Research Article Open Access

A Comparative Study of Concrete Strength Using Metamorphic, Igneous, and Sedimentary Rocks (Crushed Gneiss, Crushed Basalt, Alluvial Sand) as Fine Aggregate

Mambou Ngueyep Luc Leroy1,2*, Tchapga Gniamsi Guy Molay1, Ndop Joseph1,3, Fofe Meli Colince2 and Ndjaka Jean-Marie Bienvenu11Laboratory of Material Sciences, Department of Physics, Faculty of Sciences, University of Yaoundé 1, P.O.BOX 812 Yaoundé, Cameroon

2Department of Mine Mineral Processing and Environment, School of Geology and Mining Engineering, University of Ngaoundéré, P.O. BOX 115 Meiganga, Cameroon

3Douala Institute of Technology, P.O. BOX 1623 Douala, Cameroon

- *Corresponding Author:

- Mambou Ngueyep Luc Leroy

Laboratory of Material Sciences

Department of Physics, Faculty of Sciences

University of Yaoundé 1, P.O.BOX 812 Yaoundé, Cameroon

Tel: +237697419489

E-mail: mamboulucleroy@gmail.com

Received Date: March 03, 2017; Accepted Date: March 09, 2017; Published Date: March 16, 2017

Citation: Leroy MNL, Molay TGG, Joseph N, Colince FM, Bienvenu NJM (2017) A Comparative Study of Concrete Strength Using Metamorphic, Igneous, and Sedimentary Rocks (Crushed Gneiss, Crushed Basalt, Alluvial Sand) as Fine Aggregate. J Archit Eng Tech 6: 191. doi: 10.4172/2168-9717.1000191

Copyright: © 2017 Leroy MNL, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Architectural Engineering Technology

Abstract

A comparative study of the technical and economic performances of hydraulic concretes based on three sands with different geological nature has been investigated in this work. Sand from crushed basalt (SB), sand from crushed gneiss (SG) and sand from the river Sanaga were used for the formulation of these concretes. The formulation of these concretes was carried out according to the method of ‘Dreux-Gorisse’. The results of the analysis show that concrete made from crushed basalt (CSB) has very good mechanical strengths (34 MPa at 28 days) followed by concrete made with alluvial sand (CSS), (24 MPa at 28 days) and finally concrete made from crushed gneiss(CSG), (22 MPa at 28 days). This is due to the fact that basalt is a compact rock, hard, tough and also consists of hard minerals such as olivine, plagioclase, clinopyroxene. Nevertheless concretes made with these sands are less malleable and have blemishes after stripping due to the angularity and very sharp edges of grains of sand. Fresh concrete (CSS) prepared with river sand is more malleable than the CSB concrete and CSG concrete. Besides the technical aspect, due to the cost of transport and the scarcity of river sand, concretes made with alluvial sand is more costly (49.893 FCFA/m3 of concrete) compared to concretes made with crushed gneiss and basalt costing 47.053 FCFA and 46.854 FCFA/m3 , respectively. In view of these results, it is therefore possible to replace river sand with quarry sands in the production of concrete and then reduce the environmental problems generated by the overconsumption of alluvial sand.

Keywords

Concrete; Crushed sand; Alluvial sand; Compressive strength

Introduction

Sand is an essential component of concrete. It is used to ensure the continuity between cement and gravel for better cohesion of concrete. River sand has been the most popularly used in the production of concrete, but due to the overuse of the material, the price of river sand has increased and then disturbs our environment [1]. For example, in developing countries, the demand of natural sand is quite high to satisfy the rapid infrastructural growth. In the quarry industries, it can be observed that a huge amount of quarry dust produced during the crushing is often considered as waste and often used as landfills [2]. In order to reduce the dependence on natural sand as the main source of fine aggregate in concrete, the scientist community develops the need to find alternatives solutions to replace the river sand in the making of concrete. Some alternative materials have already been used in place of natural sand. For example, fly ash, slag and lime stone, siliceous stone powder, rock dust and quarry waste is used in concrete as a partial or total replacement of Sand River [3].

Then the experiments have been conducted on the mechanical properties of concrete for various percentage replacements of fine aggregates by alternative sands [4]. Compressive strength of concrete is commonly considered to be its most valued property. Although in many practical cases, other characteristics, such as durability, impermeability and volume stability, may in fact be more important [5]. Nevertheless, compressive strength usually gives an overall picture of the quality of concrete [5].

In 2012, Wakchaure et al. studied the effect of the type of fine aggregate on the properties of cement concrete. They showed that a compressive strength of concrete with natural sand increased by 7.72% after a fully replacement by artificial sand at 7 days and 3.98% at 28 days.

Recently in 2015, Chijioke Chiemela et al. [6] presented the results of an experiment carried out to compare the compressive strength of concrete made with river sand and quarry dust as fine aggregates. River sand was fully replaced in the concrete. Tests were performed for the properties of fresh concrete. Compressive strength was determined at 28 days. Test results indicated that the compressive strength is higher for the concrete made with quarry dust than some mixed proportions and less at some other mix proportions compared to conventional concrete. They concluded that quarry dust can effectively be used to replaced river sand and then reduce the negative impact on environments due to constant plunging of our rivers.

From the literature review [5,7] it can be observed that quarry dust can be used as replacement of river sand in concrete. However, few works has been carried out on basalt or gneiss powder as replacement of alluvial sand.

In this paper we are interested by the effect of the petrography and mineralogy of the quarry dust (Crushed Gneiss, Crushed Basalt) on mechanical properties of concrete.

This paper presents the result of a comparative study of strength concrete using metamorphic, volcanic and sedimentary rocks (crushed gneiss, crushed basalt and alluvial sand) as fine Aggregate. Economical study is also presented.

This report describes work that is aimed at improving the understanding of the role of fine aggregates in concrete. The variables considered are aggregate type, aggregate cost, and aggregate content in normal and high-strength concretes.

Materials and Experimental Methods

Materials

Cement: The cement used is a Portland cement composed of CPJ CEM II/A class 42.5 R. This is CIMAF’s cement (Cement of Africa) produced and marketed in Cameroon. Its physico-mechanical characteristics are given in Table 1.

Physical characteristics |

Mechanical characteristic | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Retaining on sieves (mm) | Apparent density(t/m3) | Consistency (%) | Specific density (t/m3) | Specific surface (cm2/g) | Expansion (mm) | Compressive strength (MPa) | ||||

| 0.8 | 0.045 | 0.95 | 29 | 3.14 | 3425 | cold | heat | 2days | 7days | 28days |

| 0.7 | 0.60 | 2 | 2 | 25 | 35 | 45 | ||||

Table 1: Physical and mechanical characteristics of cement.

Water for mixing: The water used for the mixing of different concrete comes from Cameroon's water (CDE). The water is supposed to be potable and contains no harmful impurities. It is therefore very useful for making concrete.

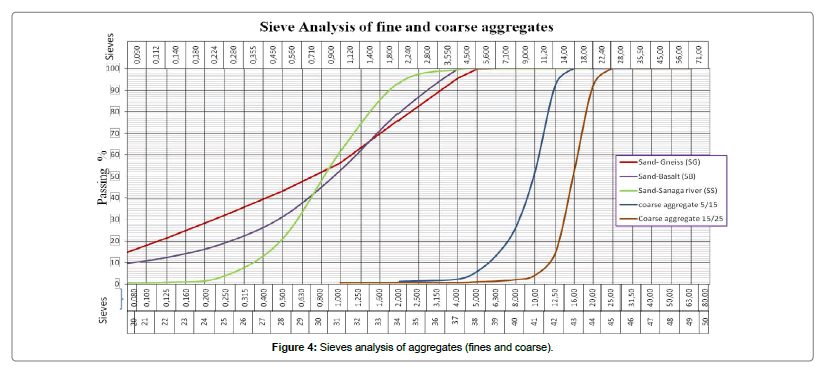

The fine aggregate: Three types of sands with the same size range (0/5) were used in this work. Two coming from quarry sands and other from River Sanaga (alluvial sand). River Sanaga is the longest river in Cameroon, about 918 Km of length. Concerning quarry sands, one comes from an industrial quarry located in Bamougoum, western region of Cameroon, which exploits a rock mass of magmatic origin (Basalt) and the other comes from an industrial quarry Located in Eloumdem, a locality in the central region of Cameroon which exploit a rock mass of metamorphic origin (Gneiss). These quarry sands are respectively denoted SB for basalt and SG for gneiss. The main physical properties of these sands are shown in Table 2.

| Types of sand | Density (g/m3) | Apparent density (g/m3) | Percentage of fine aggregate (<80 μm) | Fineness modulus | Piston sand equivalent (ES,%) |

|---|---|---|---|---|---|

| SB (basalt) | 2.87 | 1.466 | 7.9 | 3.05 | 65.15 |

| SS (alluvial) | 2.6 | 1.395 | 0.3 | 3.22 | 96.98 |

| SG (gneiss) | 2.95 | 1.686 | 10.5 | 2.76 | 75.30 |

Table 2: Physical characteristicsof sands.

Coarse aggregate: In order to make our concrete, we used coarse aggregates from gneiss with fractions (5/15) and (15/25). These crushed stones originate from an industrial quarry exploited in Eloumdem, Some of their properties are summarized in Table 3.

Coarse aggregate |

Apparent density (g /m3) | Specific Density (g /m 3) | Los Angeles |

|---|---|---|---|

| Gravel 5/15 | 1.48 | 2.8 | 28 |

| Gravel 15 /25 | 1.49 | 2.8 | 28 |

Table 3: Properties of coarse aggregate 5/15 and 15/25.

Method

Petrographic properties: The observations of thin section of gneiss and basalt rocks permit us to know the various minerals that these sands contain.

Formulation (composition study): The methodology for the formulation of concrete is the Dreux-Gorisse method [8]. We choose to make concretes with the characteristics contained in Table 4.

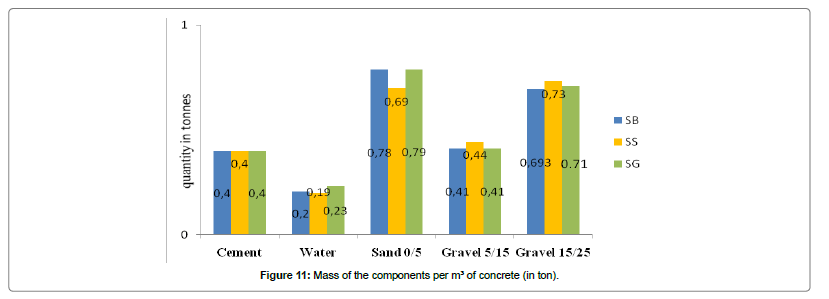

| Mass of components (Kg/m3) | Rapports | ||||||

|---|---|---|---|---|---|---|---|

| Cement | Water | Sand | Gravel 5/15 | Gravel 15/25 | E/C | Theoritical density | |

| SB | 400 | 197.04 | 786.58 | 411.77 | 692.33 | 0.49 | 2.488 |

| SS | 400 | 197.04 | 698 | 443 | 733 | 0.49 | 2.471 |

| SG | 400 | 197.04 | 788/8 | 411.8 | 711.2 | 0.49 | 2.509 |

Table 4: Compositions of the different concretes tested.

Measurement of density and workability of fresh concrete: The density was determined according to the standard norm (NF EN 12350-6, 1999) [9].

The workability of the concrete is evaluated by using the Abrams cone, according to the standard norm (NF EN 12350-2, 1999) [10].

Compressive strength of hardened concrete: Strength of concrete is commonly considered as the most valuable property in Portland cement concrete. Although in many practical cases other characteristics such as durability and permeability may in fact be more important. Nevertheless, strength usually gives an overall picture of the quality of concrete because strength is directly related to the structure of the hydrated cement paste. Moreover, the strength of concrete is almost invariably a vital element of structural design [11].

Compressive strength of concrete is commonly considered to be its most valued property, although in many practical cases, other characteristics, such as durability, impermeability and volume stability, may be more important. Moreover, compressive strength usually gives an overall picture of the quality of concrete.

The simple compressive strength of the concrete was determined on 12 × 16 cm cylindrical specimens. The test is carried out according to the standard (NF EN 12390-3, 2003) [12]. The specimens are loaded till failure in a compression testing machine conforming to the standard (EN 12390-4, 2000) [13]. The maximum load reached is recorded and the compressive strength is obtained by the following equation:

Where F the charge applied, σc the compressive strength and r the radius of specimen

Cost of producing a m3 of concrete: The main financial investment costs that are related to the realization of a m3 of concrete can be broken under certain headings namely:

• Cost of the transport of sand from the production site to the use site;

• Cost of production of concrete.

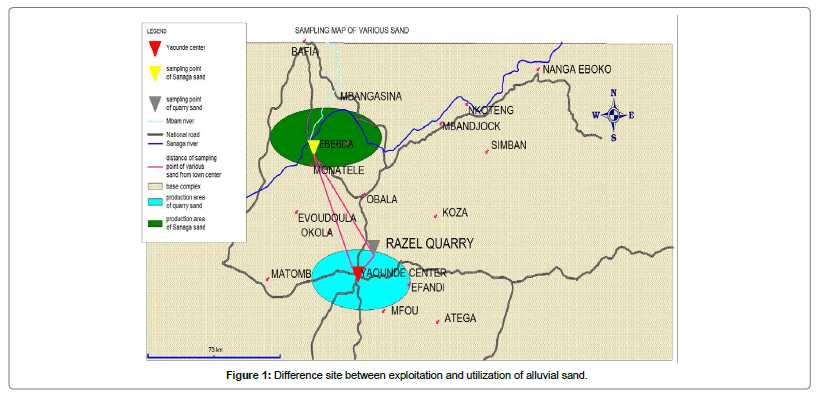

This Figure 1 shows the different sites of extraction and commercialization of the alluvial sand. The most alluvial sand used to make a normal concrete is extract in the bed of river Sanaga.

In this map, we show the difference distances between the exploitation area and the center of commercialization.

Results and Analysis

In order to achieve the objective of this work, petrographic and geotechnical analyzes were performed in the laboratory. Concretes made from different sands were analyzed in their fresh and hardened state. Below are the results obtained and the details of the discussions. The analysis of the results are shown and contained in the tables and figures below (Figures 2-11 and Tables 5-7).

Sand Type |

Grain shape | d/D(mm) | Fineness | Structure | Origin | % of fine elements |

|---|---|---|---|---|---|---|

| SB | Very angular | 0/5 | Fine | Rough surface | Crushed basaltic origin stone | More (7.9%) |

| SG | Few angular | 0/5 | Fine | Rough surface | Cruhed gneissic stone | High (10.5%) |

| SS | rounded | 0/5 | coarse | Smooth surface | Alluvial sand | Very low (0.3%) |

Table 5: Macroscopic analysis of different sands.

| Types of Concrete | ||||

|---|---|---|---|---|

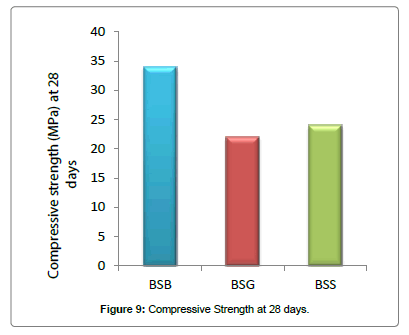

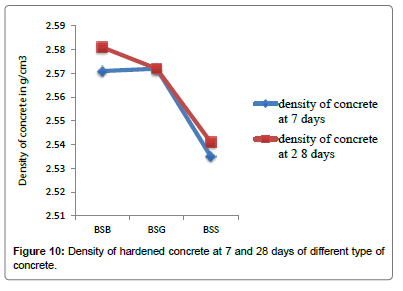

| BSB | BSS | BSG | ||

| Compressive strength (Mpa)Wishes at 28 days | 30 | 30 | 30 | |

| Compressive strength (Mpa) | 7 days | 24 | 18 | 19 |

| 28 days | 34 | 24 | 22 | |

| Density (g /cm3) |

7 days | 2.571 | 2.535 | 2.572 |

| 28 days | 2.581 | 2.541 | 2.572 | |

Table 6: Hardened concrete properties.

Components of concrete |

Cement | Water | Sand 0/5 | Gravel 5/15 | Gravel 5/25 | Total cost | Realizedsavings |

|---|---|---|---|---|---|---|---|

| For CSB | 32000 | 75 | 3945 | 3914 | 6930 | 46854 | 3090 |

| For CSS | 32000 | 72 | 6282 | 4209 | 7330 | 49893 | 0 |

| For CSG | 32000 | 84 | 3945 | 3914 | 7110 | 47053 | 2840 |

Table 7: Cost in FCFA of the components for the formulation of 1 m3 of concrete.

Analysis of Results

The objective of this work is to carry out a comparative study between alluvial sands of the river Sanaga and quarry sands from basalts and gneisses in order to optimize the formulation of concrete.

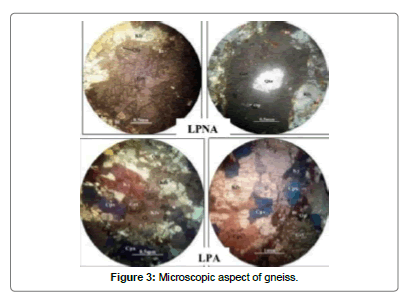

Analysis of the thin sections of the various sands from the rocks was carried out at the Institute of Geological and Mining Research (IRGM). These studies revealed that: SG sand coming from the crushing of gneiss is composed of garnet (10 to 15%), quartz (10 to 15%), biotite (15 to 20%), disthene (5%), alkaline feldspar (30-40%) and clinopyroxene (8%).

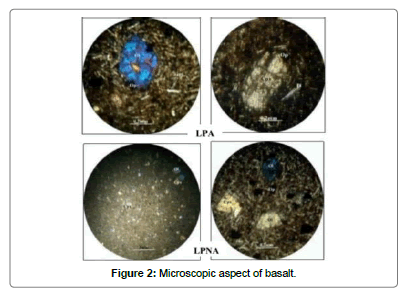

Sand SB coming from the crushing of olivine basalts contains olivine (5 to 10%), plagioclases (10 to 15%), clinopyroxene (3 to 5%) and opaque minerals (7 to 10%). On the other hand, a macroscopic observation of SS sand reveals that it is of terrigenous sedimentary origin and contains quartz (more than 90%) and micas (Figures 2 and 3).

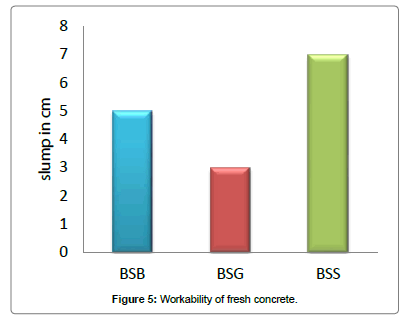

The geotechnical results carried out at the National Laboratory of Civil Engineering (LABOGENIE) on these different sands showed that: the crushed sands SB and SG are slightly clean sands (ES=65,15 for SB and ES=75,30 for SG); They have respectively a percentage of fines of 7.9% (maximum content for concretes of current grade according to the standard relating to this grade) and 10.5%; The alluvial sand SS is a very clean sand (ES=96.98) having almost no fines (0.3%) (Tables 2, 5 and Figure 5). These results show that quarry sands have very high fines and are less clean than alluvial sands (Table 5).

Using the DREUX GORISSE formulation method, we made six concrete test pieces for each sand. Following these formulations, we subjected these specimens to the uniaxial mechanical compression test at 7 and 28 days (Tables 4 and 6).

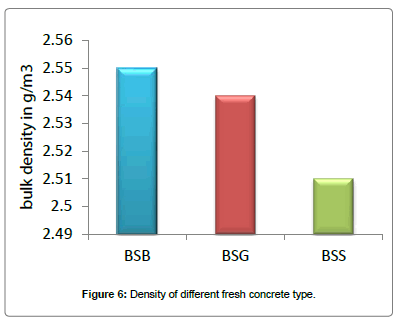

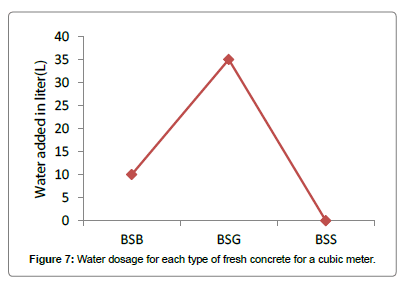

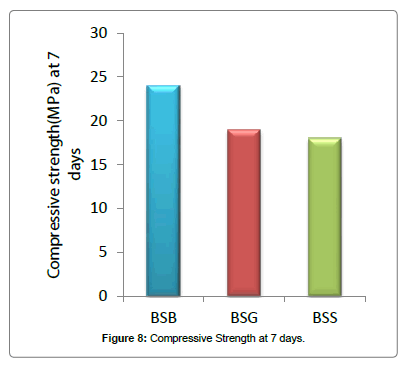

The results of the study of the properties of fresh concrete revealed that the alluvial sands of the Sanaga are very malleable compared to SG and SB sands. Nevertheless SG sand is more malleable than crushed SB sand, because of its very angular shape. In addition to malleability, concretes made with quarry sands SB and SG have higher densities (fresh and hardened) than that of SS alluvial sand. This is explained on one hand by the shape of the grains and on the other by the intrinsic characteristic of each sand (Figures 5 and 6). Indeed, the crushed SB sand is formed from very angular sand grains, which allows a very good bonding granulate-binder Moreover, these sand quarries contain enough fines to fill almost all the inter-granular voids and thus make the concrete more compact. In contrast, the alluvial sand has a blunted shape and has very few fines; which limits a good bonding-aggregate bond and makes the concrete not very compact. In addition these sands quarries are constituted of very dense minerals and having high densities compared to the alluvial sand (Figure 6).

The compressive strength at 28 days of the concretes formulated with the SS sand and the quarry SB, SG sands are respectively 24 MPa, 34 MPa and 22 MPa. The crushed SG sand has a low resistance due to the high fines content on the one hand. The higher the fines content, the more water will be needed; and at the same cement dosage, the resistance decreases.

On the other hand, this is related to the mineralogical properties of this sand. The SG sand is mainly composed of a very soft and alterable mineral (biotite) but also moderately hard and alterable minerals. The latter will give clays under the effect of meteoric alteration (alkaline feldspar) and thus contribute to a decrease in resistance.

In addition, this sand contains biotite which disturbing by their shape and their weak inter-foliar cohesion not favorable to the adhesion of the binders (Figures 7-9).

The crushed SB sand has very angular grains. This promotes a good binder-aggregate bond and therefore makes it possible to obtain compact and resistant concretes. Moreover, this sand is made up of very hard and resistant minerals.

In view of all these results, it can be concluded that SB sand resulting from the crushing of olivine basalts offers a more resistant concrete. However, the alluvial SS sand and the SG sand have similar resistances.

Conclusions

This study was conducted to assess the effect of the type of sand on the mechanical properties of hydraulic concrete. This study led to the following conclusions:

• The mechanical properties of concrete are influenced by the nature and physical properties of sand:

• Concrete with crushed Sands (SB and SG) produced Small slump when compared to the river sand.

• Concrete with crushed sands need much water to obtain the same workability than the concrete with the natural sand. This improved workability for the crushed sand due to the presence of high quantity of fine particles.

• A compressive strength of concrete with natural sand (SS) increased by 33.33% after a fully replacement by basaltic crushed sand (SB) and 5.5% with gneiss crushed sand at 7 days.

• The same results were observed at 28 days. Concrete with natural sand increases by 41, 67% after a full replacement by basaltic crushed sand (SB) and 8.33% with gneiss crushed sand at 7 days (SG).

• The presence of mineral like biotite in the sand can reduce the strength of the concrete.

• The effect on compressive strength of concrete by replacement of natural sand with artificial sand is more prominent at 7 days than that at 28 days.

References

- Barritt CMH (1984) Advance building construction. (2ndedn), JW Arrowsmith Ltd, Bristol.

- Raschid THMR, Hassan MR, Mondol EF (2013) Influence of Stone Dust as Replacing Material of Cement and Sand on Some mechanical properties of Mortar. Int Journal of Advance structural and Geotechnical Engineering p: 2.

- Safiuddin M, Raman SN,Zain MFM (2007) Utilization of quarry waste fine in concrete mixture. Journal of applied science research 3: 202-208.

- Suresh N,Manjunatha M (2016) Effect of different types of fine aggregates on mechanical properties of concrete-A review. The Indian Concrete Journalpp: 69-71.

- Kala F (2013) Effect of Granite Powder on Strength Properties of Concrete. International Journal of Engineering and Science 2: 36-50.

- Chiemela C, Walter IE, Ogedi IH, Peter OC,Mong O (2015) Comparing the compressive strengths Of concrete made with river sand and quarry dust. International Journal of Recent Research and Applied Studies 22: 31-38.

- Abdullah M (2012) Effect of aggregate type on Compressive strength of concrete. International Journal of Civil and Structural Engineering 2: 791-800.

- Dreux G, Festa J, (1998) New guide for concrete and its constituents, Eyrolle Edition.(8thedn), Paris, France p: 409.

- European Standard NF EN 12350-2 (1999) Test for fresh concrete, Part 2 Sink test.

- European Standard NF EN 12350-6 (1999) Test for fresh concrete, Part 6 Density, AFNOR.

- Aguida BI, Aissa A (2011) Influence of additions of limestone addition on the mechanical properties of sand concrete. International Seminar, Innovation & Valuation in Civil Engineering & Construction Materials, Rabat, Morocco, pp: 1-12, 23-25.

- European Standard NF EN 12390-3 (2003) Test for hardened concrete, Part 3 Compressive strength of test specimens, AFNOR.

- European standard NF EN 12390-4 (2000) Tests for hardened concrete, Part 4 Compressive strength-Characteristics of test machines, AFNOR.

Relevant Topics

- Architect

- Architectural Drawing

- Architectural Engineering

- Building design

- Building Information Modeling (BIM)

- Concrete

- Construction

- Construction Engineering

- Construction Estimating Software

- Engineering Drawing

- Fabric Formwork

- Interior Design

- Interior Designing

- Landscape Architecture

- Smart Buildings

- Sociology of Architecture

- Structural Analysis

- Sustainable Design

- Urban Design

- Urban Planner

Recommended Journals

Article Tools

Article Usage

- Total views: 10923

- [From(publication date):

April-2017 - Nov 23, 2024] - Breakdown by view type

- HTML page views : 9871

- PDF downloads : 1052