Research Article Open Access

Lab-Scale Assessment to Support Remediation of Outdoor Surfaces Contaminated with Bacillus anthracis Spores

M. Worth Calfee1*, Young Choi2, James Rogers2, Thomas Kelly2, Zachary Willenberg2 and Karen Riggs2

1U.S. EPA, Office of Research and Development, National Homeland Security Research Center, Research Triangle Park, NC, USA

2Battelle Memorial Institute, Columbus, OH, USA

- *Corresponding Author:

- M. Worth Calfee

U.S. EPA, MD E343-06 109 TW Alexander Dr.

Research Triangle Park, NC 27711, USA

Tel: 919- 541-7600

Fax: 919- 541-0496

E-mail: calfee.worth@epa.gov

Received Date: May 23, 2011; Accepted Date: June 14, 2011; Published Date: July 23, 2011

Citation: Calfee MW, Choi Y, Rogers J, Kelly T, Willenberg Z, et al. (2011) Lab-Scale Assessment to Support Remediation of Outdoor Surfaces Contaminated with Bacillus anthracis Spores. J Bioterr Biodef 2:110. doi: 10.4172/2157-2526.1000110

Copyright: © 2011 Calfee MW. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Bioterrorism & Biodefense

Abstract

Six liquid sporicides were evaluated for their ability to decontaminate common outdoor materials contaminated with spores of Bacillus anthracis Ames. Liquid aliquots containing spores of B. anthracis Ames were dried onto small coupons made of the outdoor materials: stainless steel, glass, aluminum, porcelain, granite, concrete, brick, asphalt, treated wood, and butyl rubber. Survivorship of spores was assessed following treatment of the coupons with each of six spray-applied sporicidal liquids (pH-amended Bleach, CASCAD™ SDF, Decon Green, EasyDECON® 200, Spor-Klenz® RTU, and Peridox® RTU). Results indicated that nonporous surfaces were easily decontaminated (all = 6 log10 reduction in viable spores) while porous surfaces, particularly concrete, asphalt, and treated wood, posed significant challenges for the sporicides tested. CASCAD™ SDF was the only sporicide tested that resulted in complete inactivation of spores on all materials. Overall, decontamination efficacy was highly dependent upon surface type, where generally higher efficacies were observed on nonporous materials for each sporicide. Results from this study will allow informed decisions to be made regarding selection of sporicides, based upon efficacy, to decontaminate outdoor surfaces contaminated with spores of Bacillus anthracis and therefore shorten the time and effort required to remediate following a bioterror incident.

Keywords

Decontamination; Spore; Sporicide; Anthrax; Bacillus anthracis

Introduction

In late 2001, a deliberate dissemination of Bacillus anthracis spores via letters sent through the U.S. Postal Service resulted in 12 cases of cutaneous anthrax and 11 cases of inhalation anthrax, five of which were fatal [1,2]. Following this event, remediation costs for the contaminated government and private facilities were greater than $650 million and took more than three years to complete [3,4]. While an unprecedented amount of money and resources were used to recover from this bioterror event, it is conceivable that a biological agent could be disseminated over a much larger spatial scale, such as an entire city. Such a "wide-area attack" would require significantly more time and money to remediate [5,6].

Surface treatment with liquid sporicides and/or fumigation with gaseous chemicals were used to decontaminate facilities in the wake of the 2001 events. The relatively small number of buildings directly contaminated with B. anthracis spores allowed the use of volumetric decontamination technologies such as fumigation with chlorine dioxide, paraformaldehyde, and hydrogen peroxide [3,4]. The effectiveness of fumigant technologies has been demonstrated by inactivation of biological indicator strips [7,8] as well as by decontamination of building materials experimentally contaminated with spores of B. anthracis in the laboratory [7,9,10].

Based on the B. anthracis release in 2001, it is expected that the number of buildings contaminated during a wide-area attack would overwhelm the current capacity of fumigant generators available for deployment. In addition, decontamination of outdoor surfaces following a wide-area release may be logistically challenging for fumigation. Effective alternatives to fumigation-based decontamination technologies are needed for rapid recovery from a large-scale biological incident. Such alternatives should be efficacious, easy to use, and readily available.

Liquid sporicides and disinfectants have long been used in pharmaceutical and hospital settings to reduce the risk of infection, contamination, and spoilage [11,12]. The numerous studies published in this area have provided substantial background for homeland security-related decontamination. However, it is important to note that the complexity of surfaces and materials encountered outside of hospitals and clean rooms makes the task of decontamination following a bioterror incident much more challenging. Rigorous testing of potential decontaminant technologies is paramount for bioterrorism response preparedness. While numerous studies have evaluated the effectiveness of liquid sporicides for inactivating Bacillus spores [13-16], most have been conducted using immersion-based test methods against surrogate, nonpathogenic organisms. Such studies are necessary to identify efficacious technologies in a safe and efficient manner. However, testing of candidate technologies using virulent agent, as well as application methods, contact times, and material surfaces realistic of the anticipated use, is critically important.

The objective of this study was to evaluate several liquid sporicides that are currently available for their ability to decontaminate common outdoor materials contaminated with spores of Bacillus anthracis, the causative agent of anthrax. In order to obtain field-relevant data, a novel approach was utilized whereby sporicides were applied to material surfaces in a manner consistent with how they would be applied during a biological agent clean-up. These data will assist remediation experts when assembling a decontamination strategy following a bioterror incident.

Materials and Methods

Bacterial culture and spore preparation

All portions of testing were performed under biosafety level 3 (BSL-3) conditions in accordance with Biosafety in Microbiological and Biomedical Laboratories (BMBL), 5th [17]. Spores of virulent Bacillus anthracis Ames were prepared as previously described [7]. Spore preparations with >95% refractile spores and <5% cellular debris were enumerated, diluted to approximately 1 x 109 colony-forming units (CFU) ml-1, and stored at 2-8ºC until used.

Preparation and inoculation of material coupons

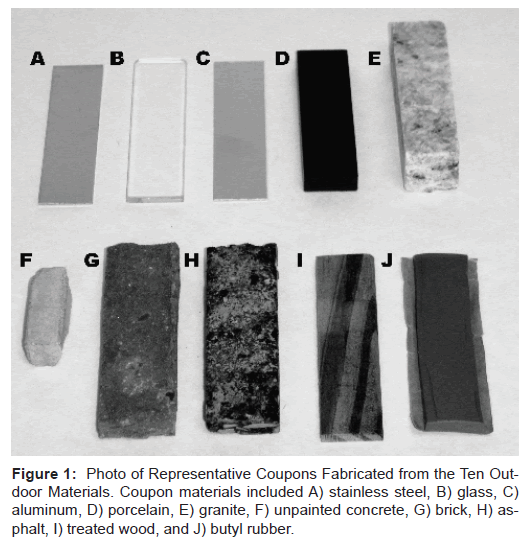

Material types were selected to represent outdoor urban environments and consisted of the nonporous materials stainless steel, glass, aluminum, porcelain, and granite, and the porous materials concrete, brick, asphalt, treated wood, and butyl rubber (Table 1, Figure 1). With the exception of asphalt, which was salvaged material, all test coupons were made from new materials. Coupons were approximately 1.9 x 7.5 cm in size, except for unpainted concrete, which was poured into molds to form coupons 1.0 x 3.5 cm in size. Coupons were sterilized before use by gamma irradiation (for asphalt, treated wood, and butyl rubber) or autoclaving (all other materials).

| Materials | Origin | Specifications |

|---|---|---|

| NONPOROUS | ||

| Stainless Steel | Alro Steel Inc. Columbus, OH | Stainless, 304, 20 gauge, 2B Finish |

| Glass | Brooks Brothers Glass and Mirror Columbus, Ohio | C1036, 0.32 cm thick |

| Aluminum | Petersen Aluminum Elk Grove Village, IL | 0.81 mm thick, 300 Clear Anodized |

| Porcelain | AF Supply Corporation New York, NY | BRIX Frimmenti DEF70 Black MOS. Tile (7 cm × 1.9 cm × 0.7 cm) |

| Granite | Lang Stone Co. Columbus, OH | Giallo Ornamental, Brushed finish, milled to 1.9 cm thick |

| POROUS | ||

| Concrete | Wysong Concrete Fairfield, OH | 5 parts sand and 2 parts cement, 1 cm thick (Battelle-made) |

| Brick | Hamilton Parker Co. Columbus, OH | Belcrest 560, common red, chemical resistant |

| Asphalt Paving | Shelly Aggregate and Asphalt Columbus, OH | Used upper layer asphalt (fine aggregate, salvaged material from urban parking lot, washed with water before cutting coupons) |

| Treated Wood | Lowe’s Top Choice Columbus, OH | Alkaline Copper Quaternary (ACQ) treated, 5 cm x 10 cm x 2.4 m, 6.4 kg/m3 retention (no water proofing). Item #46905, Model # TC248T225N |

| Butyl Rubber | Copperstate Roofing Supply Phoenix, AZ | GSSI #9897, high temperature self adhering double-sided butyl rubber sealant tape, 1.9 cm × 0.48 cm thick |

Table 1: Materials Used during Decontamination Testing.

Bacillus anthracis Ames spores were inoculated onto test coupons in a Class III biosafety cabinet (BSC III) as previously described (Rogers et al., 2009). Coupons were placed flat in the BSC III and inoculated with approximately 1 x 108 viable spores per coupon by dispensing ten droplets (each 10 µl in volume) of a spore stock suspension (approximately 1 x 109 CFU ml-1) using a micropipette uniformly across the surface of the test coupon. After inoculation, the test coupons remained undisturbed overnight in the BSC III to dry.

Sporicide neutralization testing

In this study, the products tested were used as an experimental parameter and were not evaluated to verify any product label claims. Prior to conducting decontamination tests, sporicide neutralization tests were carried out to determine the concentration of chemical neutralizer required to completely inactivate each sporicide. Neutralization of the sporicides was necessary to achieve the exact exposure times prescribed by each test, and to prevent biocidal or biostatic effects of the sporicides during extraction, processing, and culturing of B. anthracis following the exposure period. Neutralization tests were based upon method ASTM E 1054-02; however, instead of 30 to 100 cells ml-1, 1 x 108 CFU per assay were used in order to increase sensitivity.

First, the volume of each sporicide applied to coupons of each material during the sporicide application procedures was determined gravimetrically. For each sporicide, the determined volume of sporicide was then averaged for all porous and nonporous materials separately. For each sporicide, the average porous and nonporous volume was then subjected to neutralization testing, in which a high, medium, and low concentration of neutralizer; sodium thiosulfate (STS), was evaluated for its ability to quench the sporicide. The degree of inactivation was determined by comparison to positive control samples in which no sporicide or neutralizer was added. In addition, samples containing spores, extraction buffer, and sporicide; as well as samples containing only sporicide and spores were included as additional controls in the neutralization tests. Completely inactivated sporicide would result in no decreased viability of exposed spores, and therefore yield 100 percent recovery. To be consistent with the conditions of the decontamination tests, the components of the neutralizer test solutions consisted of 10 ml of phosphate-buffered saline (PBS) (Sigma, St. Louis, MO) amended with 0.1% Triton X-100 (Sigma), 1 x 108 CFU B. anthracis spores, the predetermined volume of sporicide, and a high, medium, or low concentration of STS. Coupon materials were not included in the neutralization tests. For all sporicides except Decon Green, the high, medium and low concentrations of STS were 1.5, 1.0, and 0.5 percent, respectively. Sodium thiosulfate concentrations of 3.0, 2.5, and 2.0 percent were utilized for Decon Green neutralization tests. The extent of neutralization for each combination of sporicide and neutralizer concentration was determined by serial dilution and plate counts following the exposure. Percent recovery was determined by comparison to control samples in which all constituents except the sporicide were added. The concentration of neutralizer that yielded the highest recovery was used in the decontamination tests.

Test conditions and sporicide application procedures

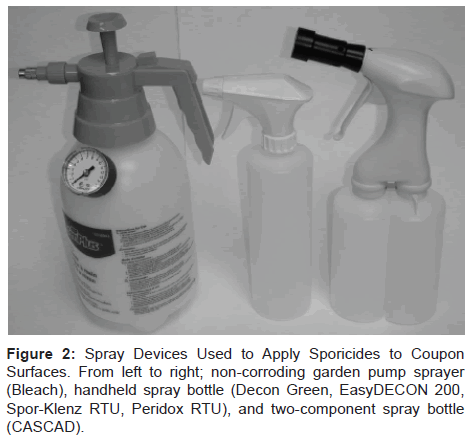

All decontamination tests were conducted in a 317 L glove box (Plas Labs, Inc., Lansing, MI), with environmental conditions of = 70% relative humidity and 20 to 25ºC. All test coupons were oriented horizontally (i.e., lying flat) throughout the sporicide applications. A spray distance of 30.5 cm was used for all tests. A summary of the sporicides tested and their contact times are presented in Table 2 and outlined below. Application methods and contact times were chosen based upon input from the technology vendors and upon available data at the time of testing. One of three types of commercially available spray devices was used for each sporicide (Figure 2).

| Sporicide (Source) | Active Ingredient | Application | Contact Time (min) | |

| Nonporous | Porous | |||

| Bleach (Clorox Corp.) | Hypochlorite / hypochlorous acid | Garden Pump Sprayer All materials = 4 applications (0, 15, 30, 45 min) | 60 | 60 |

| CASCAD SDF (Allen-Vanguard) | Hypochlorite / hypochlorous acid | Two-Component Spray Bottle Nonporous = 1 application Porous = 2 applications (0, 30 min) | 30 | 60 |

| Decon Green (US Army) | Peroxide | Handheld Spray Bottle All materials = 2 applications (0, 30 min) | 60 | 60 |

| EasyDECON 200 (EFT Holdings, Inc.) | Peroxide | Handheld Spray Bottle Nonporous (glass, aluminum, porcelain) = 3 applications (0, 10, 20 min) Nonporous (stainless steel, granite) = 6 applications (0, 5, 10, 15, 20, 25 min) Porous = 3 applications (0, 20, 40 min) | 30 | 60 |

| Spor-Klenz RTU (STERIS Corp.) | Peroxide / Peracetic acid | Handheld Spray Bottle Nonporous = 2 applications (0, 25 min) Porous = 5 applications (0, 10, 25, 30, and 50) | 30 | 60 |

| Peridox RTU (Clean Earth Technologies, LLC) | Peroxide / Peracetic acid | Handheld Spray Bottle Nonporous = 3 applications (0, 10, 25 min) Porous = 6 applications (0, 10, 20, 30, 40, 50 min) | 30 | 60 |

Table 2: Summary of Liquid Sporicides and Application Procedures.

Ultra Clorox Germicidal Bleach (1 part) was diluted with 9.4 parts sterile, cell culture grade, filtered water (SFW) and 1 part 5 % acetic acid, resulting in a solution with pH of approximately 6.8 and a mean total chlorine content of 6,200 parts per million (ppm). Bleach was acidified prior to use, as it is a more effective sporicide at near-neutral pH [18]. The bleach solution was spray-applied to the coupons using a non-corroding garden pump sprayer (GardenPlus sprayer Model No. 5318, LG Sourcing Inc., Wilkesboro, NC), outfitted with a pressure gauge (0-103 kPa, Ashcroft Inc., Stratford, CT), at a pressure of 28 to 41 kPa, until the coupon surface was wetted completely. The solution was reapplied three times at 15, 30 and 45 min after the initial application. A 60 min contact time was used for all materials.

CASCAD SDF was applied to test coupons using a vendorsupplied dual-compartment spray applicator. This applicator mixed the two components of CASCAD SDF and generated a foam spray upon actuation. CASCAD SDF was applied to test coupons until they were completely covered with no less than 1 cm depth of foam. A first application was delivered to all test coupons, and a second application after 30 min was administered only to porous test coupons. Total contact time for nonporous and porous coupons was 30 and 60 min, respectively.

Decon Green is a three-part solution that was mixed according to the manufacturer's directions just prior to use. The solution of Decon Green was applied to test coupons using a handheld spray bottle until all test coupons were completely wetted by the solution. Decon Green was reapplied to all coupons once 30 min had elapsed from the first application, and a 60 min total exposure time was used.

EasyDECON 200 consists of a three-part formula that was mixed according to the manufacturer's directions just prior to use. EasyDECON 200 was applied to test coupons using a handheld spray bottle, until all test coupons were completely wetted. For glass, aluminum, and porcelain test coupons, the sporicide was reapplied at 10 and 20 min after the first application, and a 30 min contact time was used. For stainless steel and granite test coupons, EasyDECON 200 was reapplied at 5, 10, 15, 20, and 25 min following the first application, with a 30 min total contact time. For all porous test coupons, EasyDECON 200 was reapplied at 10, 20, 30, 40, and 50 min after the initial application, and a 60 min total contact time was used.

Both Spor-Klenz Ready to Use (RTU) and Peridox RTU were applied undiluted using a handheld spray bottle until the surfaces of the test coupons were completely wetted. With Spor-Klenz RTU, nonporous test coupons were rewetted after 25 min had elapsed from the first application; porous coupons were rewetted at 10, 25, 30, and 50 min after the first application. A total contact time of 30 and 60 min was used for nonporous and porous materials, respectively. For Peridox RTU, a 30-min contact time was used for nonporous test coupons, with reapplications at 10 and 25 min after the first application. A 60-min contact time was used for porous test coupons, with reapplications at 10, 20, 30, 40, and 50 min after the first application.

Extraction and analysis

Immediately upon completion of the contact time, test coupons along with any collected runoff were aseptically transferred to 50 ml conical tubes containing 10 ml of sterile PBS amended with 0.1% Triton X-100, and the amount of STS determined from the neutralization tests. Stainless steel, aluminum, glass, porcelain, treated wood, and butyl rubber test coupons were then extracted by agitation on an orbital shaker (200 rpm) for 15 min to dislodge viable spores from the coupon surfaces. Granite, concrete, brick, and asphalt were extracted by sonication for 45 min. Following extraction, a series of 10-fold serial dilutions were prepared and subsequently spread-plate in triplicate onto tryptic soy agar plates. Plates were incubated at 35-37 ºC for 18-24 hours, and CFU were enumerated.

The ability to recover spores from the test materials was determined by comparing the number of recovered spores from the positive controls (sprayed with SFW instead of sporicides) to the spore inoculum titer. For each of the six sporicide tests, the average recovery value was calculated for each material type using the five positive control samples. The mean of these six values was determined and used to estimate the overall recovery efficiency across all tests (i.e., n = 6 for each material). Percent recovery was determined for each material according to equation (1):

Mean Percent Recovery = [Mean CFUpositive control / CFUinoculum] x 100 (1)

The efficacy of each sporicide was quantified by determining the difference in recovered viable spores between positive control coupons and test coupons for each coupon material and expressed as "Log Reduction". Five replicates of each were used to determine Log Reduction (LR) values for each sporicide on each material according to equation (2):

(2)

(2)

where CFUc is the abundance of colonies observed on positive control plates, and CFUt is the abundance of colonies observed on test coupon plates.

Results

Recovery from material surfaces

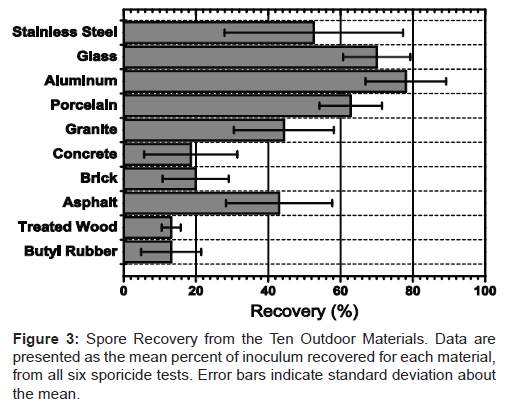

Mean recoveries of viable spores from the ten outdoor materials ranged from 13.2% (treated wood and butyl rubber) to 78.1% (aluminum) (Figure 3). Pooled recoveries from all porous materials were significantly less than those of nonporous materials (t-test, p < 0.001). Interestingly, the mean recovery from the porous material asphalt (43.0 ± 14.7%) was only slightly outside the range of mean recoveries for nonporous materials (44.3 to 78.1%).

Neutralization tests

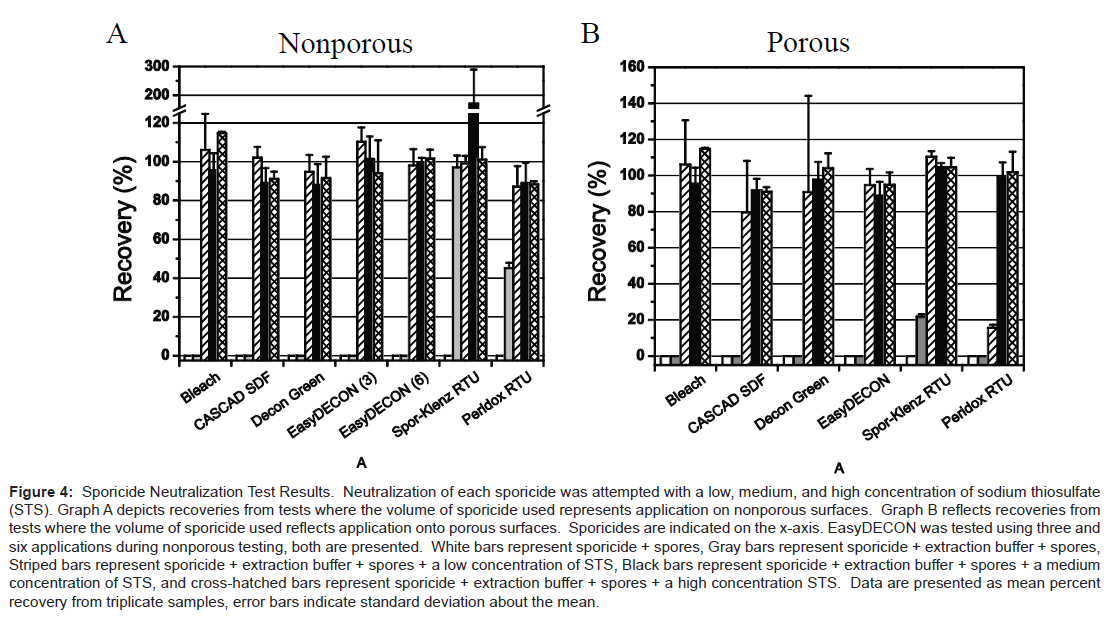

Tests conducted to determine the optimal amount of neutralizer needed to quench the sporicidal activity of each liquid technology indicated that STS was an effective neutralizer for all technologies tested, but at different concentrations (Figure 4). For nonporous materials, 0.5, 0.5, 2.0, 0.5, and 1.0% STS was effective at neutralizing pH-adjusted bleach, CASCAD SDF, Decon Green, Spor-Klenz, and Peridox RTU, respectively. Similarly, 0.5, 1.0, 3.0, 0.5, and 1.5% STS, respectively, was used to neutralize these sporicides during tests with porous materials. Neutralization tests with EasyDECON 200 indicated that 1.0% STS was effective for glass, aluminum, and porcelain, and 1.5% STS was effective for all other materials. Recovery of viable spores from the optimal neutralized sample for each material ranged from 88.9% (Peridox RTU, nonporous materials) to 110.4% (Spor-Klenz RTU, porous materials).

Figure 4: Sporicide Neutralization Test Results. Neutralization of each sporicide was attempted with a low, medium, and high concentration of sodium thiosulfate (STS). Graph A depicts recoveries from tests where the volume of sporicide used represents application on nonporous surfaces. Graph B reflects recoveries from tests where the volume of sporicide used reflects application onto porous surfaces. Sporicides are indicated on the x-axis. EasyDECON was tested using three and six applications during nonporous testing, both are presented. White bars represent sporicide + spores, Gray bars represent sporicide + extraction buffer + spores, Striped bars represent sporicide + extraction buffer + spores + a low concentration of STS, Black bars represent sporicide + extraction buffer + spores + a medium concentration of STS, and cross-hatched bars represent sporicide + extraction buffer + spores + a high concentration STS. Data are presented as mean percent recovery from triplicate samples, error bars indicate standard deviation about the mean.

For all sporicides tested, no viable spores were recovered from neutralization control samples containing only B. anthracis spores suspended in the liquid sporicides. Similarly, for most sporicides tested, no viable spores were recovered from control samples that contained B. anthracis spores, extraction buffer (PBS + Triton X-100), and liquid sporicide. The exceptions were that 97.1 and 21.7 percent recovery was observed for Spor-Klenz RTU during nonporous and porous testing, respectively. In addition, neutralization testing with Peridox RTU yielded a 45.1% recovery for this control (spores + extraction buffer + sporicide). These results suggest that the extraction buffer itself reduced the effectiveness of the sporicide either by partial neutralization or by dilution of the sporicide concentration.

Efficacy of liquid sporicides

Efficacy of the six sporicides tested ranged less than 1 log reduction to nearly 8 logs reduction for the ten materials tested (Table 3). Overall, efficacy was much greater on the five nonporous materials than on the porous materials. All sporicides achieved greater than 6 logs reduction on all nonporous materials, and most resulted in no viable spores recovered following application on those materials (as demonstrated by "=" in Table 3). Spor-Klenz RTU was the only sporicide tested that did not achieve complete inactivation of spores on all nonporous materials; however the efficacy of Spor-Klenz RTU was greater than 7 logs for those materials (stainless steel, glass, and aluminum) where complete kill was not observed.

| Test Material | Bleach | CASCAD SDF | Decon Green | Easy DECON 200 | Spor-Klenz RTU | Peridox RTU |

| Stainless Steel | ≥ 7.73 | ≥ 7.67 | ≥ 7.64 | ≥ 7.61 | 7.28 | ≥ 6.69 |

| Glass | ≥ 7.81 | ≥ 7.74 | ≥ 7.78 | ≥ 7.79 | 7.36 | ≥ 7.76 |

| Aluminum | ≥ 7.91 | ≥ 7.80 | ≥ 7.80 | ≥ 7.75 | 7.17 | ≥ 7.82 |

| Porcelain | ≥ 7.80 | ≥ 7.68 | ≥ 7.67 | ≥ 7.78 | ≥ 7.72 | ≥ 7.71 |

| Granite | ≥ 7.62 | ≥ 7.59 | ≥ 7.32 | ≥ 7.51 | ≥ 7.57 | ≥ 7.42 |

| Concrete | 6.27 | ≥ 6.93 | 4.00 | ≥ 7.14 | 1.02 | 1.39 |

| Brick | ≥ 6.91 | ≥ 7.40 | ≥ 7.25 | ≥ 7.28 | ≥ 7.27 | 3.81 |

| Asphalt Paving | 3.60 | ≥ 7.58 | 2.97 | 1.63 | 2.56 | 7.22 |

| Treated Wood | 1.90 | ≥ 6.97 | 1.91 | 0.82 | 6.06 | ≥ 6.99 |

| Butyl Rubber | ≥ 7.00 | ≥ 6.80 | ≥ 6.94 | ≥ 6.99 | ≥ 7.39 | ≥ 6.65 |

Table 3: Summary of Quantitative Efficacy Results for Bacillus anthracis (Ames) by Sporicide and Test Material. Data are presented as the mean Log Reduction of five replicate coupons. “=” indicates no viable spores were recovered following treatment with the sporicide (i.e., complete kill). Efficacy values in all instances where complete kill was observed should be regarded as equal, as numerical differences are due to variation in inoculum titer and recovery efficiencies from the various surfaces.

Overall, porous materials were more challenging to decontaminate. Butyl rubber was the only porous material that was completely decontaminated by all sporicides tested. All sporicides except Peridox RTU were highly effective (i.e., complete kill) for decontamination of brick. Concrete, asphalt, and treated wood were consistently the most difficult materials to decontaminate. CASCAD SDF was the only sporicide tested that achieved complete kill on all materials tested. It is important to note that CASCAD SDF was the product applied as foam, all other sporicides were applied as liquids.

The effect of the decontamination process on the test materials was evaluated by visual inspection of test coupons after decontamination. None of the tested sporicides caused any visible damage or discoloration to any of the test materials.

Discussion

Decontamination following a bioterrorism event poses unique challenges, such as contamination of complex and heavily soiled surfaces, the potential for vast areas of contamination, and incompatibility of contaminated materials with liquids or particular sporicides. Whereas hospital practice is to sterilize instruments, implants, and other items that come into direct contact with patients, and to disinfect surfaces, walls, floors, and other items; decontamination of sites following the anthrax mailings of 2001 were held to a non-detect clearance goal for all environmental samples [19], a significantly more challenging endeavor than disinfection. These challenges are currently being addressed by numerous government and private entities, including the U.S. Environmental Protection Agency's National Homeland Security Research Center (NHSRC). Through systematic research, NHSRC works to increase our ability to detect, respond to, and recover from biological, chemical, and radiological terror events. The current study was conducted to enhance our ability to decontaminate common outdoor materials following a biological attack with spores of B. anthracis.

Sporicides, or sterilants, are chemicals that can inactivate all living forms of microbial life, including bacterial spores [12]. Following the 2001 anthrax events, Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) crisis exemptions were issued by the U.S. EPA as there were no existing sporicides registered for use against B. anthracis spores [4]. Since 2001, several liquid sporicides have been granted FIFRA registration for use against B. anthracis (e.g., Peridox® with EDS and Steriplex Ultra™). Registration requires that sporicides demonstrate a predetermined level of efficacy when tested against B. anthracis spores, or spores of a suitable surrogate, using one of several validated test methods. These methods are often test tubebased and involve submersion of replicate coupons of contaminated test material (e.g., silk suture loops, porcelain penicylinders, ceramic tile, glass, etc) in the liquid product to be evaluated [14,20,21]. While the tests required for FIFRA registration are excellent at accurately and repeatably determining sporicidal activity in vitro, they are not designed to predict product performance on all complex surfaces. By utilizing spray application of sporicides and outdoor surface materials, the current study offers operationally-relevant insight into the expected performance of sporicides when used to decontaminate outdoor surfaces contaminated with spores of B. anthracis.

Surrogates for B. anthracis, such as B. subtilis, B. atrophaeus, and Geobacillus stearothermophilus, are often utilized for experimentation because they are physiologically similar, nonpathogenic, less expensive, and require no special containment for testing [7,22-24]. Tests with surrogates are effective for identifying potential strategies for decontamination; however, identified strategies should eventually be tested on fully virulent agent [15,25]. The current study evaluated liquid sporicides for their effectiveness against the fully-virulent B. anthracis Ames strain, a Category A select agent [26].

The purpose of the study at hand was not to evaluate sporicides for FIFRA registration, but rather to evaluate their effectiveness under conditions representative of actual use. For example, the current study spray-applied sporicides to surfaces contaminated with B. anthracis spores, and utilized test materials typical of those that would be encountered during decontamination of outdoor surfaces. Sporicides selected for testing were among those currently available for use in an anthrax response. Bleach was included in these tests as it is widelyavailable, easily obtained during emergency situations, and has been tested previously in numerous decontamination studies [27-31]. Moreover, bleach provides an excellent point of reference for crosscomparisons among decontamination studies [20].

Testing of complex materials, not unlike those used in the current study, requires special consideration of potentially problematic variables such as recoverability of spores from test coupons, repeatable and appropriate application of sporicides to the test coupons, and complete neutralization of sporicides promptly at the end of the exposure time. Considering recoverability, the results at hand indicate that recovery of viable spores from positive control coupons was highly dependent upon material type. Recovery of spores from the five nonporous materials was significantly greater than that from the five porous materials (Figure 3). Similar results have previously been documented [21], and are somewhat intuitive. While recoveries from these materials by whole-coupon extraction is not likely to be equivalent to sampling methods used during an anthrax response (wipes, swabs, etc), trends in recovery were similar to those observed during sampling studies. In general, recoveries approximated those reported using field sampling methods [32-34].

A minimum criterion of the current study was to recover from positive control coupons at least one percent of the inoculum (i.e., 1% of 1 x 108 CFU equals 1 x 106 CFU). Since efficacy was calculated from the difference in recovery between positive control samples and test samples, this criterion assured at least a 6 log dynamic range for determination of efficacy. Recoveries for all materials in all tests were well above the 1% requirement; the two lowest observed recoveries were for butyl rubber (6.7 and 6.3%). When averaged across all six tests, treated wood and butyl rubber demonstrated the lowest average recoveries, both equaling 13.2% (Figure 3).

Variations in test conditions and in the application of sporicides to the contaminated surfaces can significantly impact effectiveness. In addition, it is important to choose test parameters that are realistic of how the product would be used in the field. For the current study, detailed application procedures were outlined and strictly followed for each sporicide. When possible, input from the product vendors was collected to determine application rates, reapplication frequency, contact times, and application method. Temperature and relative humidity of the test environment were also held constant to maximize the ability to compare efficacies among sporicides.

For efficacy testing, ensuring adequate neutralization of the sporicide immediately upon completion of the desired contact time is imperative, since residual sporicide can continue to inactivate spores and may inhibit germination and/or growth during the required culturing portions of the assay. If complete neutralization is not achieved, test results may overestimate the true effectiveness of the sporicide tested. For these reasons, preliminary tests were conducted to determine the optimal concentration of neutralizer required to quench the activity of each sporicide. Greater than 90% recovery was achieved during neutralization tests for all sporicides.

Efficacy of the tested sporicides ranged from 0.82 logs (Easy DECON 200 on treated wood) to greater than 7 logs for numerous combinations of materials and sporicides. It is important to point out that in all instances where complete kill was achieved, the efficacy values should be regarded as equivalent, as the upper bound of these values is limited by the amount of inoculum recovered from positive controls. For instance, CASCAD SDF demonstrated =6.80 logs reduction on butyl rubber and pH-amended bleach demonstrated =7.00 logs reduction on this material. Both sporicides demonstrated complete kill, however during the experiments with CASCAD SDF recovery from the positive controls equaled 6.80 logs (6.3 x 107) whereas recovery from this material during testing of bleach was equal to 7.00 logs (1.0 x 107). Thus, the difference in efficacy values where complete kill resulted with both sporicides should be regarded as an artifact of the calculation method.

Of the ten material types, the five porous materials were most challenging for the sporicides (i.e., resulting in the lowest efficacy). Similar trends for decontamination with vaporous hydrogen peroxide and liquid decontaminants have been documented previously [7,31]. Concrete, asphalt, and treated wood were especially difficult to decontaminate. Considering that a large portion of outdoor urban areas are comprised of these materials, decontamination following an outdoor incident could be challenging. Furthermore, our results may underestimate the difficulty of decontaminating B. anthracis spores on outdoor materials since the materials we tested were free of dirt, grime, and organic matter. The presence of organic matter can negatively affect the efficacy of decontaminants [9,30]. Decontamination of outdoor surfaces may require a source reduction step prior to application of sporicides, to reduce the amount of surface grime, and thereby increase the efficacy of the treatment. Currently, few studies have been conducted to evaluate the efficacy of liquid sporicides against B. anthracis in the presence of dirt, grime, or organic matter [30].

Efficacy on nonporous surfaces was significantly higher than on porous materials. While not all sporicides achieved complete kill on all nonporous materials, at least 6 logs reduction was observed for these materials. These data suggest sporicide selection for decontamination of nonporous materials may not be as critical as the appropriate pairing of sporicides with compatible surfaces necessary for decontamination of porous surfaces.

Responders, On-scene Coordinators, and Remediation Experts rely on available data for technology selection during decontamination efforts following a bioterror incident. Efficacy data for sporicides tested under field-use conditions and on relevant surface materials are necessary for development of remediation action plans. Following a wide-area biological incident there will be a need for decontamination technologies and procedures that can readily be applied over large areas. While fumigation may meet a portion of the anticipated needs, additional options are necessary. The use of liquid-based decontamination technologies, such as those tested in the current study, will help reduce the total time of restoration. In order to be adequately prepared for a wide-area biological attack, all options for decontamination should be carefully vetted. Studies such as this provide essential data for selection of effective remediation strategies following such bioterror incidents.

Conclusions

All sporicides tested in the current study were highly effective against B. anthracis (Ames) spores on nonporous surfaces; however, significant differences in effectiveness were apparent when decontaminating porous surfaces. Asphalt, treated wood, and unpainted concrete were the most difficult materials to decontaminate with several of the sporicides, although for each of these materials at least one of the sporicides achieved a complete kill of spores. A wide-area release of biological agent may necessitate the decontamination of vast areas of outdoor surfaces. Factors influencing decontaminant selection may include effectiveness against the contaminating organism, compatibility with the contaminated surface, ease of use, availability, and cost. Evaluation of sporicide effectiveness prior to field use allows for more informed decisions regarding decontaminant selection following a bioterror incident.

Acknowledgements

The U.S. Environmental Protection Agency through its Office of Research and Development funded and directed the research described herein under GS23F0011L-3 with Battelle Memorial Institute. It has been subject to an administrative review but does not necessarily reflect the views of the Agency. No official endorsement should be inferred. EPA does not endorse the purchase or sale of any commercial products or services.

References

- Barakat LA, Quentzel HL, Jernigan JA, Kirschke DL, Griffith K, et al. (2002) Fatal Inhalational Anthrax in a 94-year-old Connecticut woman. JAMA 287: 863-868.

- Jernigan DB, Raghunathan PL, Bell BP, Brechner R, Bresnitz EA, et al. (2002) Investigation of bioterrorism-related Anthrax, United States, 2001: Epidemiologic Findings. Emerg Infect Dis 8: 1019-1028.

- Canter DA (2005) Remediating anthrax-contaminated sites: learning from the past to protect the future. Chemical Health & Safety 12: 13-19.

- Canter DA, Gunning D, Rodgers P, O'connor L, Traunero C, et al. (2005) Remediation of Bacillus anthracis Contamination in the U.S. Department of Justice Mail Facility. Biosecur Bioterror 3: 119-127.

- Franco C, Bouri N (2010) Environmental Decontamination Following a Large- Scale Bioterrorism Attack: Federal Progress and Remaining Gaps. Biosecurity and Bioterrorism: Biodefense Strategy Practice and Science 8: 107-117.

- Graham B, Talent J (2008) World at Risk: The report of the commission on the prevention of WMD proliferation and terrorism. First ed Vintage Books New York NY.

- Rogers JV, Sabourin CLK, Choi YW, Richter WR, Rudnicki DC, et al. (2005) Decontamination assessment of Bacillus anthracis, Bacillus subtilis, and Geobacillus stearothermophilus spores on indoor surfaces using a hydrogen peroxide gas generator. J Appl Microbiol 99: 739-748.

- Ryan S, Rastogi VK, Wallace L, Martin GB, Smith LS, et al. (2006) A study on the Use of Biological Indicators in Determining the Efficacy of the Decontamination of Building Materials Contaminated with Bacillus Anthracis. in National Conference on Environmental Sampling and Detection for Bio Threat Agents. Brooklyn NY.

- Rastogi VK, Wallace L, Smith LS, Ryan SP, Martin B (2009) Quantitative Method To Determine Sporicidal Decontamination of Building Surfaces by Gaseous Fumigants, and Issues Related to Laboratory-Scale Studies. Appl Environ Microbiol 75: 3688-3694.

- Beuchat LR, Pettigrew CA, Tremblay ME, Roselle BJ, Scouten AJ (2004) Lethality of chlorine, chlorine dioxide, and a commercial fruit and vegetable sanitizer to vegetative cells and spores of Bacillus cereus and spores of Bacillus thuringiensis. J Food Prot 67: 1702-1708.

- Block SS (2001) Disinfection, sterilization, and preservation (5th edn), Lippincott Williams, Wilkins Philadelphia PA.

- Rutala W (2007) Disinfection, Sterilization and Antisepsis: Principles, Practices, Current Issues, and New Research. Association for Professionals in Infection Control and Epidemiology, Washington, D.C.

- Springthorpe VS, Sattar SA (2005) Carrier tests to assess microbicidal activities of chemical disinfectants for use on medical devices and environmental surfaces. J AOAC Int 88: 182-201.

- Tomasino SF, Pines RM, Cottrill MP, Hamilton MA (2008) Determining the efficacy of liquid sporicides against spores of Bacillus subtilis on a hard nonporous surface using the quantitative three step method: Collaborative study. J AOAC Int 91: 833-852.

- Majcher MR, Bernard KA, Sattar SA (2008) Identification by quantitative carrier test of surrogate spore-forming bacteria to assess sporicidal chemicals for use against Bacillus anthracis. Appl Environ Microbiol 74: 676-681.

- Kreske AC, Ryu JH, Beuchat LR (2006) Evaluation of chlorine, chlorine dioxide and a peroxyacetic acid- based sanitizer for effectiveness in killing Bacillus cereus and Bacillus thuringiensis spores in suspensions, on the surface of stainless steel and on apples. J Food Prot 69: 1892-1903.

- Chosewood LC, Wilson DE (2009) Biosafety in Microbiological and Biomedical Laboratories. 5th ed US Government Printing Office Washington DC.

- Perez J, Springthorpe VS, Sattar SA (2005) Activity of selected oxidizing microbicides against the spores of Clostridium difficile: Relevance to environmental control. Am J Infect Con 33: 320-325.

- Canter DA (2005) Addressing residual risk issues at anthrax cleanups: How clean is safe? J Toxicol and Env Health 68: 1017-1032.

- Tomasino SF, Hamilton MA (2007) Comparative evaluation of two quantitative test methods for determining the efficacy of liquid sporicides and sterilants on a hard surface. J AOAC Int 90: 456-464.

- Tomasino SF, Rastogi VK, Wallace L, Smith LS, Hamilton MA, et al. (2010) Use of Alternative Carrier Materials in AOAC Official Method 2008.05, efficacy of liquid sporicides against spores of Bacillus subtilis on a hard, nonporous surface, quantitative three-step method. J AOAC Int 93: 259-276.

- DeQueiroz GA, Day DF (2008) Disinfection of Bacillus subtilis sporecontaminated surface materials with a sodium hypochlorite and a hydrogen peroxide-based sanitizer. Lett Appl Microbiol 46: 176-180.

- Klapes NA, Vesley D (1990) Vapor-phase hydrogen peroxide as a surface decontaminant and sterilant. Appl Environ Microbiol 56: 503-506.

- Rice EW, Adcock NJ, Sivaganesan M, Rose LJ (2005) Inactivation of spores of Bacillus anthracis Sterne, Bacillus cereus, and Bacillus thuringiensis subsp israelensis by chlorination. Appl Environ Microbiol 71: 5587-5589.

- Sagripanti JL, Carrera M, Insalaco J, Ziemski M, Rogers J, et al. (2007) Virulent spores of Bacillus anthracis and other Bacillus species deposited on solid surfaces have similar sensitivity to chemical decontaminants. J Appl Microbiol 102: 11-21.

- CDC Office of Public Health Preparedness and Response. (2010) Bioterrorism. Accessed August 5, 2010.

- Dukan S, Touati D (1996) Hypochlorous acid stress in Escherichia coli: resistance, DNA damage, and comparison with hydrogen peroxide stress. J Bacteriol 178: 6145-6150.

- Winter J, Ilbert M, Graf PCF, Ozcelik D, Jakob U (2008) Bleach Activates a Redox-Regulated Chaperone by Oxidative Protein Unfolding. Cell 135: 691-701.

- US Environmental Protection Agency (2006) Technology Evaluation Report, Evaluation of Spray-Applied Sporicidal Decontamination Technologies, US EPA, ORD/NHSRC, Washington DC, EPA/600/R/06/146.

- Hilgren J, Swanson KMJ, Diez-Gonzalez F, Cords B (2007) Inactivation of Bacillus anthracis Spores by Liquid Biocides in the Presence of Food Residue. Appl Environ Microbiol 73: 6370-6377.

- US Environmental Protection Agency (2009) Technology Evaluation Report, Evaluation of Liquid and Foam Technologies for the Decontamination of B. anthracis and B. subtilis Spores on Building and Outdoor Materials. US EPA, ORD/NHSRC, Washington DC, EPA/600/R/09/150.

- Brown GS, Betty RG, Brockmann JE, Lucero DA, Souza CA, et al. (2007) Evaluation of a Wipe Surface Sample Method for Collection of Bacillus Spores from Nonporous Surfaces. Appl Environ Microbiol 73: 706-710.

- Edmonds JM, Collett PJ, Valdes ER, Skowronski EW, Pellar GJ, et al. (2009) Surface Sampling of Spores in Dry-Deposition Aerosols. Appl Environ Microbiol 75: 39-44.

- Brown GS, Betty RG, Brockmann JE, Lucero DA, Souza CA, et al. (2007) Evaluation of vacuum filter sock surface sample collection method for Bacillus spores from porous and non-porous surfaces. J Environ Monit 9: 666-671.

Relevant Topics

- Anthrax Bioterrorism

- Bio surveilliance

- Biodefense

- Biohazards

- Biological Preparedness

- Biological Warfare

- Biological weapons

- Biorisk

- Bioterrorism

- Bioterrorism Agents

- Biothreat Agents

- Disease surveillance

- Emerging infectious disease

- Epidemiology of Breast Cancer

- Information Security

- Mass Prophylaxis

- Nuclear Terrorism

- Probabilistic risk assessment

- United States biological defense program

- Vaccines

Recommended Journals

Article Tools

Article Usage

- Total views: 15789

- [From(publication date):

July-2011 - Apr 02, 2025] - Breakdown by view type

- HTML page views : 11083

- PDF downloads : 4706