. In addition, some gases in underground coal mines contain toxic levels of benzene, toluene, xylene and ethylbenzene.

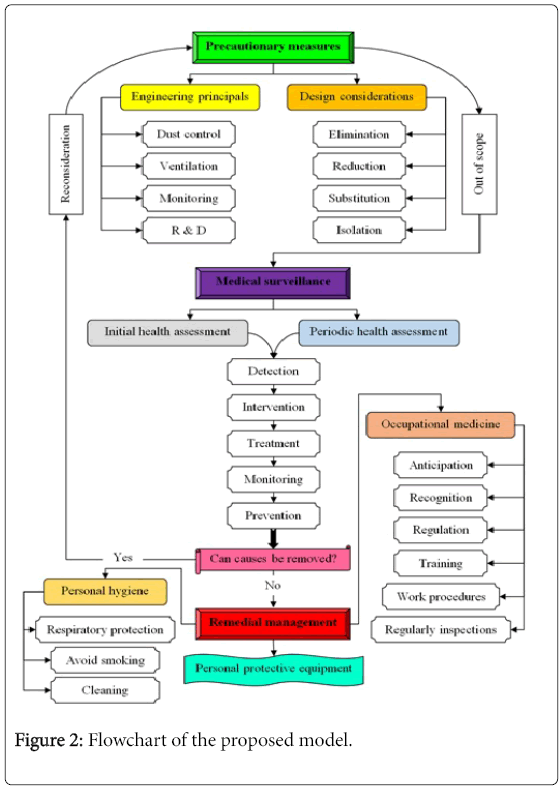

It is true that underground coal mining is inherently more hazardous than other industries, but this does not mean that one can simply agree to be more dangerous. In order to manage the gradual growth of the diseases, a risk mitigation framework by focus on precautionary measures is proposed in this research. As shown in Figure 2, the model is composed of the three major levels: (I) precautionary measures, (II) medical surveillance and (III) remedial management.

The proposed model is a framework that begins with the precautionary measures, which is always the best solution, and ends with reliance on personal protective equipment, which should be the last resort measure.

As the first step of the proposed framework, precautionary measures are the most important part of the model, which should be taken into account by mining engineers. Beyond doubt, coal mining is inherently dangerous; therefore, precautionary measures play a vital role in controlling the unwanted hazards.

As shown, the precautionary measures are divided into two major parts of design considerations and engineering principals. The major design considerations are introduced as elimination, reduction, substitution and isolation. The first step of engineering principals is, where possible, to control dusts.

This requires a structured process to identify hazardous situations and to implement design options to eliminate or control the source of dust emission. The most important parts of the proposed framework are engineering measures to control the dusts at their sources.

Design of an adequate and suitable ventilation system, and regular monitoring of its efficiency is one of the ordinary engineering actions. Success in this activity simply results in controlling the dust dissemination, removing igneous and toxic gases (methane, CO, etc.) and minimizing the risk of explosion and fire.

A continuous dust-monitoring program may be useful to provide an accurate measurement of airborne respirable dust and information to reduce the exposure. In addition, potential dust control technologies such as spray manifolds on the shearer, improved water sprays on longwall shields, stand-alone dust collectors, and the application of optical remote sensing technology to monitor the source and movement of dust over extended areas are very useful in mitigating the risk of disease.

A major challenge facing mining engineers is to develop effective strategies for control and to minimize occupational health hazards associated with coal dust exposure. Research and development operations play a critical role in preventing the diseases and resulted fatalities and injuries. Some applicable precautionary measures may be as observing or developing standards, assessing and developing prevention strategies, training workplace responsibility, developing workplace safety procedures, identifying strategies for monitoring and updating health and safety information, effective occupational health and safety communications, and improving occupational health and safety performance.

In the second step of the proposed framework, medical surveillance is suggested to early detection, intervention and treatment of an existing disease. In some cases, the root cause of an occupational respiratory disease is readily apparent. However, in other cases the root cause may be elusive and difficult to establish. Occupational medical surveillance is the ongoing, systematic collection, analysis, and interpretation of data in order to improve health and safety. The final task of the medical surveillance is the application of these data to prevent and control miners’ health and to monitor trends and progress over time followed by intervention to prevent exacerbation of symptoms.

Medical surveillance in the proposed model includes two parts of initial and periodic health assessment. The employer must ensure that an initial health assessment is carried out on each employee at the mine. In addition, the health assessment should be carried out under the supervision of a medical practitioner. The health assessment usually includes the record of the miner’s work history, respiratory questionnaire, lung function test, and chest X-ray. The chest radiograph remains a cornerstone of the diagnosis of CWP and silicosis. However, because it is insensitive to the presence of macules and nodules, CT-scan may be more useful in individual cases.

The disease may be diagnosed based on the combination of an appropriate history of exposure to the dust, compatible changes in chest imaging and lung pathology. Lung biopsy, a procedure where a sample of lung tissue is taken for lab examination, is not usually required if a compatible exposure history and findings on chest imaging are present. Pulmonary function tests and blood tests to measure the amounts of oxygen and carbon dioxide in the blood (arterial blood gases) can help in objectively assessing the level of impairment [8].

Coal miners should also be regularly monitored for reduced lung function due to dust exposure using spirometry. Abdel-Rasoul et al. [9] recommended the pre-employment and periodic medical examinations through spirometry. Spirometry plays an important role in the medical surveillance of occupational respiratory health. Spirometry can assist the health professional by determining if a miner demonstrates a specific pattern of respiratory impairment and also can help to assess the effectiveness of measures implemented to protect the miners.

After ruling out technical causes for low or declining pulmonary function, efforts must be made to identify the cause. If the cause is related to a workplace exposure, then steps must be taken to better control or eliminate the exposure and prevent further damage to the miner’s lungs.

The third step of the proposed framework is dedicated to remedial management. In addition to the respiratory diseases, there are many other serious risks at the active faces including fires and explosions, toxic gas excess, outburst, rockburst and rock falls [1]. Therefore, personal hygiene and occupational medicine can be applicable actions to enhance the overall confidence level of the working conditions. In this respect, the importance of the occupational medicine as an integral part of the mining engineering is more appeared day by day, particularly by increasing the mechanization. Appropriate equipment that protects all miners is the least preferred method of personal hygiene. Examples are wearing a protective mask when working at coalface, avoiding smoking or daily cleaning. Vulnerable miners are to be isolated from the hazardous situations.

There are many guidelines for management the mining operations. In an effort to prevent the development of silicosis in miners, Mine Safety and Health Administration (MSHA) [7] suggested that when quartz levels in respirable dust samples are greater than 1%, a respirable dust standard (permissible exposure limit) is calculated by dividing 10 mg/m3 by the sum of the percent quartz plus 2. For example, if a sample contains 8% quartz, the respirable standard would be equal to 1 mg/m3 (i.e., 10 ÷ (8 + 2)). This regulation places the upper limit of exposure to respirable quartz at 100 μg/m3. Finally, it should be emphasized that the ultimate success of ongoing protection for miners is dependent upon continued maintenance of the implemented engineering measures.

Discussion

Nowadays by increasing the mine mechanization, more dust is being produced and consequently controlling respirable and inhalable dust continues to be the greatest challenge in underground coal mining. Respiratory diseases from occupational exposures have a major adverse effect on miners’ health, such that deaths from workrelated respiratory disease and malignancies account for about 70% of all occupational disease mortality [10].

Some dust is generated when coal is mined, crushed and transported. Workers at underground mines are directly in contact with the generated dusts and regularly inhaled them during working shifts. Prolonged exposure to these dusts, which contain significant quantities of fine carbon-rich suspended particulate matters, bring about inhaled dusts remain in the lungs, especially those with diameter less than 2.5 μm. This can lead to chronic health conditions such as CWP and silicosis in underground coal miners, which result in decreased lung function, and finally premature death. Pneumoconiosis are the major lung diseases frequent in miners, leading to reduce life expectancy. Annually, more than 4,000 new cases of CWP in the USA and 10,000 in China are reported.

According to our experience in the Kerman coalfield, CWP appears to be the most harmful pneumoconiosis, since the inhaled coal dust progressively builds up in the lungs and cannot be removed by the body; this leads to inflammation, fibrosis and in some cases necrosis. Silicosis as the other dangerous pneumoconiosis in this region appears to be similar to the long-term effects of tobacco smoking. Hence, the miners at Kerman coalfield are more susceptible to CWP disease. Four major respiratory disorders are found to be more serious by the first examinations. As shown in Figure 3, the shortness of breath with the relative percentage of 72.3% is the most important health problem for miners who worked at the face. For the patients with severe lung disease, symptoms of breathlessness and cough are accompanied by abnormalities in lung function, which are along with reductions in both FEV1 and FVC and an increased FEV1/FVC ratio.

The incidences of the both diseases are varied in a wide range indicating that the influence of the other parameters such as age, experience, type of activity at the mine, severity of exposure, and smoking may be significant. The difference between smokers and nonsmokers has not been determined. However, the majority of the miners are addicted to the smoking. By comparing face miners and non-face miners, the severity of the diseases is found to be a function of the amount of dust in the air and the cumulative times a miner inhales respirable dust. However, a distinctive relationship has not been indicated yet. In this regard, Hurley et al. [11] indicated a direct relationship between the mass of inhaled coal dust and the incidence and severity of CWP.

Our experiences are also in accordance with the recent risk estimates provided by Soutar et al. [12] from research on British coal miners who work 40 years at the designated dust level. They estimated the risks of PMF range from 0.8% at 1.5 mg/m3 to about 5% at 6 mg/m3, while the risks of CWP range from about 1.5% at 1.5 mg/m3 to 9% at 6 mg/m3.

Soutar et al. [12] also provided information on the risk of silicosis in underground coal miners by dividing the analysis between exposures < 2 mg/m3 and ≥ 2 mg/m3. This dichotomy was associated with more rapid development of silicosis in the ≥ 2 mg/m3 exposure range compared to chronic silicosis development at exposures < 2 mg/m3. Although prognoses depend on the length and level of exposure to respirable dust, there is no cure for the disease. Therefore, it can be concluded that all precautions should be taken to minimize dust exposures.

In developing countries, where the informal or non-regulated mining sector is significant and dust control is less than optimal, a relationship between silica exposure and tuberculosis has acquired a renewed importance with the growing epidemic of HIV [13]. Consequently, engineering principal should be implemented in an effort to prevent or even mitigate the development of the disease. As a precautionary measure, a respirator can be provided for miners who are more exposed to the dust.

According to the epidemiologic studies, the diseases may develop or progress even after ceasing occupational exposure to coal dust [14]. Therefore, removing a worker from exposure after diagnosis, does not guarantee that the diseases will stop progressing. However, it is important to protect the patient against respiratory infections once disease is detected.

Up to the present, our researches in Kerman coalfield demonstrate that the investigation of respiratory diseases is very complicated due to the various dusts and gases generated in a coalface. Actually, in addition to generation various dusts in coal mines some combustible and toxic gases are also generated from machines and oxidation of coal and wooden supports or emitted from the coal seams and surrounding rock strata.

Most of the coal dust is carbon, the major combustible gases are methane, hydrogen, acetylene, ethylene and ethane, and the most important toxic gases are carbon monoxide and hydrogen sulfide [15]. In this regard, Finkelman [16] discussed the health problems that could be caused by volatilization of arsenic, selenium and fluorine from the uncontrolled coal fires.

A high concentration of carbon monoxide is the most dangerous and can cause physiological and pathological changes and ultimately death. When the coal is combusted, any remaining pyritic sulfur and organic sulfur is oxidized to sulfur dioxide. Emissions of sulfur dioxide and nitrogen oxides can react with water vapor in the atmosphere to form sulfurous acid, sulfuric acid and nitric acid, which are the components of acid rain. Acid rain is also a human health risk for asthma and bronchitis.

In some cases, there may also be potential health hazards from exposure to high concentrations of trace elements and/or gases emitted due to high concentrations of certain elements in the burning coal or surrounding rock strata. One hazard that is now receiving greater attention is the presence of radon in mine waters and mine atmospheres. Radon gas is soluble in water and may be carried for great distances. Although it is externally harmless, inhaled radon gas remains in the respiratory system. The major health hazard from radon is thought to be an increased risk of lung cancer [17].

The concentrations of these gases and dusts should be controlled to improve the safety and health of the miners. Among various methods, engineering precautionary measures are found to be the most effective and efficient method to control these contaminants in the mine atmosphere. Therefore, according to the fact that there is no specific certain treatment for CWP and silicosis diseases, a model was proposed in this research to provide a safe working environment by monitoring the pollutants and presenting reliable solutions based on the engineering and precautionary measures.

Conclusion

Coal mining-related respiratory diseases were investigated in Kerman coalfield. For this purpose, 556 coal miners from three coal mines namely Babnizu, Hashouni and Hojedk were randomly examined. Among them 460 persons has directly been worked at the coalface for at least five years. According to the results, an early decline in FEV1 was observed which was nonlinear over the first five years of employment. The shortness of breath with the relative percentage of 72.3% was the most important health problem for miners who worked at the coalface. For the patients with severe lung disease, symptoms of breathlessness and cough are accompanied by abnormalities in lung function, which are along with reductions in both FEV1 and FVC and an increased FEV1/FVC ratio. By comparing face miners and non-face miners, the severity of the disease is found to be a function of the amount of dust in the air and the cumulative times a miner inhales respirable dust. Due to the high concentrations of coal dust and generation of various gases at coalface, this research was scheduled to investigate the mines by paying a more attention on miners’ occupational health. It may be concluded that instead of looking for suitable medical treatment, the most essential task is to prevent such diseases through precautionary measures. Therefore, in order to cope with development of such agonized diseases, a framework by focus on precautionary measures was presented in this research, which composes of the three major levels: (I) precautionary measures, (II) medical surveillance and (III) remedial management. Because there is no specific certain treatment for CWP and silicosis diseases, one of the most duties of the mining engineer is to provide a safe working environment by monitoring the pollutants and presenting reliable solutions based on the engineering and precautionary measures.

References

- Mahdevari S, Shahriar K, Esfahanipour A (2014) Human health and safety risks management in underground coal mines using fuzzy TOPSIS. Sci Total Environ 489: 85-99.

- Bureau of Labor Statistics (2015) U.S. Department of Labor.

- Laney AS, Weissman DN (2014) Respiratory diseases caused by coal mine dust. J Occup Environ Med 10: S18-22.

- Mohr Jr. LC (2012) The occupational and environmental history. Chapter 2, In: Huang Y-C.T (ed.) A clinical guide to occupational and environmental lung diseases, respiratory medicine.

- Ghio AJ (2012) Pneumoconiosis in the twenty-first century. Chapter 9, In: Huang Y-C.T (eds.), A clinical guide to occupational and environmental lung diseases, respiratory medicine.

- Finkelman RB, Orem W, Castranova V, Tatu CA, Belkin HE, et al. (2002) Health impacts of coal and coal use: possible solutions. International Journal of Coal Geology 50: 425-443.

- Cincinnatti OH (2003) The work-related lung disease surveillance report. National Institute for Occupational Safety and Health.

- Colinet JF, Cecala AB, Chekan GJ, Organiscak JA, Wolfe AL (2010) Best practices for dust control in metal/nonmetal mining. Office of Mine Safety and Health Research, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, Information Circular 9521.

- Abdel-Rasoul GM, Al-Batanony MA, Abu-Salem ME, Taha AA, Unis F (2013) Some health disorders among workers in a glass factory. Occup Med Health Aff 1: 106.

- National Research Council and Institute of Medicine (2008) Respiratory diseases research at NIOSH. Report No. 4, The National Academies Press.

- Hurley JF, Burns J, Copland L, Dodgson J, Jacobsen M (1982) Coal workers’ pneumoconiosis and exposure to dust at 10 British coal mines. British Journal of Industrial Medicine 39: 120-127.

- Soutar CA, Hurley JF, Miller BG, Cowie HA, Buchanan D (2004) Dust concentrations and respiratory risks in coalminers: key risk estimates from the British Pneumoconiosis field research. Occup Environ Med 61: 477-481.

- Ross MH, Murray J (2004) Occupational respiratory disease in mining. Occup Med 54: 304-310.

- Miller BG, Hagen S, Love RG, Soutar CA, Cowie HA, et al. (1998) Risks of silicosis in coal workers exposed to unusual concentrations of respirable quartz. Occup Environ Med 55: 52-58.

- Bise CJ (2013) Modern American coal mining: methods and applications. Society for Mining Metallurgy.

- Finkelman R (2004) Potential health impacts of burning coal beds and waste banks. International Journal of Coal Geology 59: 19-24.

- Thomas LJ (2013) Coal Geology.2nd Edition, John Wiley & Sons.

Relevant Topics

- Child Health Education

- Construction Safety

- Dental Health Education

- Holistic Health Education

- Industrial Hygiene

- Nursing Health Education

- Occupational and Environmental Medicine

- Occupational Dermatitis

- Occupational Disorders

- Occupational Exposures

- Occupational Medicine

- Occupational Physical Therapy

- Occupational Rehabilitation

- Occupational Standards

- Occupational Therapist Practice

- Occupational Therapy

- Occupational Therapy Devices & Market Analysis

- Occupational Toxicology

- Oral Health Education

- Paediatric Occupational Therapy

- Perinatal Mental Health

- Pleural Mesothelioma

- Recreation Therapy

- Sensory Integration Therapy

- Workplace Safety & Stress

- Workplace Safety Culture

Recommended Journals

Article Tools

Article Usage

- Total views: 15046

- [From(publication date):

June-2016 - Apr 16, 2025] - Breakdown by view type

- HTML page views : 13991

- PDF downloads : 1055